Online full-redundancy mass and mass center measurement device based on upper weighing sensor and lower weighing sensor arranged in vertical mirror image mode

A technology of weighing sensor and measuring device, which is applied in the direction of measuring device and instrument to achieve the effect of simple mechanical structure, simple design, simple and convenient test operation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with embodiment (accompanying drawing):

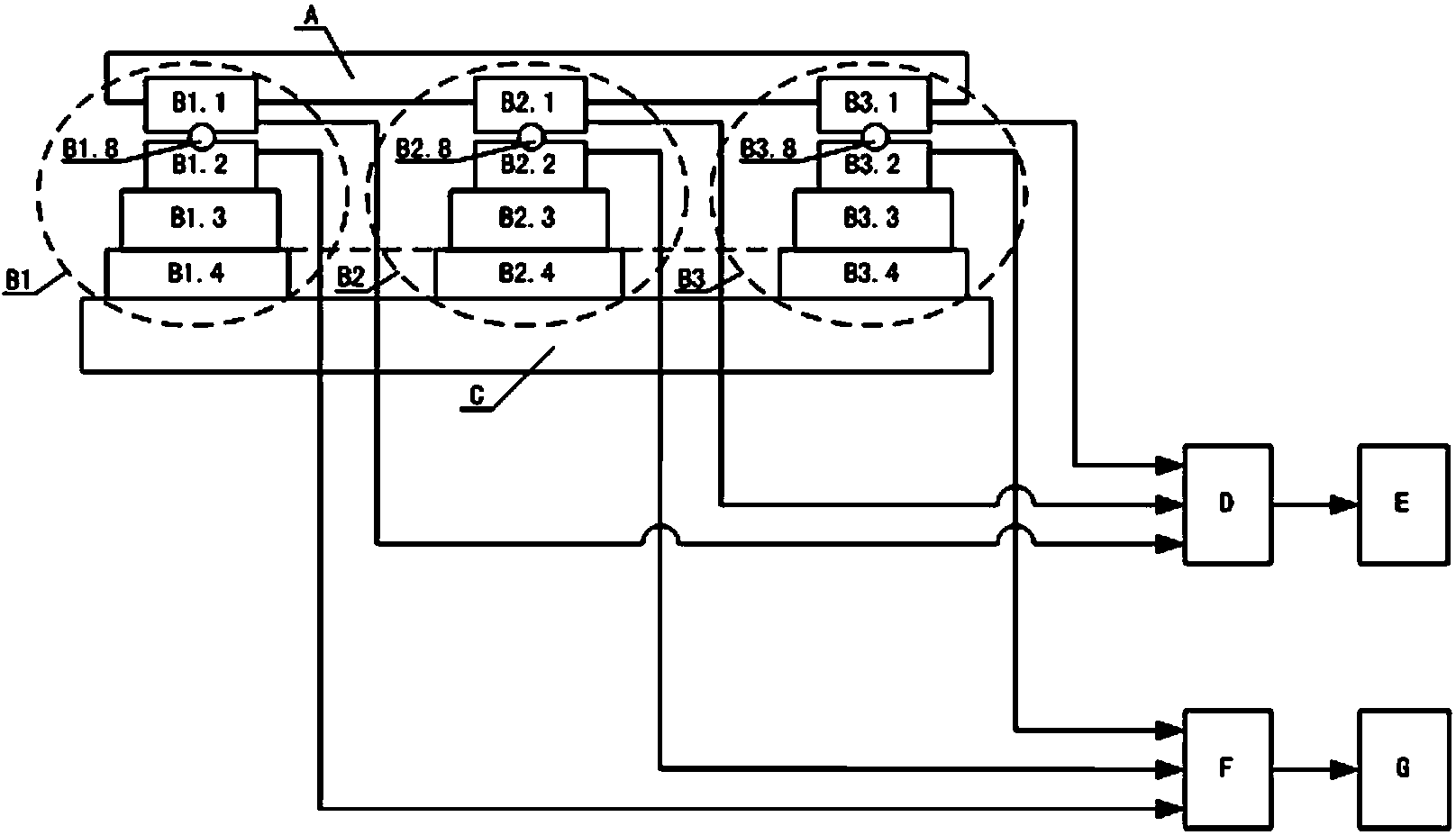

