Patents

Literature

35results about How to "Uniform glue injection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

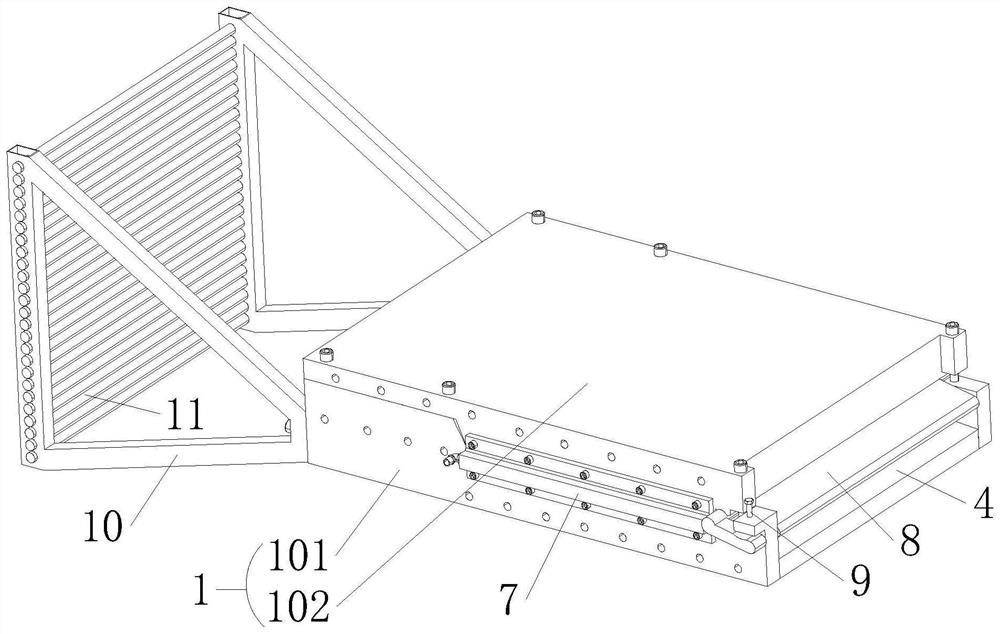

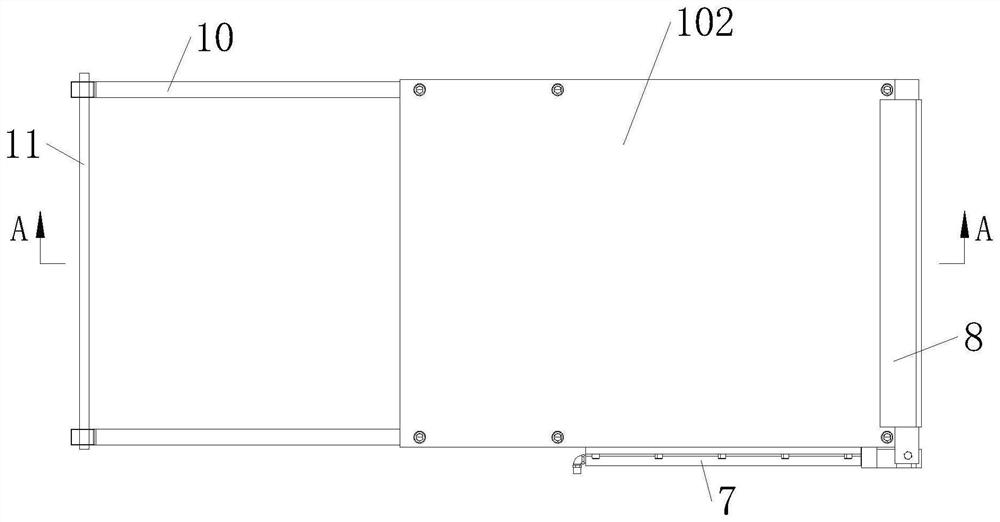

Glue injection sealing machine used after rapid assembly of glass door and glass window

ActiveCN110548646AInjection speed unchangedUniform glue injectionLiquid surface applicatorsCoatingsEngineeringGlass sheet

