Patents

Literature

73results about How to "Easy to inject glue" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

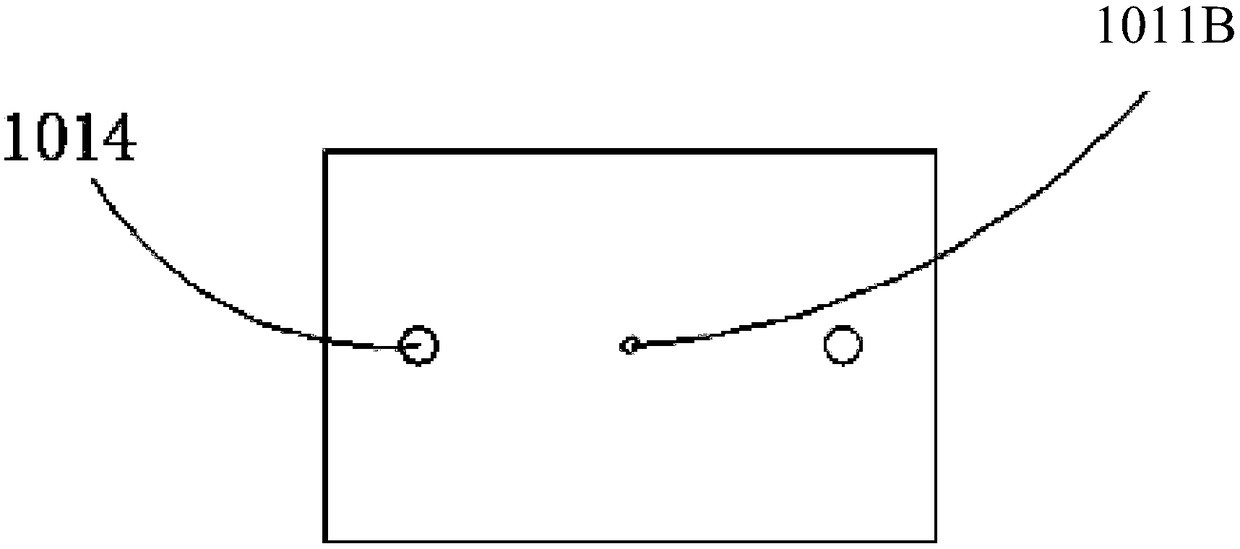

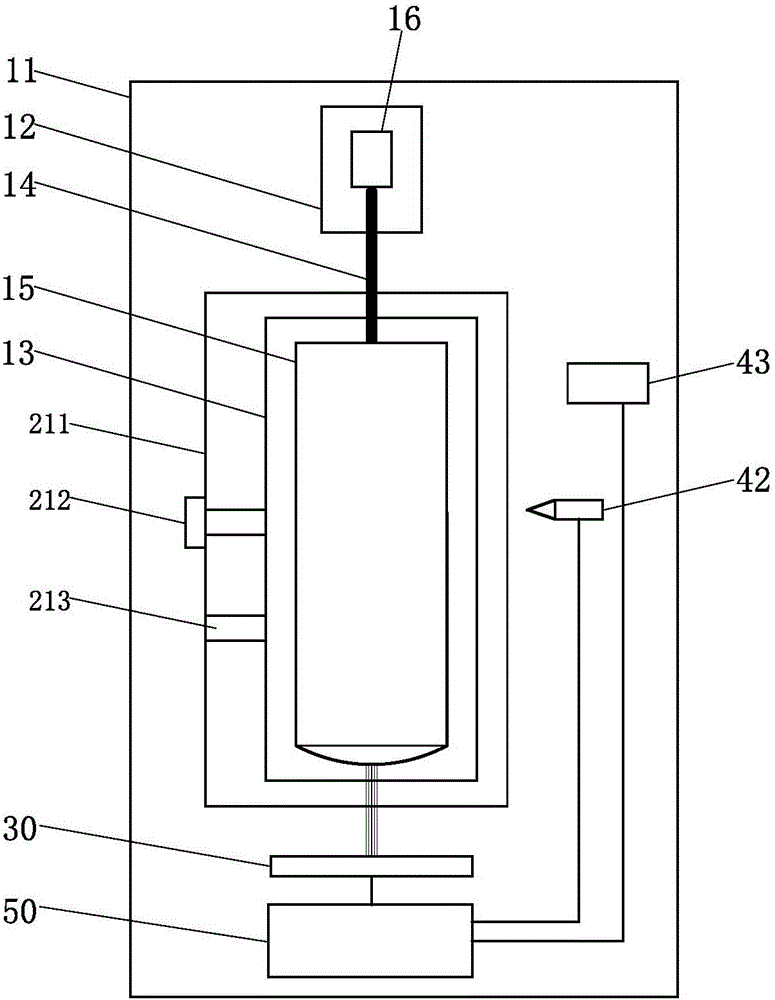

EEG (Electroencephalograph) electrode cap

ActiveCN104382594AEasy to fixExtended service lifeDiagnostic recording/measuringSensorsHigh densityMedicine

