A cardboard laminating machine synchronous cutting natural curing equipment

A technology of curing equipment and laminating machine, which is applied in the direction of conveyor objects, chemical instruments and methods, lamination auxiliary operations, etc., which can solve the problems of low quality of corrugated cardboard lamination, and achieve tight bonding, uniform and uniform glue injection cutting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

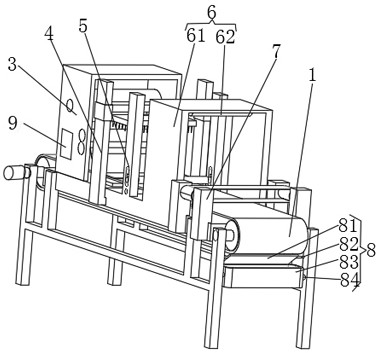

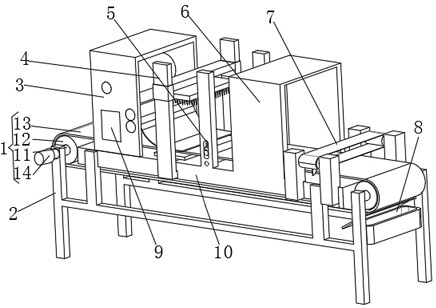

[0031] Such as Figure 1-7 As shown, a cardboard laminating machine synchronously cuts natural curing equipment, including a transmission device 1, the transmission device 1 includes a roller 11 that is movably connected to the truss 2, and the roller 11 runs through the surface of the truss 2, and the surface of the roller 11 is provided with Drive roller 12, and drive roller 12 is fixedly connected with roller shaft 11, and drive roller 12 surface is provided with conveyer belt 13, and conveyer belt 13 and drive roller 12 surface offset, and one end of drive roller 12 is provided with servomotor 14, and servomotor 14 and The drive roller 12 is movably connected, the side of the transmission device 1 is provided with a truss 2, and the truss 2 is fixedly connected with the transmission device 1, and the transmission device 1 is provided with a baffle 10 inside, and the baffle 10 is parallel to the length direction of the conveyor belt 13, and the baffle 10 Fixed connection wi...

Embodiment 2

[0035] Such as figure 1 , 3 , 5, according to different cardboards and coatings, high-temperature glue is stored in the glue storage box 44 in the glue injection device 4, and the glue injection needle 45 on the bottom surface of the glue storage box 44 can inject high-temperature glue between the coating and the cardboard. The cardboard after film coating enters the heating device 6 after passing through the pressing device 5, and the heating device 6 includes a second casing 61 arranged on the surface of the baffle 10, the second casing 61 is fixedly connected with the baffle 10, and the second casing The inner wall of 61 is provided with a heating wire, and the heating wire is embedded in the inner wall of the second housing 61, and the power of the heating wire is 1KW-1.5KW, and the film-coated cardboard in the heating device 6 is heated to promote the rapid drying and bonding of high-temperature glue.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com