Valve detection method and detection equipment

A detection method and technology of detection equipment, which are applied in mechanical valve testing, workpiece clamping devices, workbenches, etc., can solve the problems such as the inability to adjust the clamping force of the valve detection device and the inability to adapt to different requirements of the clamping force, and achieve a simple structure. , Reliable clamping, easy adjustment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

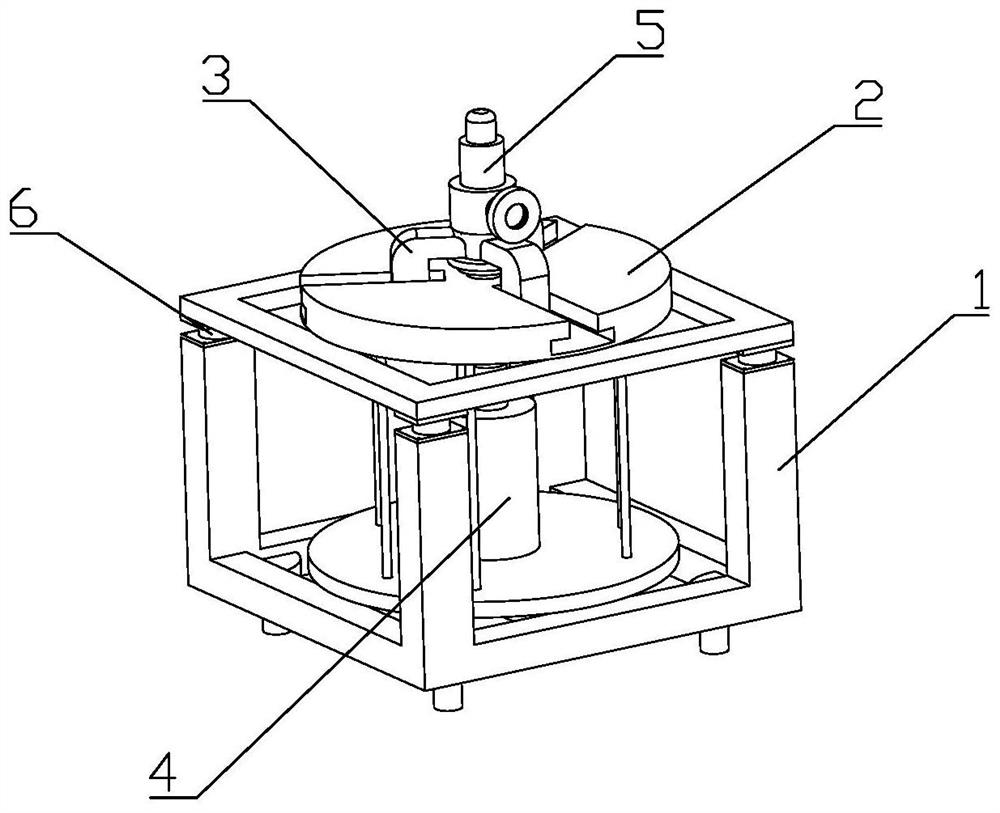

[0035] Embodiment 1 Overhead valve detection equipment

[0036] The upper-top valve detection device includes a clamping table, a valve clamping device and a control system arranged on the clamping table, and the clamping table includes a clamping frame 1 and a fixing plate 2 arranged on the clamping frame 1, so The valve clamping device includes several clamps 3 evenly arranged on the fixed plate 2 and a driving device 4 for applying and adjusting the clamping force. The clamping frame 1 is a rectangular frame, including an upper frame and a lower frame, and four sensors 6 for weighing the valve 5 to be tested are arranged between the upper frame and the lower frame; the clamp 3 is a jaw type clamp 3, The fixed plate 2 is provided with a radial chute, and the jaw type clamp 3 is slid in the chute; the clamping frame 1 is fixedly provided with a mounting plate, and the bottom of the driving device 4 is set on the mounting plate And the piston rod is vertically upward, the upp...