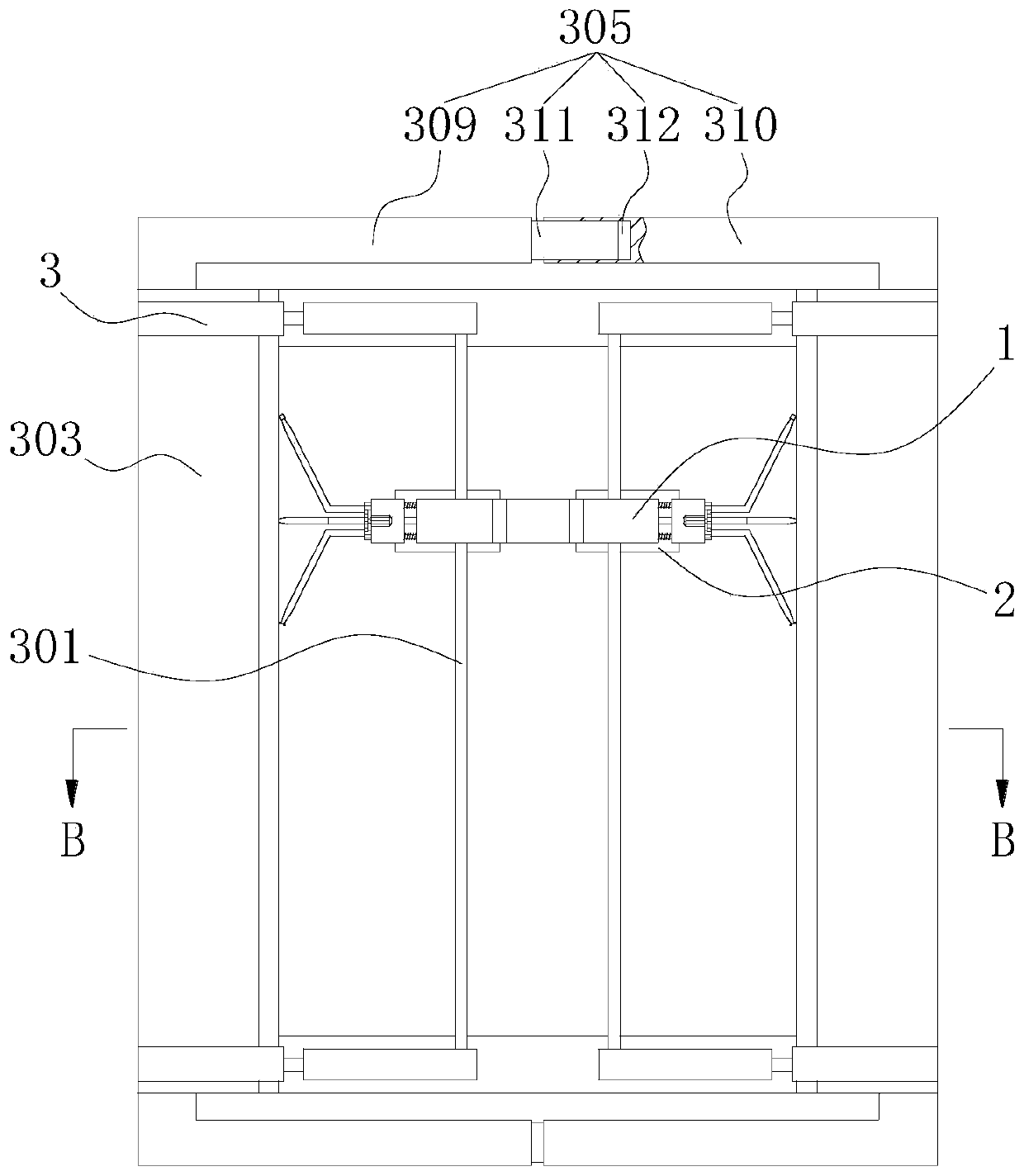

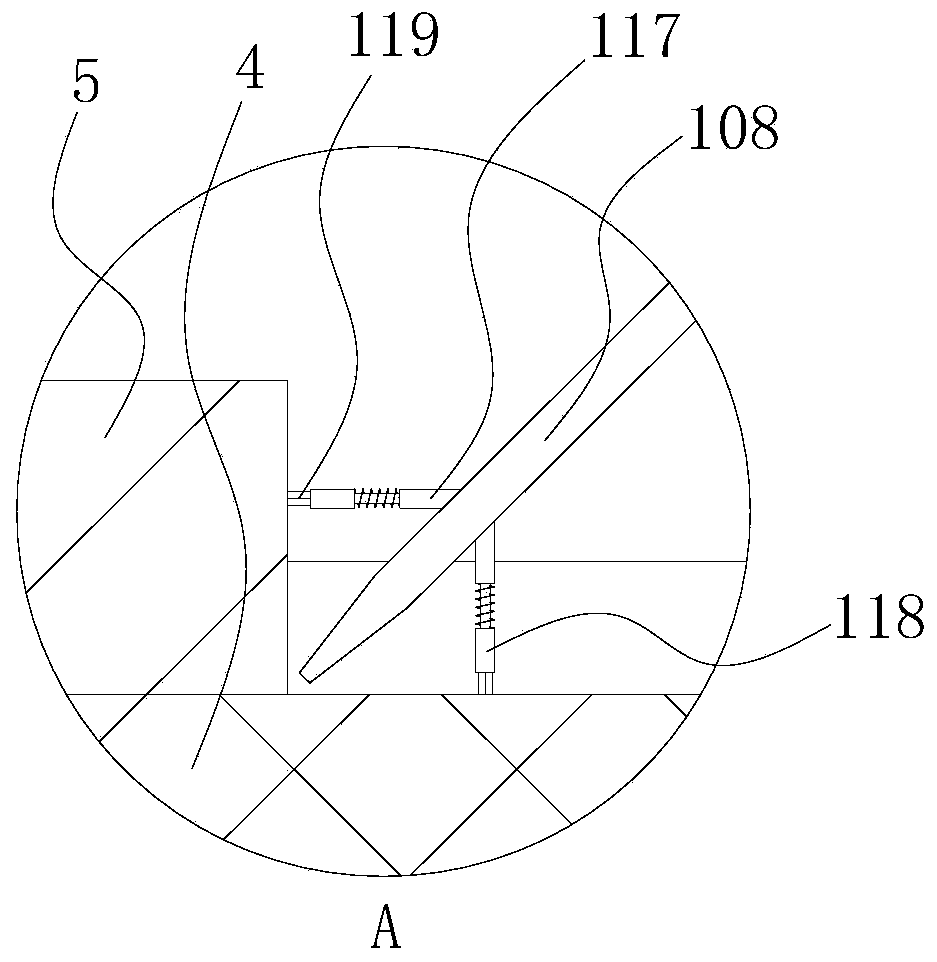

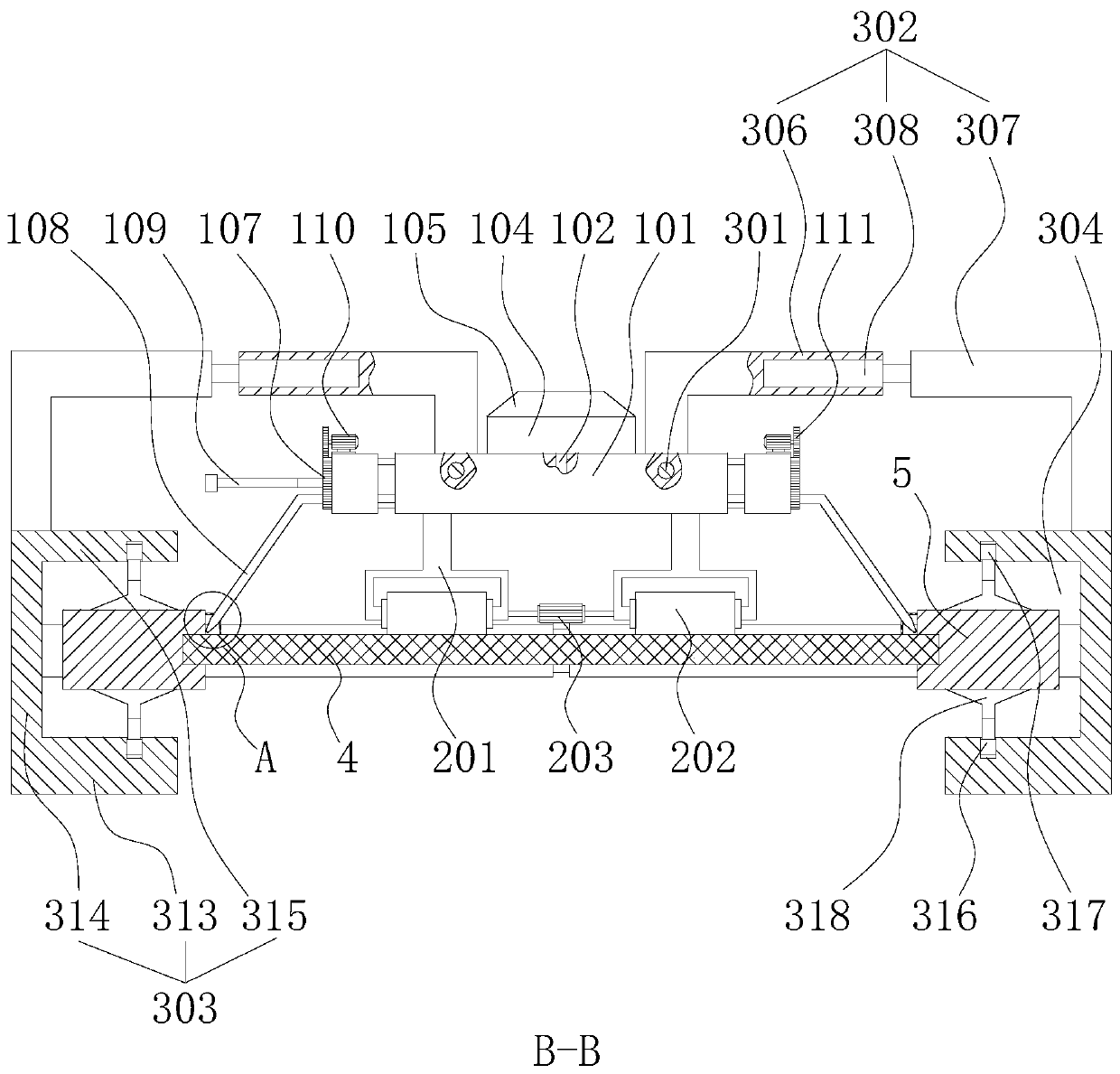

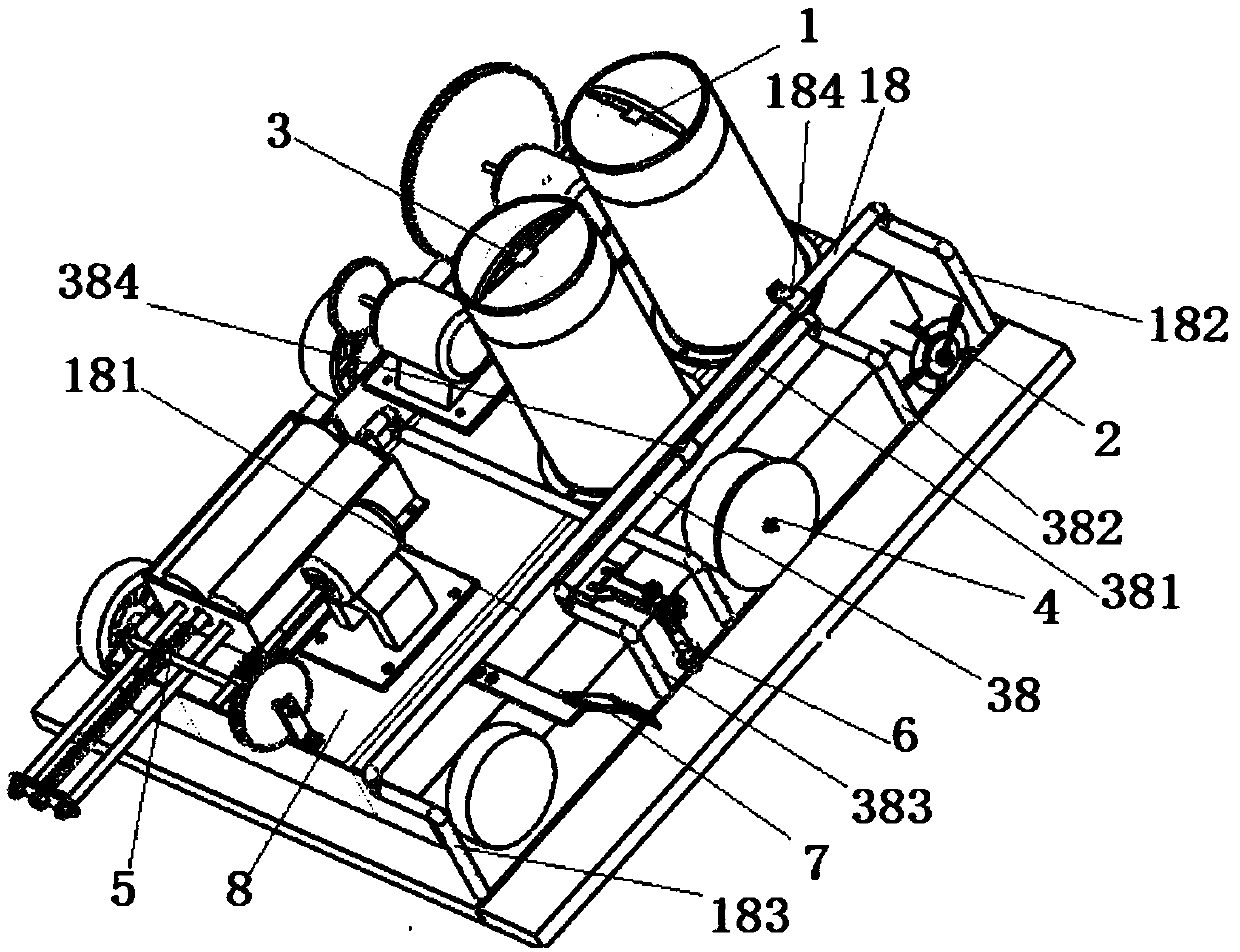

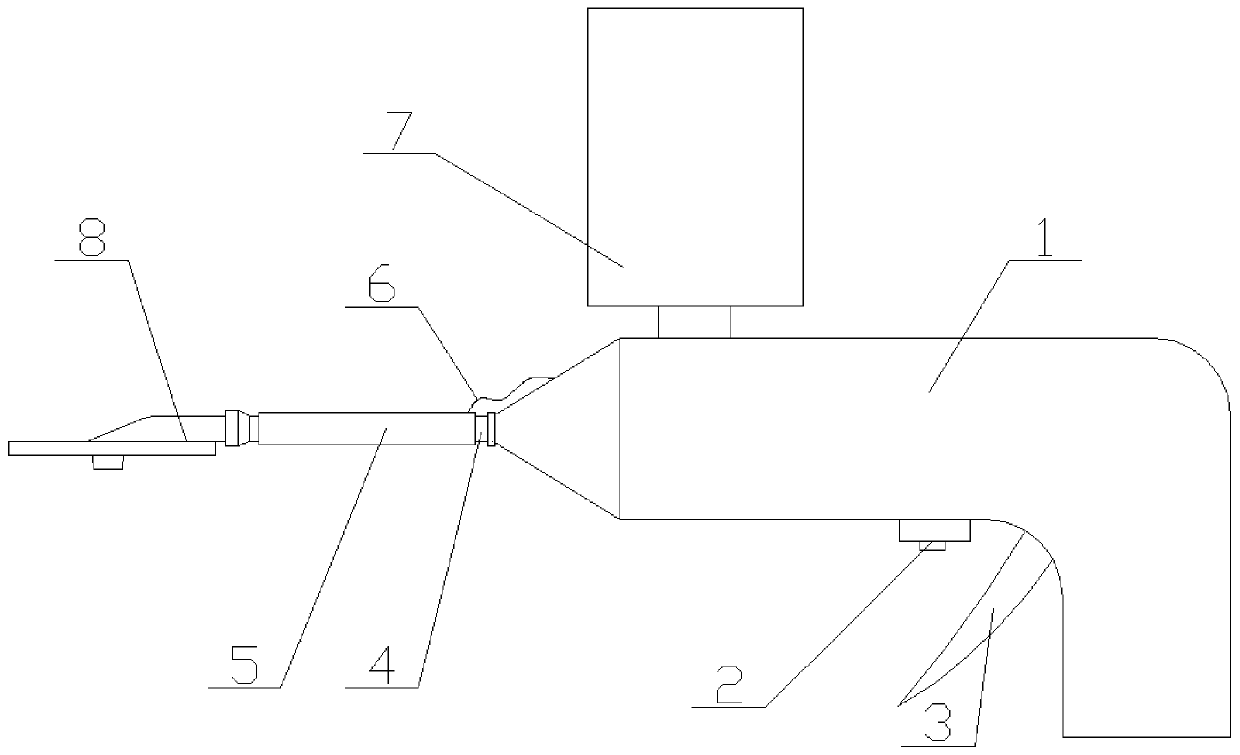

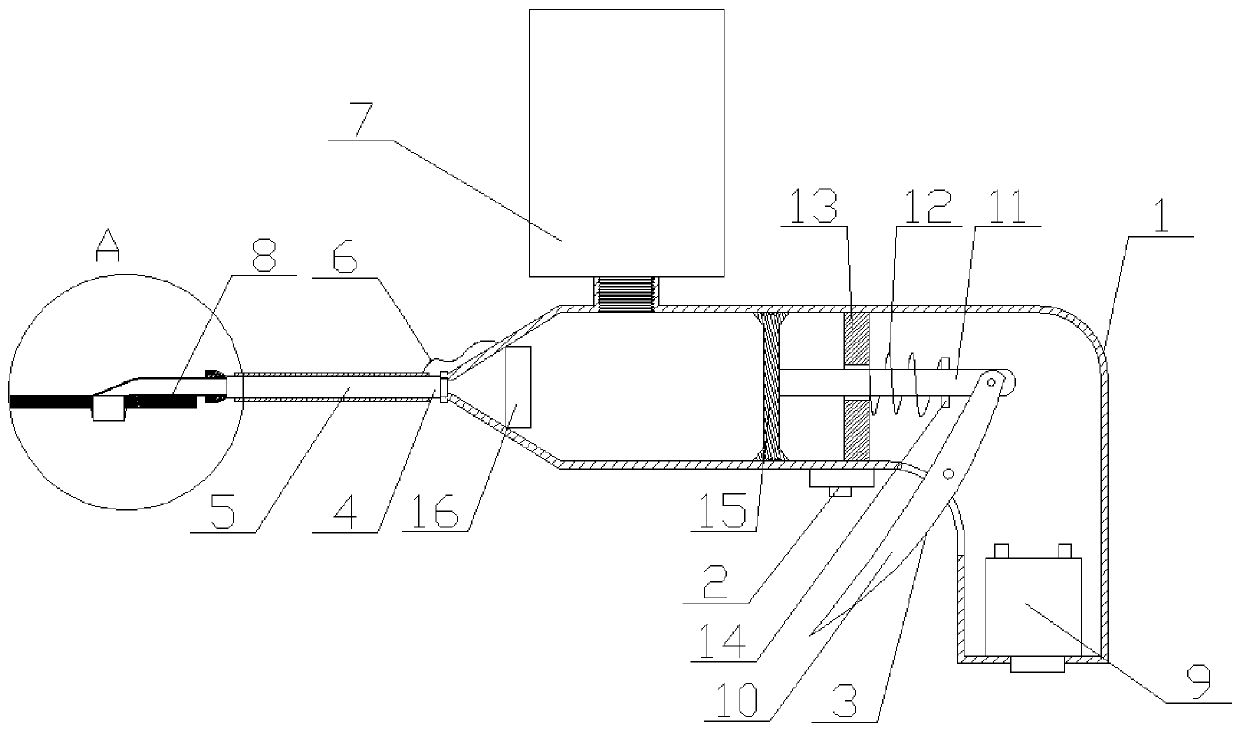

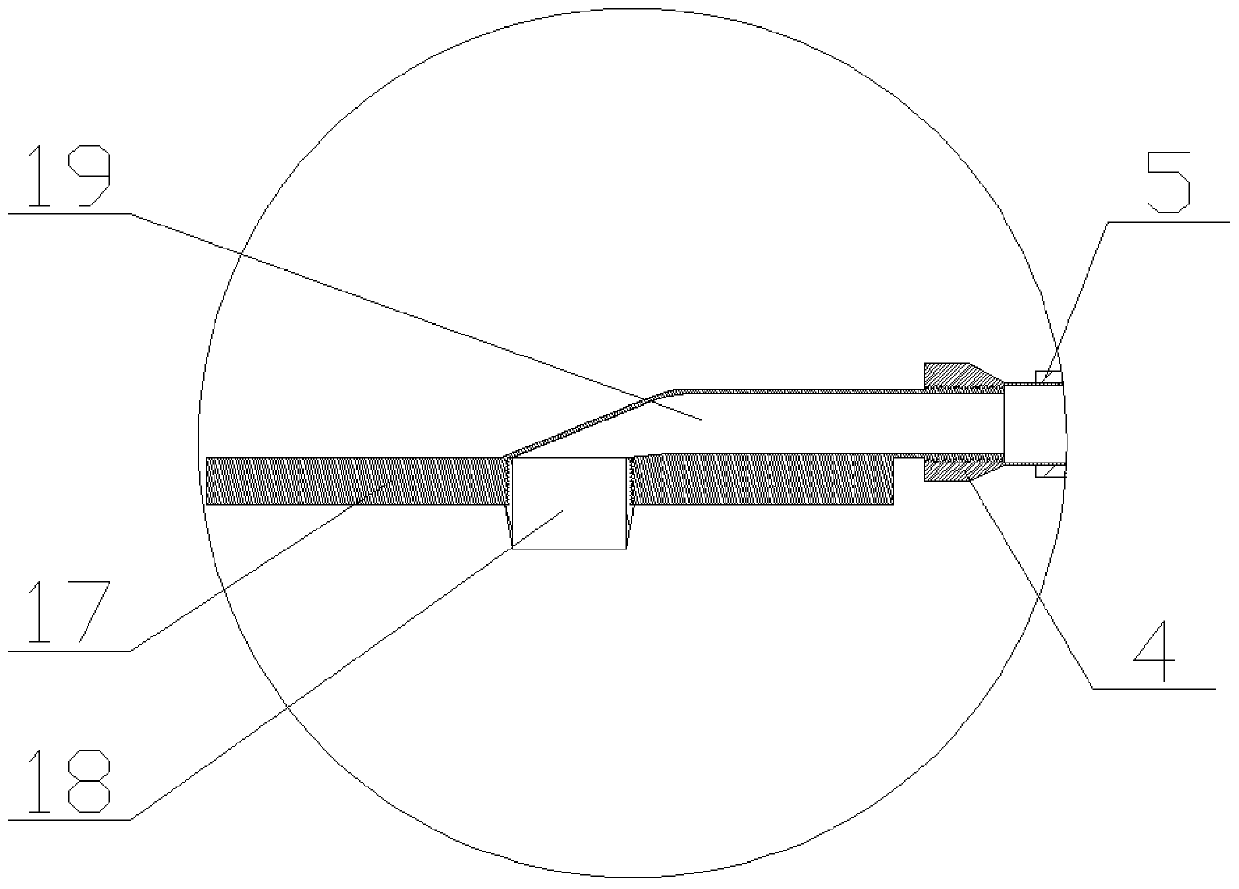

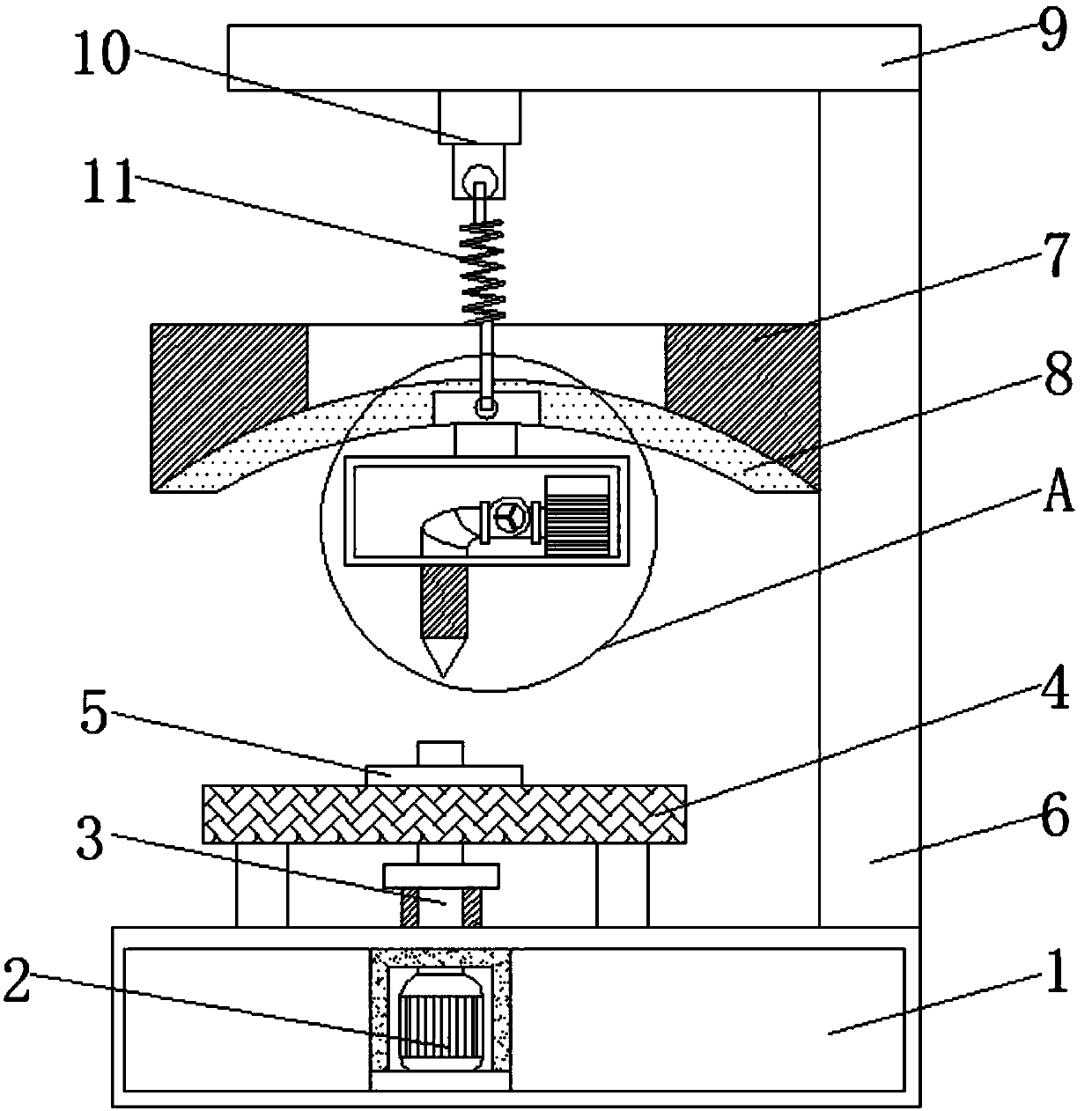

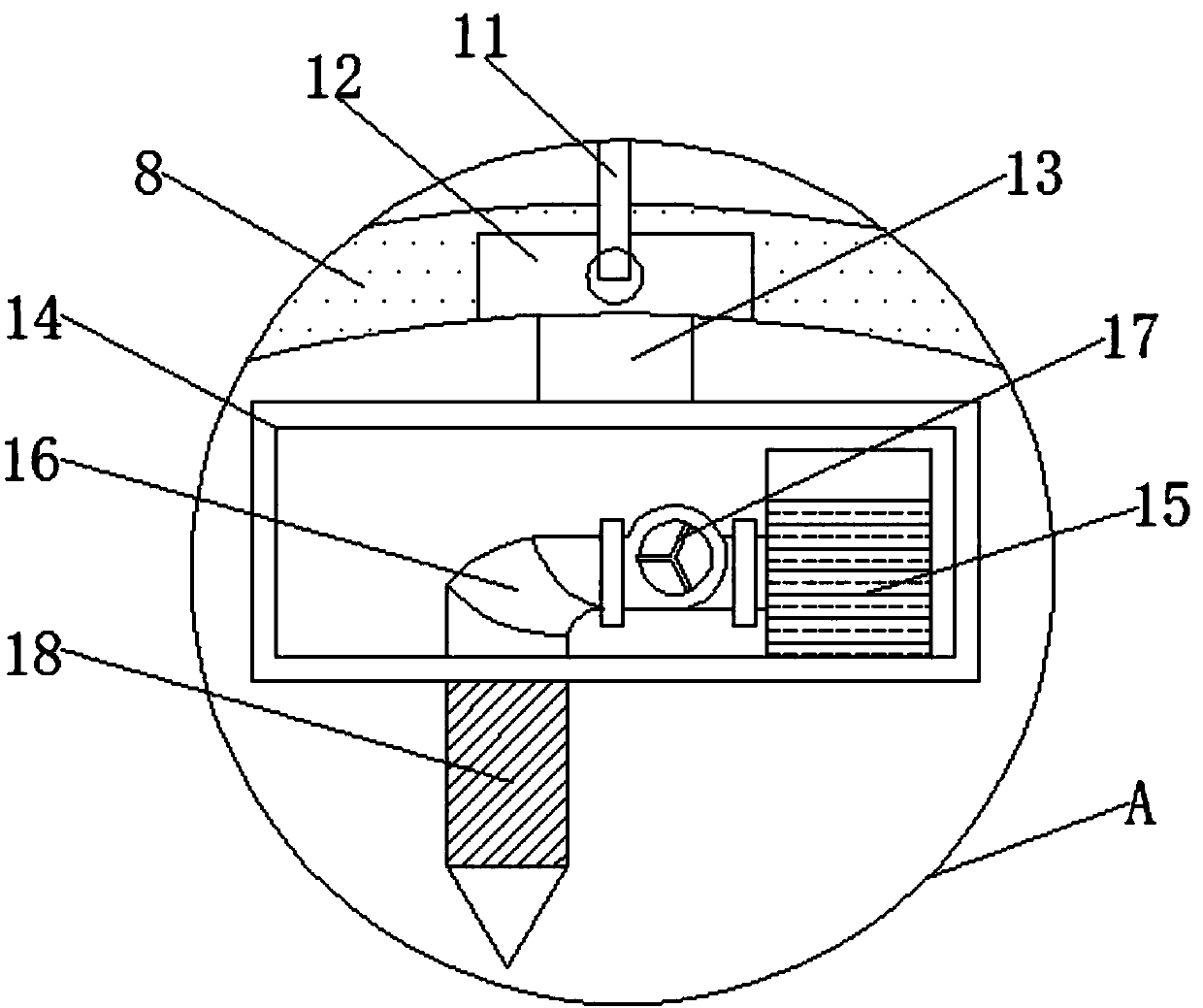

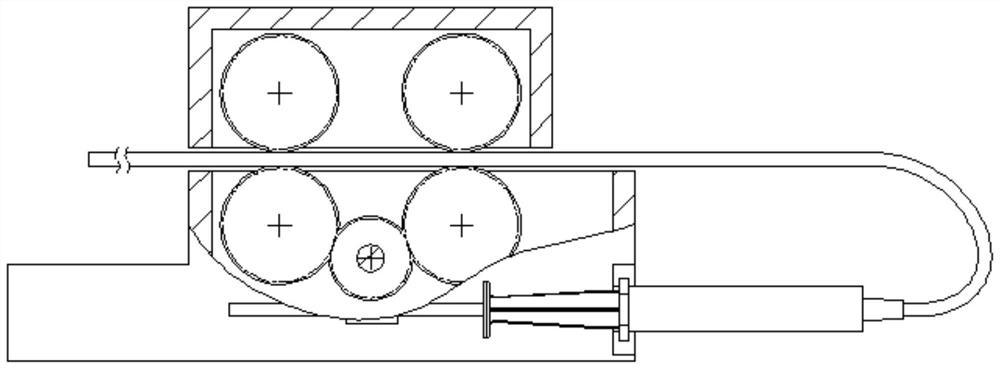

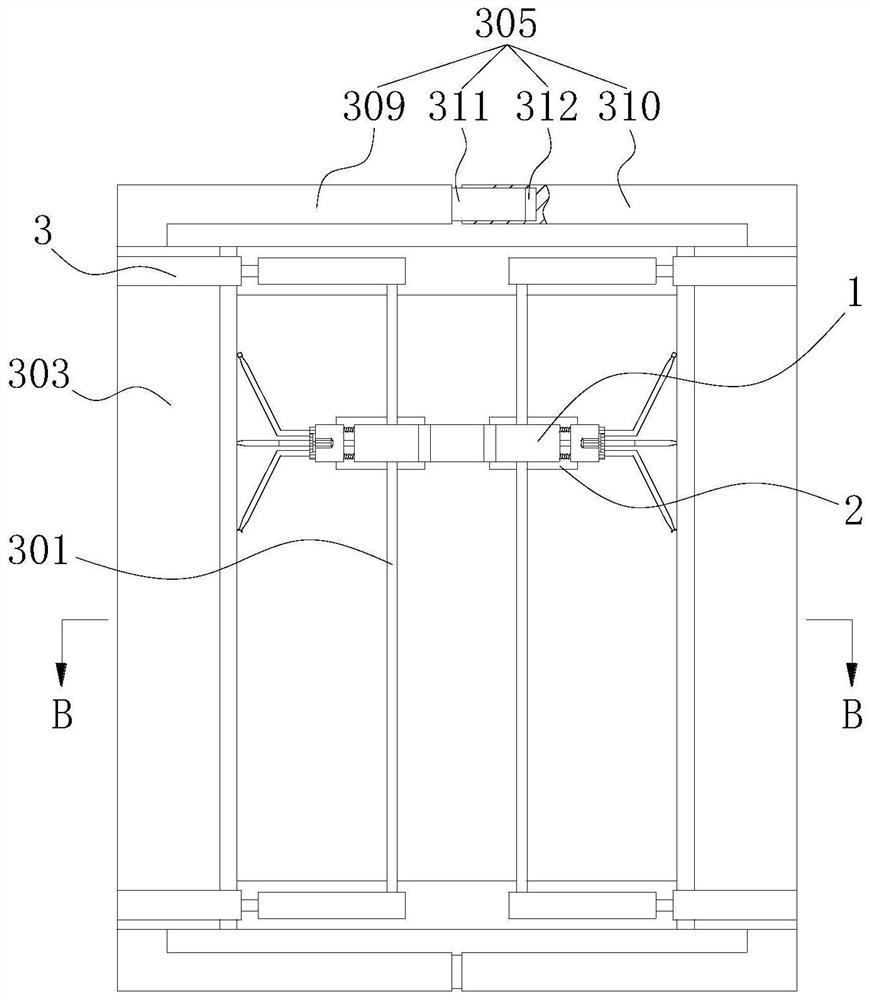

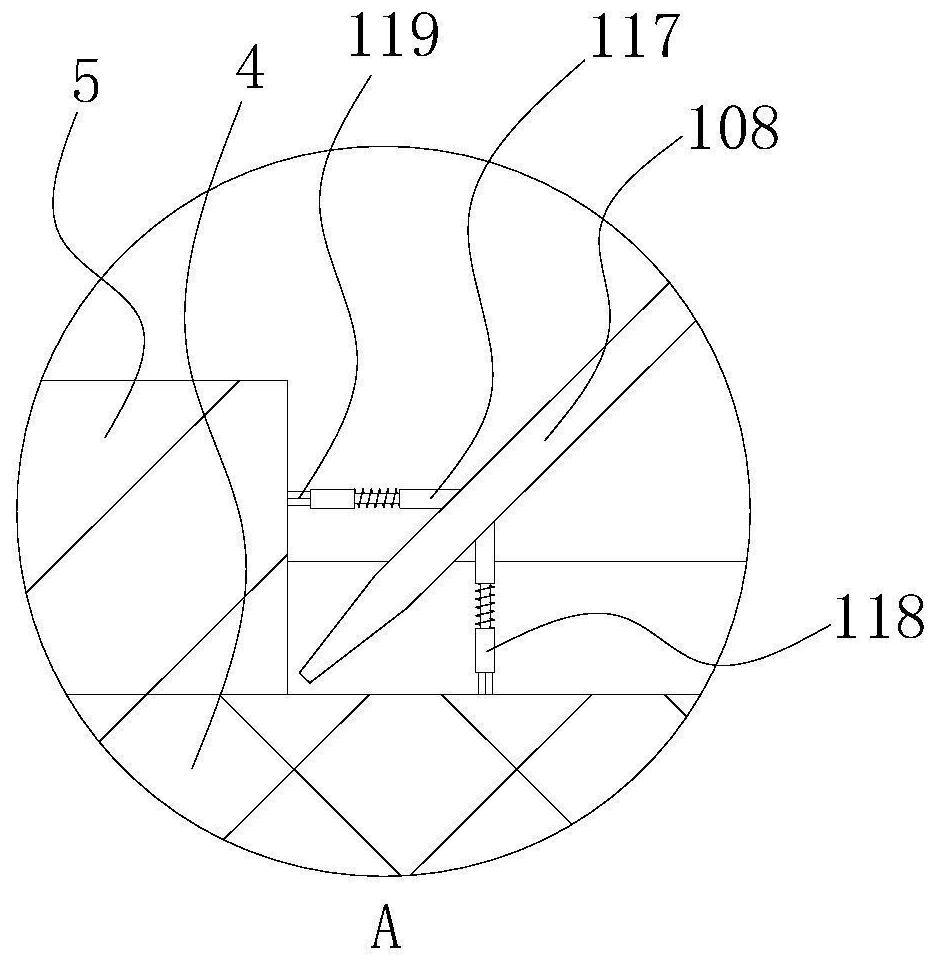

The invention belongs to the door and window processing technology field, and particularly relates to a glue injection sealing machine used after rapid assembly of a glass door and a glass window. Theglue injection sealing machine used after the rapid assembly of the glass door and the glass window comprises a glue injection mechanism, a walking mechanism and a fixing mechanism, wherein the glueinjection mechanism comprises a cavity, a glue injection pipe and a glue smearing rod are fixedly connected with the end face of the cavity, uniform glue applying and uniform glue smearing are realized by driving the glue injection pipe through uniform motion of the walking mechanism, the walking mechanism comprises a roller frame fixedly connected with the bottom face of the cavity, a rubber roller supported on a glass plate is rotatably connected onto the roller frame, an output end of a second motor is fixedly connected with a rubber roller rotation shaft, and the fixing mechanism enables the cavity to only move in the direction parallel to joints of the glass door and the glass window through a limiting function on one hand, and clamps a frame of the glass door and the glass window soas to limit movement of the glass door and the glass window on the other hand. The glue injection sealing machine used after the rapid assembly of the glass door and the glass window can realize simultaneous glue injection for the two joints of glass plates and the frame, thereby achieving uniform glue injection. The glue injection sealing machine used after the rapid assembly of the glass door and the glass window smears the joints after the glue injection, uniformly covers two sides of each joint with glass glue, and improves sealing effect.

Owner:赣州宇智材料有限公司

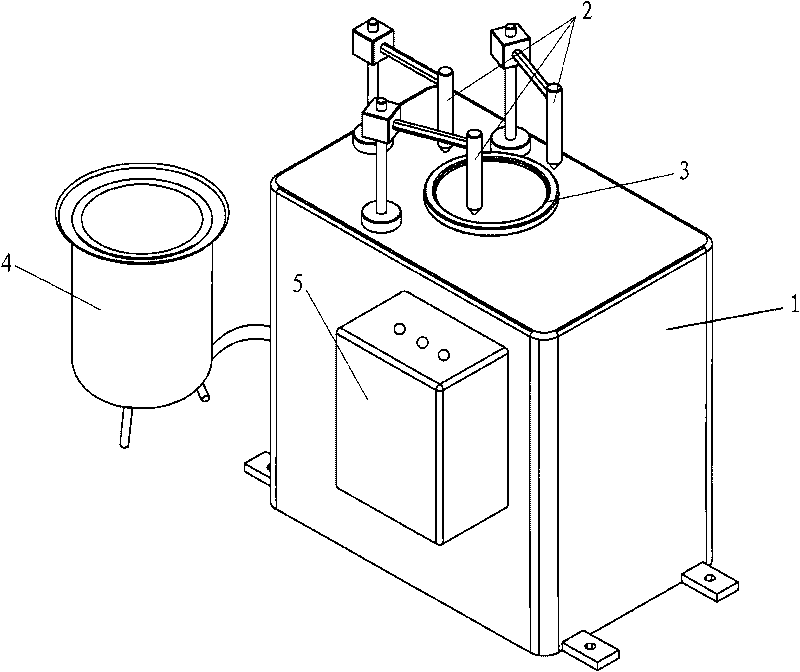

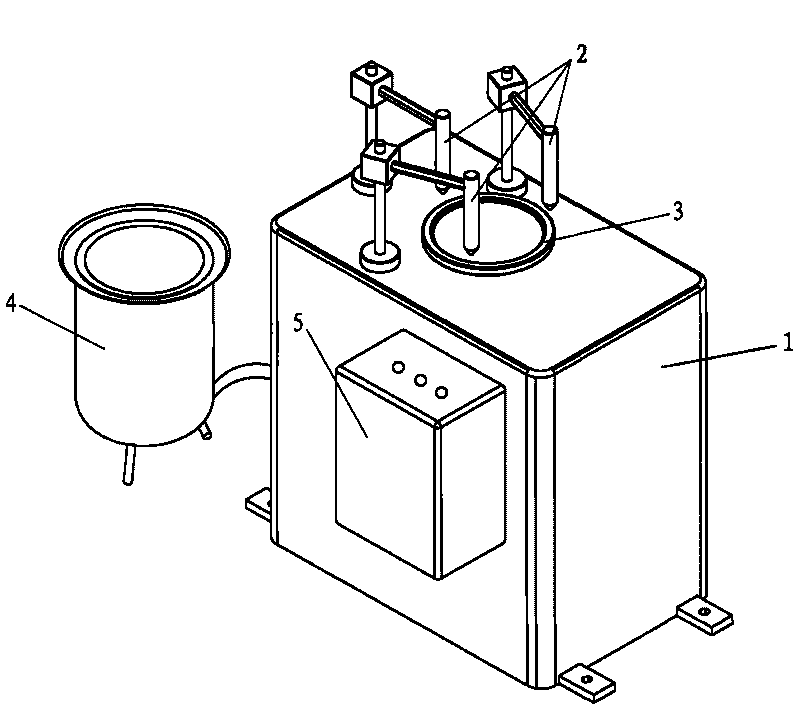

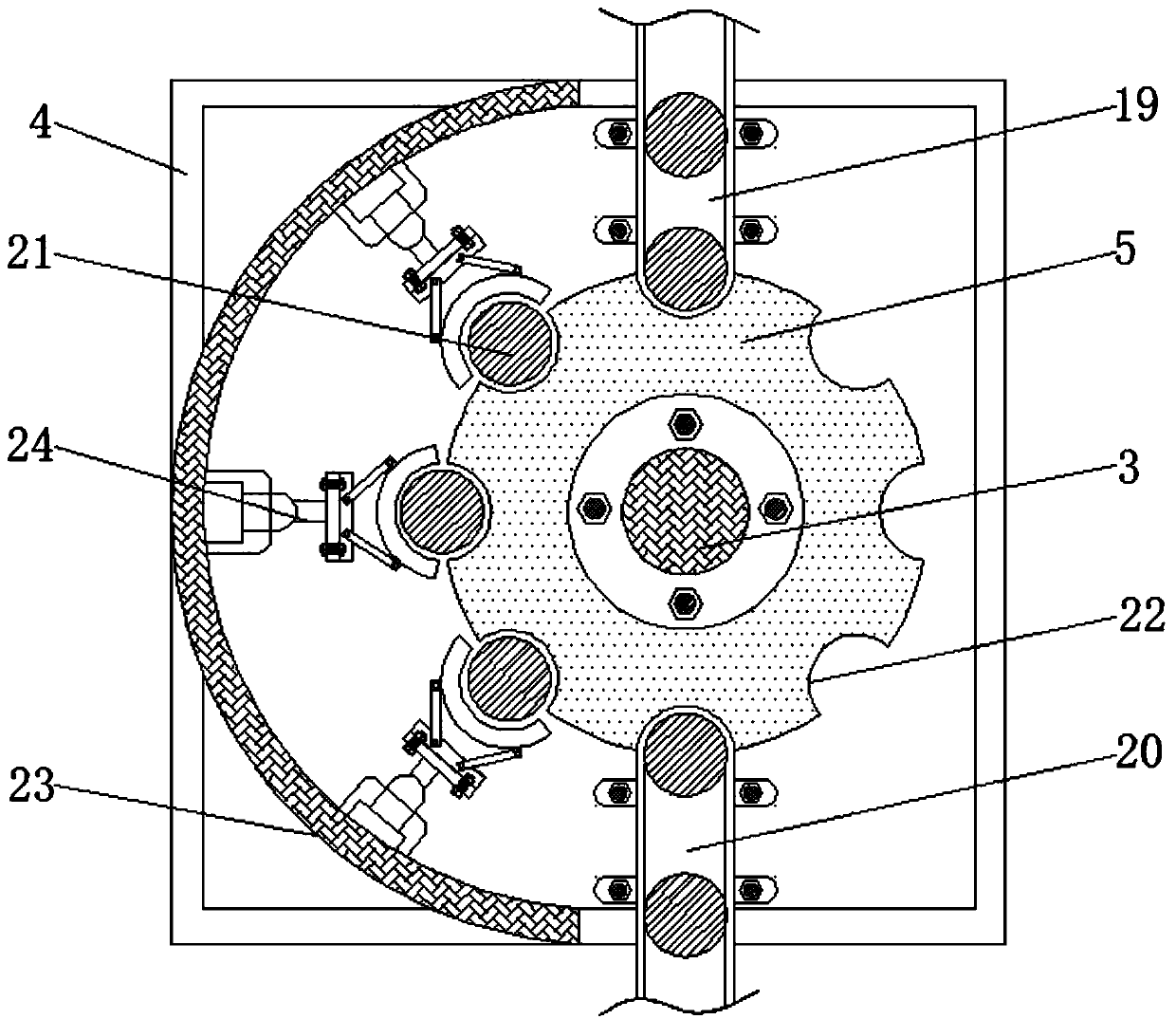

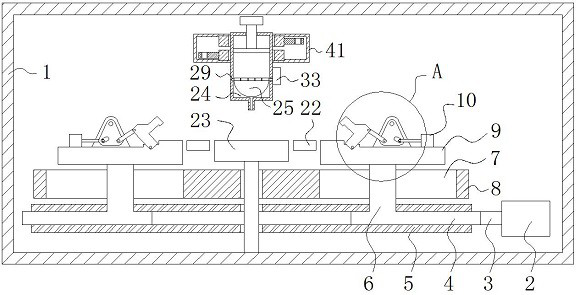

Joint cleaning and filling device

The invention discloses a joint cleaning and filling device. The device comprises a base, a joint cleaning device, a glue injecting device and a guide driving device; the joint cleaning device is arranged at the front end of the right side of the base, the joint cleaning device is used for cleaning sundries in a to-be-treated joint; the guide driving device is arranged at the rear side of the joint cleaning device. Accordingly, by adopting the guide driving device, the joint cleaning and filling device moves along ceramic tile joints, and in the moving process, by means of the cleaning deviceat the front end of the device, the sundries in the joint are preliminarily cleaned away; by means of the glue injecting device, filler injecting of the joint is achieved; the structure is compact, the time needed in the working process is greatly shortened, while all work is completed, the requirements on workers are low, and the work efficiency is better improved.

Owner:CHANGAN UNIV

Multi-sprayer glue injector

InactiveCN101733232AIncrease production capacityReduce consumptionLiquid surface applicatorsCoatingsSprayerEngineering

The invention relates to a multi-sprayer glue injector which comprises an injector body, a sprayer, a tray and a glue can, wherein the sprayer is connected with the glue can via tube; the number of the sprayer is at least two; the sprayer is right opposite to the edge of the tray and the sprayers are uniformly arranged on a circle which has a same center of the tray. The multi-sprayer glue injector further comprises a PLC control electric box. The multi-sprayer glue injector of the invention has a capacity which is almost three times of the capacity of a single sprayer glue injector. Due to the PLC control, the glue mixing ratio and the output are stable and the glue is injected uniformly.

Owner:SUZHOU HYCAN HLDG CO LTD

Glue injecting device for unit glass curtain wall and glue injection method of glue injecting device

ActiveCN110552485AUniform glue injectionEasy to assemble and disassembleLiquid surface applicatorsBuilding constructionsPower componentElectric heating

The invention belongs to the technical field of glue injection of curtains and particularly discloses a glue injecting device for a unit glass curtain wall and a glue injection method of the glue injecting device. The glue injecting device comprises an L-shaped glue injecting gun body; the gun opening end of the glue injecting gun body is in threaded connection with a horizontally-arranged glue injecting pipe; an electric heating sleeve is arranged on the glue injecting pipe in a sleeving manner; the end, far away from the glue injecting gun body, of the glue injecting pipe is in threaded connection with a glue injection orifice; the position, close to the gun opening end, of the top of the glue injecting gun body communicates with a glue storage mechanism; the outer wall of the glue injecting gun body is provided with a power switch; a glue injection driving mechanism is arranged inside the glue injecting gun body; a glue injection chamber is formed between the glue injection drivingmechanism and the gun opening end of the glue injection gun body; an electric heater is arranged inside the glue injection chamber; a power component is further arranged inside the glue injecting gunbody; and a power input end of the power switch is connected with a power output end of the power component. The glue injecting device for the unit glass curtain wall and the glue injection method ofthe glue injecting device, disclosed by the invention, has the advantages of realizing uniform glue injection, being movable at any time and realizing convenience in mounting and dismounting of the glue injecting device.

Owner:新疆远麟阳光幕墙装饰工程有限公司

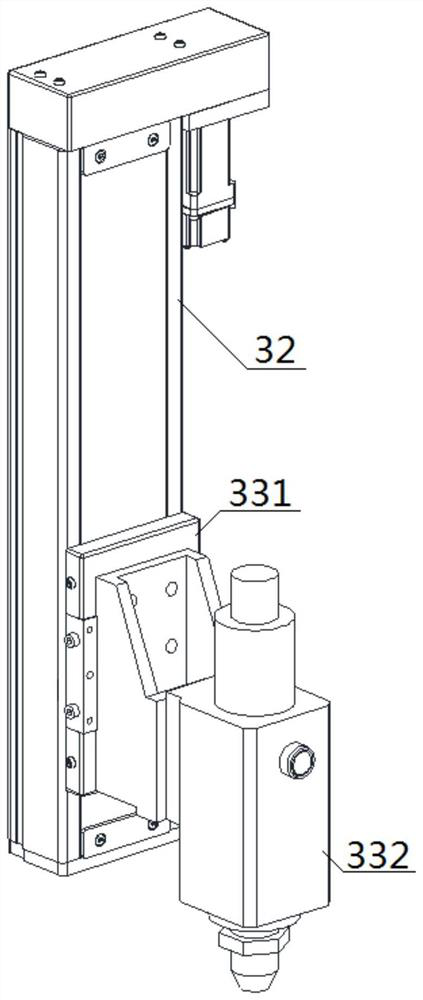

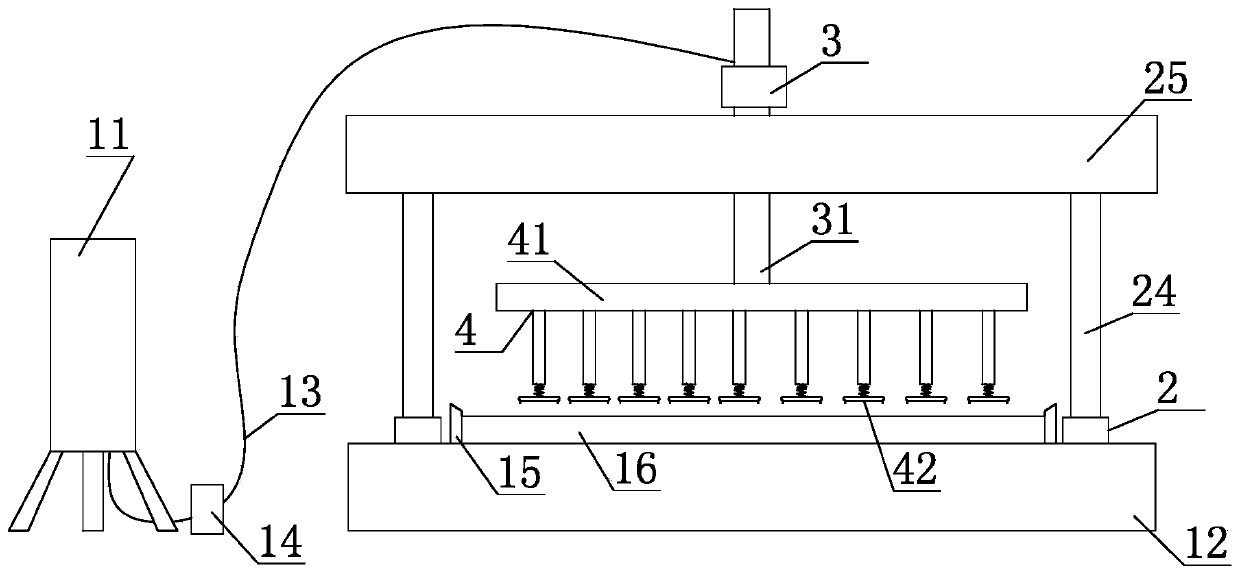

LED lamp belt automated assembling equipment with groove glue injection height detection

InactiveCN111974623AAvoid wastingEasy to useLiquid surface applicatorsMaterial gluingStructural engineeringWorkbench

The invention discloses LED lamp belt automated assembling equipment with groove glue injection height detection. The equipment particularly comprises a base, a workbench, a laser displacement sensorand a U-shaped half sleeve, wherein a frame body is installed on one side of the top of the base, a vacuum pump is installed at the middle position of the top of the frame body, electromagnetic sliderails are arranged at both ends of the top of the frame body, sliding blocks are installed inside the electromagnetic slide rails, hydraulic telescopic rods are fixed to the bottom ends of the slidingblocks, and vacuum suction cups are arranged at the bottom ends of the hydraulic telescopic rods. According to the LED lamp belt automated assembling equipment with groove glue injection height detection, through the arrangement of the laser displacement sensor and an alarm, the laser displacement sensor can detect the glue injection groove depth of the U-shaped half sleeve, if the glue injectiongroove depth is detected as unqualified, a control panel can control the alarm to send an alarm to remind staff to take away a bad U-shaped half sleeve, and unqualified assembled LED lamp belts are avoided.

