A kind of curing system and solid propellant containing the curing system and preparation method

A technology of solid propellant and solidification catalyst, which is applied in attack equipment, compressed gas generation, explosive processing equipment, etc., can solve the problems of low propellant energy and mechanical properties, restrict the application of propellant, etc., and achieve controllable reaction rate, High curing reactivity and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

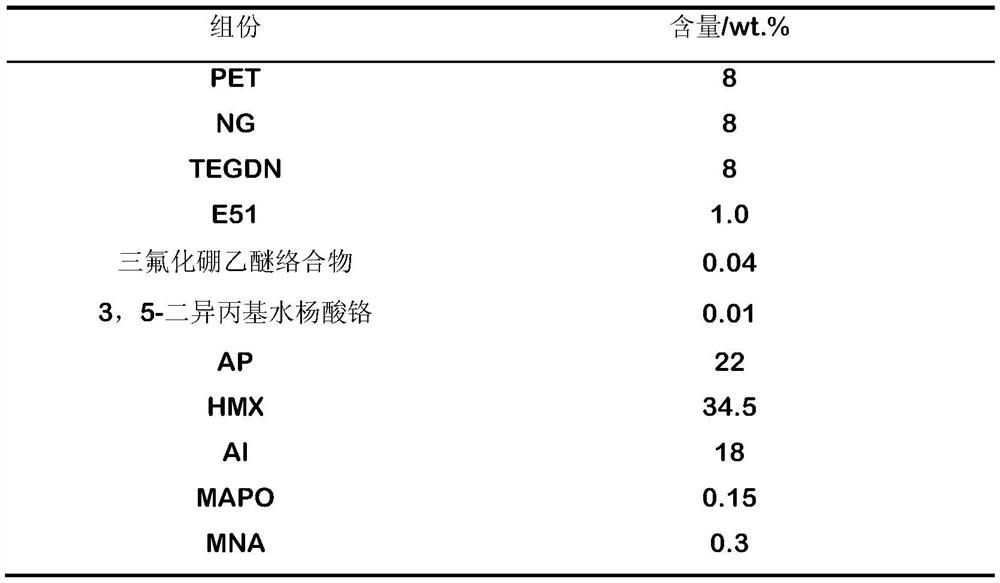

[0058] (1) Propellant formula composition (mass percentage %):

[0059]

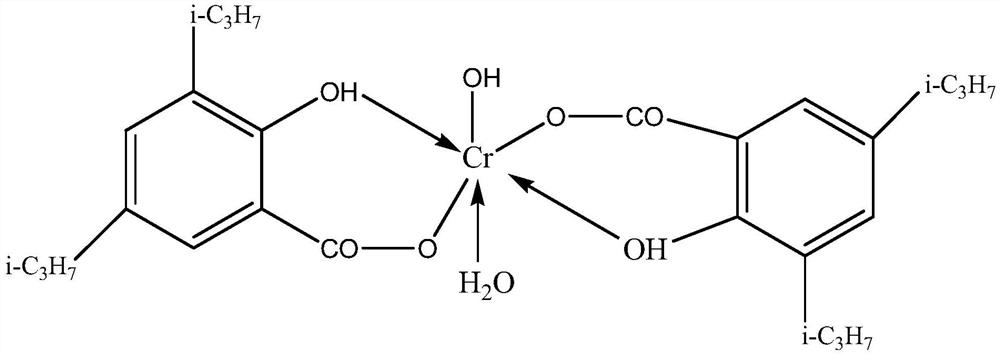

[0060] 3, the preparation method of chromium diisopropyl salicylate, the step of this method comprises:

[0061] In the first step, a 1000mL four-necked flask is equipped with a mechanical stirrer, a condenser, and a thermometer, and 50.0g of chromium trioxide, 250mL of distilled water, and 100mL of acetic acid are added to the four-necked flask. Slowly add 80 mL of anhydrous methanol dropwise to the dropping funnel, heat to 60-65°C and start to reflux until the solution turns dark green. The solvent was removed by rotary evaporation to obtain crude chromium acetate, which was dissolved in 500 mL of anhydrous methanol, filtered, the filtrate was rotary evaporated under reduced pressure to remove the solvent, and dried to obtain 128 g of chromium acetate product.

[0062] In the second step, a 500mL four-necked flask is equipped with a mechanical stirrer, a condenser, and a thermometer. Add 50.0g of c...

Embodiment 2

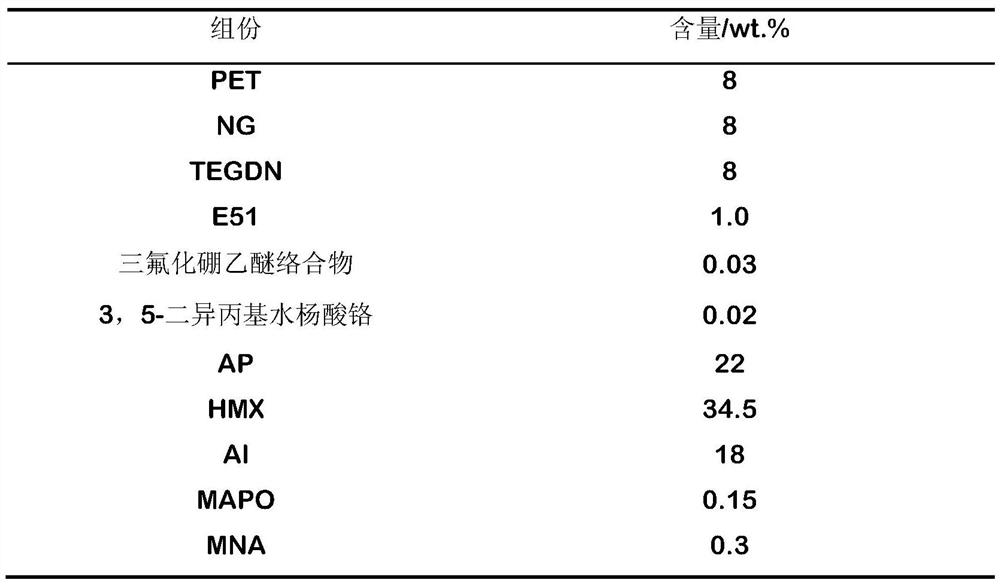

[0068] (1) Propellant formula composition (mass percentage %):

[0069]

[0070] (2) Curing conditions and mechanical properties:

[0071] Curing time 120h, curing temperature 50°C

[0072] Theoretical standard specific impulse: 2634.3N.s / kg

[0073] Mechanical properties: Maximum tensile strength σ at 20°C m =0.63MPa, maximum elongation ε m =56.9%; Maximum elongation at 70°C ε m =39.9%, the maximum elongation at -40°C ε m = 44.6%.

Embodiment 3

[0075] (1) Propellant formula composition (mass percentage %):

[0076]

[0077] (2) Curing conditions and mechanical properties:

[0078] Curing time 72h, curing temperature 45°C

[0079] Theoretical standard specific impulse: 2583.9N.s / kg

[0080] Mechanical properties: Maximum tensile strength σ at 20°C m =0.71MPa, maximum elongation ε m =47.9%; Maximum elongation at 70°C ε m =41.2%, the maximum elongation at -40°C ε m = 48.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com