Liquid state silica gel sizing device

A shaping device and liquid silicone technology, applied in the field of mechanical processing molds, can solve problems such as poor control of dispensing volume, increased raw material usage, and difficulty in controlling dispensing dosage, so as to achieve clear structure and reduce the use of raw materials , Improve the effect of beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific implementation manners of the present invention will be briefly described below in conjunction with the accompanying drawings.

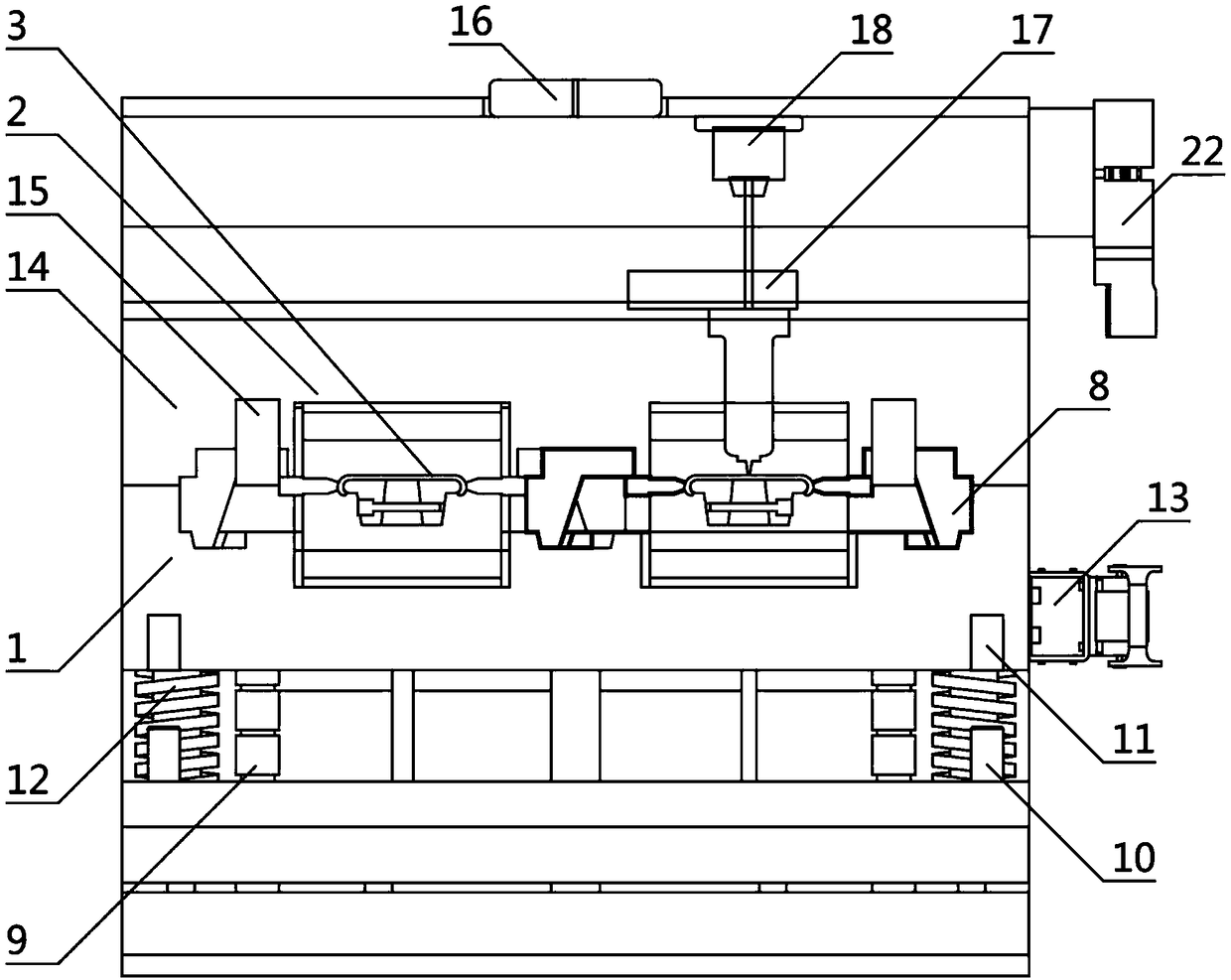

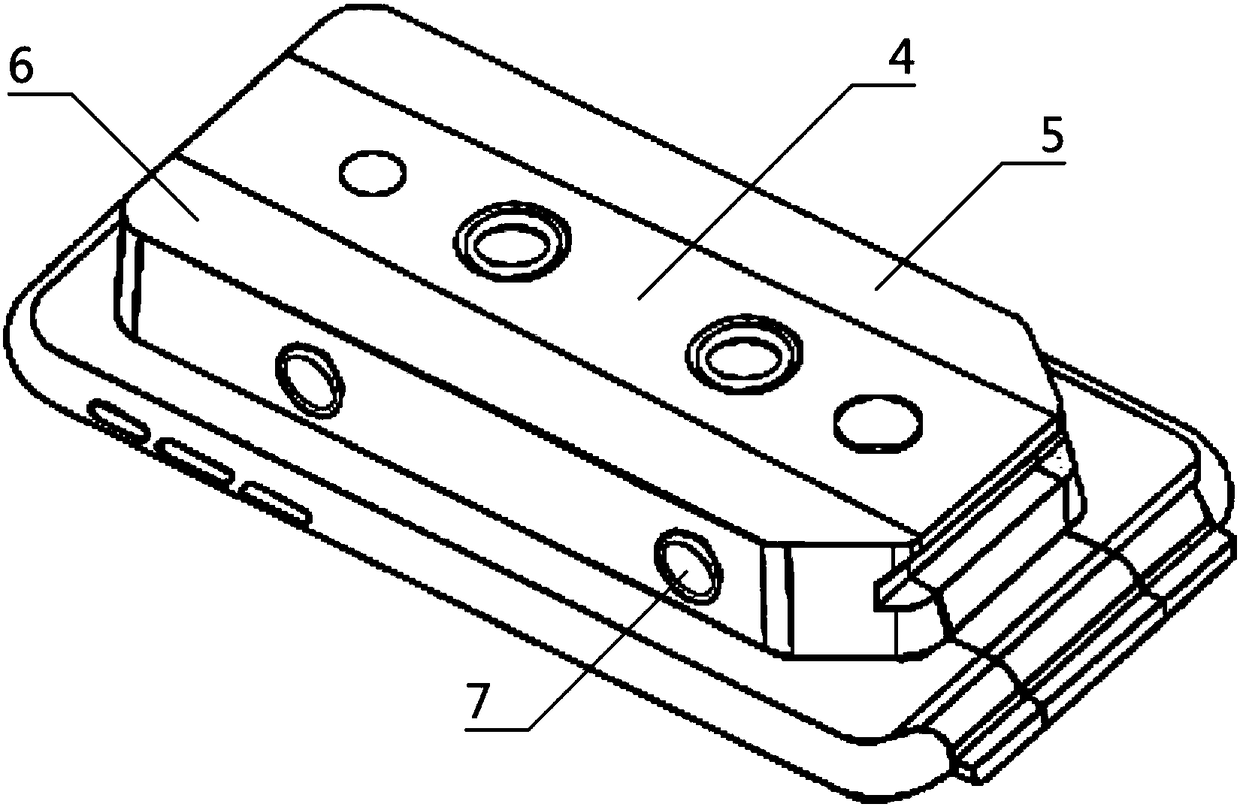

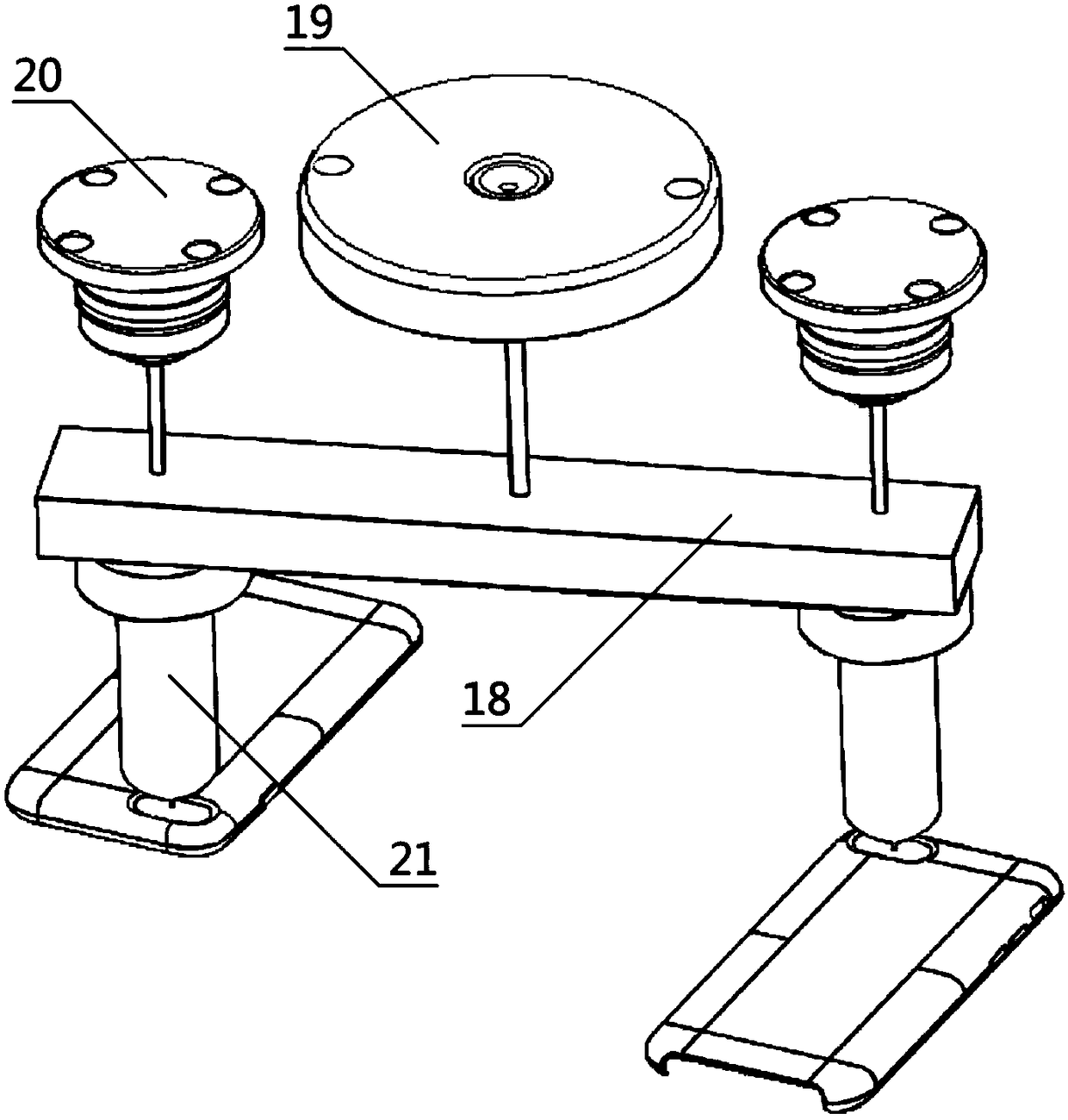

[0028] Such as figure 1 , figure 2 , image 3 , Figure 4A liquid silicone sizing device shown is characterized in that it consists of a lower template 1, several product implantation grooves 2, several product clamping blocks 8, a low-position glue release device 13, an upper template 14, a glue injection port 16, a cooling The runner dispensing device 17 and the high-position glue dispenser 22 are composed. Any of the product implantation grooves 2 is located in the middle of the lower template 1. The product implantation groove 2 is fixedly connected to the lower template 1. Any of the product implantation grooves The groove 2 is also provided with a product holder 3, the product holder 3 is located inside the product implantation groove 2, and the product holder 3 is fixedly connected with the product insertion groove 2, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com