Owner:广州市金点子机电科技发展有限公司

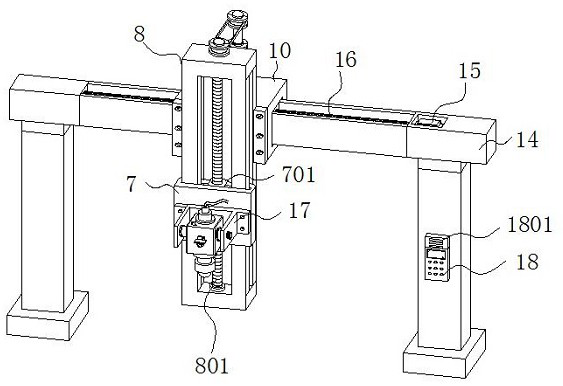

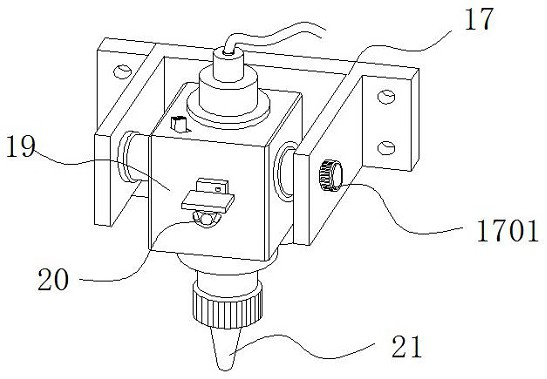

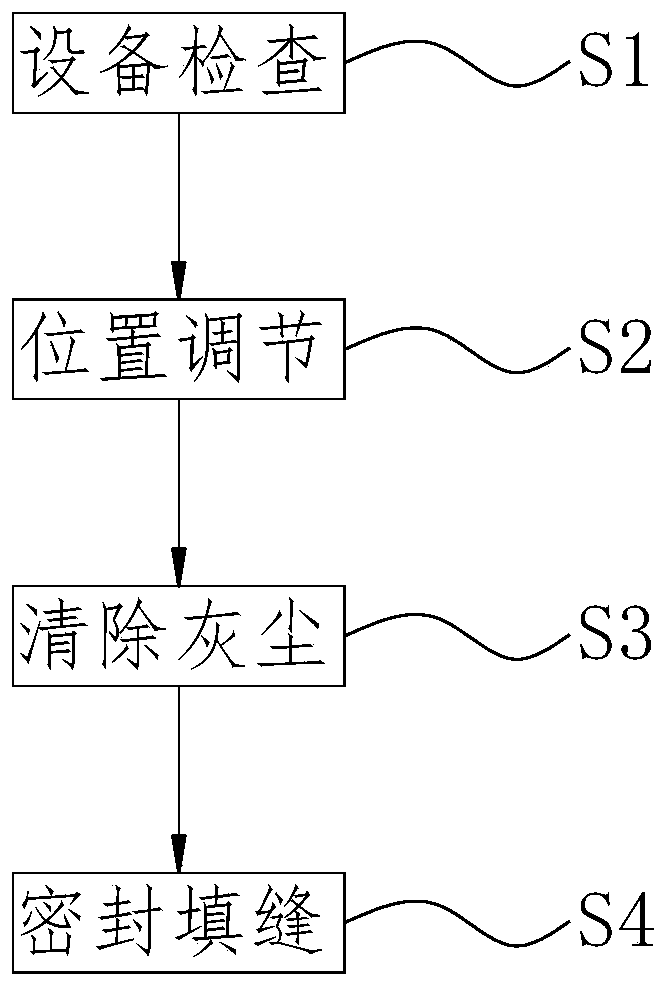

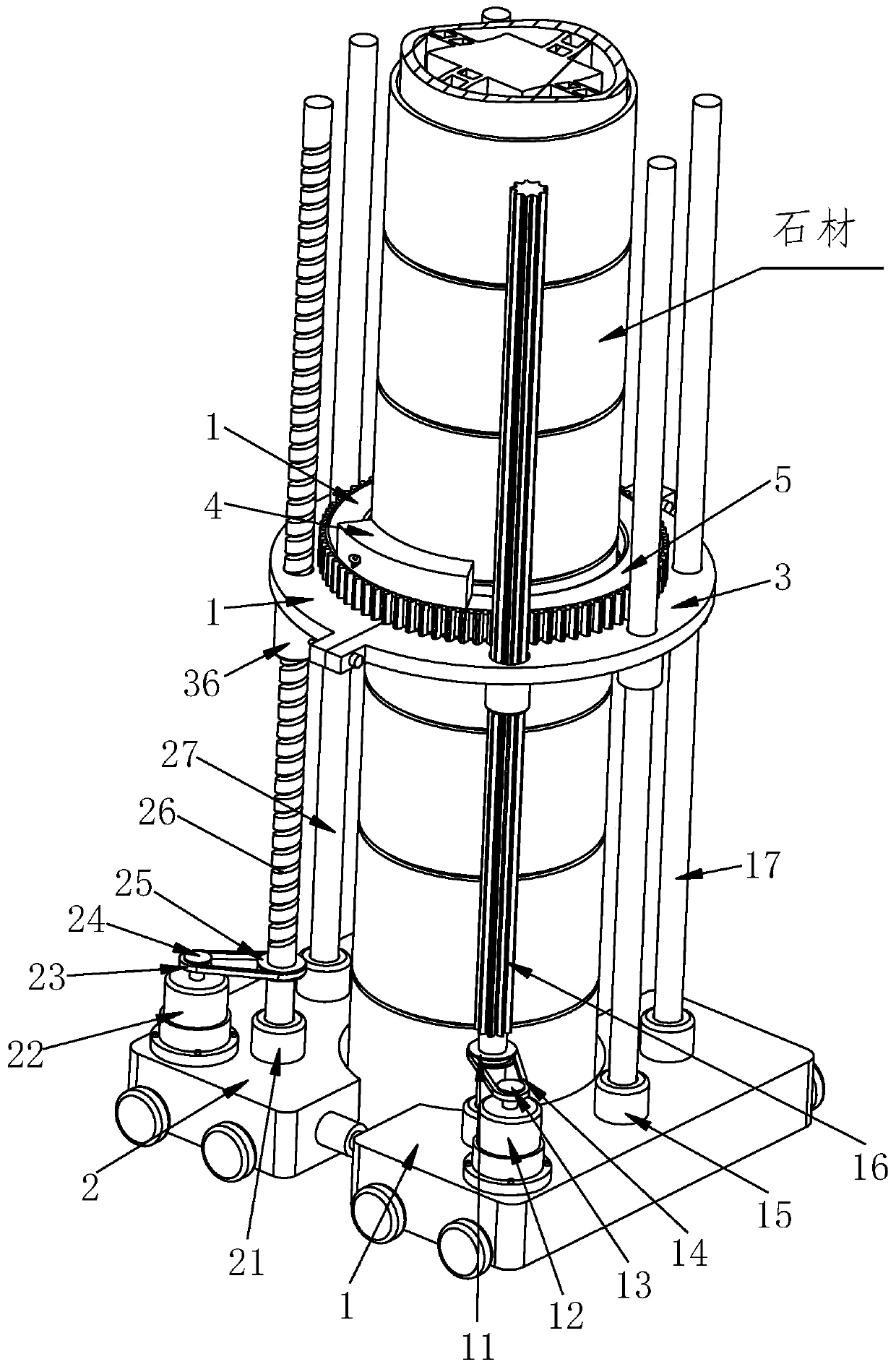

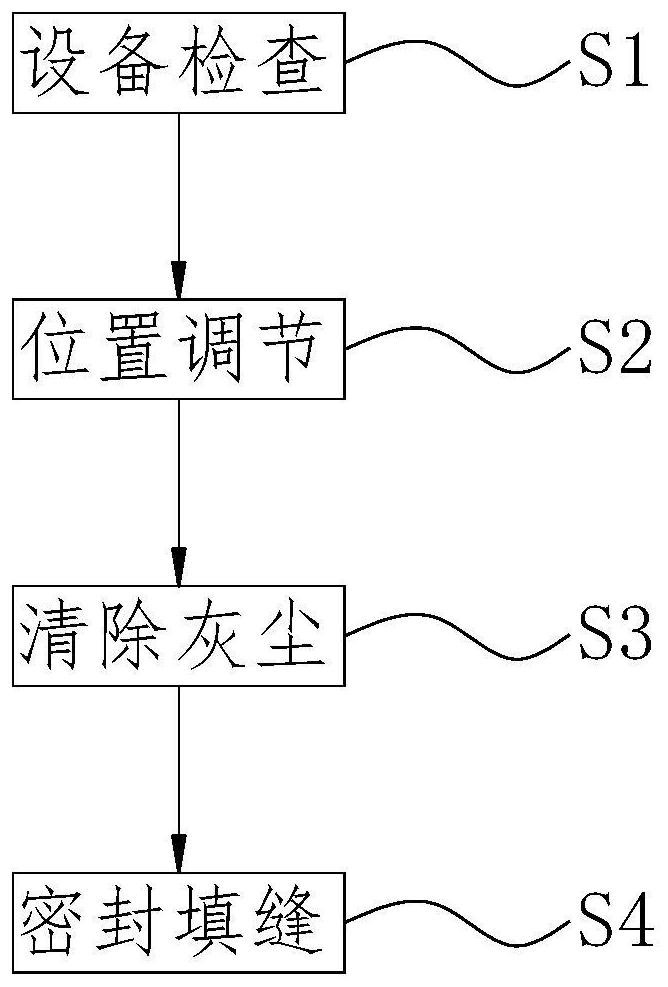

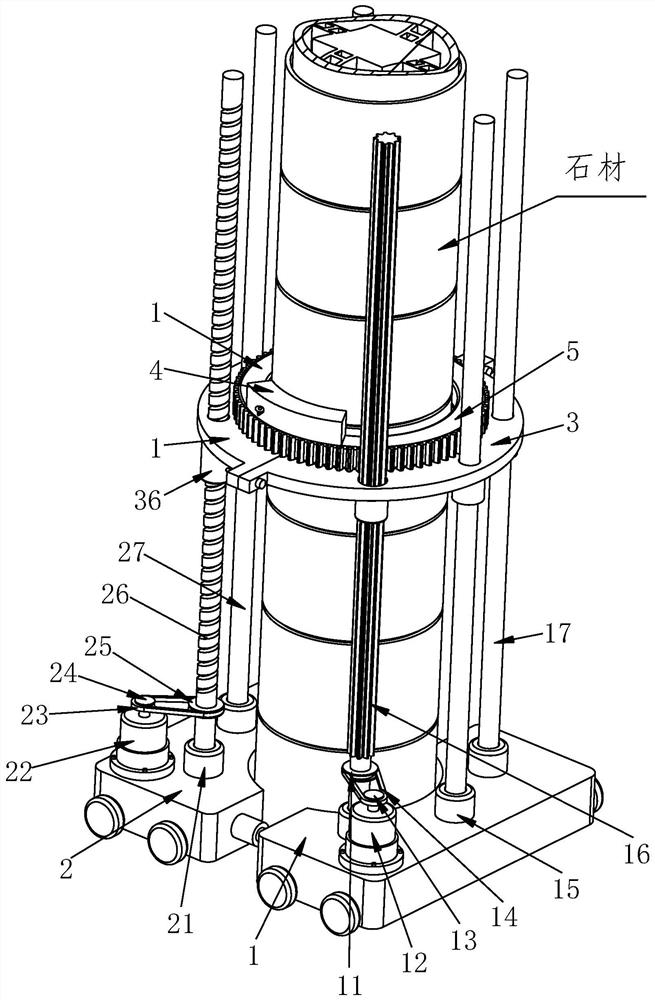

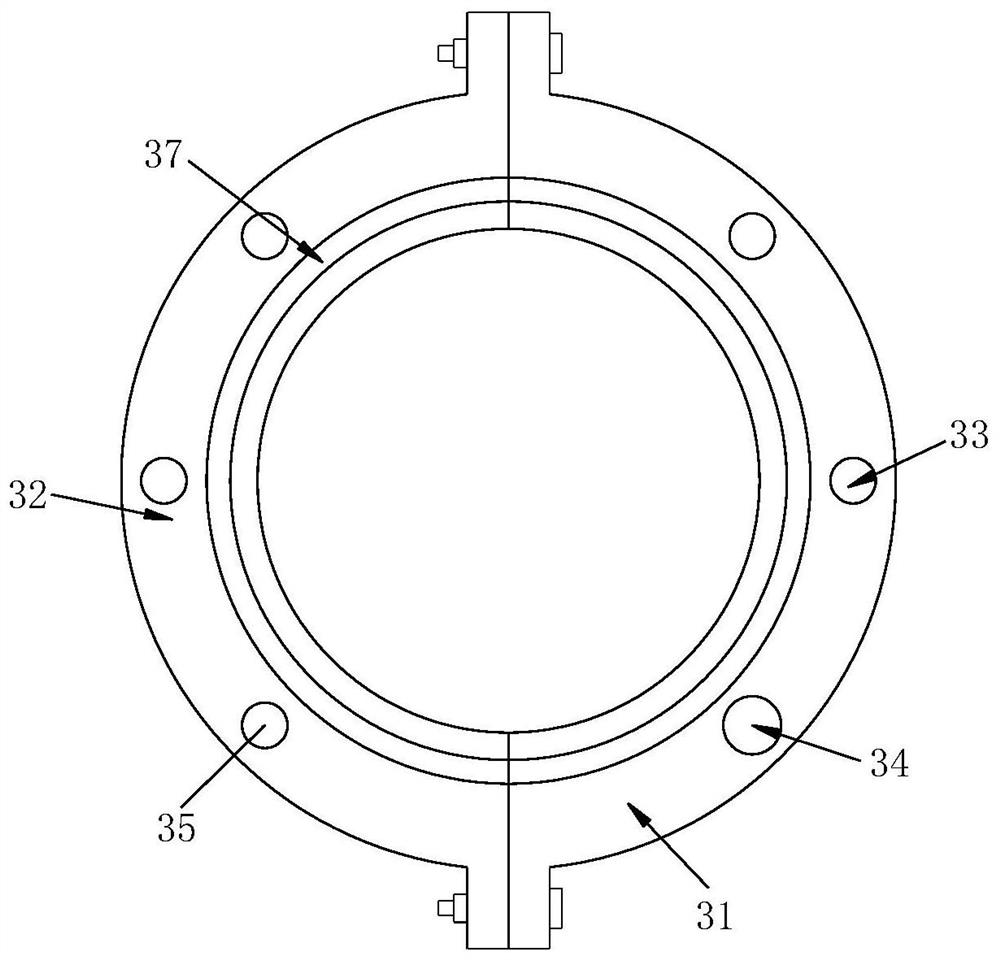

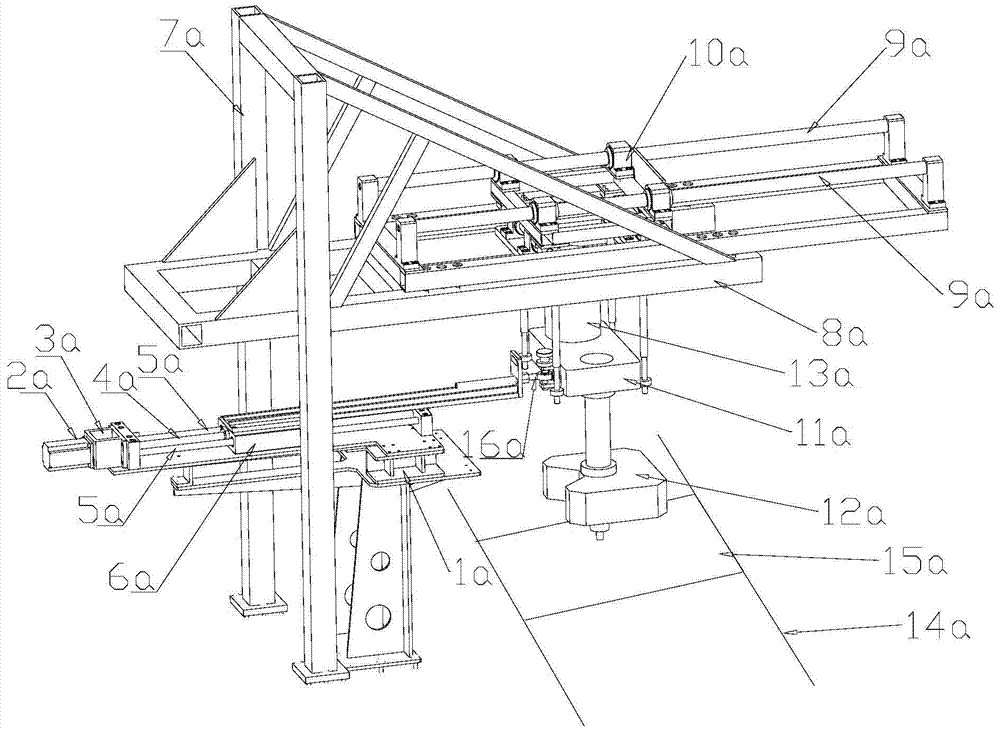

Dry-hanging, sealing and jointing treatment construction method for building wall decoration stone

ActiveCN111075168ANo need for manual visual observationReduce wasteBuilding constructionsDrive wheelArchitectural engineering

The invention relates to a dry-hanging, sealing and jointing treatment construction method for building wall decoration stone. A first support base, a second support base, a support mechanism, a dustremoval mechanism and a jointing mechanism are included, wherein one side of the first support base is connected with the second support base, the support mechanism is arranged right above the first support base and the second support base, the jointing mechanism is mounted at the upper end of the support mechanism, the dust removal mechanism is mounted on the upper end surface of the jointing mechanism, first inserting connection barrels are installed at the top of the first support base, first positioning rods and tooth groove rods are sequentially mounted in the three first inserting connection barrels, bearings A are mounted in connection positions of the first positioning rods and the tooth groove rods with the first inserting connection barrels, a first motor is mounted at the cornerof the upper end surface of the first support base, a first driving wheel is welded at an output shaft of the first motor, and a first belt is mounted on the outer side of the first driving wheel ina matched manner. The operation is simple and safe, and the sealant injection process is uniform, compact and full.

Owner:长春昆仑建设股份有限公司

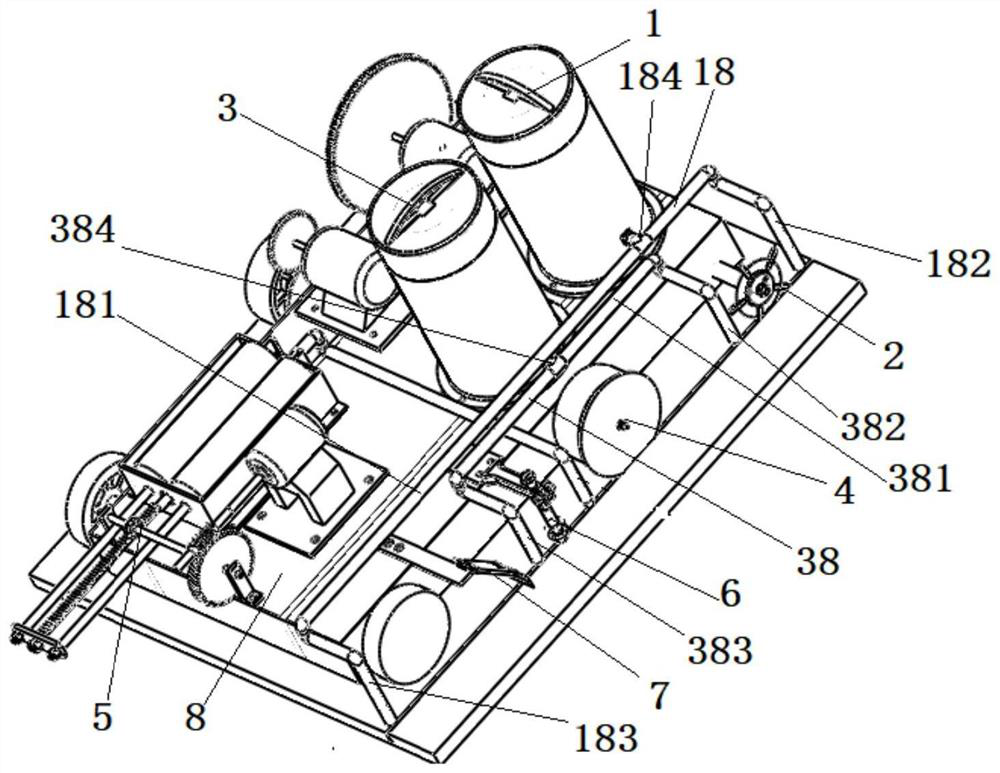

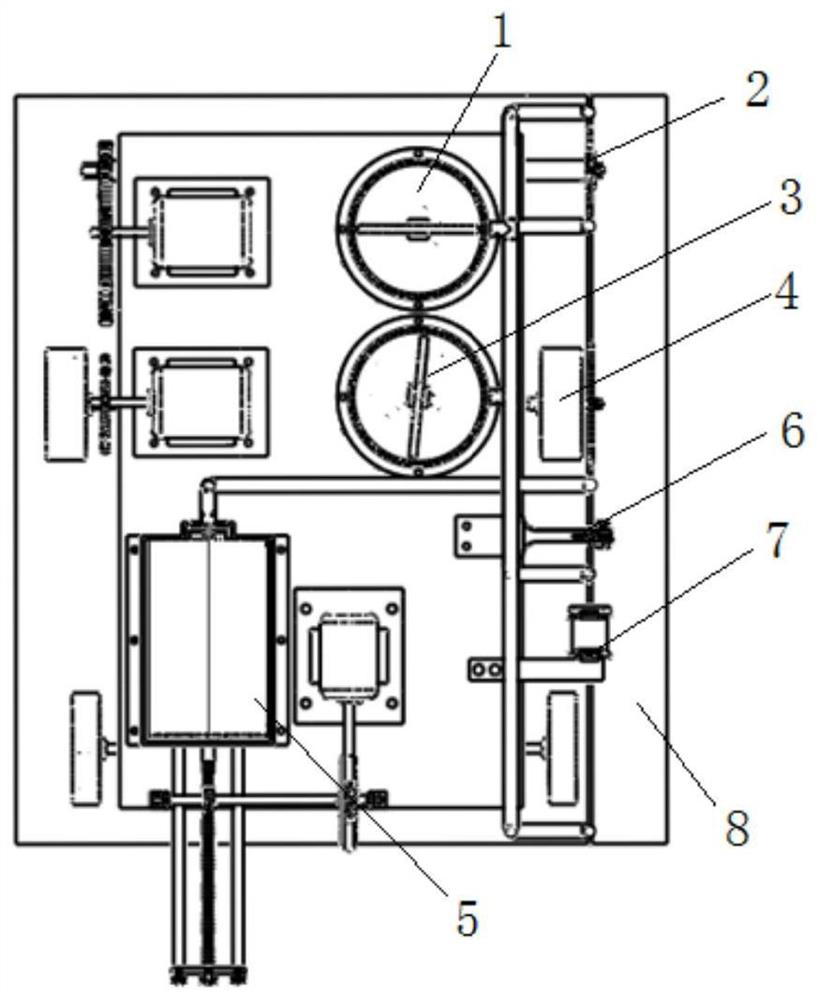

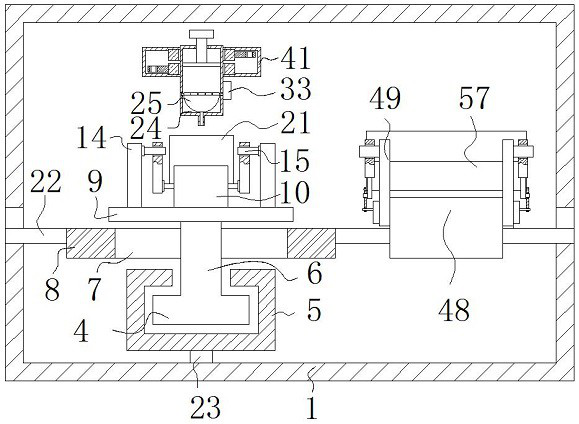

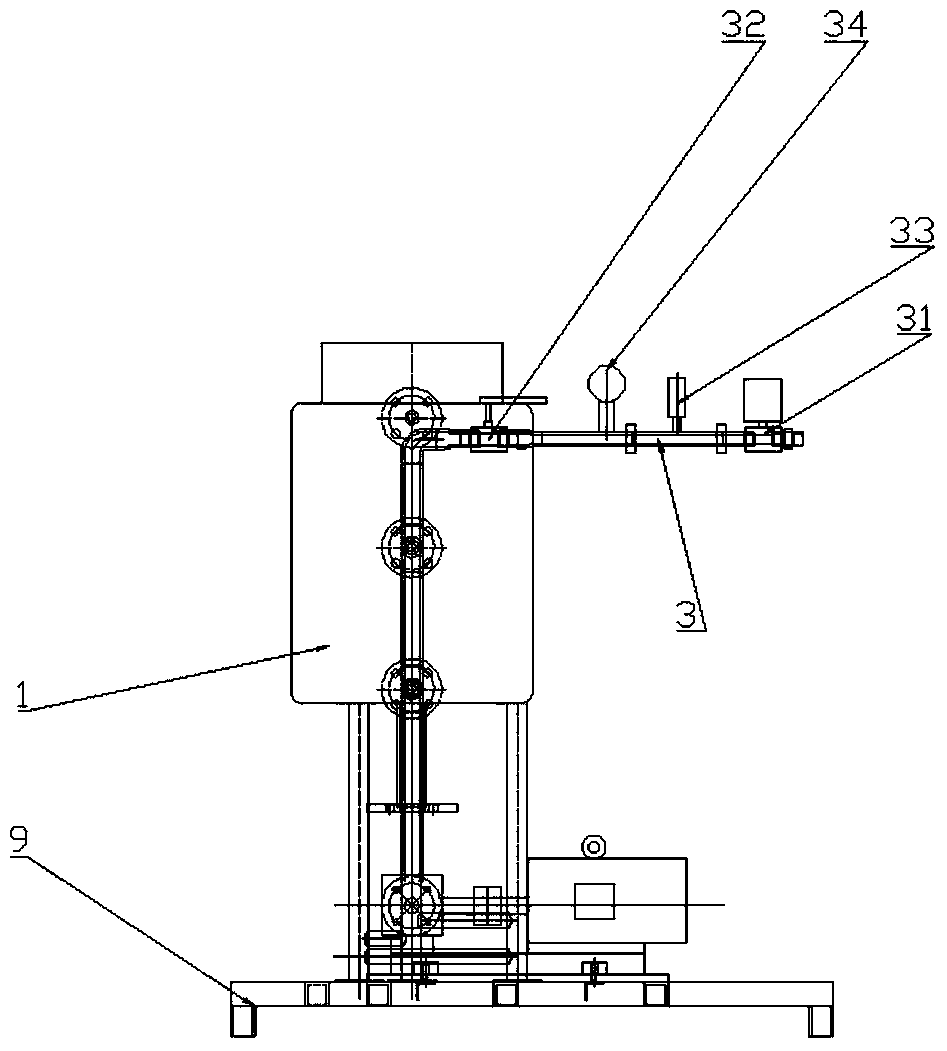

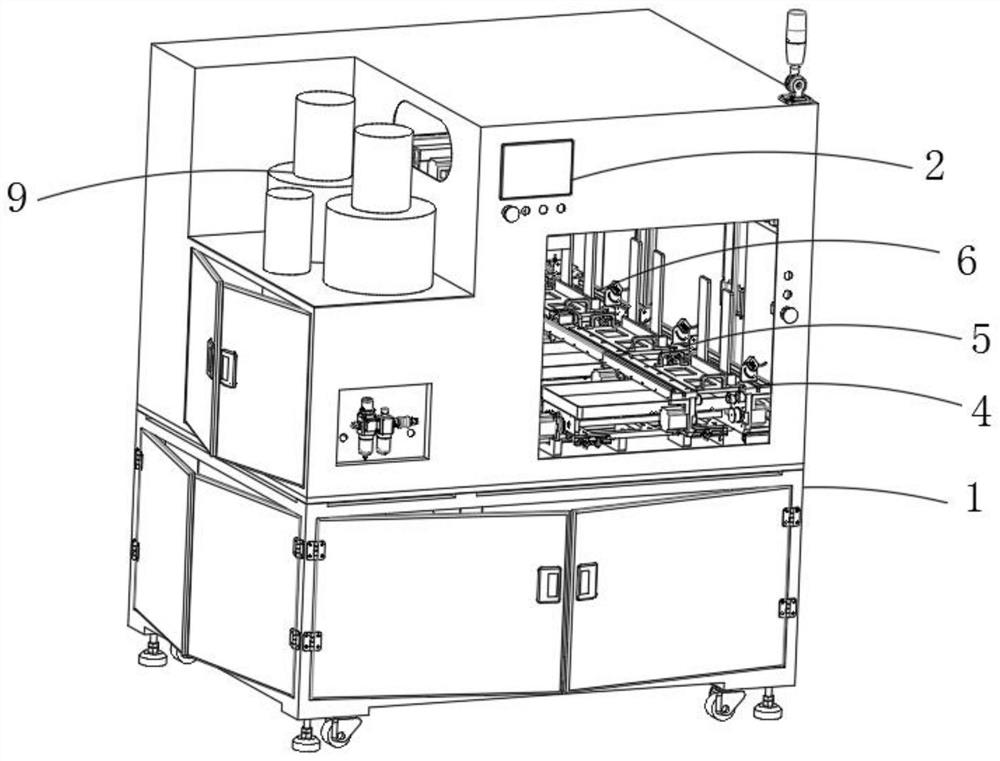

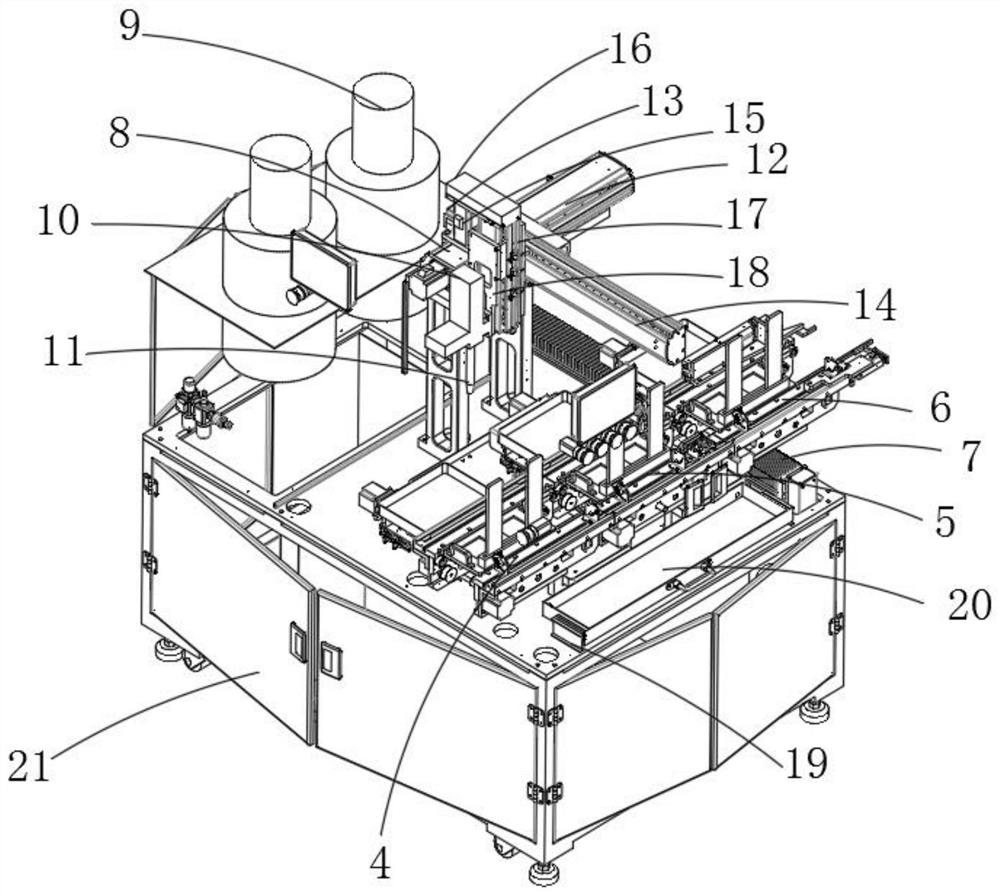

Hollow glass glue-injecting and laminating integration machine

InactiveCN111362594AGlue evenly distributedEvenly distributedElectric machineryManufacturing engineering

The invention belongs to the technical field of hollow glass production, and concretely relates to a hollow glass glue-injecting and laminating integration machine. The machine comprises four supporting rods, the same mounting plate is fixedly mounted at the top ends of the four supporting rods, a cavity is formed in the mounting plate, a first motor is fixedly mounted in the cavity, a first bevelgear is fixedly mounted on an output shaft of the first motor, a rotating shaft is rotatably mounted on the mounting plate, the bottom end of the rotating shaft extends into the cavity and is fixedlyprovided with a second bevel gear, the second bevel gear is engaged with the first bevel gear, a rotating disc is fixedly mounted at the top end of the rotating shaft, a mounting frame is fixedly mounted at the top of the mounting plate, and a hydraulic cylinder is fixedly mounted on the mounting frame. The machine is easy to operate and high in practicability, the position of glass can be automatically adjusted, glue injection can be conducted on the two sides at the same time, the glue injection efficiency is high, glue injection is uniform and tidy, and the glue injection quality is improved.

