A Low Normal Friction Assembled Shear Box for Cyclic Shearing of Rock Mass Structural Surfaces

A shear box and assembled technology, which is applied in the field of geotechnical engineering, can solve the problem that the normal direction displacement of the cyclic tensile and compressive load sample is difficult to deform freely, so as to reduce the normal deformation resistance and friction, and facilitate installation and installation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

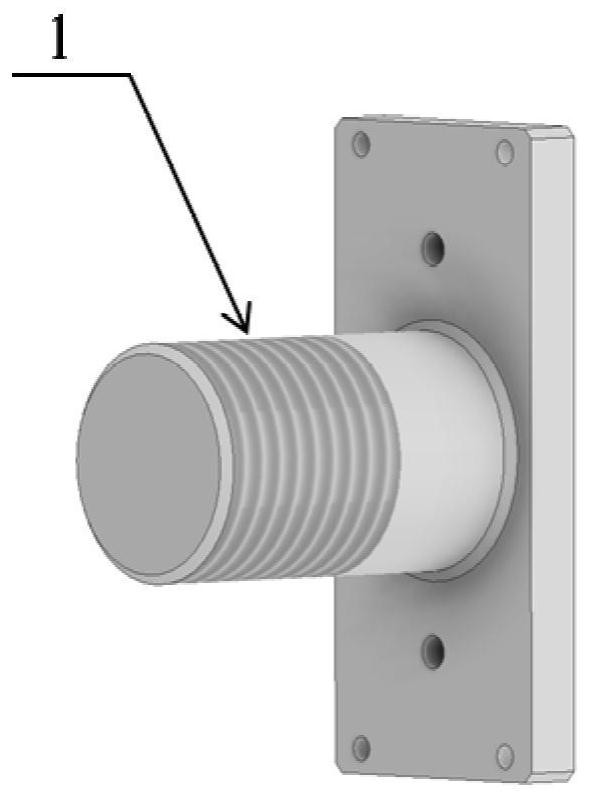

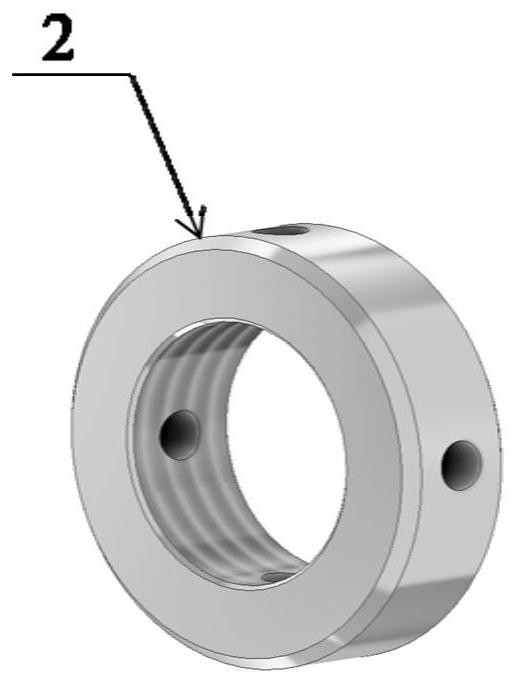

[0033] like Figure 1-9 As shown in the figure, a low-normal friction assembled shear box for cyclic shearing of rock mass structure surface is mainly composed of a pull shaft 1, a locking sleeve 2, a high-strength fastening screw 3, a limit screw 4, a groove Guide rail 5, slider 6, wing plate 7, high-strength connecting screw 8, connecting plate 9, upper folded plate 10, bolt 11, fastener 12, lower folded plate 13, nut 14, stepped stud 15, groove 16 , ball 17, connecting screw 18, and chute 19;

[0034] The section of the pull shaft 1 is T-shaped, its vertical section is a cylinder, and the end of the cylinder is an external thread. The shear box is connected to the fixed end of the shearing instrument through the pull shaft 1; , after adjusting the rotation of the shear box to the level, lock the shear box and the shearing instrument by rotating the locking sleeve 2 to ensure that they fit closely and bear the horizontal tensile load without displacement during the experime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com