Embodiment 2

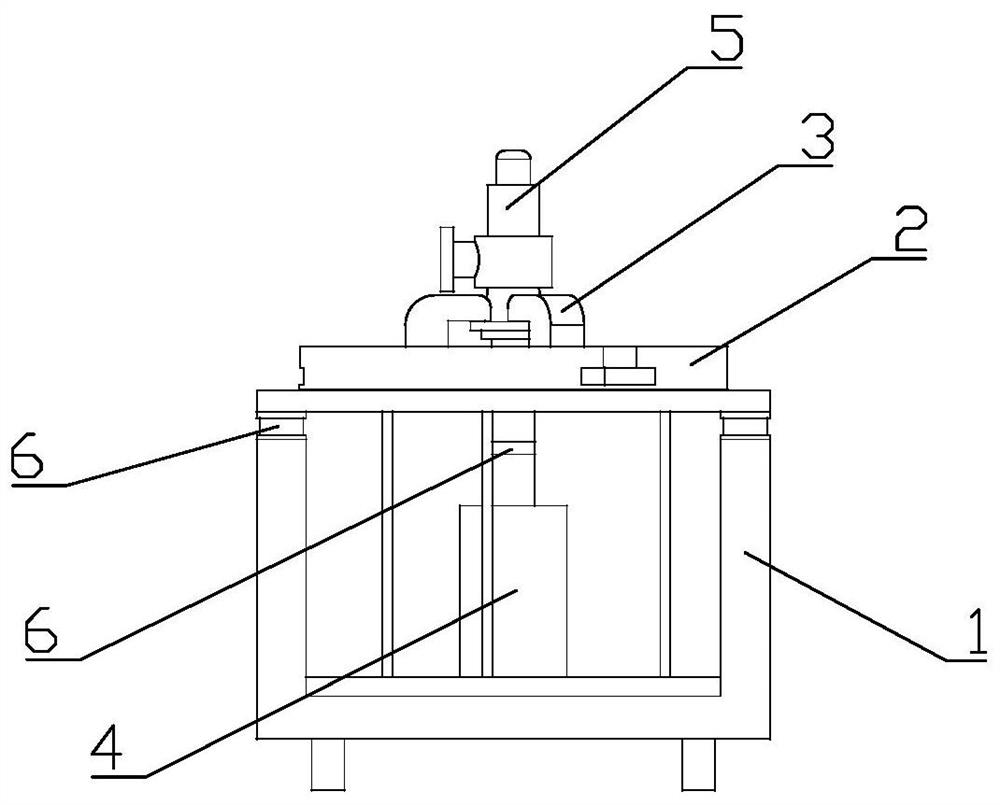

[0039] Embodiment 2 Push-down valve detection equipment 1

[0040]The push-down valve detection device includes a clamping table, a valve clamping device and a control system arranged on the clamping table, and the clamping table includes a clamping frame 1 and a fixing plate 2 arranged on the clamping frame 1. The valve clamping device includes several clamps 3 evenly arranged on the fixed plate 2 and a driving device 4 for applying and adjusting the clamping force. The clamping frame 1 is a rectangular frame, including an upper frame and a lower frame, and four sensors 6 for weighing the valve 5 to be tested are arranged between the upper frame and the lower frame; the clamp 3 is a jaw type clamp 3, The slide bar is slidably arranged in the axial installation hole of the fixed plate 2, and the lower end of the slide bar is fixed with a moving plate; the drive device 4 is vertically arranged in the clamping frame 1 and the piston rod is vertically downward, so that The lower...

Embodiment 3

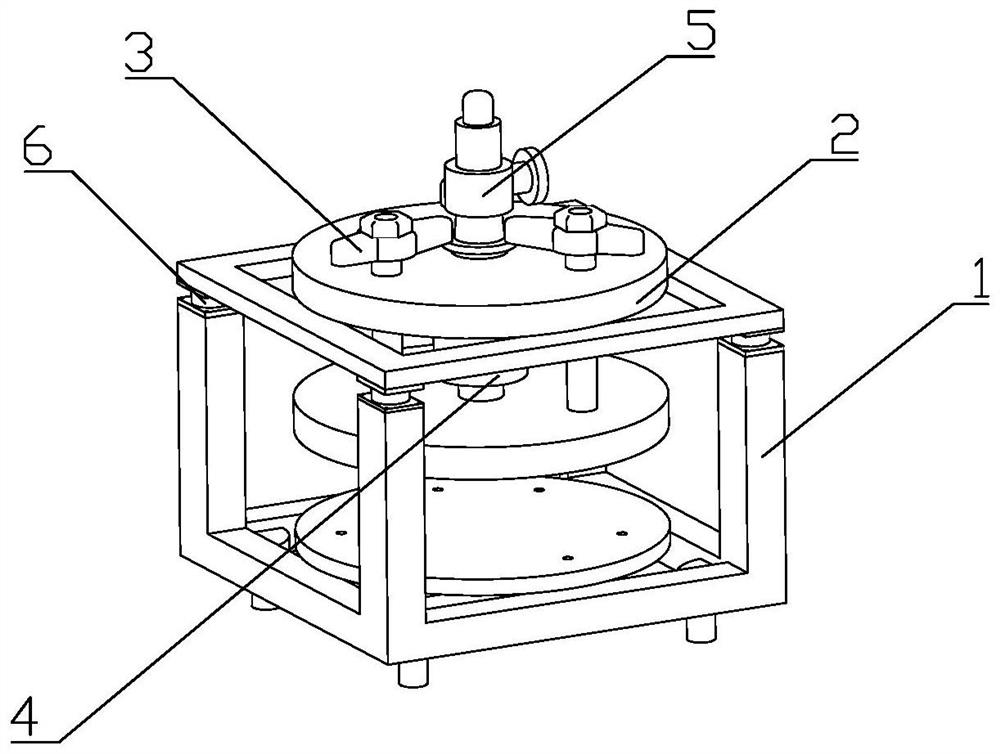

[0043] Embodiment 3 Push-down valve detection equipment 2

[0044] The push-down valve detection device includes a clamping table, a valve clamping device and a control system arranged on the clamping table, and the clamping table includes a clamping frame 1 and a fixing plate 2 arranged on the clamping frame 1. The valve clamping device includes several clamps 3 evenly arranged on the fixed plate 2 and a driving device 4 for applying and adjusting the clamping force. The clamping frame 1 is a rectangular frame, including an upper frame and a lower frame, and four sensors 6 for weighing the valve 5 to be tested are arranged between the upper frame and the lower frame; the clamp 3 is a lever clamp 3, hinged On the mounting seat, the fixed plate 2 is provided with a radial chute, and the mounting seat is slid in the chute; the driving device 4 is vertically arranged on the mounting seat and the piston rod is vertically upward, and the lever type One end of the clamp 3 is hinged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com