Owner:LIAONING TIANLI ALUMINUM & PLASTIC BUILDING MATERIALS

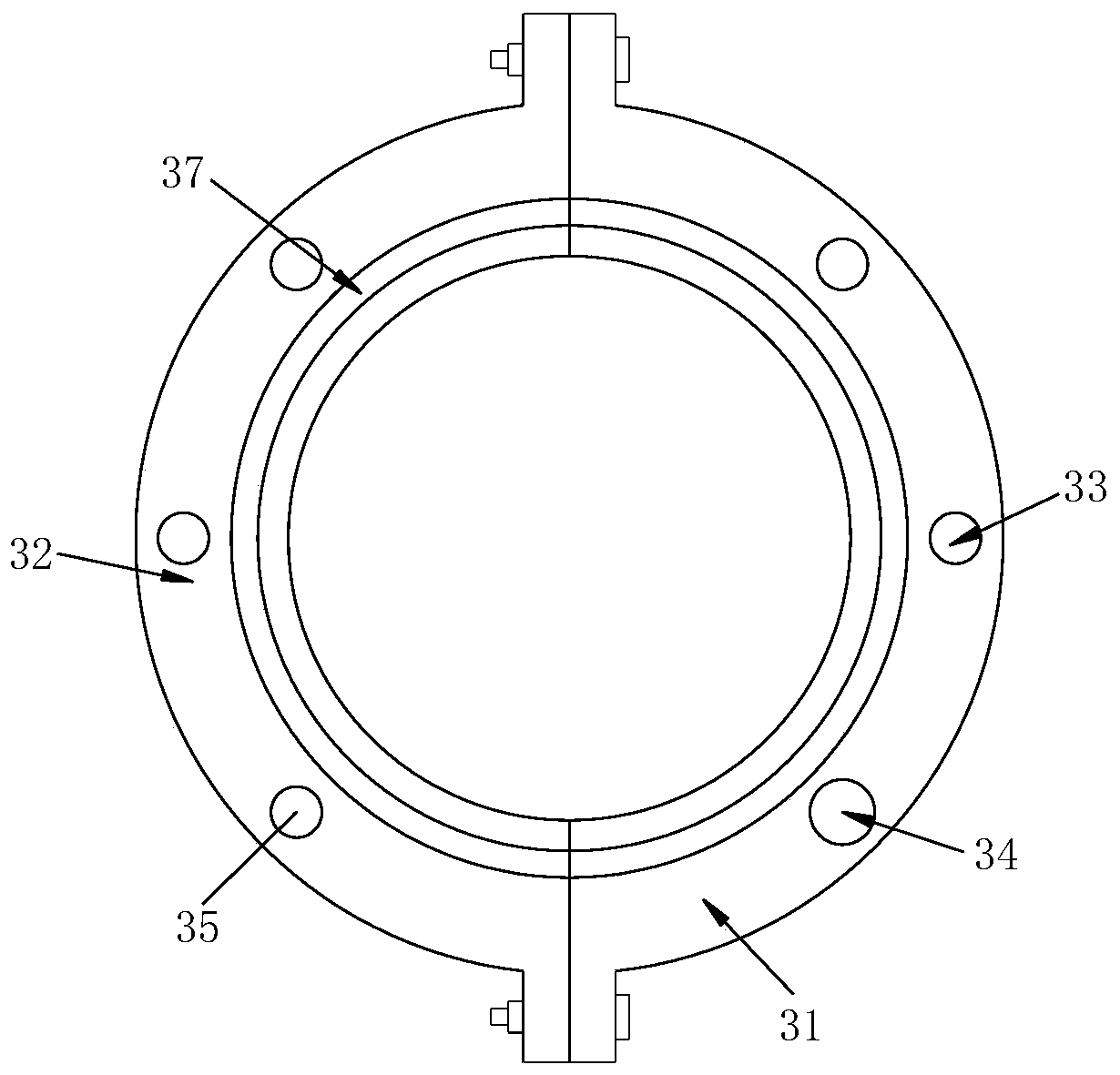

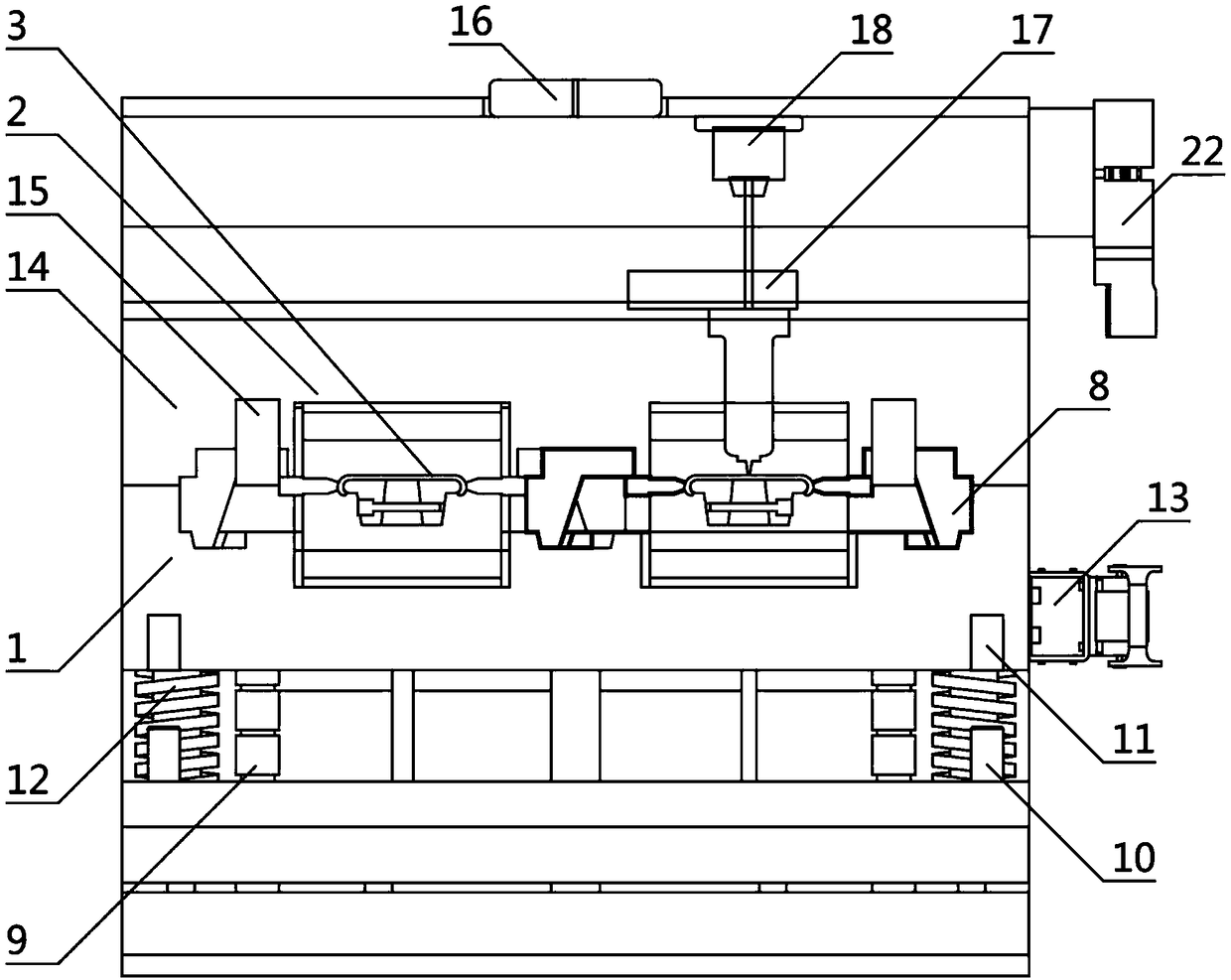

Glued bearing casting tool

InactiveCN107617535AGuaranteed practicalityUniform glue injectionLiquid surface applicatorsCoatingsEngineeringMechanical engineering

The invention relates to the technical field of bearing production, and discloses a glued bearing casting tool. The glued bearing casting tool comprises a baseplate; a motor is fixedly connected intothe baseplate; an output shaft of the motor is fixedly connected with a rotating shaft; a worktable and a stand column are arranged at the top of the baseplate in sequence from left to right; the surface of the rotating shaft is fixedly connected with a turntable positioned at the top of the worktable; one side of the stand column is fixedly connected with a fixed block; a chute is formed in the bottom of the fixed block; a slide block is slidingly connected into the chute; and the bottom of the slide block is fixedly connected with a connecting base. The glued bearing casting tool is providedwith an electric push rod, a tension spring and the chute; the electric push rod is used for driving the slide block at the bottom of the tension spring to slide in the chute; the chute is an arc chute; a glue injecting gun below the slide block is driven to move in the direction of the arc chute; and the direction of the glue injecting gun can be adjusted to achieve uniform glue injection on theouter diameter surface of a bearing on the turntable, so that the nonuniform glue injecting phenomenon is prevented, and the product consistency is improved.

Owner:NANJING JIAMING DIE CASTING FACTORY

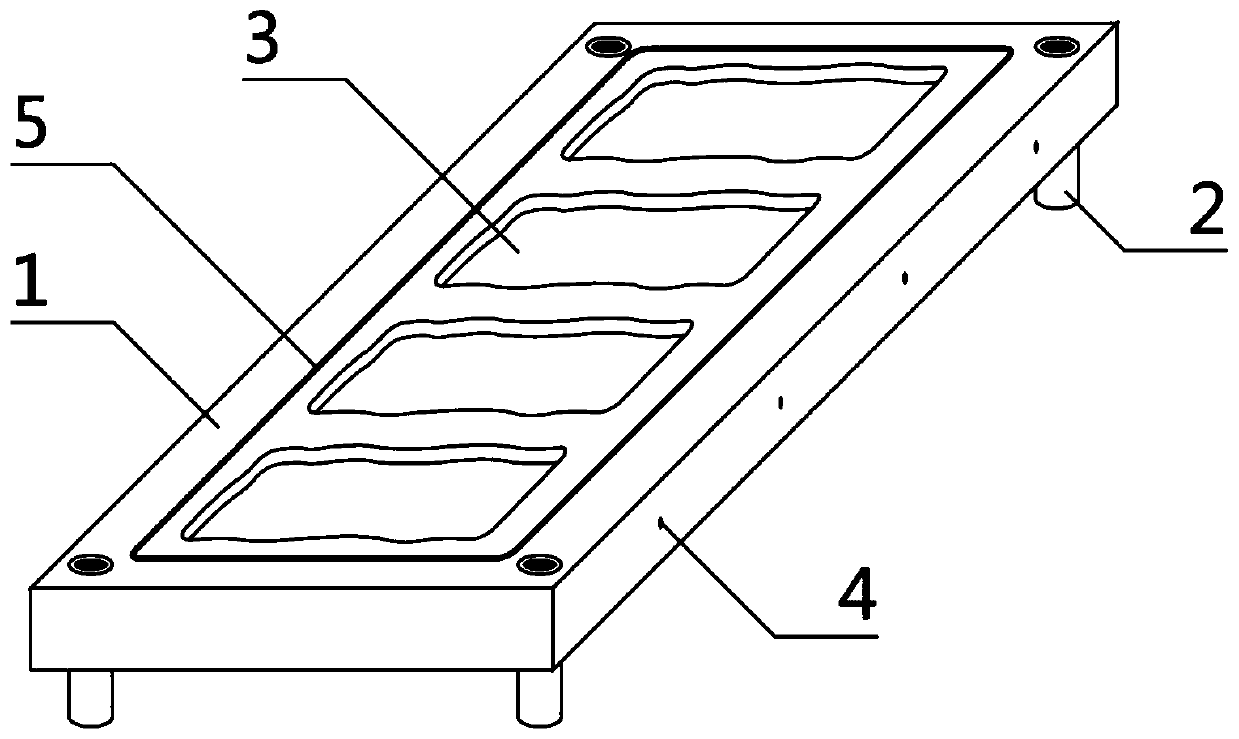

Liquid state silica gel sizing device

The invention aims to provide a liquid state silica gel sizing device. According to the technical scheme, the liquid state silica gel sizing device is composed of a lower mold plate, product implanting grooves, product position clamping blocks, a lower-position silica gel releasing device, an upper mold plate, a silica gel injecting port, a cold runner silica gel dispensing device and a high-position silica gel releasing device; a product fixer is arranged in each product implanting groove, and is composed of a center inserting block, a first edge inserting block, a second edge inserting blockand two fixing bolts; the lower mold plate is provided with positioning columns, auxiliary positioning columns, auxiliary positioning grooves and pressure springs; and the cold rubber silica gel dispensing device is composed of a supporting table, a silica gel entering storing disk, a silica gel injecting rotating disk and a silica gel injecting pipe. The whole mold structure is clear in train ofthought, and operation is convenient; the structural design of the cold runner silica gel injecting type and the structural design of raw material recycling are adopted, the overall machining stability is improved, the shape attractiveness and the production efficiency are improved, raw materials for use are greatly reduced, cost is reduced, the mold is also well protected, and pollution is reduced.

Owner:SYNERGY HANIL PRECISION POLYMER TECH CO LTD

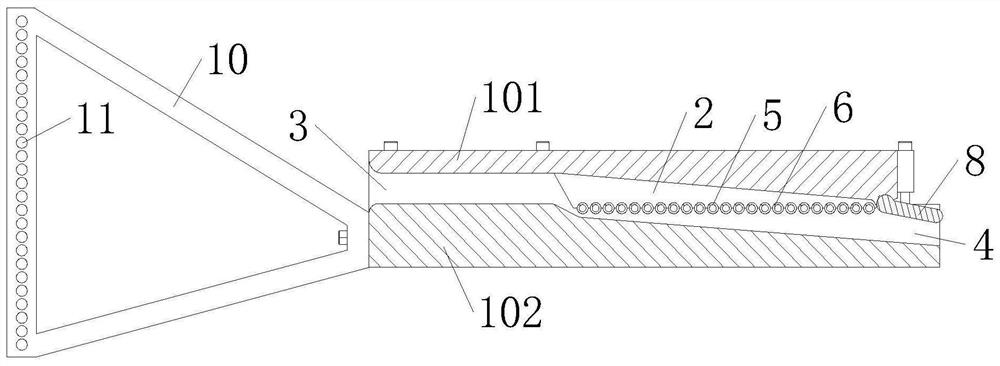

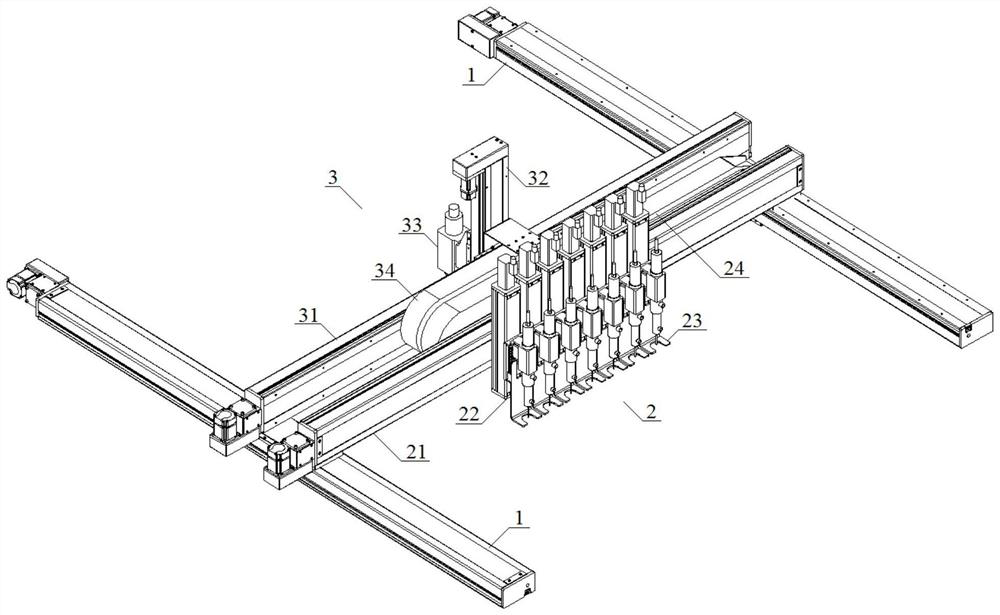

Static infiltration device for rapid pultrusion of composite material

The invention relates to the technical field of railway track material equipment, in particular to a static infiltration device for rapid pultrusion of a composite material. The static infiltration device comprises a box body, a gum dipping cavity is formed in the box body, and a yarn inlet and a yarn outlet are separately formed in two opposite side surfaces of the box body; and a plurality of parallel yarn guide rods are installed in the gum dipping cavity, are arranged in the horizontal direction and are perpendicular to the pultrusion direction of yarn. According to the static infiltrationdevice, a pre-stress jack can be moved, the angle is adjustable, thus, the pre-stress jack is convenient and easy to install, and high safety and high efficiency are achieved.

Owner:QINGDAO HILYWILL ADVANCED MATERIALS TECH

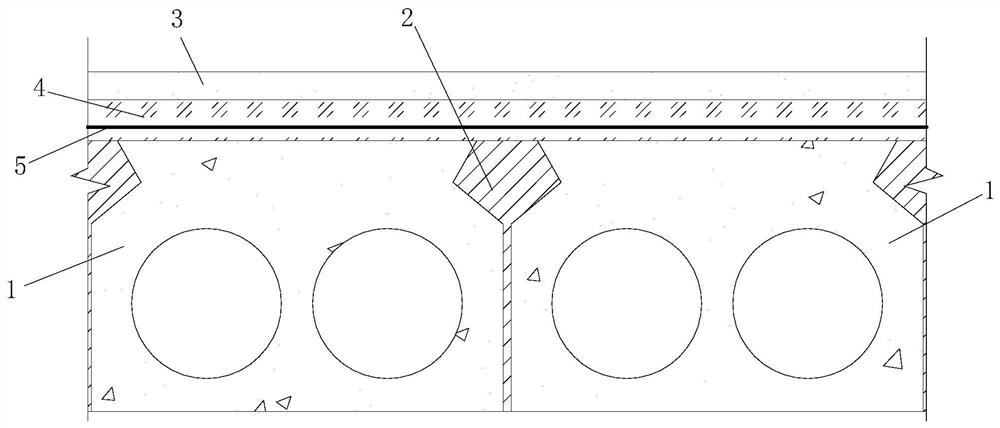

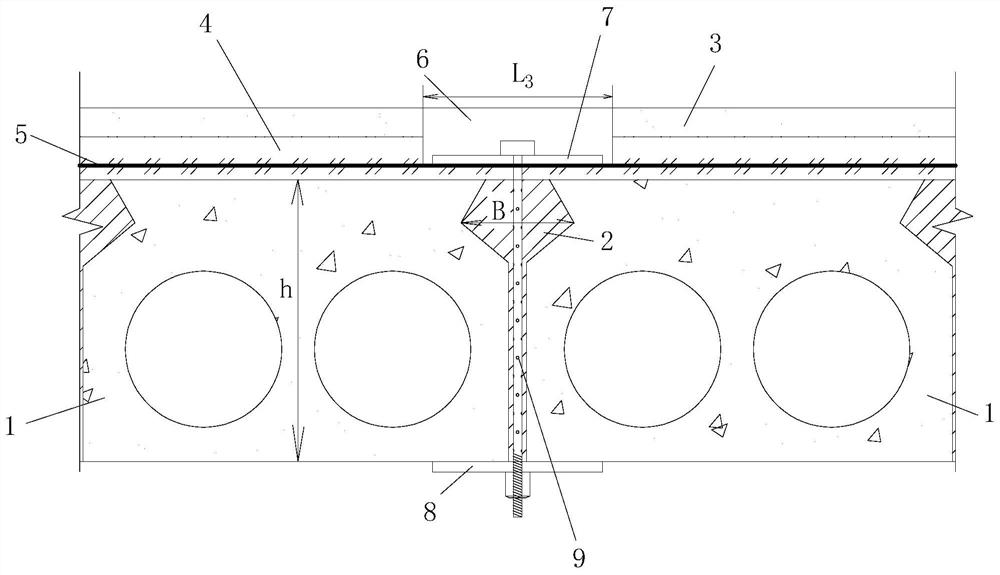

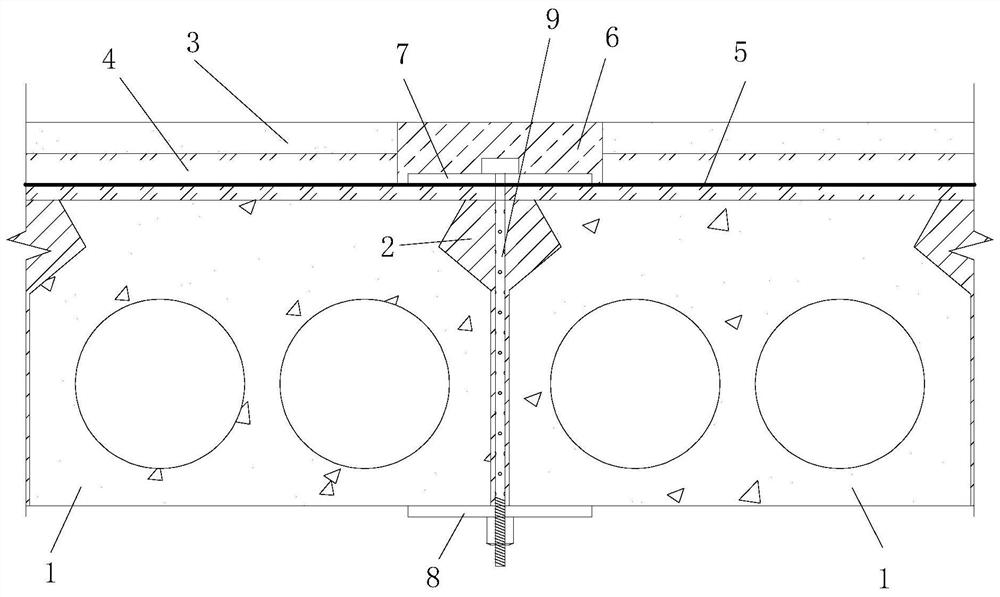

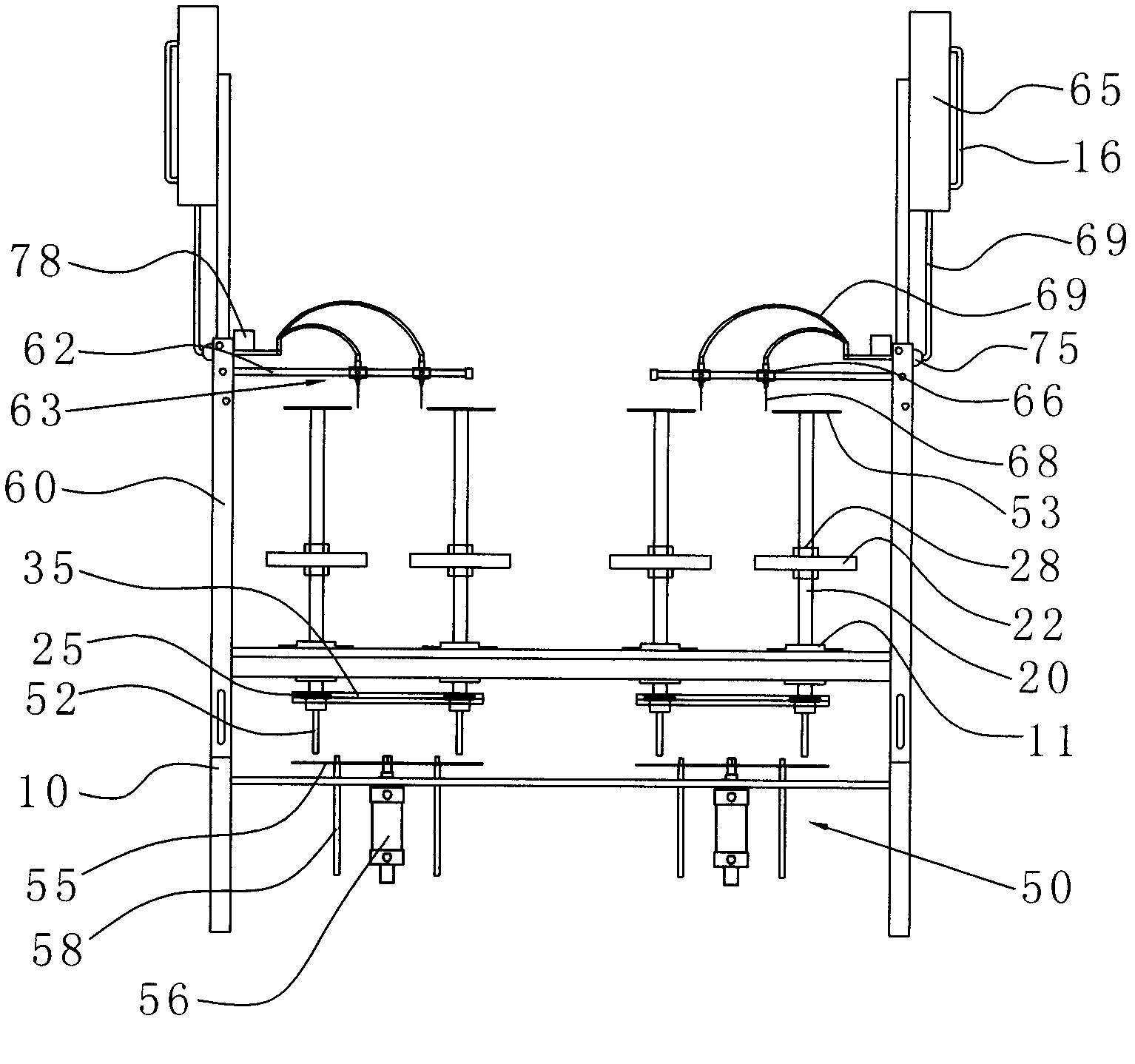

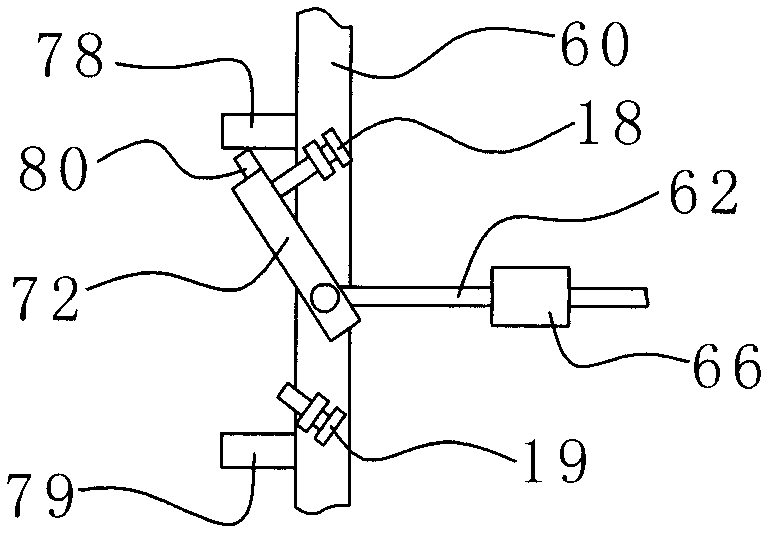

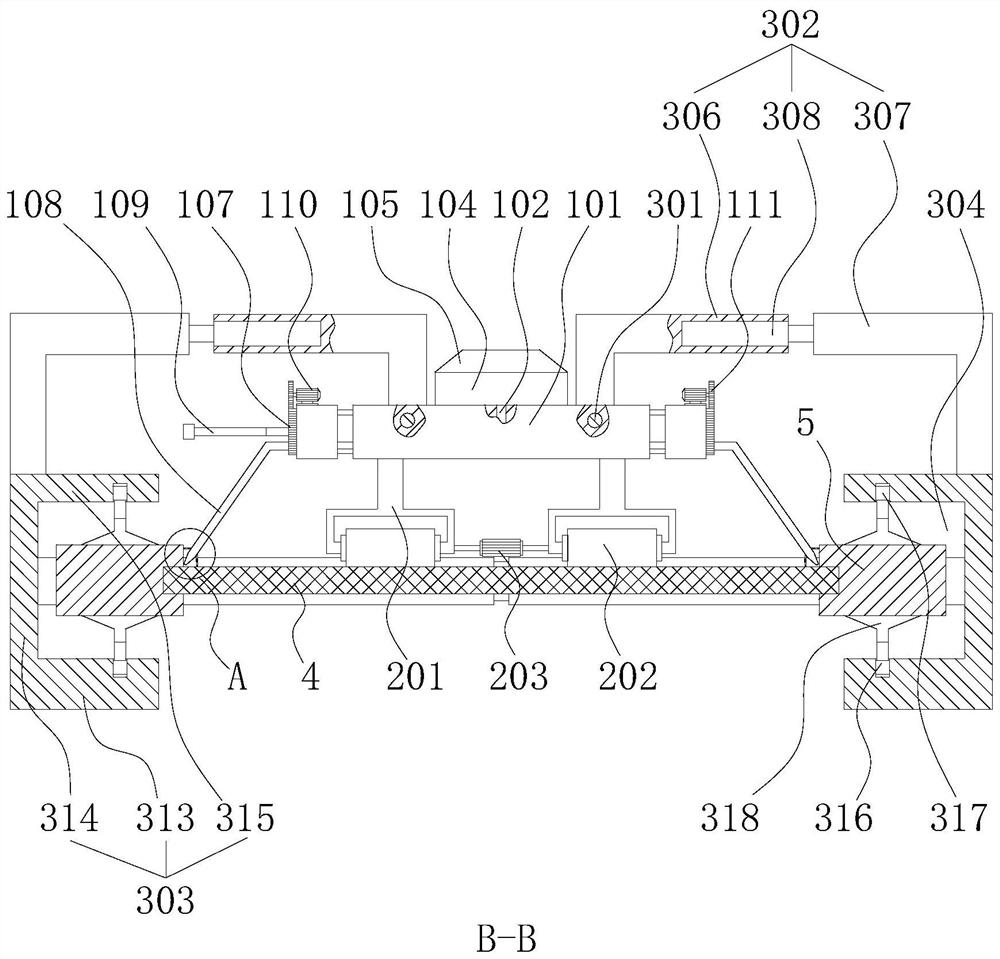

Hinge joint reinforcing maintenance method and reinforcing and maintaining device

PendingCN111945588AEnhance horizontal linkagesWeakening of horizontal linkagesBridge structural detailsBridge erection/assemblyAdhesiveArchitectural engineering

The invention discloses a hinge joint reinforcing and maintaining method and a reinforcing and maintaining device. The hinge joint reinforcing and maintaining method comprises the following steps that1, forming a notch in the position of a hinge joint; 2, drilling a vertical through hole in the hinge joint; 3, arranging an upper anchoring plate at the notch, a lower anchoring plate is arranged atthe position, corresponding to the notch, below the plate beam, arranging a counter pull rod between the upper anchoring plate and the lower anchoring plate, the counter pull rod penetrates through the upper anchoring plate and the lower anchoring plate and is arranged in the vertical through hole, and then fastening the counter pull rod, the upper anchoring plate and the lower anchoring plate; 4, repairing the notch; 5, sealing the bottom of the hinge joint; and 6, injecting glue. The reinforcing maintenance device is additionally arranged, so that the transverse connection between the platebeams is enhanced, the stress state of the single beam is weakened, the vibration of the beam plate is avoided, and the cracking and discretization of the crack repairing adhesive are avoided.

