Water Pump Turbine Spatial Surface Guide Vane

A technology of water pump turbine and guide vane, which is applied in the field of hydraulic machinery to achieve the effect of improving operation stability, reasonable distribution and eliminating influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

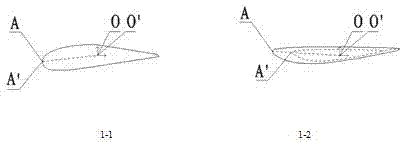

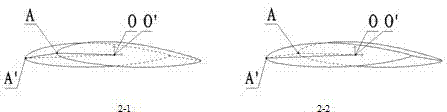

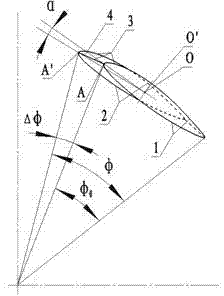

[0034] like figure 2 and image 3 As shown, the space curved guide vane of the water pump turbine mainly includes: an upper end surface (1), a lower end surface (2) and a ruled surface (3) composed of several straight lines between the upper and lower end surfaces. The connection point A between the guide vane water inlet (4) and the upper end surface (1) and the rotation center O of the guide vane on the upper end surface form a straight line OA, and the connection point A' between the guide vane water inlet edge (4) and the lower end surface (2) It is connected with the rotation center O' of the guide vane on the lower end surface to form a straight line O'A', and the straight line OA and the straight line O'A' are not parallel to each other and not in the same plane.

[0035] In the above implementation method, the water inlet side (4) of the guide vane is the high-pressure side of the guide vane, that is, the water flow inflow side of the turbine working condition.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com