Fatigue test device and fatigue test method for equal-thickness pavement structure on basis of MTS

A technology for pavement structure and fatigue testing, which is used in the application of repetitive force/pulsation force to test the strength of materials, etc., which can solve the problem of high test costs (each cost is in the hundreds of thousands to several million, cannot be widely promoted, and the loading period is long. and other problems, to achieve the effect of large variation range of loading parameters, easy popularization and application, and short loading cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

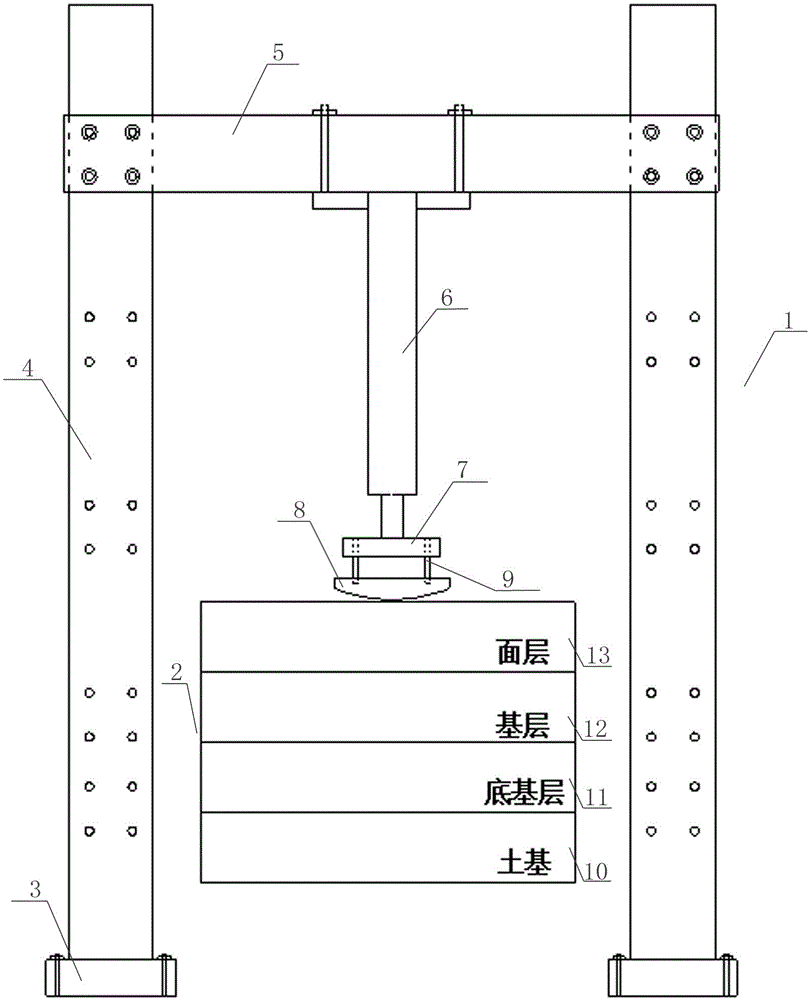

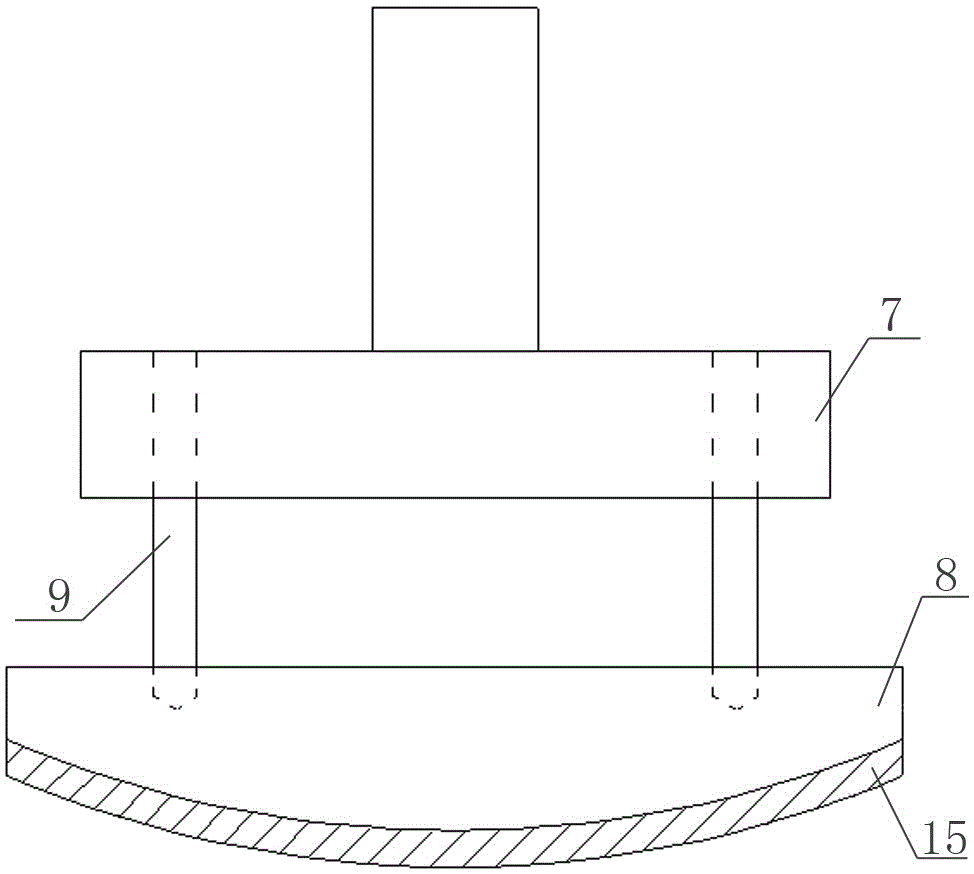