Owner:SHANGHAI PUDONG NEW DISTRICT ROAD CONSTR DEV

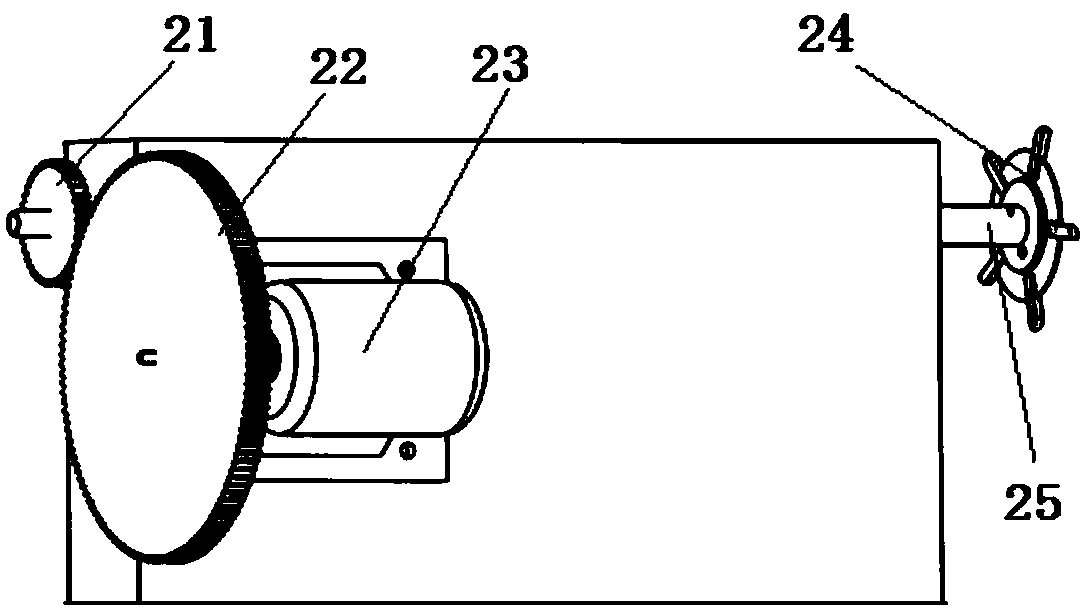

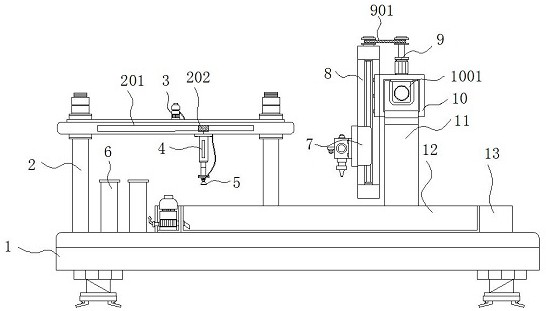

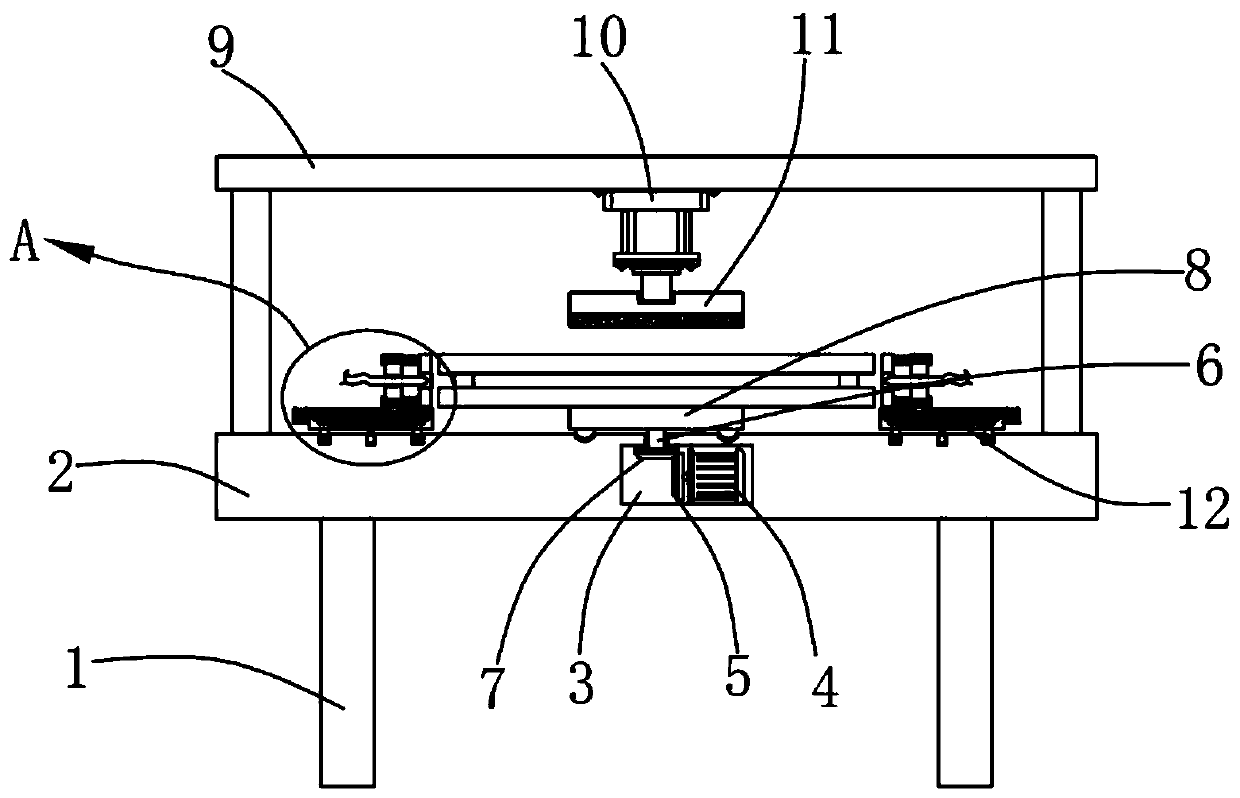

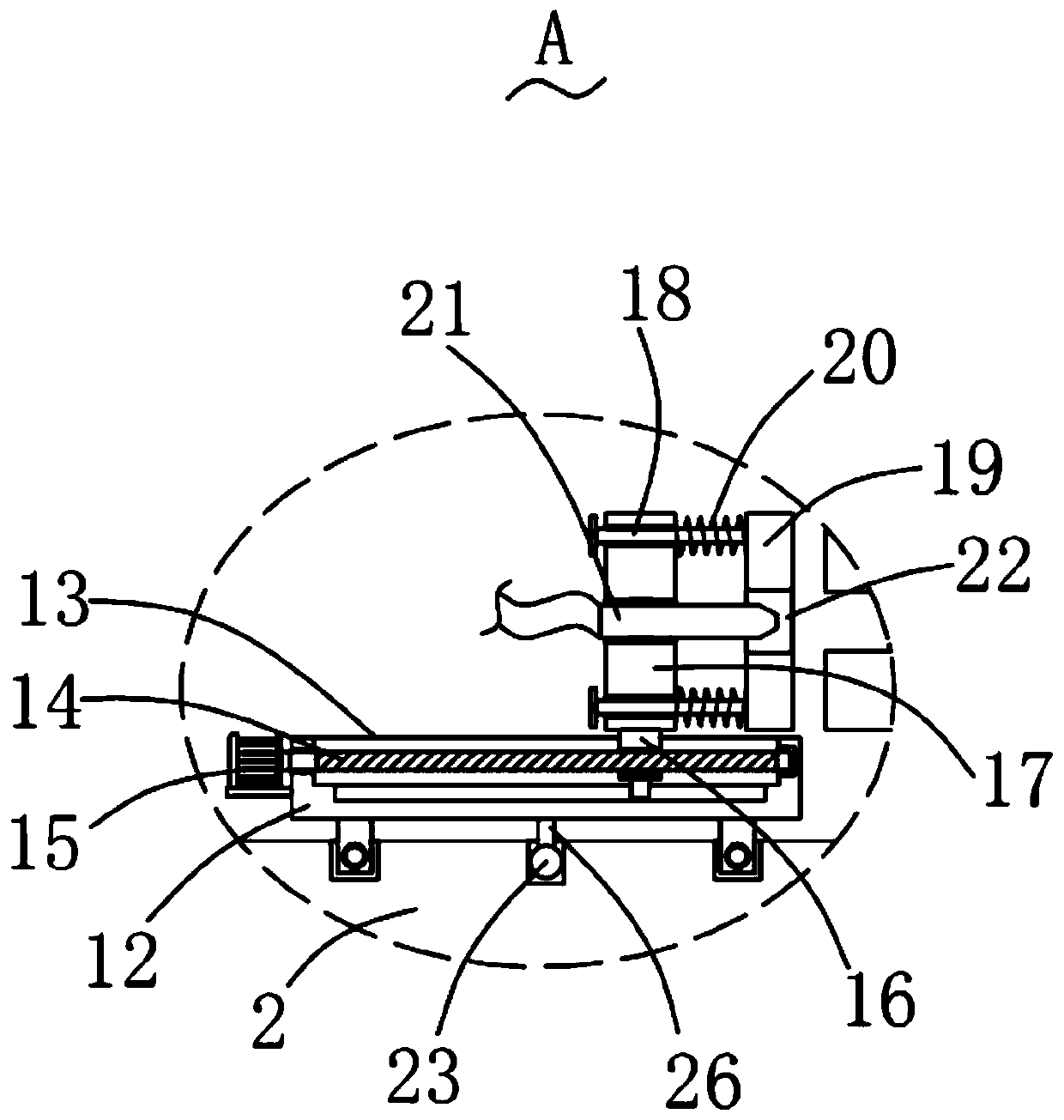

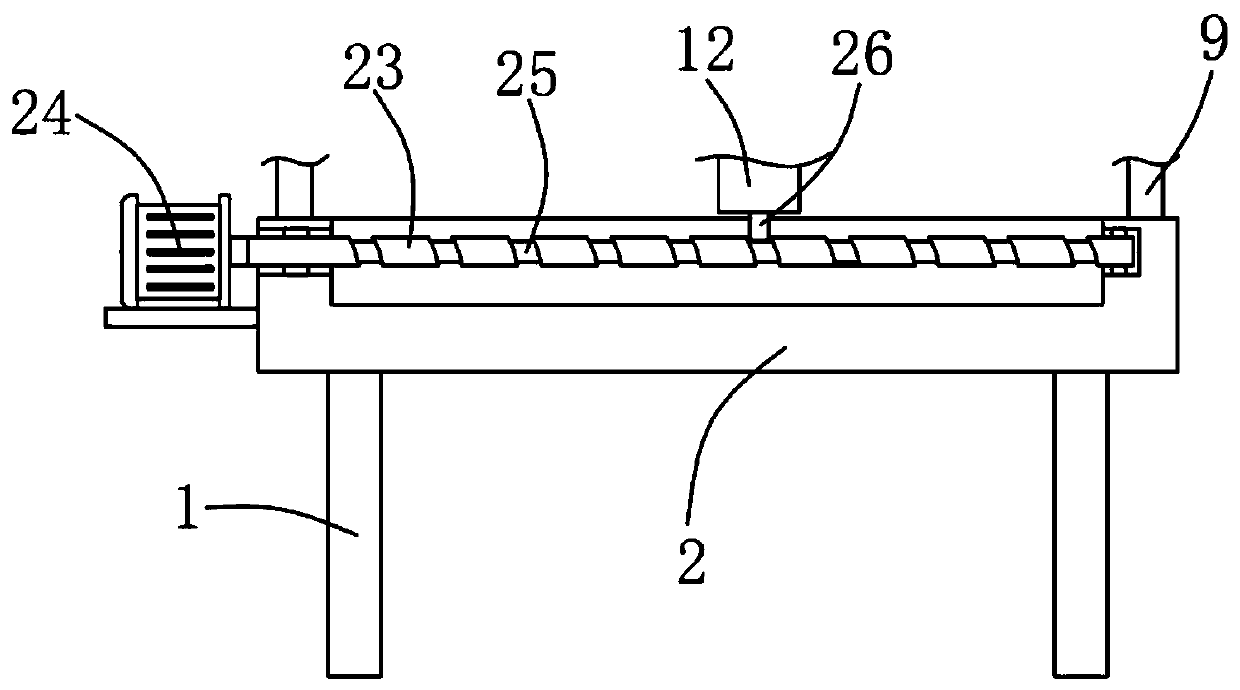

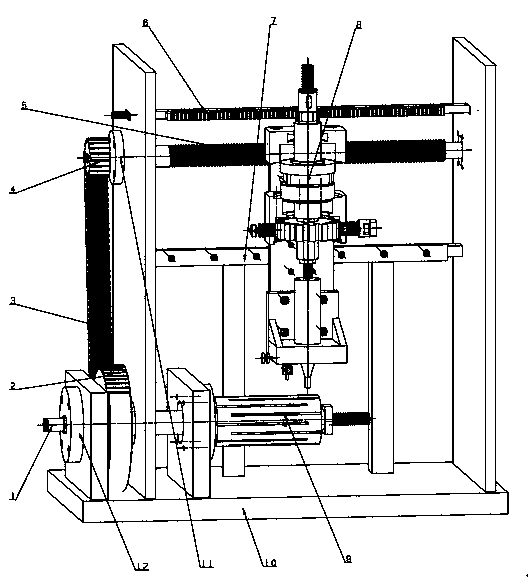

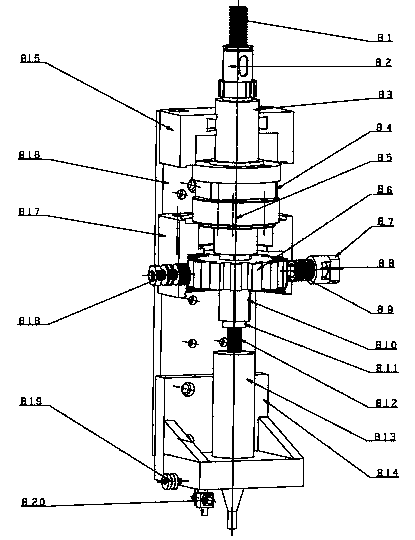

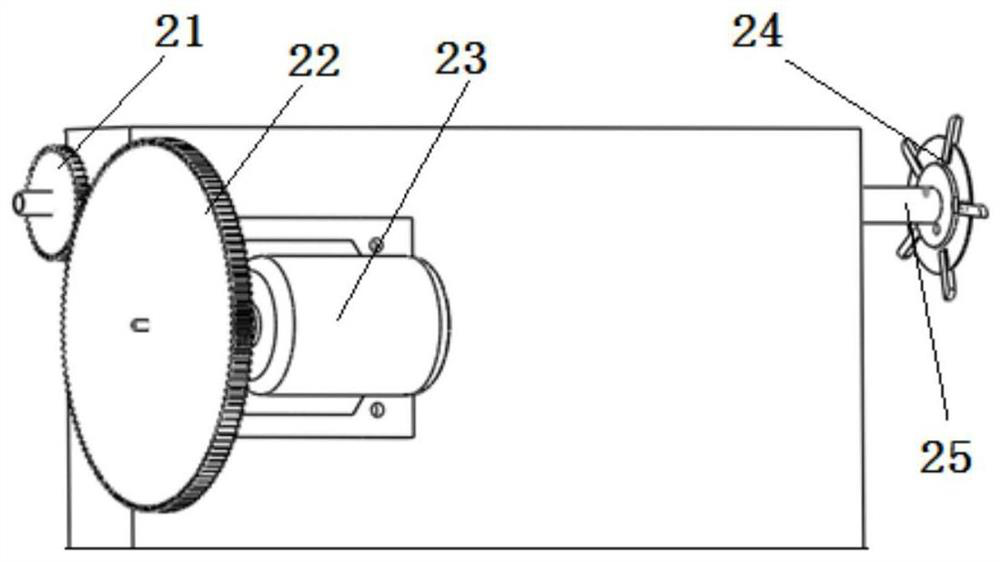

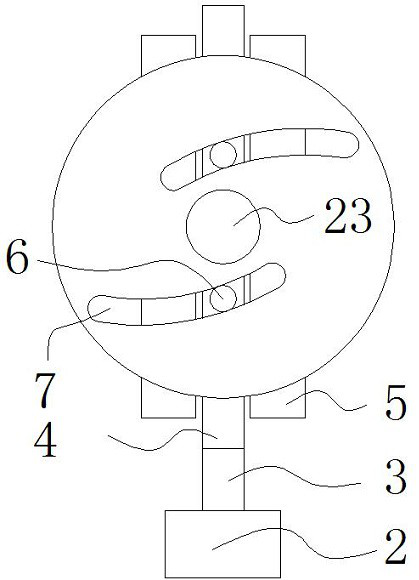

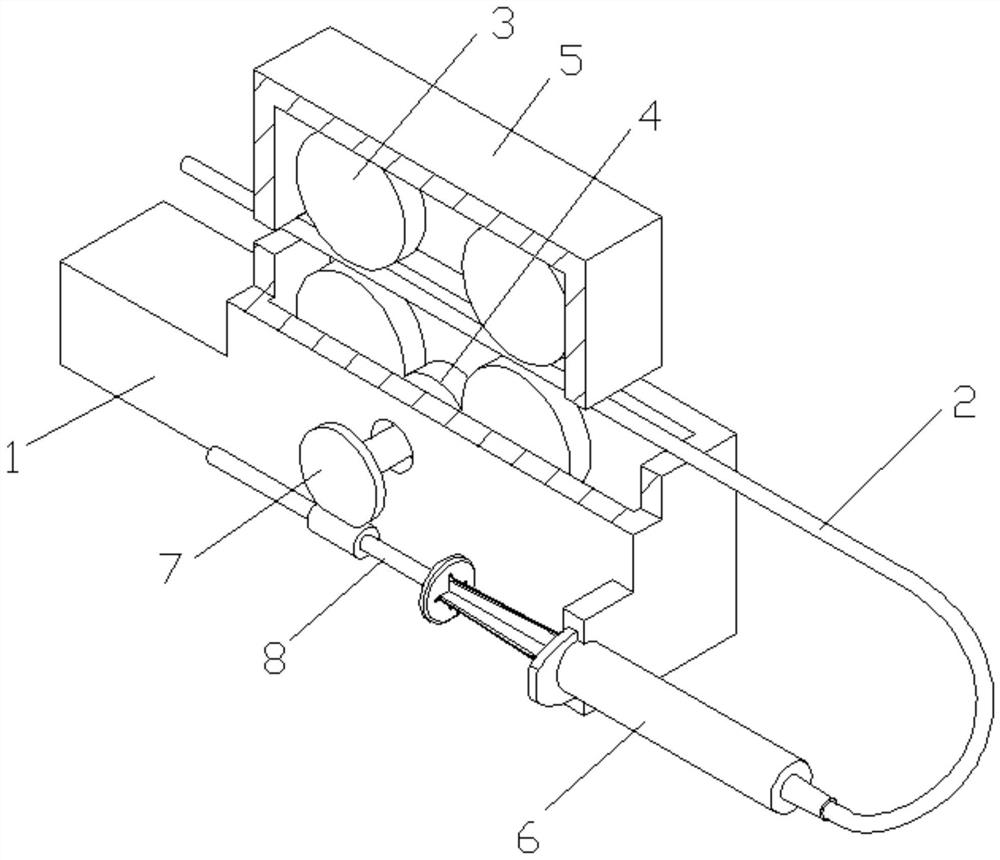

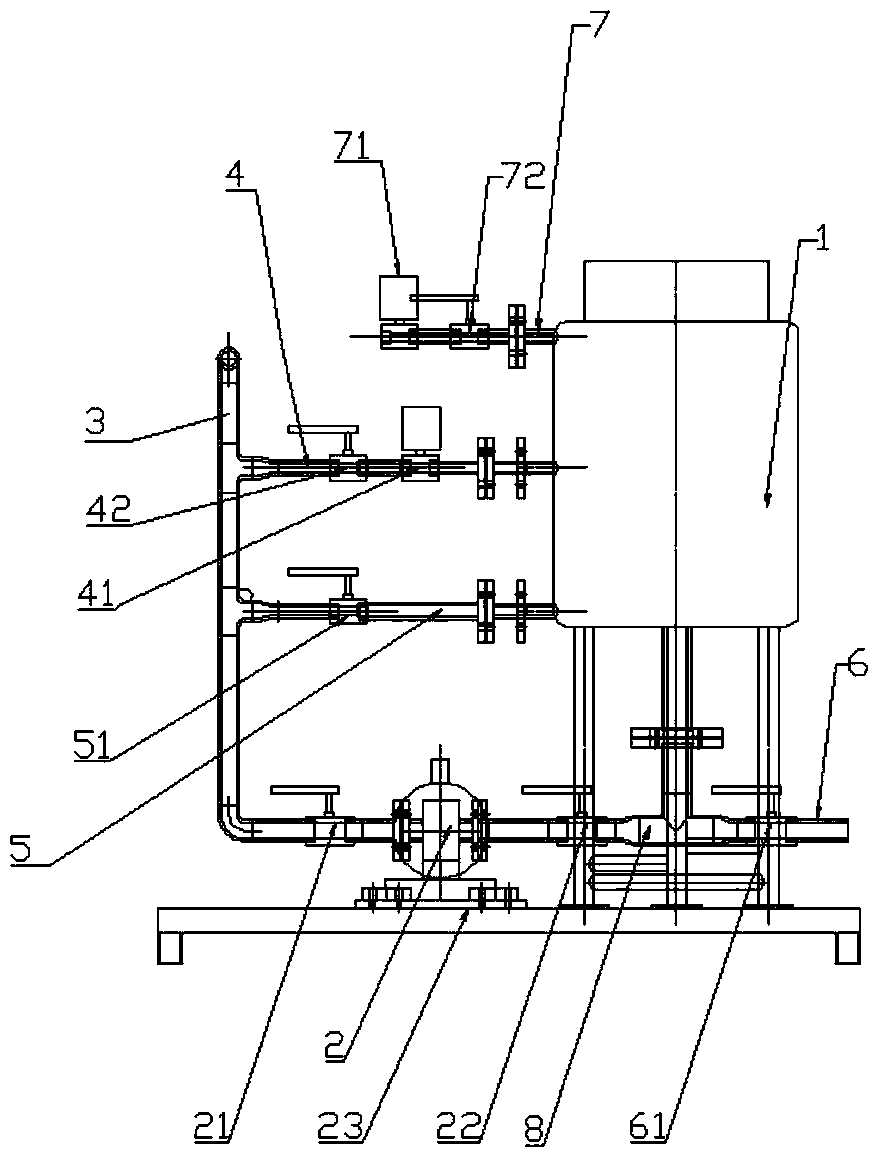

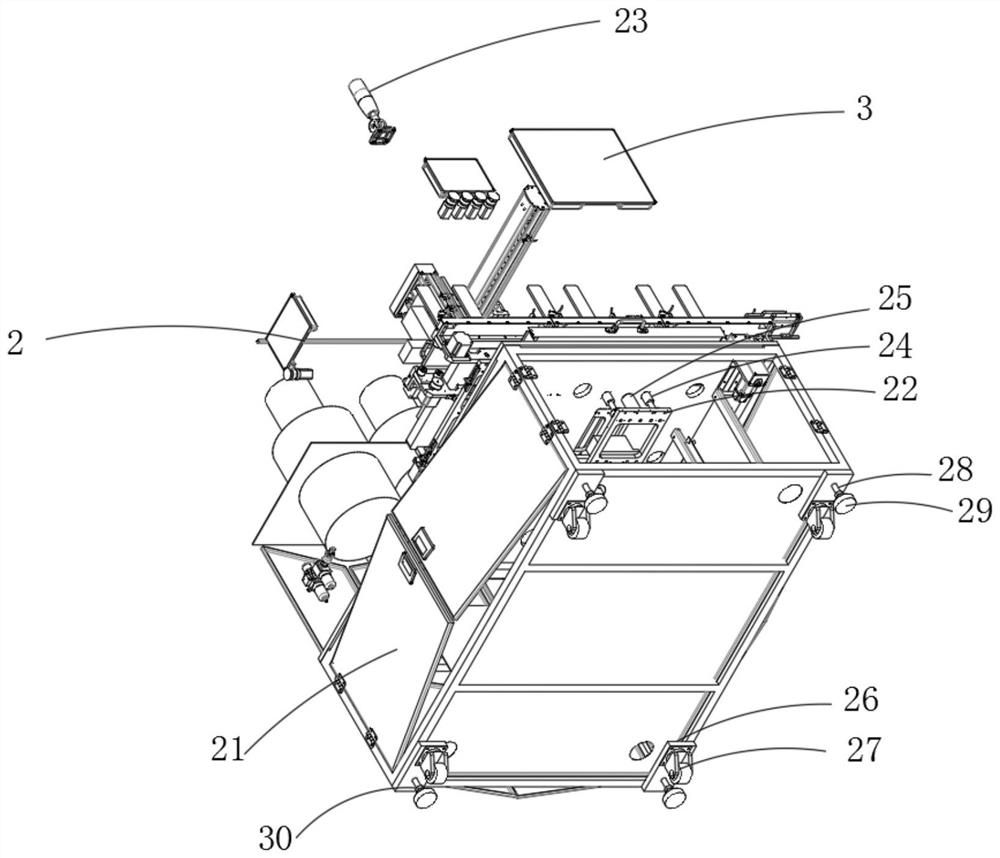

Wire winding glue-injection machine for thread coils

InactiveCN103680924AWind evenlyUniform glue injectionLiquid surface applicatorsCoatingsConductor CoilInjection molding machine

The invention discloses a wire winding glue-injection machine for thread coils. The wire winding glue-injection machine is characterized by being composed of a mechanical transmission mechanism, a glue-injection mechanism, a wire winding mechanism and a thread coil fixing and clamping mechanism. The wire winding glue-injection machine can be used for winding wires and injecting glue uniformly, continuously and efficiently and used for wire winding and glue injection production of the thread coils; because the manual operation mode is replaced, product quality and performance stability can be improved, labor intensity can be relieved, and the efficiency can be improved by more than five times.

Owner:YANTAI BRANCH NO 52 INST OF CHINA NORTH IND GRP

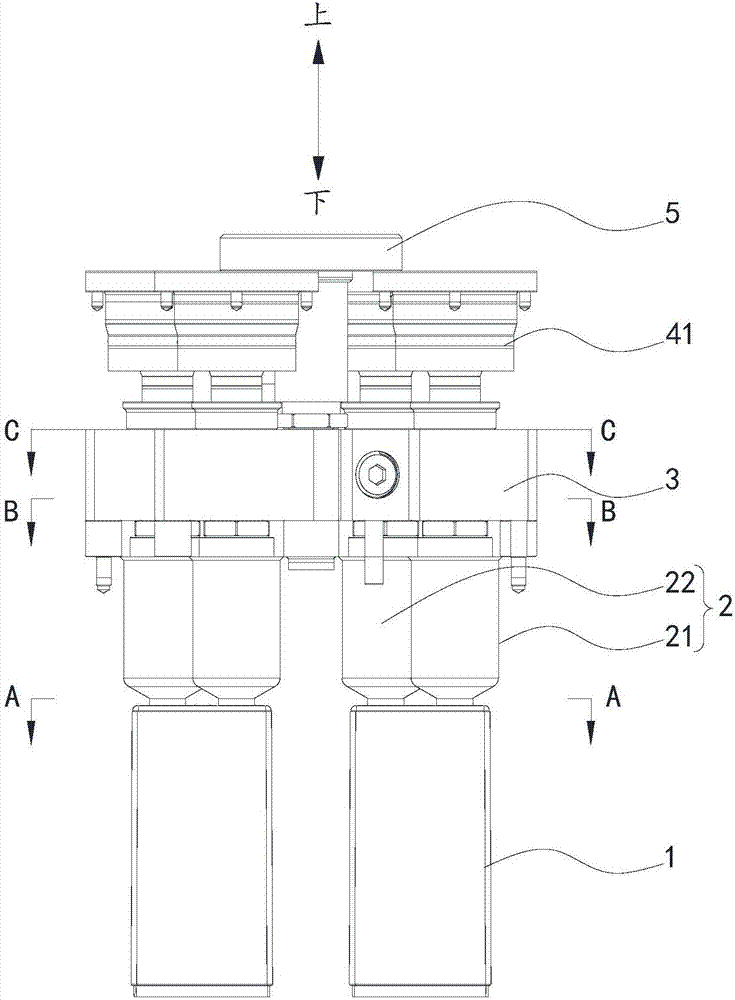

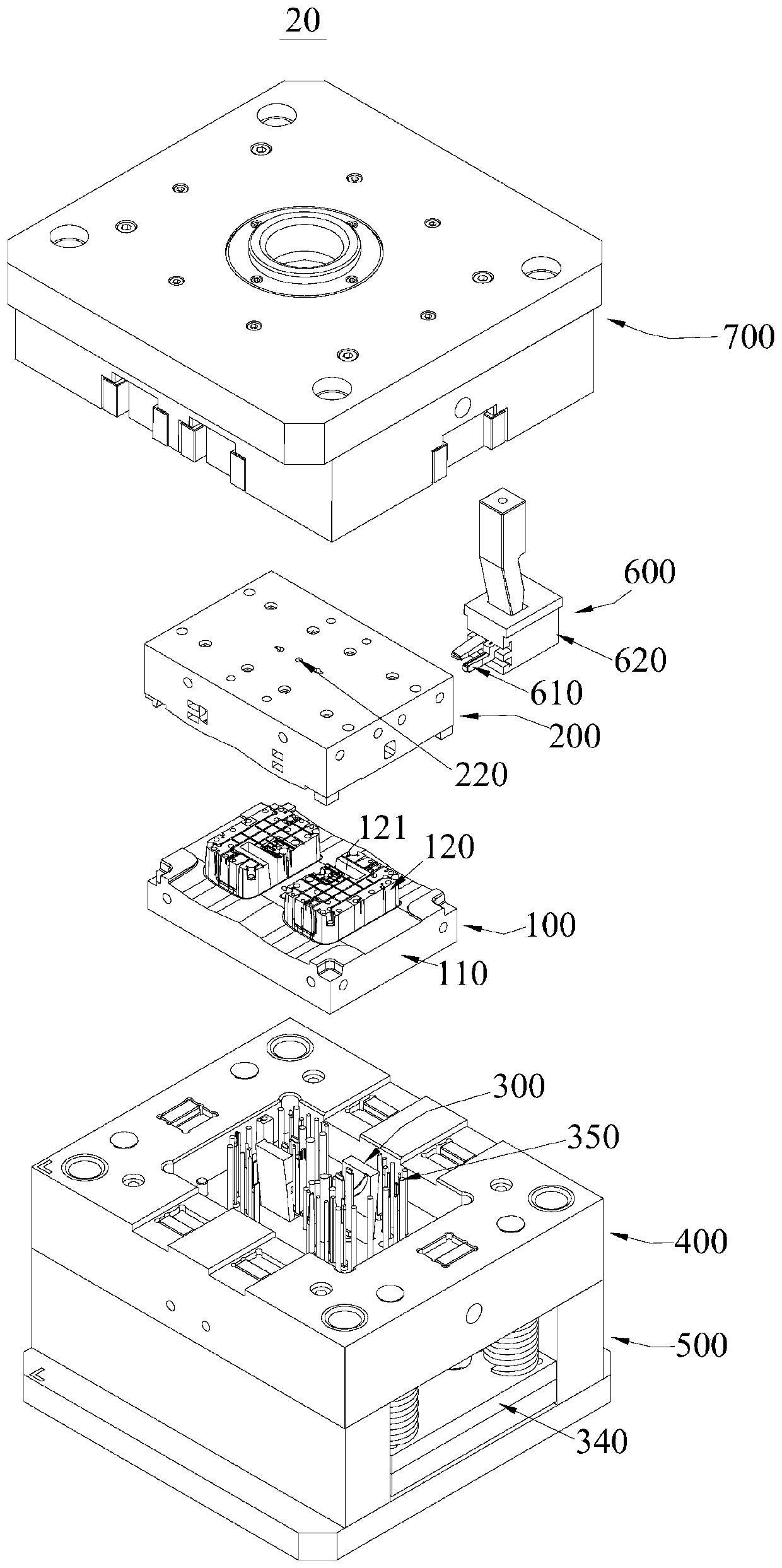

Storage battery outer shell two-point glue injection hot runner structure, injection molding method and injection molding machine

PendingCN108000810ALow costAvoid it happening againSmall-sized cells cases/jacketsLarge-sized cells cases/jacketsHot runnerPlastic injection molding

The invention provides a storage battery outer shell two-point type glue injection hot runner structure, and relates to the technical field of plastic injection molding, the technical problem of how to enable the storage battery outer shell to be subjected to balance injection molding is solved. The structure comprises two hot nozzles, a flow-dividing plate, a driving mechanism and an injection nozzle for injecting glue, the two hot nozzles are arranged in a front-and-back mode relative to the center position of the top surface of the storage battery shell, and the lower ends of the two hot nozzles are positioned on the diagonal lines of the top surface of the storage battery shell; the lower end of the flow-dividing plate is connected and communicates with the upper ends of the two hot nozzles; the driving mechanism is connected with the upper end of the flow-dividing plate, is positioned on the two sides of the injection nozzle, and synchronously drives the two hot nozzles to be opened or closed; the injection nozzle is positioned in the center of the upper end of the flow-dividing plate, is connected with the flow-dividing plate and communicates with the flow-dividing plate, andthe injection nozzle is in equal-distance communication with the two hot nozzles through the flow-dividing plate; and the injection nozzle is used for injecting the colloid into the flow-dividing plate and simultaneously flows out of the two hot nozzles at the same time to complete the balanced glue discharging.