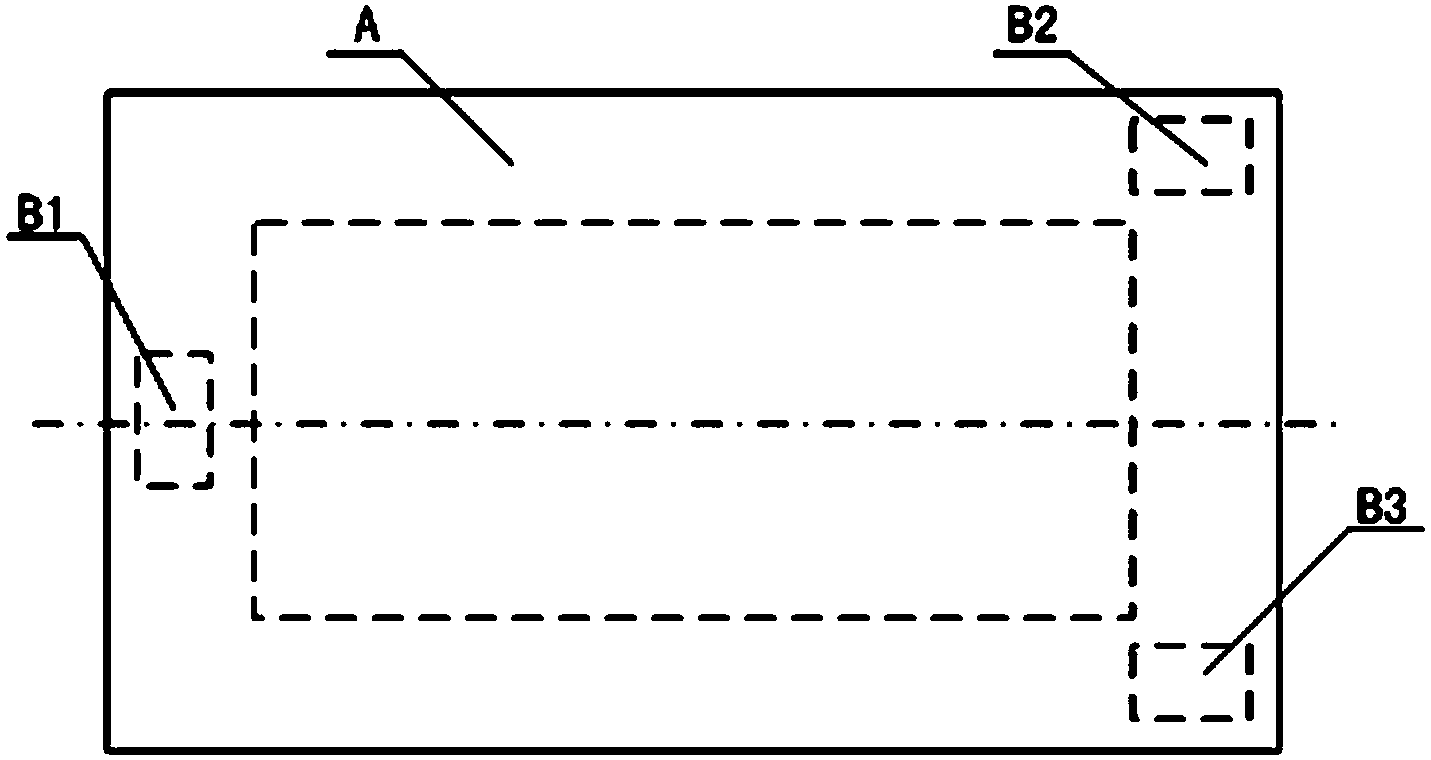

[0019] Such as figure 1 , figure 2 As shown, the online fully redundant mass center of mass measurement device based on the upper and lower mirror image installation load cells of the present invention includes a weighing pan A, three weighing units B1, B2, B3 with the same composition and structure arranged around the periphery of the weighing pan, and a base C. Two sets of independent weighing sensor signal acquisition circuits and data processing and display systems.

