Testing device for determining compression creepage performance of microelectronic packing welding spots

A technology of microelectronic packaging and compression creep, which is applied in the direction of measuring devices, applying stable tension/pressure to test the strength of materials, and using optical devices, etc. Inconsistency between variable activation energy and stress index can achieve the effects of improving measurement accuracy, avoiding uneven distribution of compressive stress, and avoiding bias

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

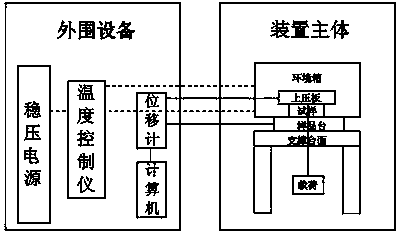

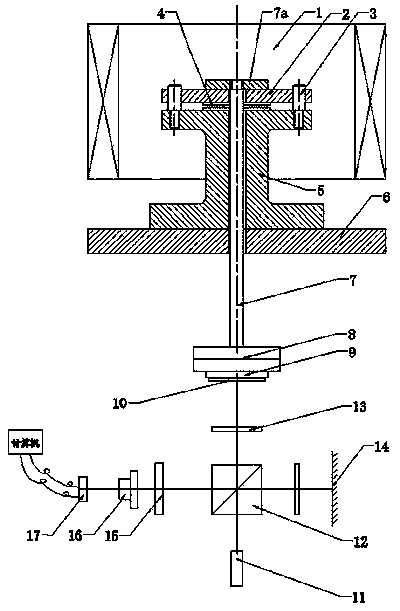

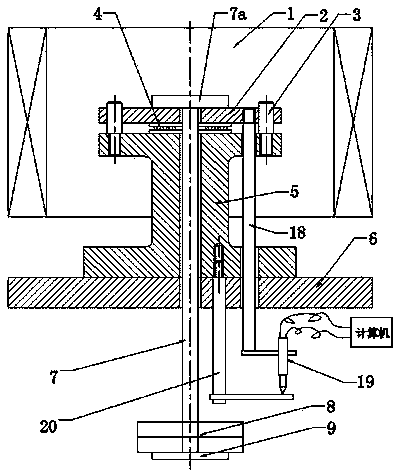

[0021] figure 1 The working principle diagram of a test device for measuring the compressive creep performance of solder joints in microelectronic packages is shown. combine figure 2 , 3 , the test device for measuring the compression creep performance of solder joints in microelectronic packaging consists of a device main body and peripheral equipment. The device main body includes an environmental chamber 1, a sample stage 5 and a loading mechanism, and the upper half of the sample stage 5 is arranged in the environmental chamber 1. The lower part of the sample table 5 is fixedly connected with the support table 6, and the sample 4 is placed on the upper plane of the sample table 5, and the sample 4 is pressed down with the upper pressing plate 2, and uniformly distributed and fixed on the sample table 5 are arranged on the periphery of the upper pressing plate 2. The guide hole that the positioning pin 3 of the upper part matches. The loading mechanism adopts the load r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com