Owner:宁波亚圣自动化科技有限公司

A seam cleaning and filling device

ActiveCN109537858BLower requirementCompact structureBuilding constructionsEngineeringMechanical engineering

Owner:CHANGAN UNIV

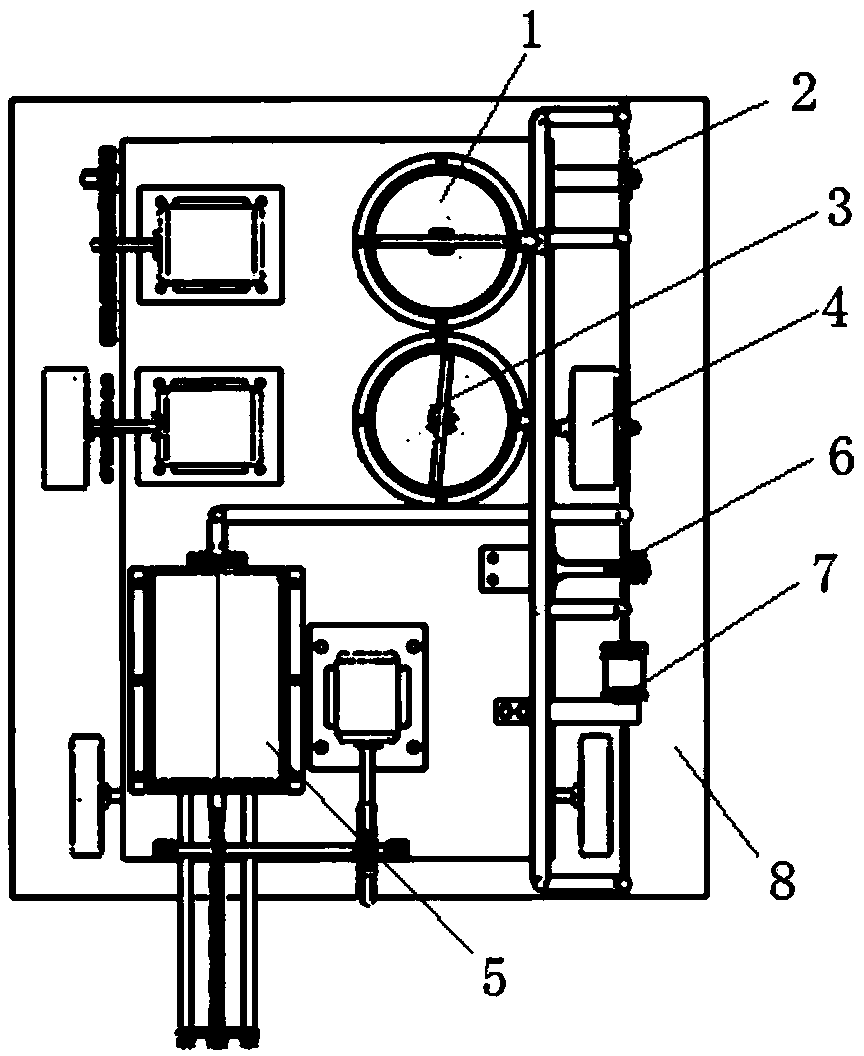

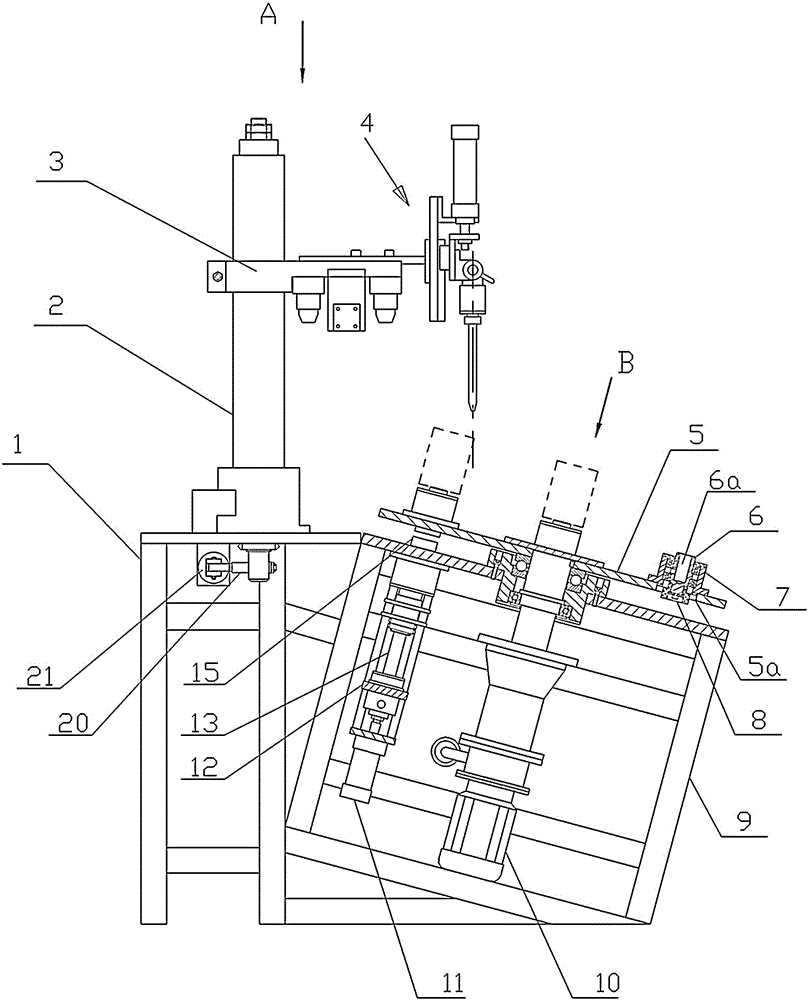

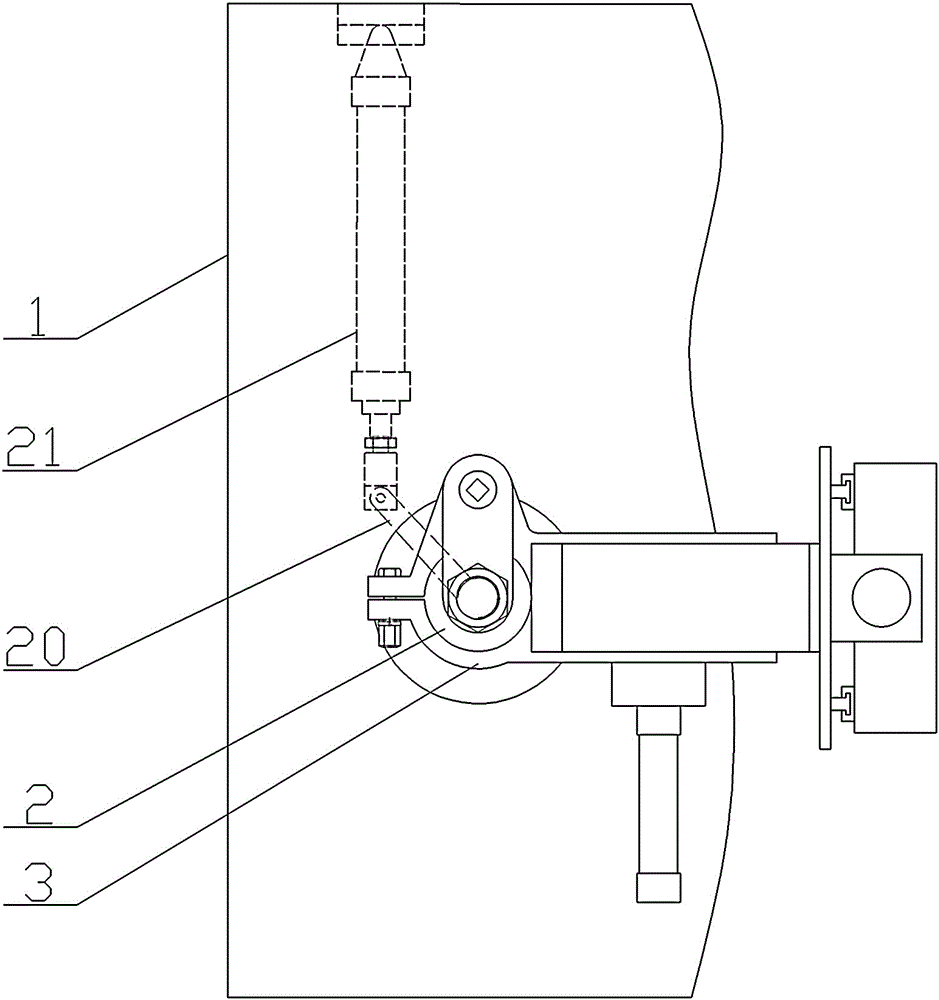

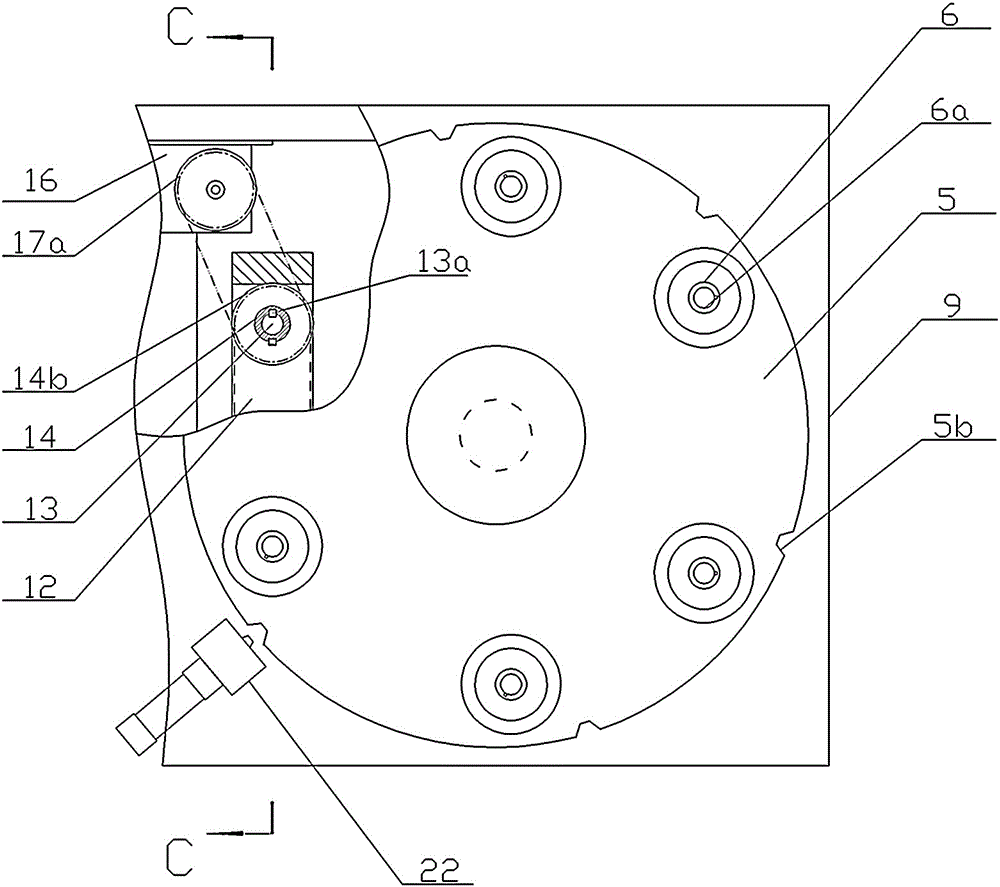

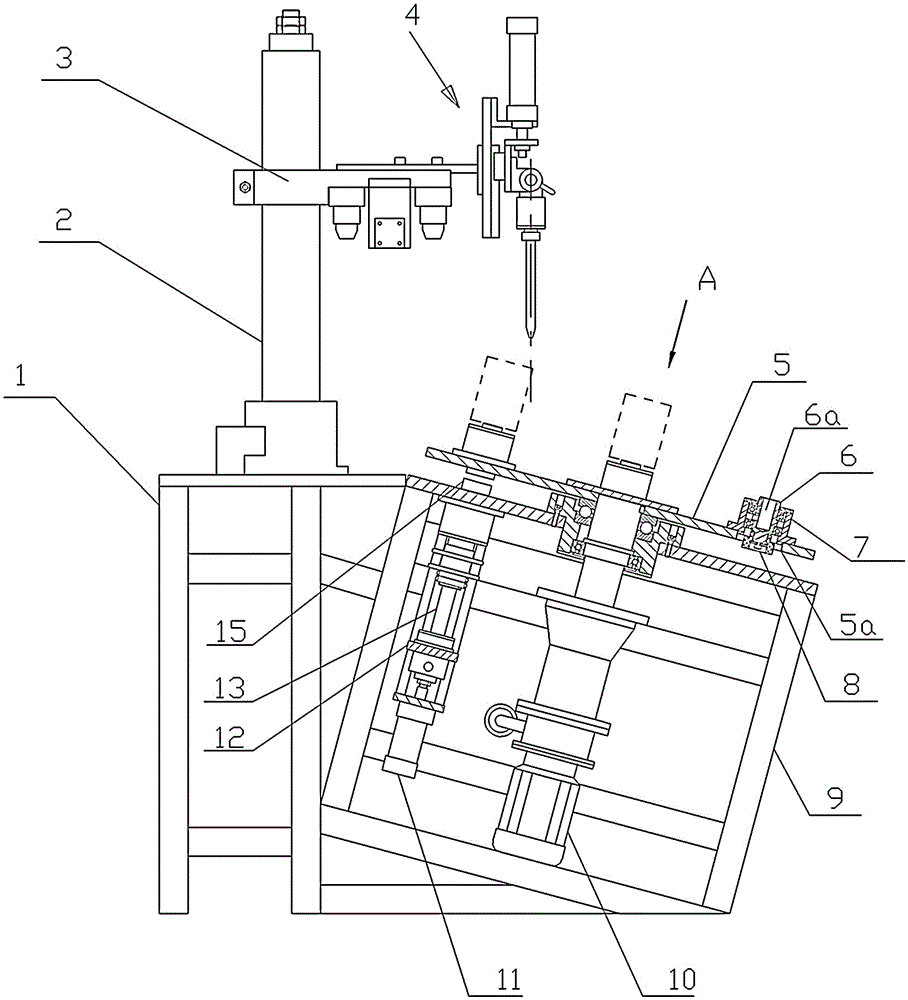

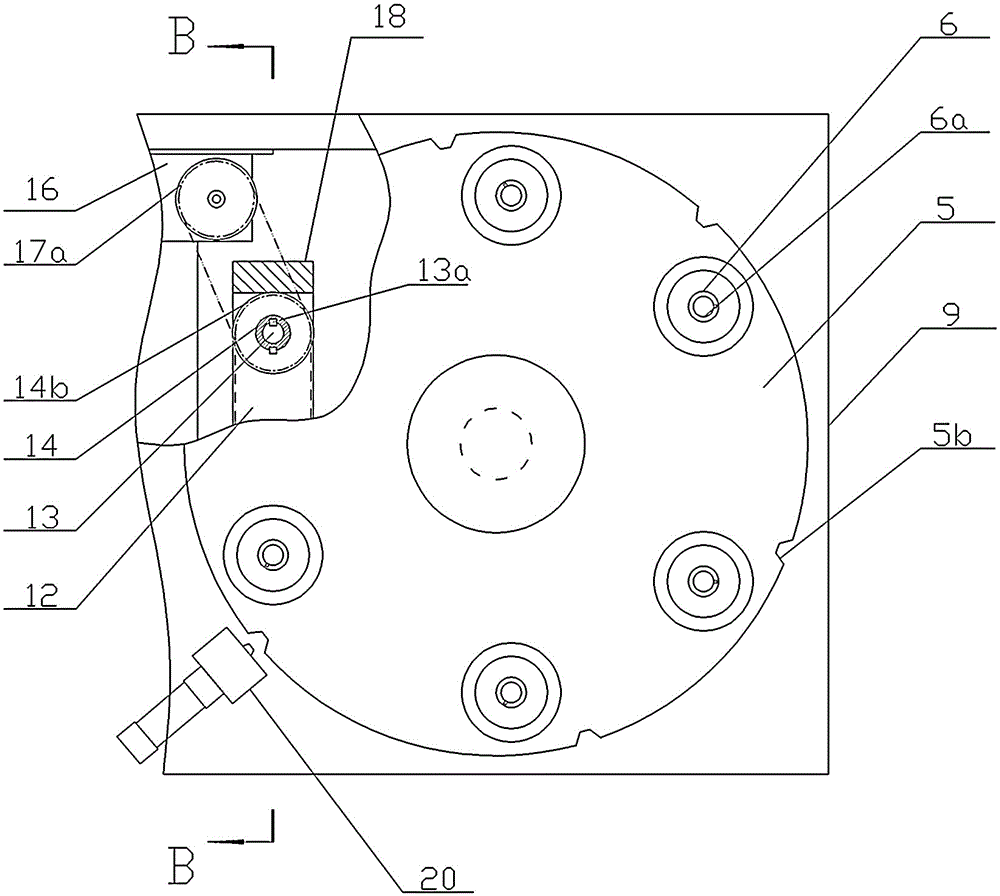

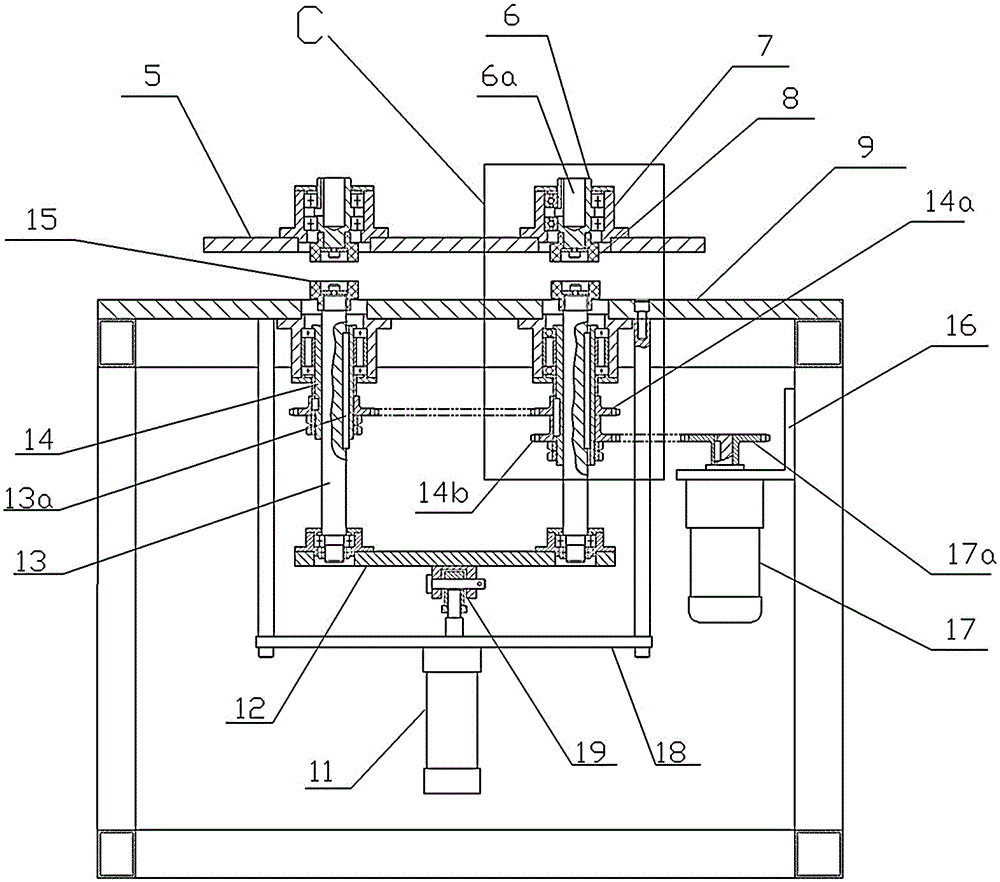

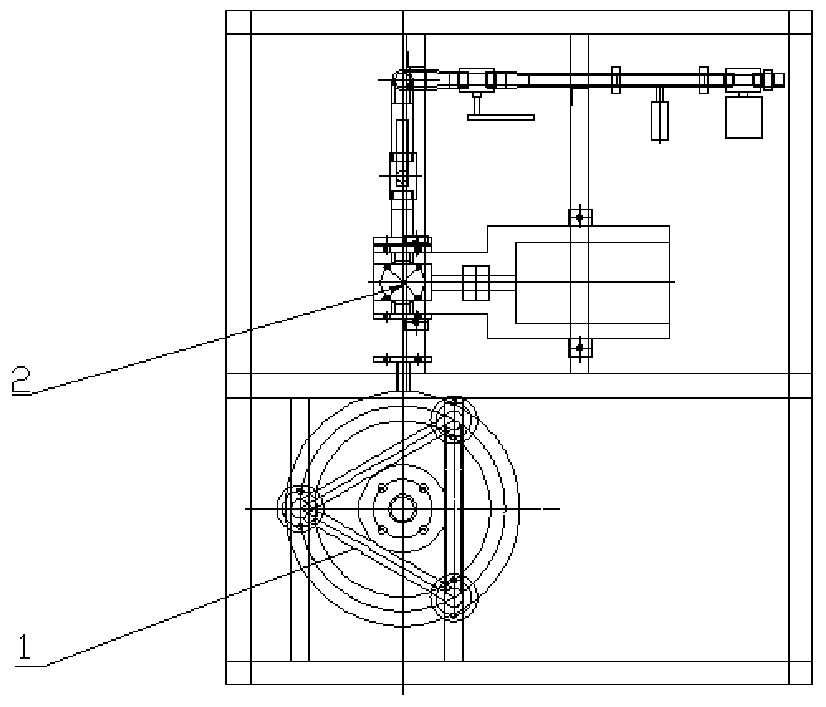

A filter housing multi-station glue injection machine with a rotary device

InactiveCN103657955BSimple structureEasy to operateLiquid surface applicatorsCoatingsElectric machineEngineering

Owner:ANHUI SCI & TECH UNIV

Production equipment with glue injection flatness detection function for LED lamp production

InactiveCN112024311AReduce damagePrecise glue injectionLiquid surface applicatorsMeasurement devicesEngineeringMechanical engineering

The invention discloses production equipment with a glue injection flatness detection function for LED lamp production. The production equipment comprises a main body frame, a first air cylinder is installed on the right side of the lower portion of the interior of the main body frame, a sliding block is welded to the right side of a first air rod, a supporting column is welded to the left side ofthe upper portion of the sliding block, and a guide disc is arranged outside a movable groove. Clamp tables are welded to the upper side of the supporting column. Compared with existing common visualinspection equipment, the production equipment with the glue injection flatness detection function for LED lamp production can perform centering and positioning operation and more precisely perform glue injection as the guide disc is arranged, the first air cylinder drives the sliding block to move through the first air rod, the supporting column is welded to the upper portion of the sliding block, the supporting column slides in the movable groove, the arc-shaped movable groove is provided such that the supporting column can stably drive the guide disc to rotate conveniently, and the guide disc rotates to drive the other supporting column to move.

Owner:重庆新禹智能科技有限公司

Glue injection packaging machine

InactiveCN102582079BLow skill level requiredUniform glue injectionLiquid surface applicatorsCoatingsDrive wheelEngineering

Owner:阮炳新

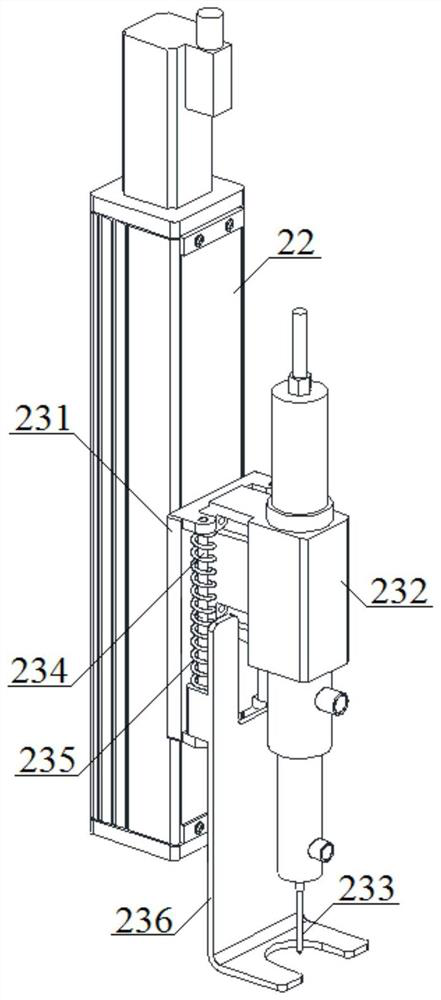

A spraying device for glue injection

ActiveCN110420801BUniform glue injectionDip evenlyLiquid surface applicatorsSpraying apparatusBiomedical engineeringMaterials science

The invention discloses a glue injection spraying method and device, belonging to the technical field of plate glue injection; the glue injection spraying method comprises: piercing a glue injection needle at a glue injection point into a piece to be injected at a uniform speed, and During this process, the glue liquid material is injected at a constant speed; when the glue injection needle reaches the limit position, withdraw from the part to be injected; repeat the above steps until the glue injection operation of the part to be injected is completed; Spraying the glue liquid material on the surface of the glue injection part until the surface spraying operation of the glue injection part is completed. The glue injection spraying method and device provided by the present invention can improve the uniformity and efficiency of glue injection for plates.