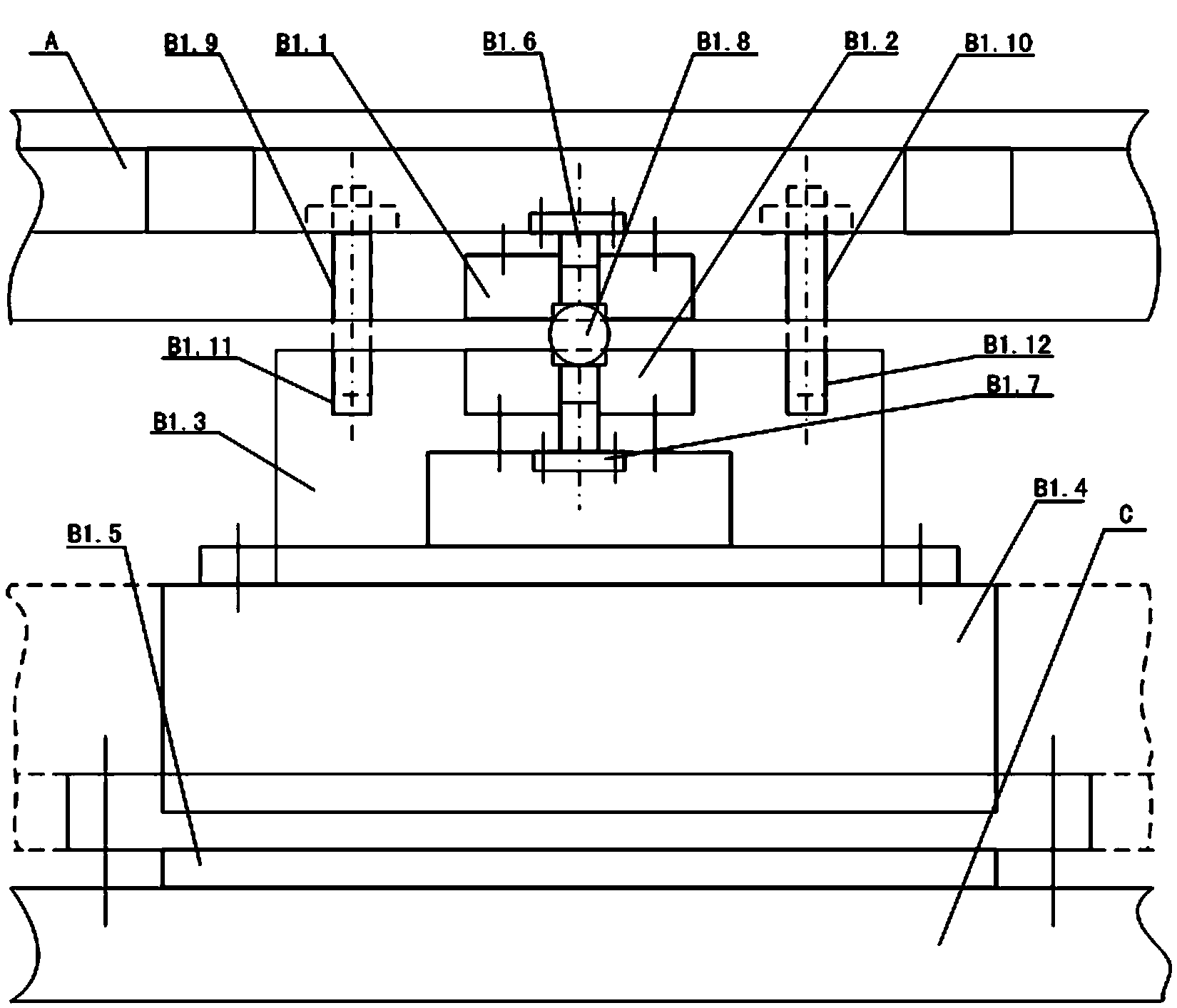

[0020] The weighing unit B1 is taken as an example for further description below: the weighing unit includes a pair of load cells B1.1, B1.2, support B1.3, and base B1 for fixing the support, which are suitable for mirror positioning and installation up and down .4 and support height adjustment block B1.5; the upper load cell B1.1 of the pair of load cells is installed on the weighing pan A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com