[0026] Such as figure 1 As shown, the structure schematic diagram of the equal-thickness pavement structure fatigue test device based on MTS of the present invention is provided, which includes MTS loading device 1, roadbed pavement model 2, MTS action head 7, loading head 8, sensor 14, rubber layer 15 . The shown MTS loading device 1 is composed of two bases 3, two vertical beams 4, a cross beam 5 and a drive rod 6. The two bases 3 shown are fixed on the foundation, the vertical beam 4 is fixed on the base 3, and the cross beam 5 It is fixed on the top of the two vertical beams 4 , and the driving rod 6 is arranged on the cross beam 5 . The MTS working head 7 is fixed on the top of the driving rod 6 , and under the driving action of the driving rod 6 , the MTS working head 7 can move up and down to load the roadbed and pavement model 2 .

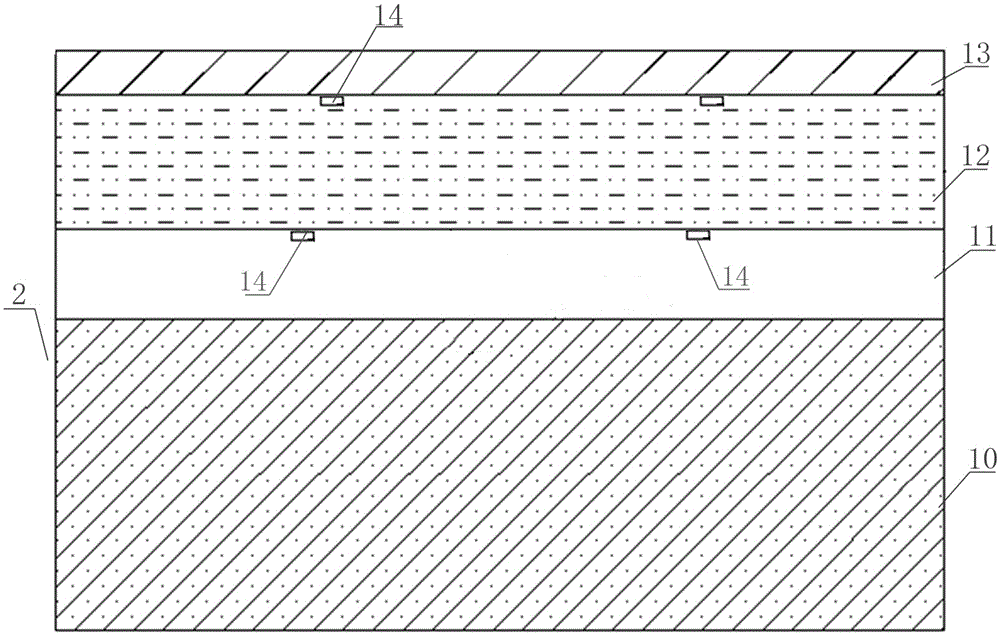

[0027] Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com