Owner:HUBEI SANJIANG AEROSPACE GRP HONGYANG ELECTROMECHANICAL

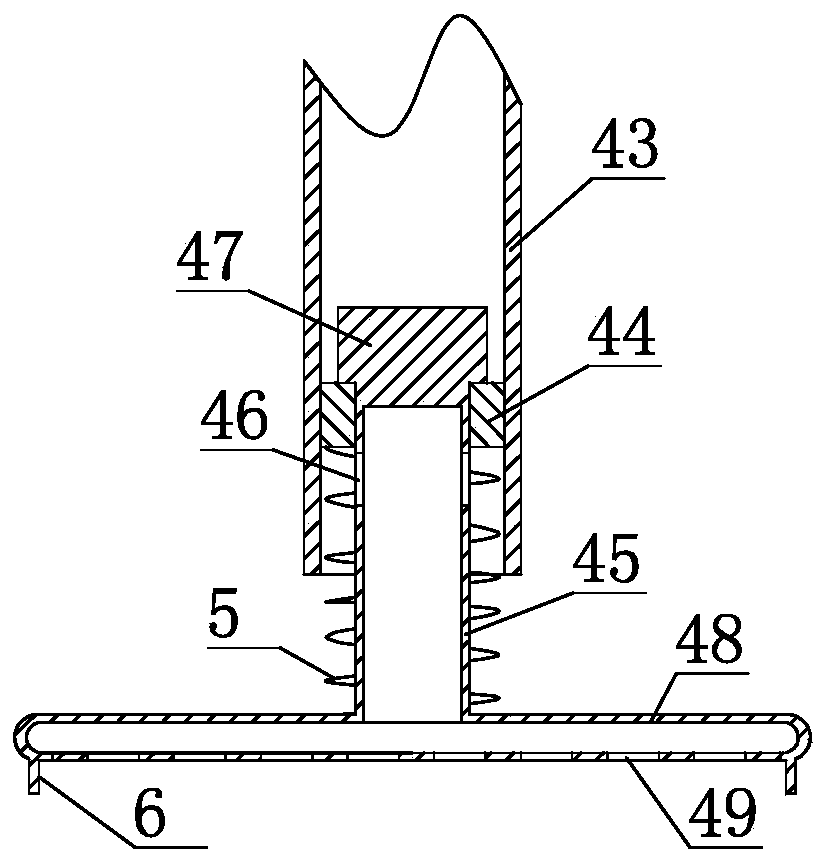

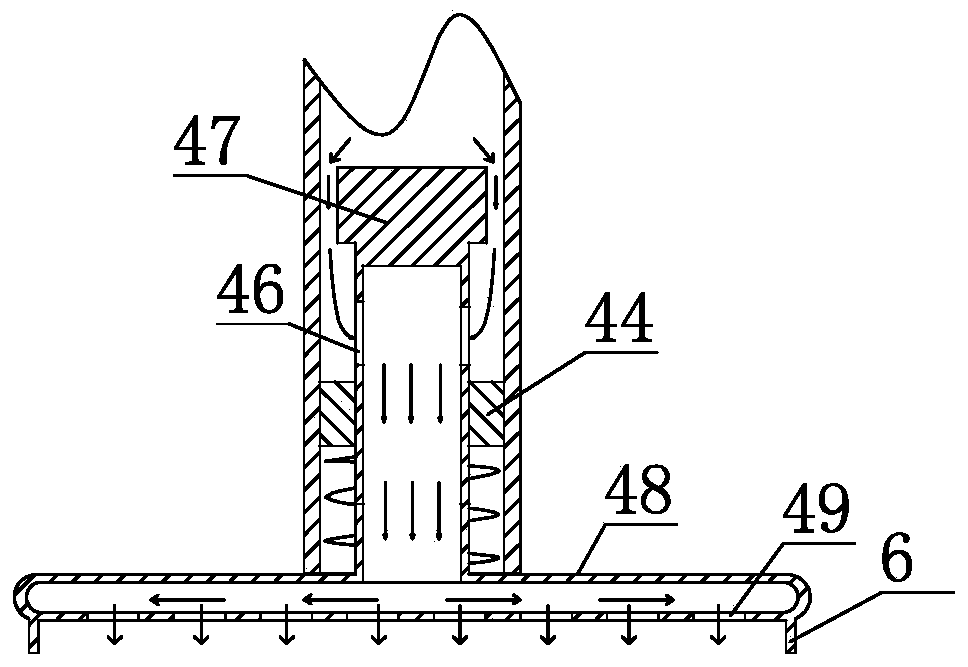

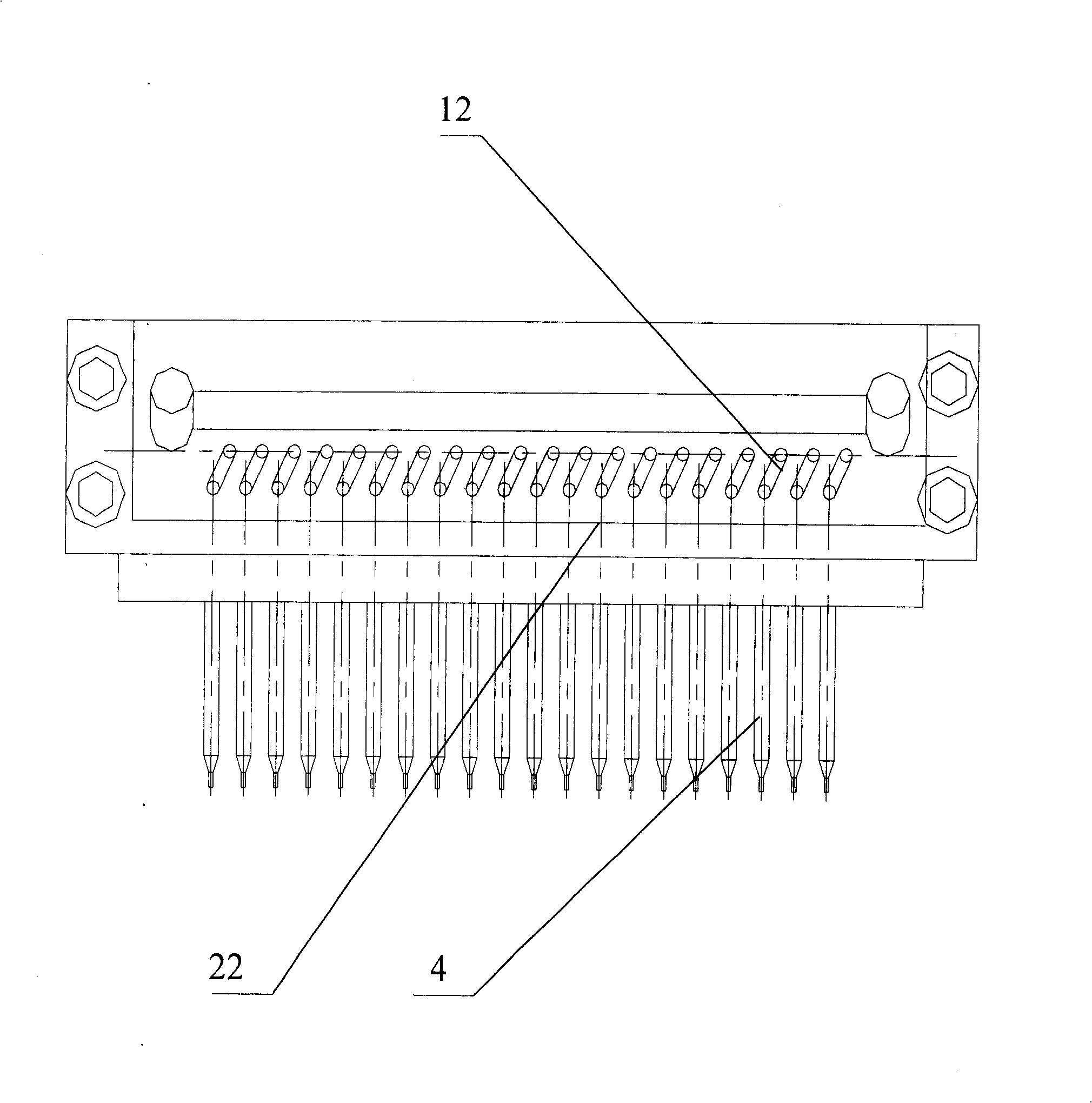

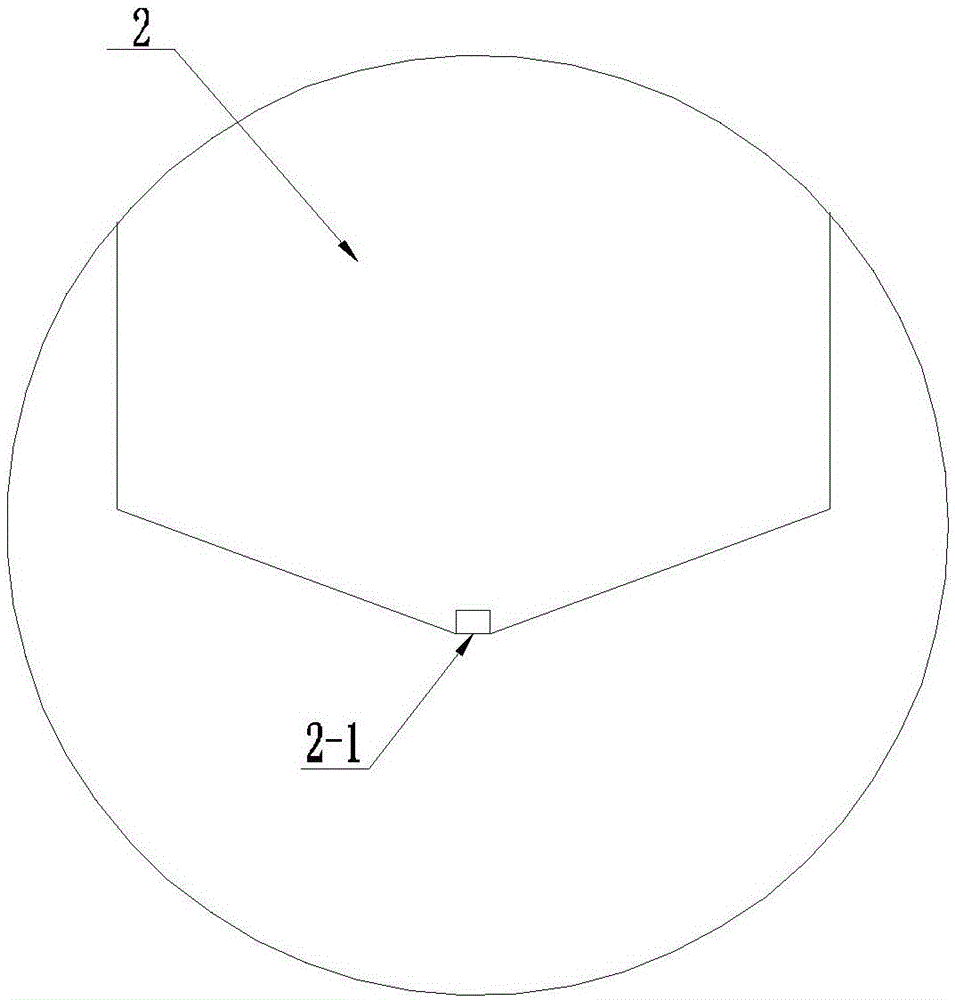

Multi-mortise uniform glue injection device

The invention discloses a multi-mortise uniform glue injection device, and relates to the technical field of glue injection machines. Moving mechanisms are arranged on the two sides of a base, and each moving mechanism comprises an air cylinder and a sliding way; a glue injection mechanism is arranged on the lower part of a lifting mechanism, and comprises a connecting plate; a plurality of glue injection heads are arranged on the lower part of the connecting plate, and comprise conveying columns; limiting blocks are arranged on the inner walls of the conveying columns, and are provided with glue injection pipes; glue inlet holes are formed in the side walls of the glue injection pipes; stopping blocks are arranged on the upper parts of the glue injection pipes; glue outlet heads are arranged on the lower parts of the glue injection pipes; and a plurality of glue spraying holes are formed in the lower parts of the glue outlet heads. The multi-mortise uniform glue injection device has the beneficial effect that glue can be uniformly injected into mortises.

Owner:滕州盛源木制品有限公司

A filter housing multi-station glue injection machine

InactiveCN103657956BSimple structureEasy to operateLiquid surface applicatorsCoatingsEngineeringSprocket

Owner:ANHUI SCI & TECH UNIV

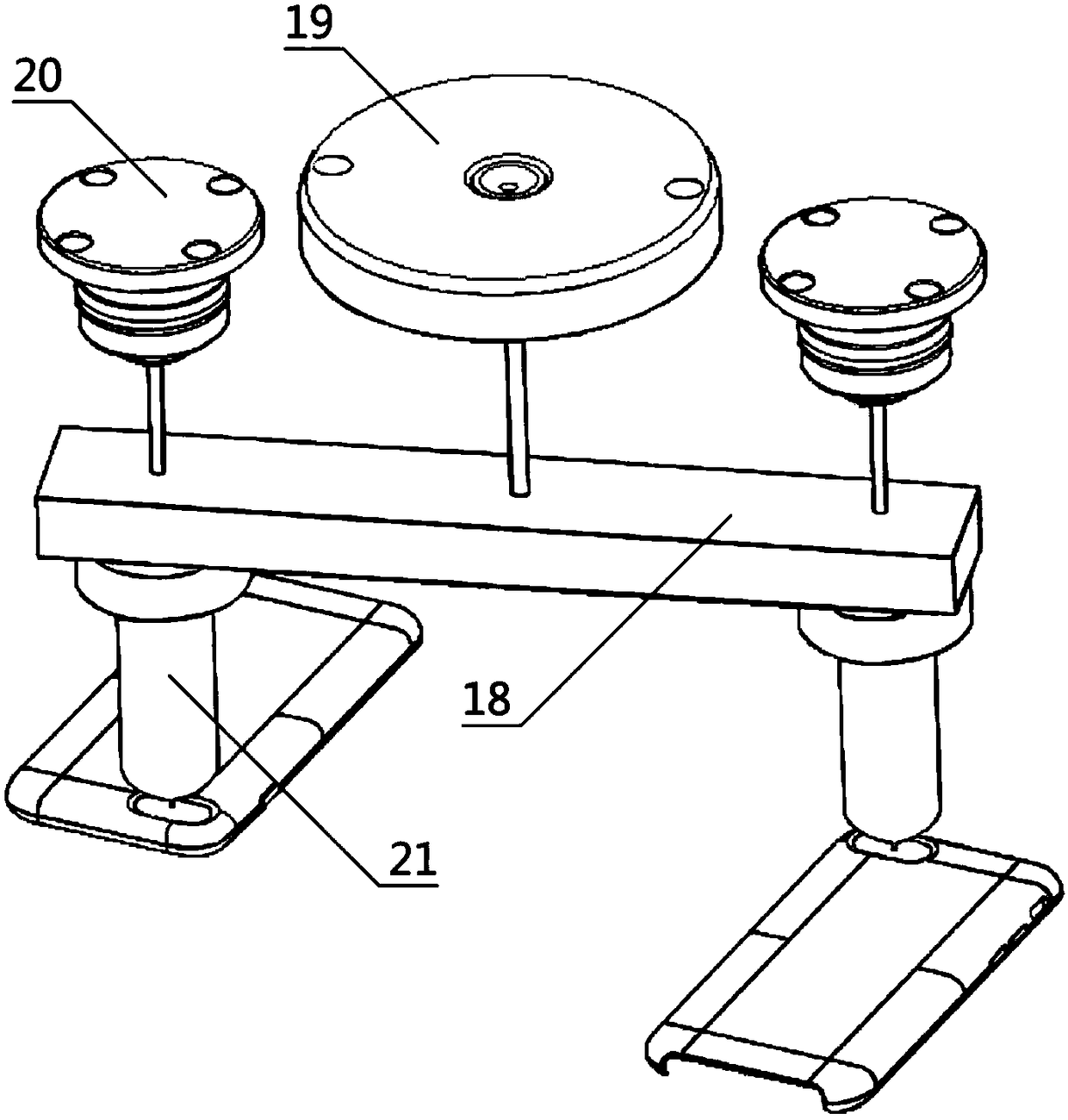

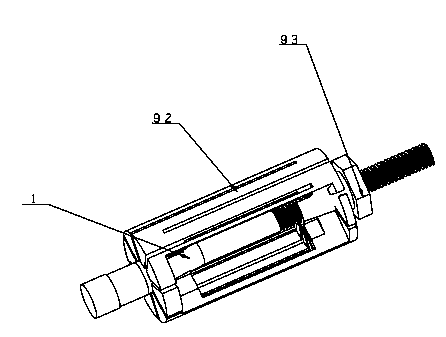

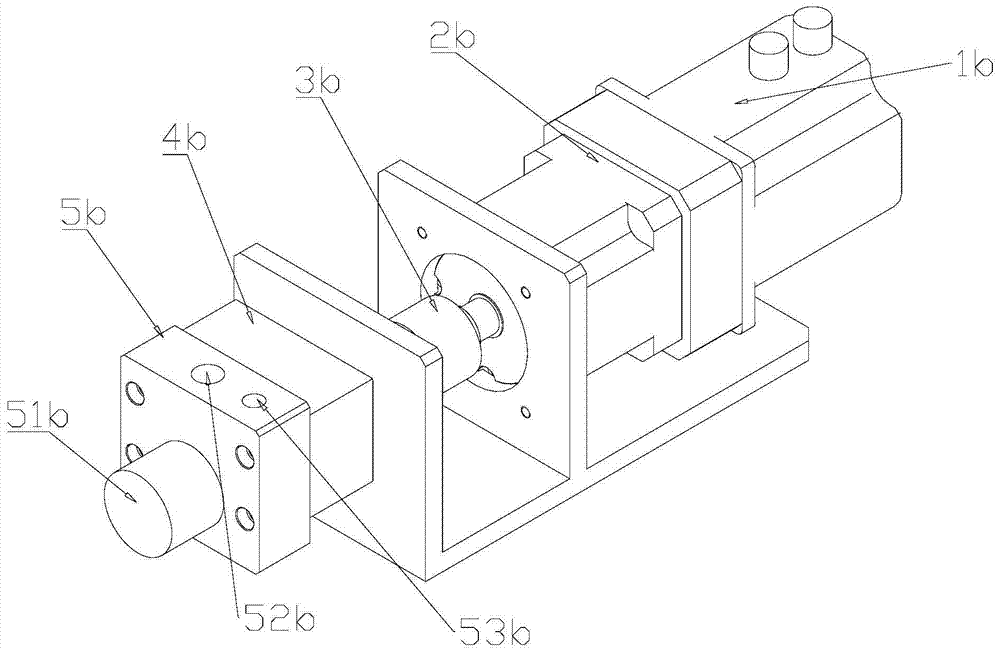

Catheter injection advancing and retreating synchronizer

InactiveCN113440715ANo crush deformation forceAdvance and retreat at a uniform speedCatheterCatheterBiomedical engineering

The invention discloses a catheter injection advancing and retreating synchronizer. The synchronizer comprises a rack, at least one set of driving mechanism used for driving a synchronizer to advance and retreat is arranged in the rack, and each driving mechanism comprises two circular rotating parts which are used for clamping the synchronizer and can rotate relatively. A power mechanism used for driving the rotating parts to rotate is further arranged in the rack. The catheter is clamped by the least one set of driving mechanism, the catheter is driven to advance and retreat at a constant speed through rotation of the driving mechanism, and an injector is pushed by a push rod synchronously moving with the catheter to perform synchronous glue injection, so that the catheter advances and retreats at a constant speed, and meanwhile, uniform glue injection is ensured when the catheter retreats.

Owner:天琴康丝微医疗器械技术(苏州)有限公司

A construction method for dry-hanging sealing and caulking treatment of decorative stone on building walls

ActiveCN111075168BNo need for manual visual observationReduce wasteBuilding constructionsDrive wheelArchitectural engineering

The invention relates to a dry-hanging, sealing and jointing treatment construction method for building wall decoration stone. A first support base, a second support base, a support mechanism, a dustremoval mechanism and a jointing mechanism are included, wherein one side of the first support base is connected with the second support base, the support mechanism is arranged right above the first support base and the second support base, the jointing mechanism is mounted at the upper end of the support mechanism, the dust removal mechanism is mounted on the upper end surface of the jointing mechanism, first inserting connection barrels are installed at the top of the first support base, first positioning rods and tooth groove rods are sequentially mounted in the three first inserting connection barrels, bearings A are mounted in connection positions of the first positioning rods and the tooth groove rods with the first inserting connection barrels, a first motor is mounted at the cornerof the upper end surface of the first support base, a first driving wheel is welded at an output shaft of the first motor, and a first belt is mounted on the outer side of the first driving wheel ina matched manner. The operation is simple and safe, and the sealant injection process is uniform, compact and full.

Owner:长春昆仑建设股份有限公司

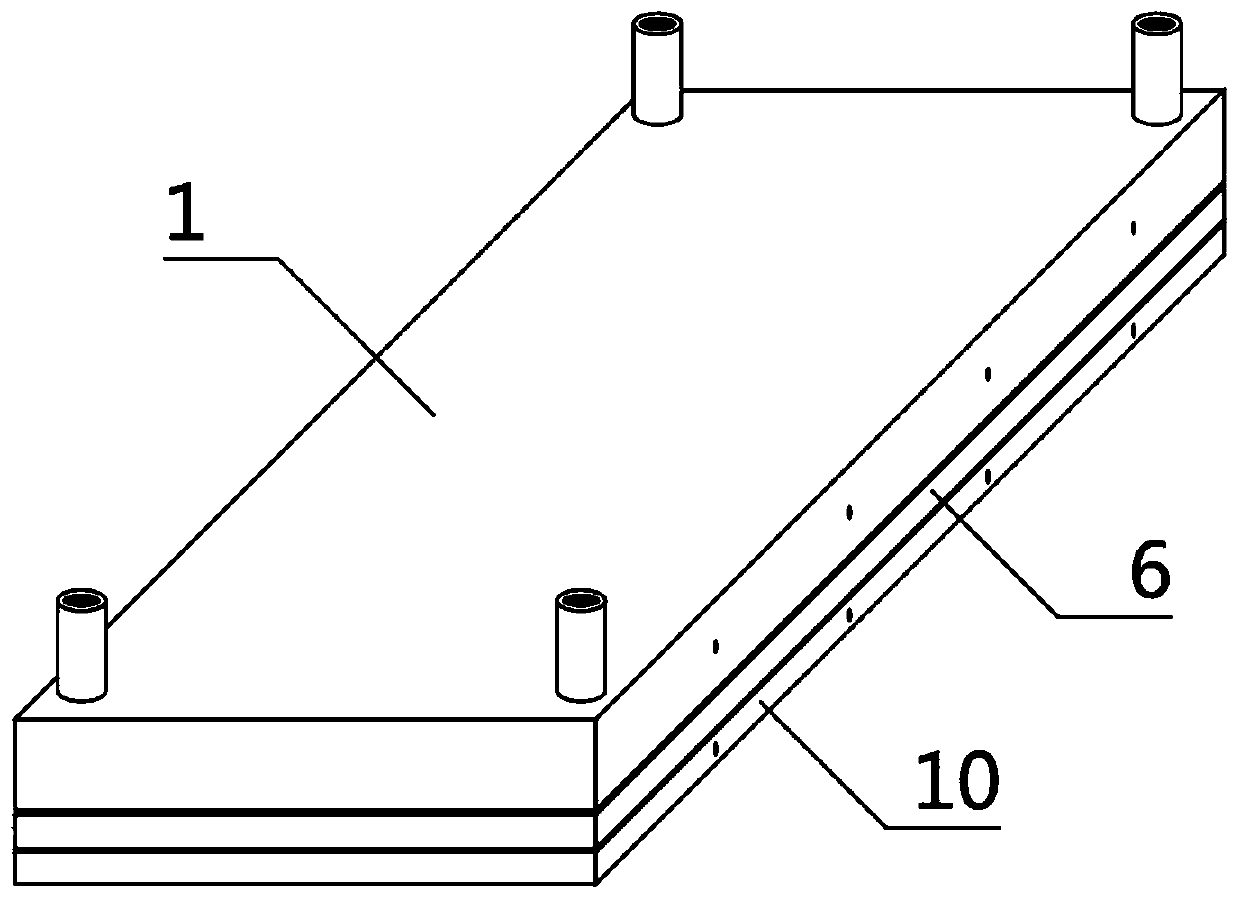

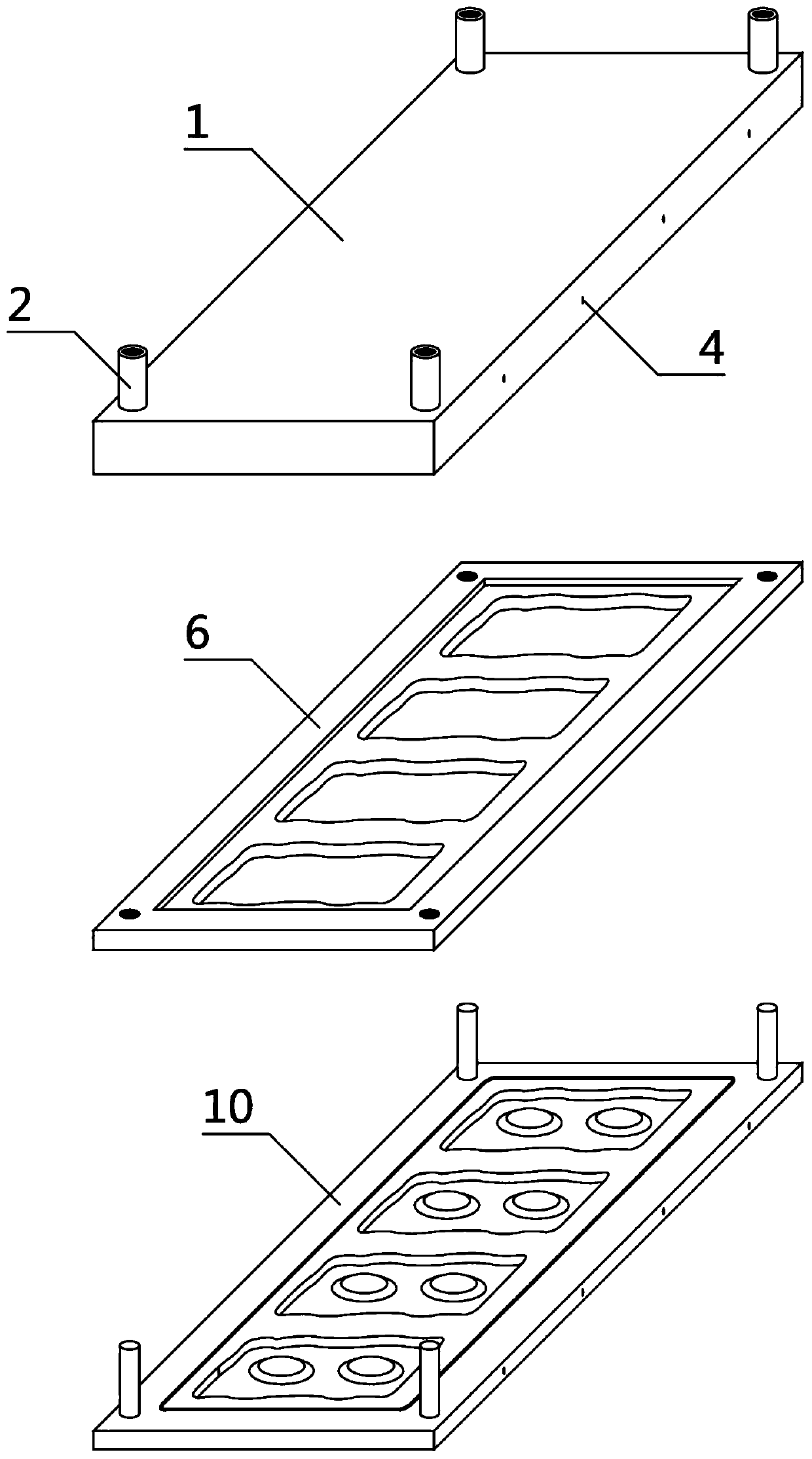

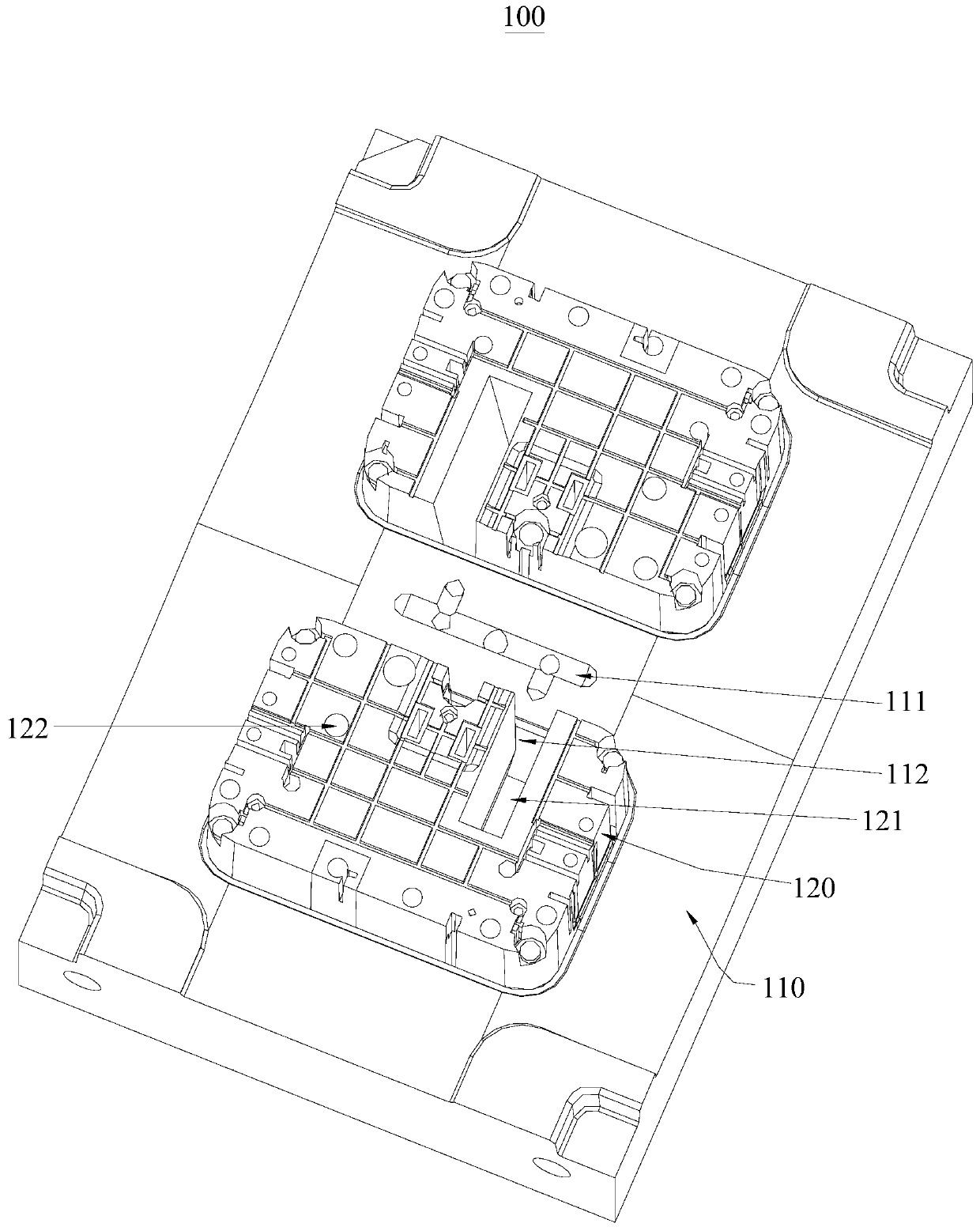

Metal key forming equipment with multi-layer die plate structure

The invention aims to provide metal key forming equipment with multi-layer die plate structure. According to the technical scheme, the forming equipment is composed of a glue injection forming upper die plate, a forming structure die plate and a glue injection forming lower die plate, four die assembly register extension hole columns, a plurality of upper die plate forming structure frames and upper die plate overflow separation grooves are arranged on the glue injection forming upper die plate, two upper die plate glue injection holes are formed in each upper die plate forming structure frame, the forming structure die plate is provided with a forming horizontal groove, the plurality of double-key part forming blocks and four positioning holes, the plurality of double-key part forming dies, a lower die plate overflow separation groove and four die assembly positioning columns are arranged on the glue injection forming lower die plate, and two lower die plate glue injection holes are formed in each double-key part forming die. According to the metal key forming equipment with multi-layer die plate structure, the die is simple in structure, accurate in die assembly and capable of preventing the die from falling off, meanwhile, the upper glue injection forming and the lower glue injection forming, so that the glue injection operation is more uniform, the product is more attractive, the output of inferior products is reduced, the enterprise cost is reduced, and the working efficiency is improved.

Owner:SYNERGY HANIL PRECISION POLYMER TECH CO LTD

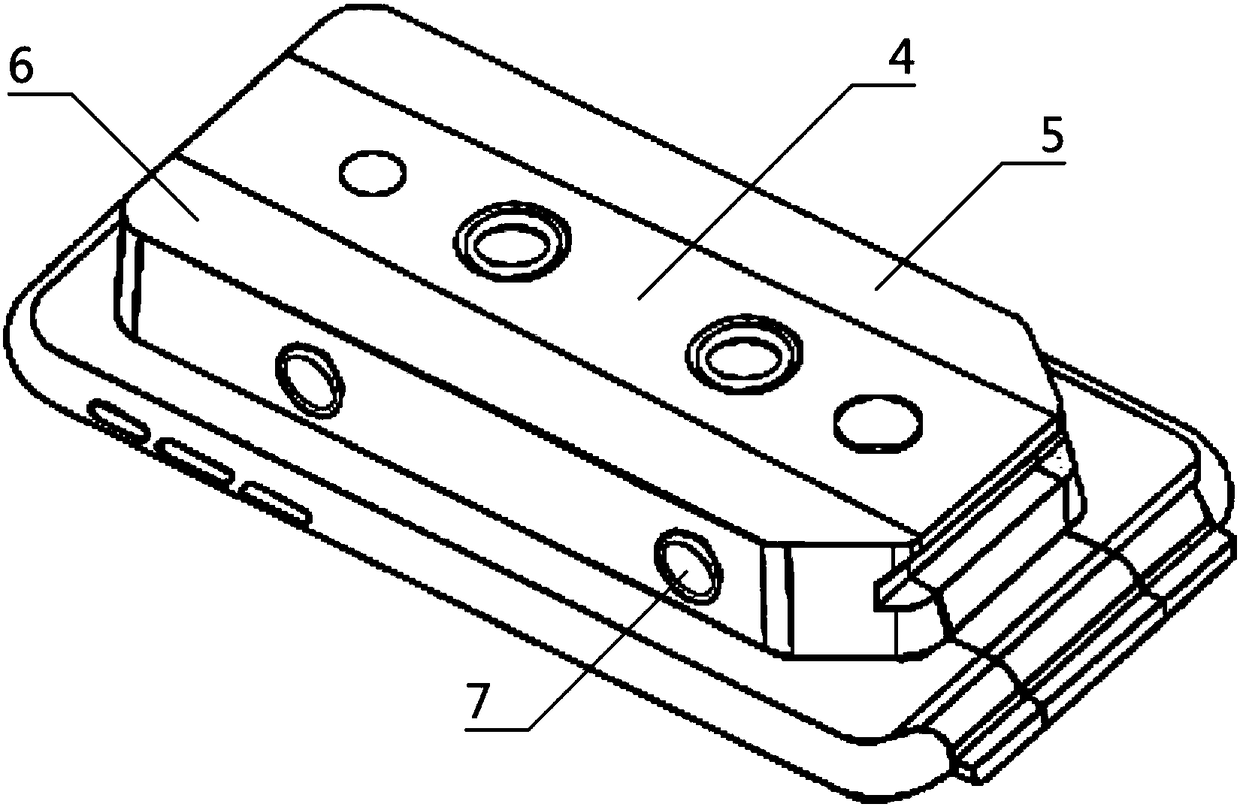

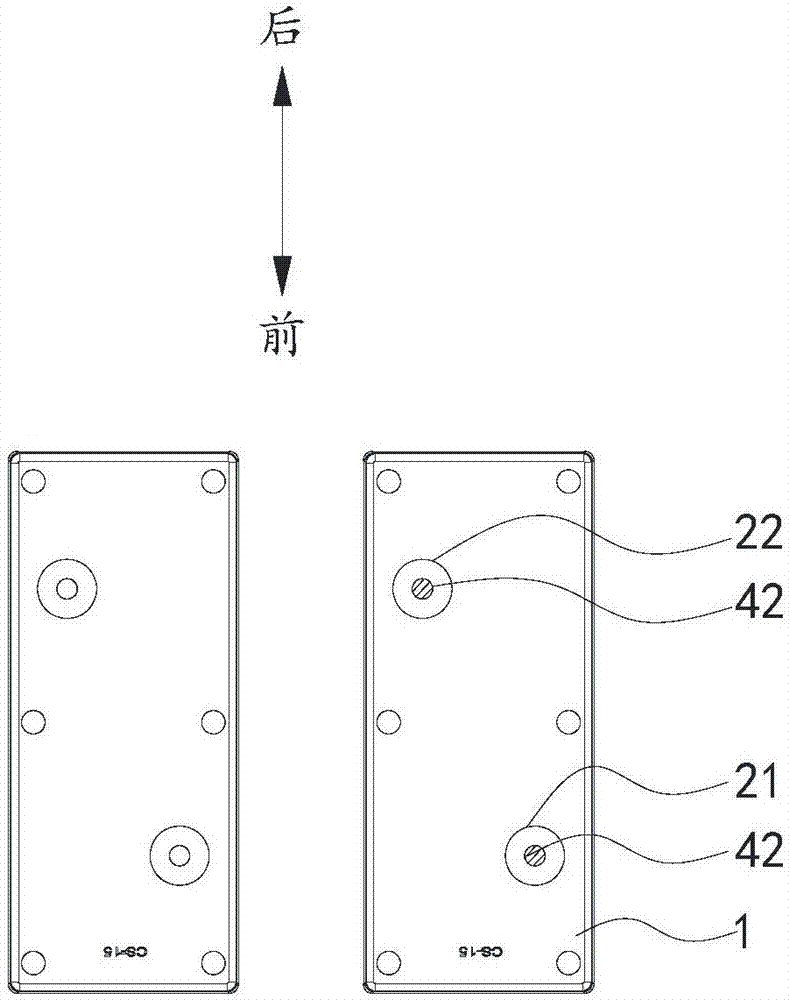

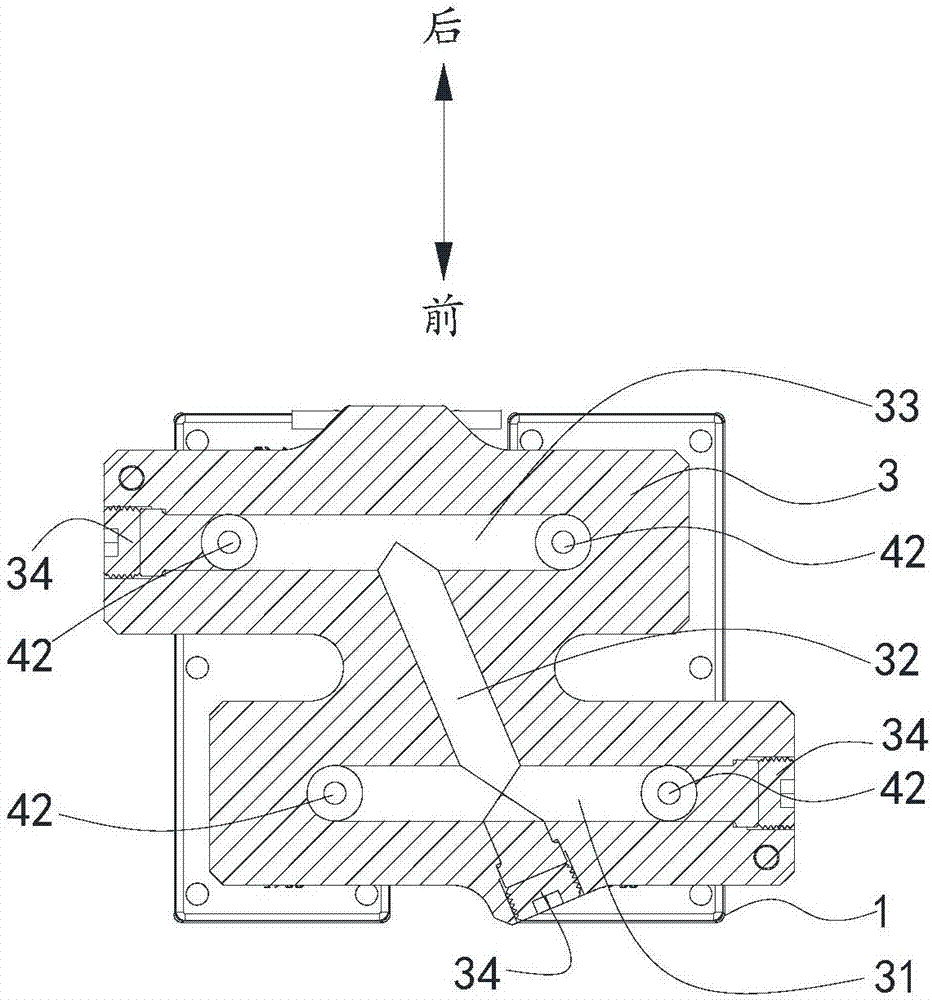

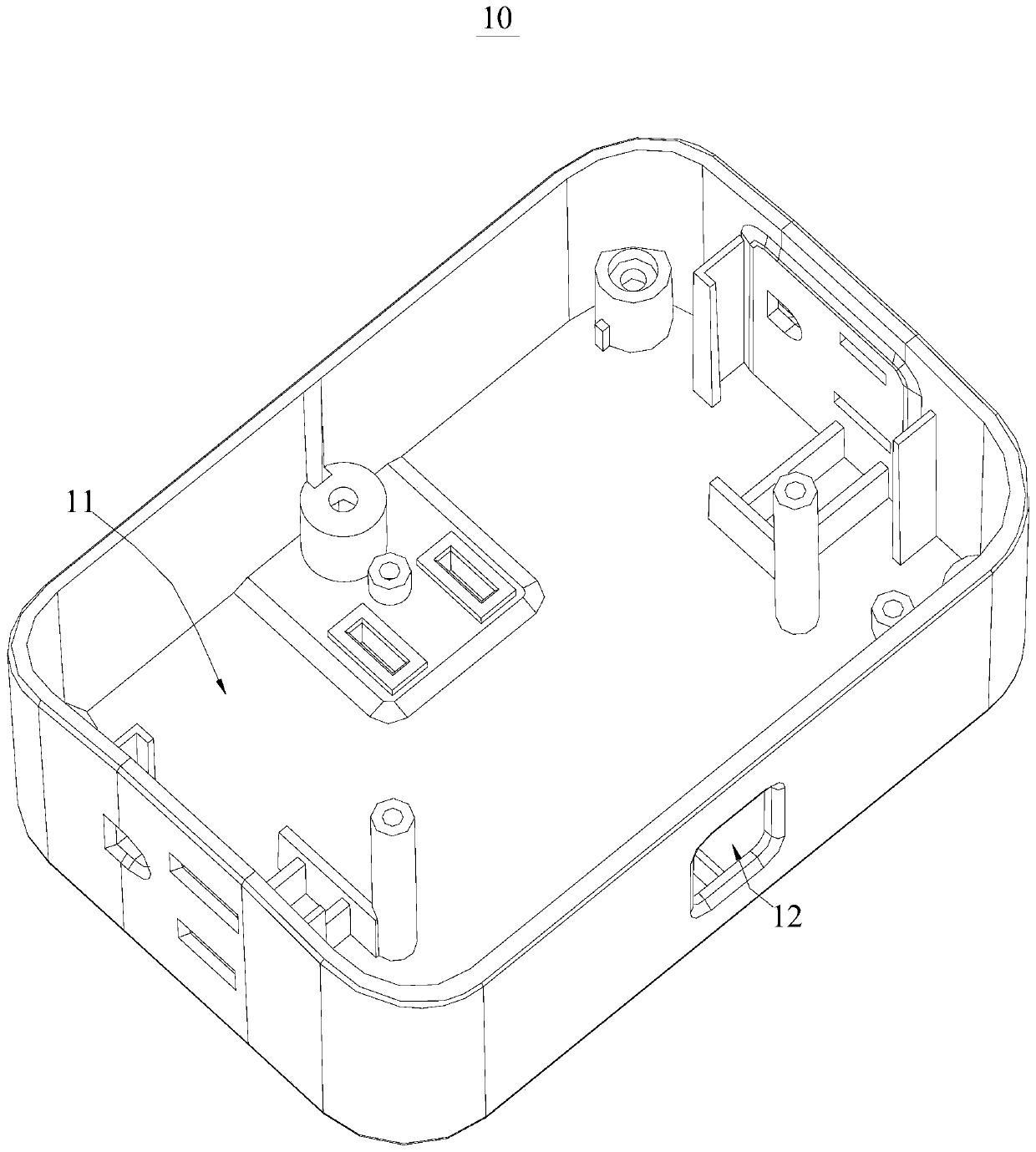

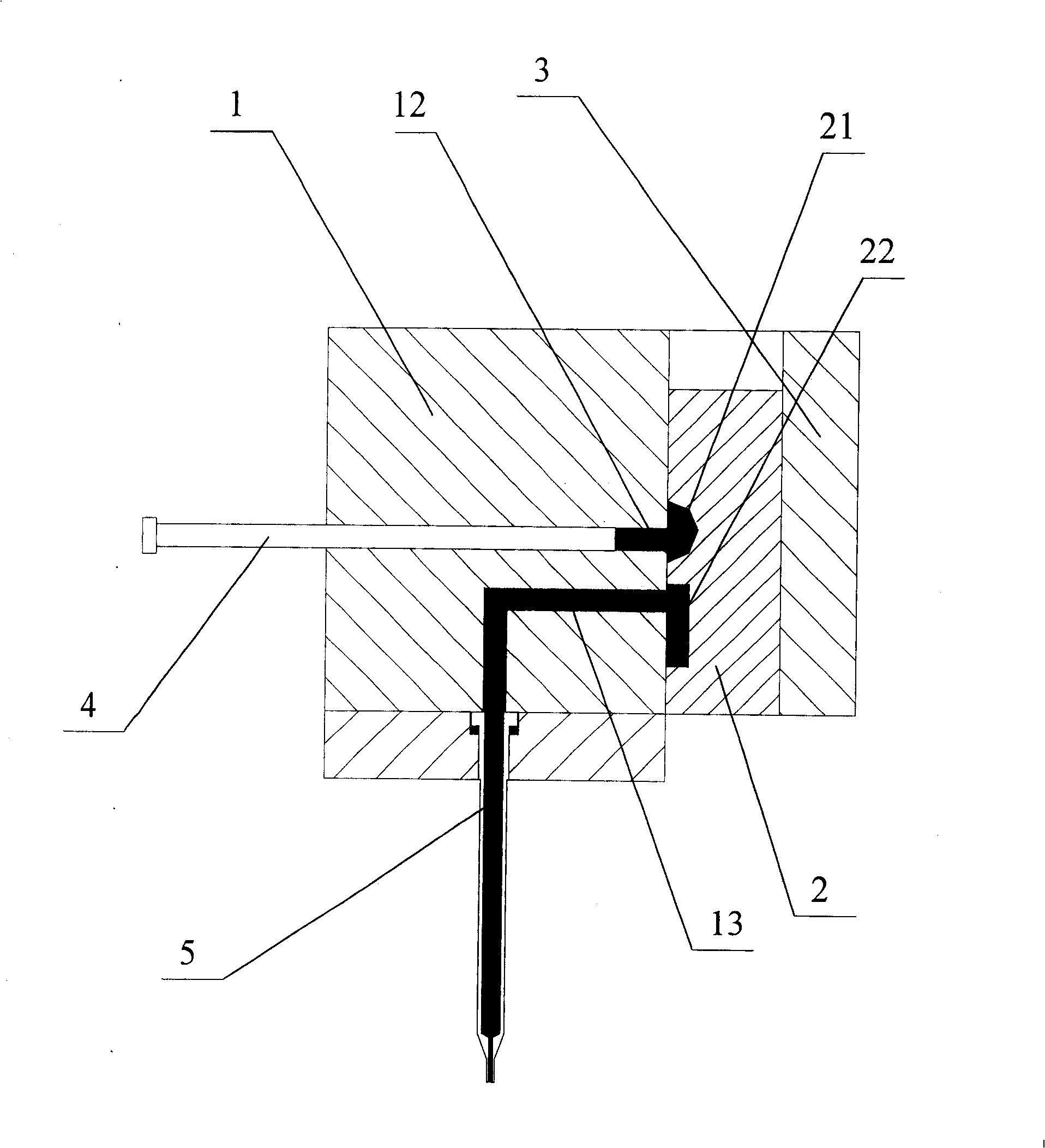

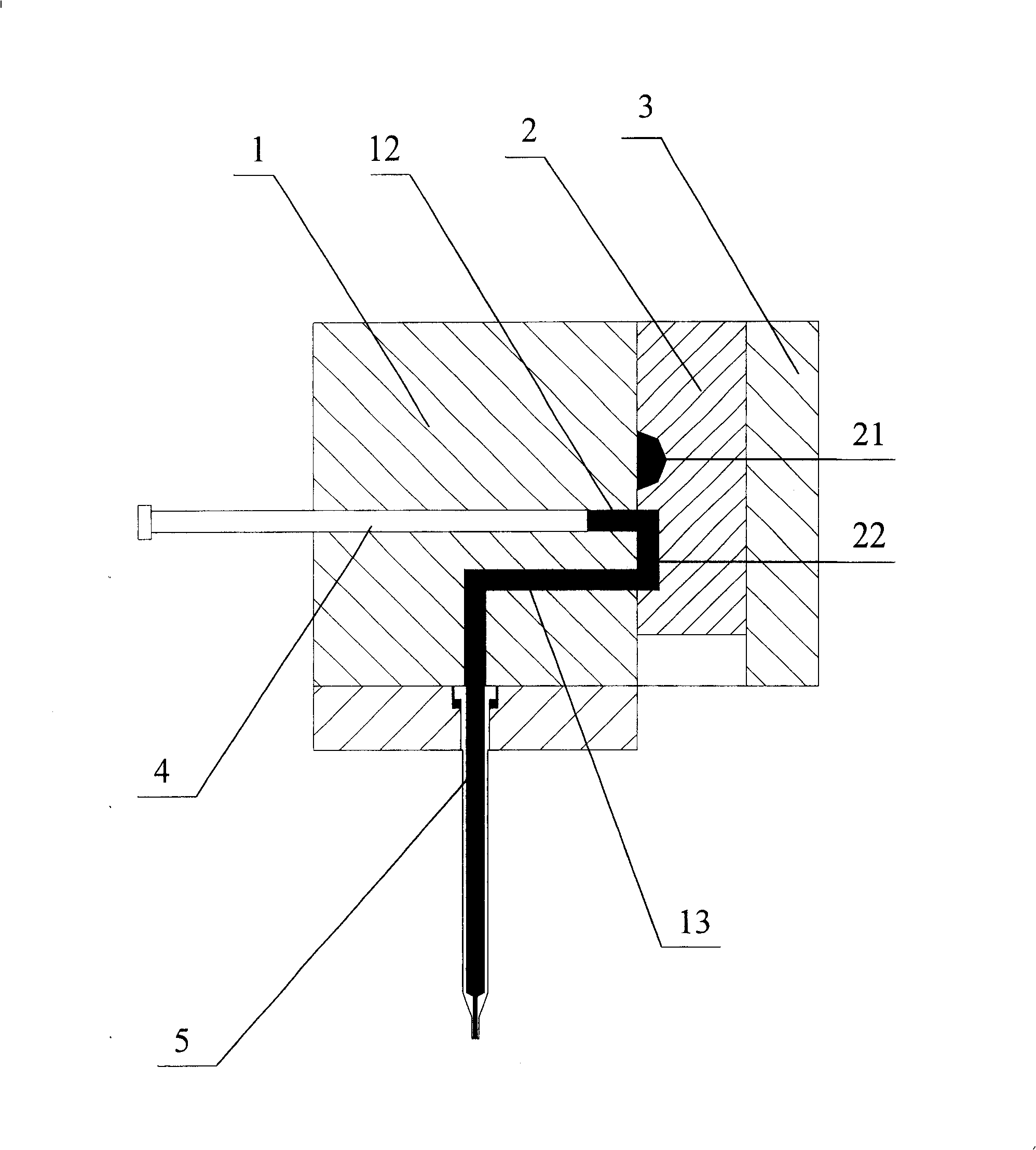

Socket shell injection molding mold uniform in glue injection

Disclosed is a socket shell injection molding mold uniform in glue injection. The socket shell injection molding mold uniform in glue injection comprises a movable mold core, a fixed mold core and a glue injection assembly. The movable mold core is buckled on the fixed mold core. An injection molding cavity for injection molding a socket shell is formed between the movable mold core and the fixedmold core. The movable mold core comprises a bottom plate and a boss. The boss is disposed on the bottom plate. The boss is provided with a slideway. The glue injection assembly comprises a glue injection block and a guide block. The glue injection block is slidably arranged in the slideway. A glue flowing groove is formed in the glue injection block to enable plastic to enter the injection molding cavity from the glue flowing groove. Therefore, the injection molding of the socket shell is achieved, the outer surface of the socket shell does not have feeding marks, and the smoothness is kept.Furthermore, the glue injection block is arranged in the slideway in a penetrating mode, and one end, connected with the injection molding cavity, of the glue injection groove is located at the position close to the center of the boss, so that the plastic can flow around from the middle position of the injection molding cavity, glue injection is uniform, the problem of deformation of the formed socket shell is effectively prevented, and the forming quality is further improved.

Owner:金裕泰(惠州)实业有限公司

A method for equable glue filling of LED and corresponding glue filler

InactiveCN100479211CImprove sealingAvoid affecting the uniformity of glue injectionSemiconductor/solid-state device manufacturingSemiconductor devicesEngineeringColloid

The invention is concerned with the glue filling machine and the glue filling method for the light-emitting diode, it includes: the engine block (-) with the blanking hole (-) under the storing hole (-); the piston gear (-) connecting with the power source (-); the storing hole (-) attaches with the piston gear (-) where the opening on the side of the engine block that connects with the flow entering hole; there-into the flute (-) and the canal (-) below are in the valve board (-)on the side of the engine block; the valve board controls the operation by moving to the storing hole (-) of the flute (-) that than detaches with the canal leading the connection between the valve board (-) and the flute (-); or moving backwards to detach the storing hole (-) with the flute (-) of the valve board (-) that leads the connection between the canal (-) and the blanking hole (-). The invention insures the equality of the LED glue filling partly and improves its quality and its productivity.

Owner:杨少辰

Quantitative uniform speed glue injection device

ActiveCN105435711BSwitching pressure stabilityAvoid timeGranulation with special binding agentsInternal pressureEngineering

The invention provides a uniform-speed quantitative glue injection apparatus. The apparatus comprises a glue storage pot and a glue supply pump; one end of the glue supply pump is connected to the glue storage pot through a glue discharge pipeline, and the other end is connected to a glue supply pipeline; the end of the glue supply pipeline is provided with a glue injection structure for injecting glue, and the glue supply pipeline is provided with a glue injection control valve for opening or closing the glue supply pipeline; a primary backflow pipeline is connected between the glue supply pipeline and the glue storage pot for backflow of glue materials in the glue supply pipeline to the glue storage pot, the primary backflow pipeline is provided with a primary backflow control valve for opening or closing a backflow pipeline, and the primary backflow control valve and the glue injection control valve are operated in alternative correlation. The uniform-speed quantitative glue injection apparatus is safe and intelligent, and the injected glue is uniform and controllable; pressure in liquid supply pipelines in the temporary state without glue injection and the state with glue injection are kept identical, so that waste of time and cost due to newly established pipeline pressure after pumping termination without glue injection is avoided.

Owner:BEIJING TIANYISHANGJIA NEW MATERIAL

PCBA automatic glue injection equipment

PendingCN113578658ARealize Segmented FlowImprove liquidityLiquid surface applicatorsCoatingsInjection equipmentAdhesive glue

The invention discloses PCBA automatic glue injection equipment, and relates to the technical field of PCBA glue injection. The equipment comprises a machine box control box. A touch controller is installed on one surface of the machine box control box, a displayer controller is installed on one side face of the machine box control box, and a feeding flow channel mechanism, a vibration flow channel mechanism, a placing flow channel mechanism, a plate placing module, a glue injection moving module and a glue injection glue mechanism are installed inside the machine box control box. Multiple glue barrels are installed on the upper surface of the machine box control box, and a glue injection head is installed on the bottom surface of the glue injection glue mechanism. According to the PCBA automatic glue injection equipment, PCBA segmented flow is realized through the design of a machine; and due to the design of the mechanisms, the modules are used for driving the glue injection mechanism, the efficiency is improved, the replacement cost is reduced, the vibration mechanism is used, the glue fluidity is improved, automatic placement is achieved, and the efficiency is improved.

Owner:港加贺电子(深圳)有限公司

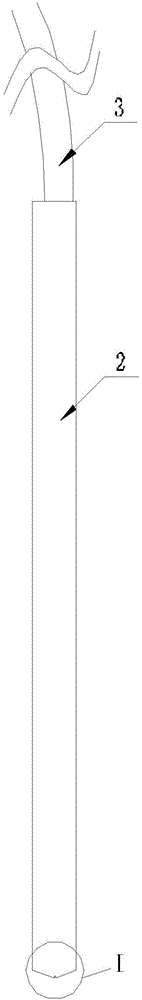

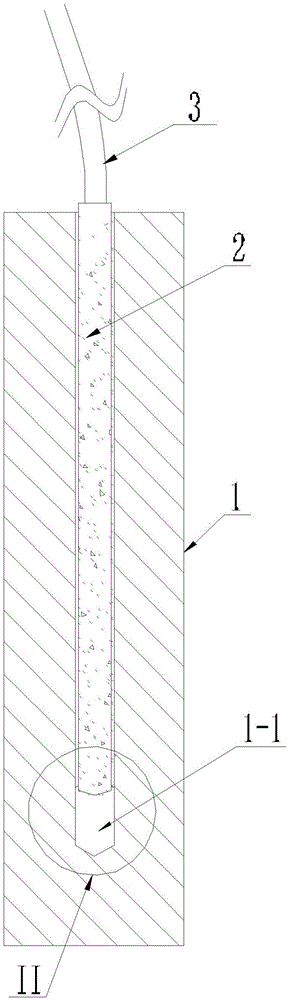

Glue injection device of temperature detection blind hole

InactiveCN105004437AReduce injection resistanceSimple structureThermometer detailsBiomedical engineeringAir bubble

A glue injection device of a temperature detection blind hole belongs to the rail vehicle deep and thin blind hole special-purpose glue injection device field, and comprises an injection head, a flexible pipe and a conventional syringe not having a syringe needle. The external diameter of the injection head is less than the internal diameter of the temperature detection blind hole, the front end of the injection head is equipped with a conical glue injection port, the tail end of the injection head is fixedly connected and communicated with the flexible pipe, and the other end of the flexible pipe is connected and communicated with the conventional syringe not having the syringe needle. The beneficial effects of the present invention are that: the glue injection device of the temperature detection blind hole utilizes the conical glue injection port made of the flexible materials, such as the rubber, etc., as a glue injection part and a sealing part simultaneously, also can utilize the viscosity characteristic of a heat-conducting glue itself to form a temporary enclosed pressure environment while reducing the glue injection resistance, thereby quitting the injection head from the temperature detection blind hole automatically and slowly while finishing the glue injection process step by step, at the same time, guaranteeing the uniform glue injection and completely eradicating the bubble residual.

Owner:CRRC CHANGCHUN RAILWAY VEHICLES CO LTD

A glass door and window fast assembly glue sealing machine

ActiveCN110548646BInjection speed unchangedUniform glue injectionLiquid surface applicatorsCoatingsElectric machineryStructural engineering

The invention belongs to the technical field of door and window processing, and specifically relates to a glue injection and sealing machine for fast assembly of glass doors and windows, which includes a glue injection mechanism, a walking mechanism and a fixing mechanism. The glue rod, through the uniform movement of the walking mechanism, drives the glue injection pipe to realize uniform glue application and smearing. The traveling mechanism includes a roller frame fixedly connected to the bottom surface of the cavity, on which a rubber roller supported on the glass plate is rotatably connected, and the output end of the second motor is fixedly connected to the rotating shaft of the rubber roller. On the one hand, the fixing mechanism makes the cavity only move along the direction parallel to the seam of the glass door and window through the position limiting function, and on the other hand, clamps the frame of the glass door and window to limit the movement of the glass door and window. The present invention can simultaneously inject glue to the two seams of the glass plate and the frame, and the glue is evenly injected; the present invention smears the joint after glue injection, so that both sides of the seam are evenly covered with glass glue, which improves the sealing effect .

Owner:赣州宇智材料有限公司

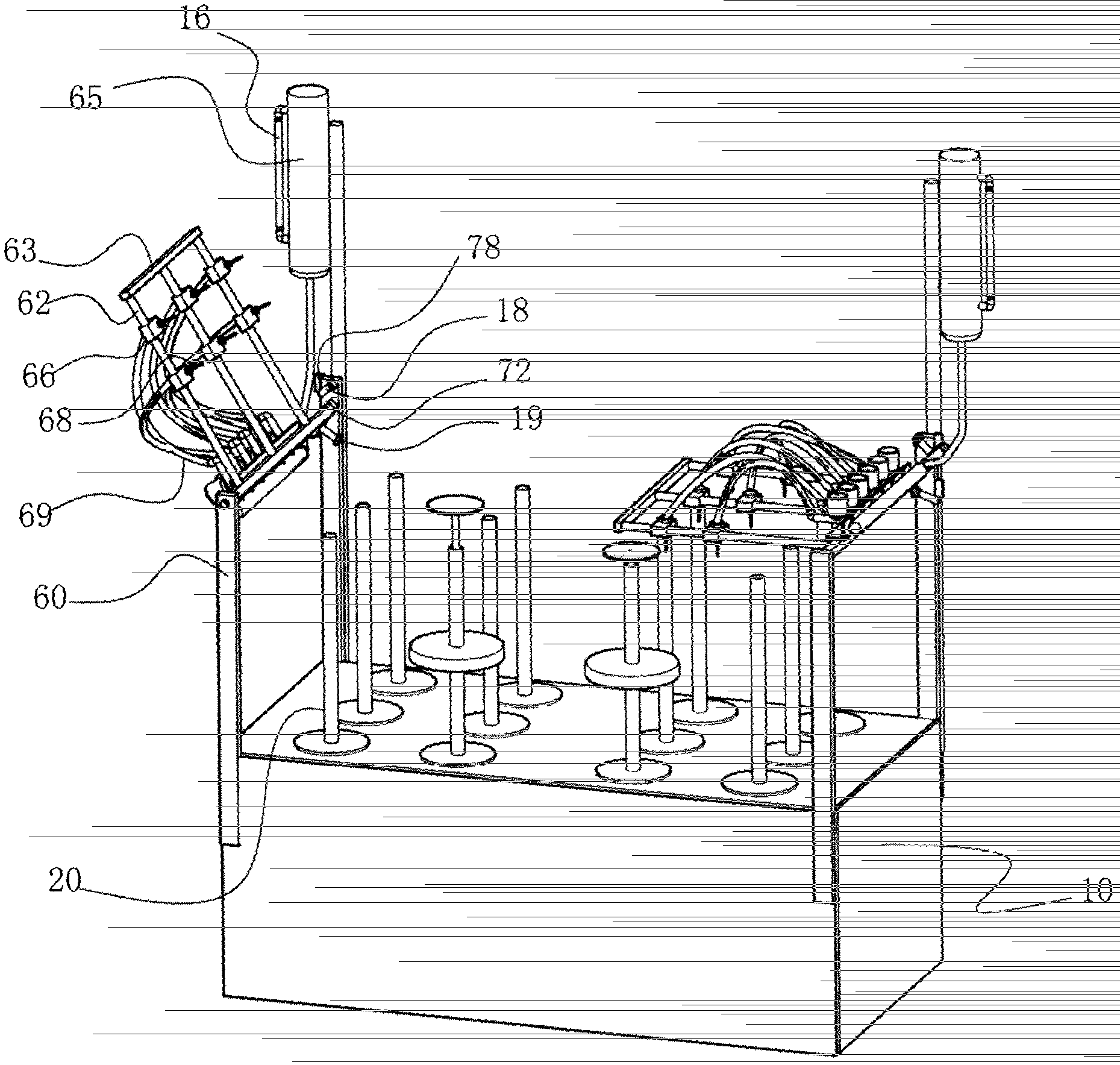

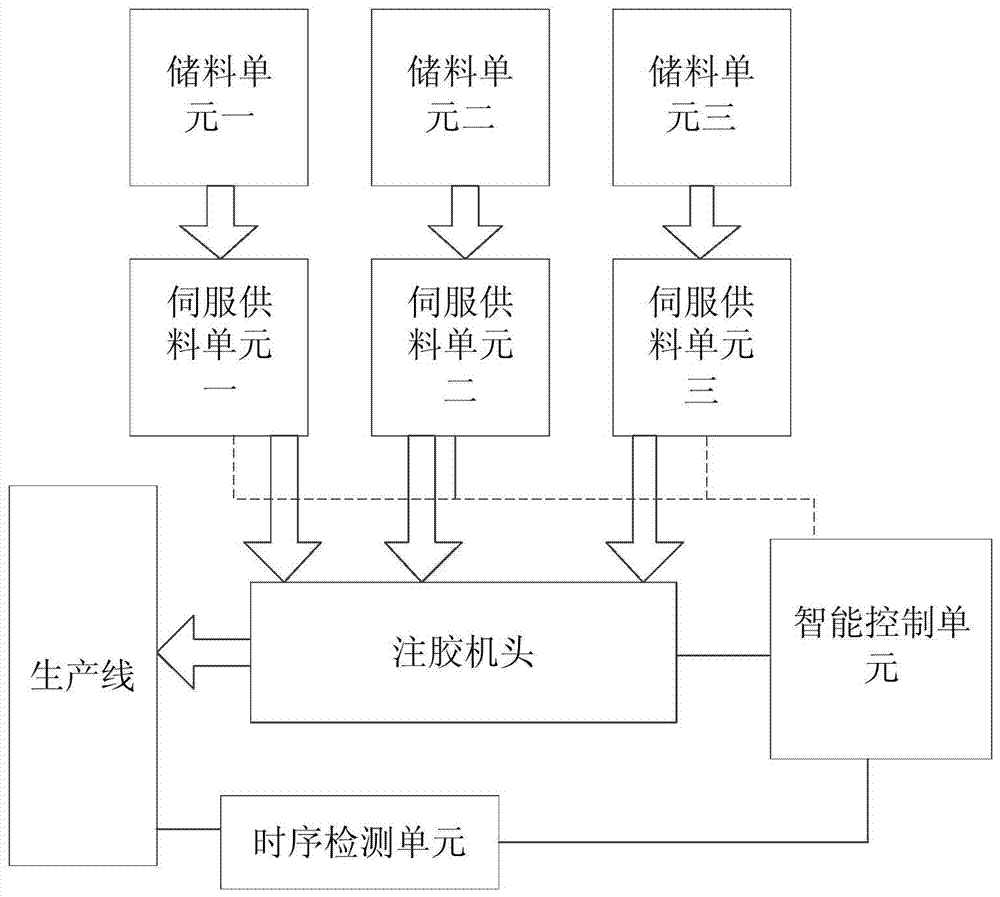

A method and system for intelligent glue injection and feeding on an automated shoemaking production line

ActiveCN104826775BReduce speedIncrease or decrease the dispensing flow rateLiquid surface applicatorsCoatingsProduction lineSimulation

The invention discloses an intelligent glue-filling material supplying method of an automatic shoemaking producing line and a system thereof, wherein the method includes following steps: (A) acquiring counting parameters of a timing sequence detection unit, determining the size of a present shoe mould to be filled according to the counting parameters, and determining total travel distance, a glue-filling start position, a glue-filling end position and required filling amount according to the size of the shoe mould, wherein the distance between the glue-filling start position and the glue-filling end position is a glue-filling travel; (B) according to a preset intermittent period by a splitter, calculating basic movement speed of a glue-filling machine head; (C) calculating the glue-filling time according to the basic movement speed and the glue-filling travel; (D) calculating glue filling amount in unit time according to the glue-filling time and the required filling amount; and (E) controlling the rotate speed of a servo motor according to the glue filling amount in unit time to achieve intelligent glue-filling material supplying. The method allows full-automatic glue filling to perform without manual operation, wherein the all glue-filling operations are controlled automatically by the system.

Owner:NANHAI KOTO MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com