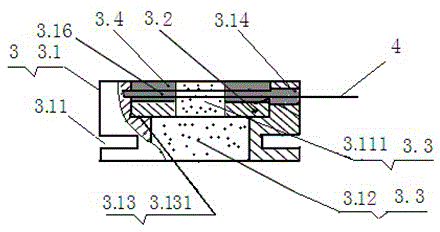

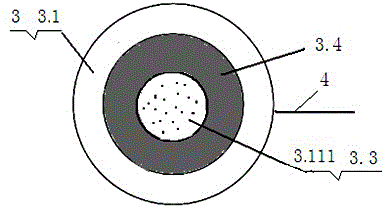

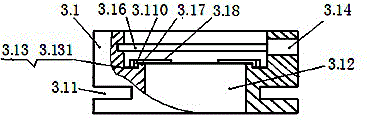

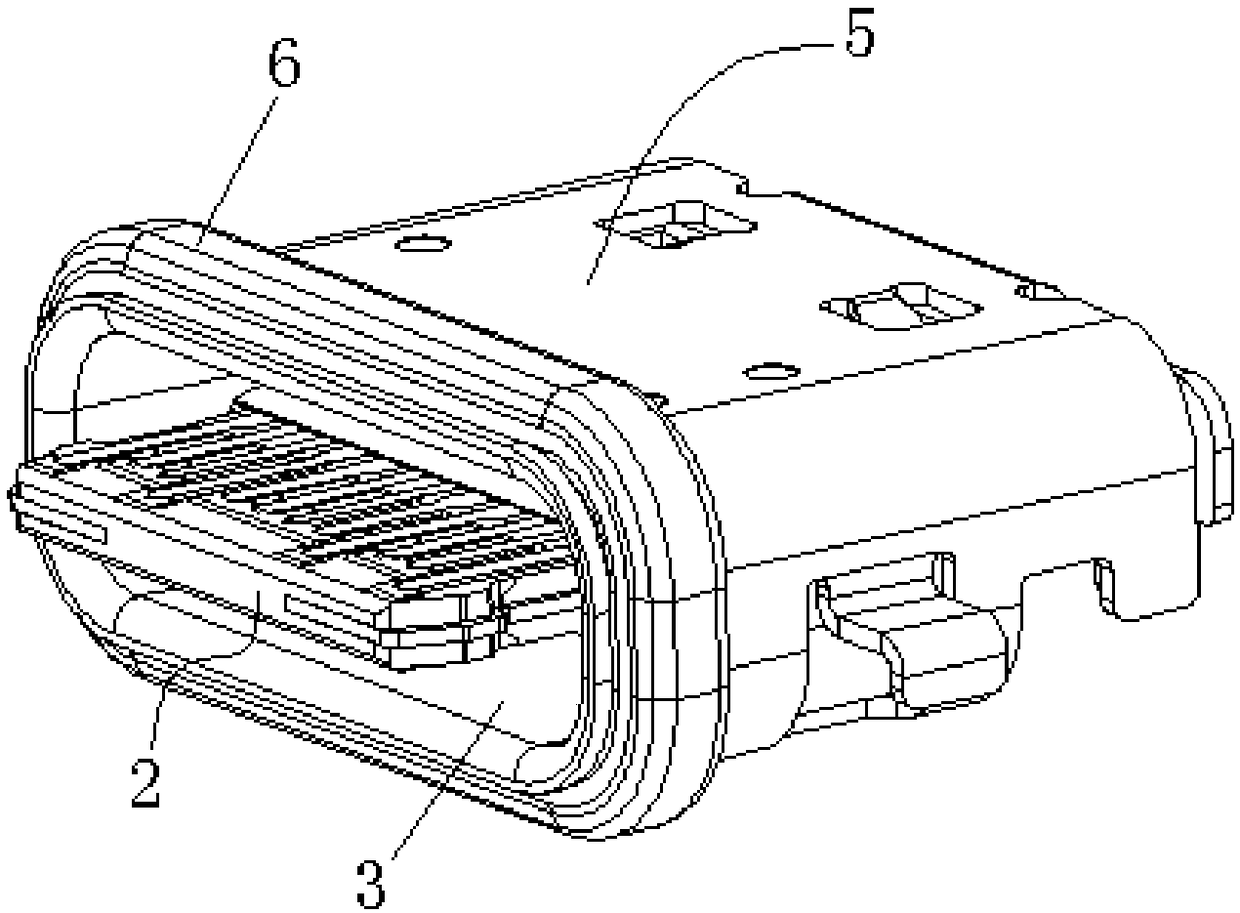

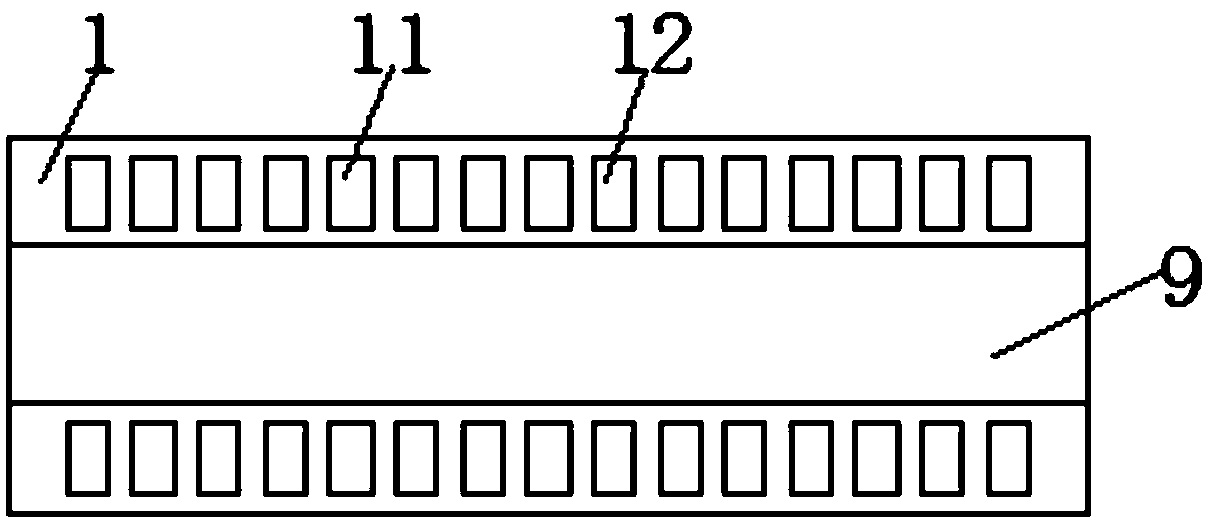

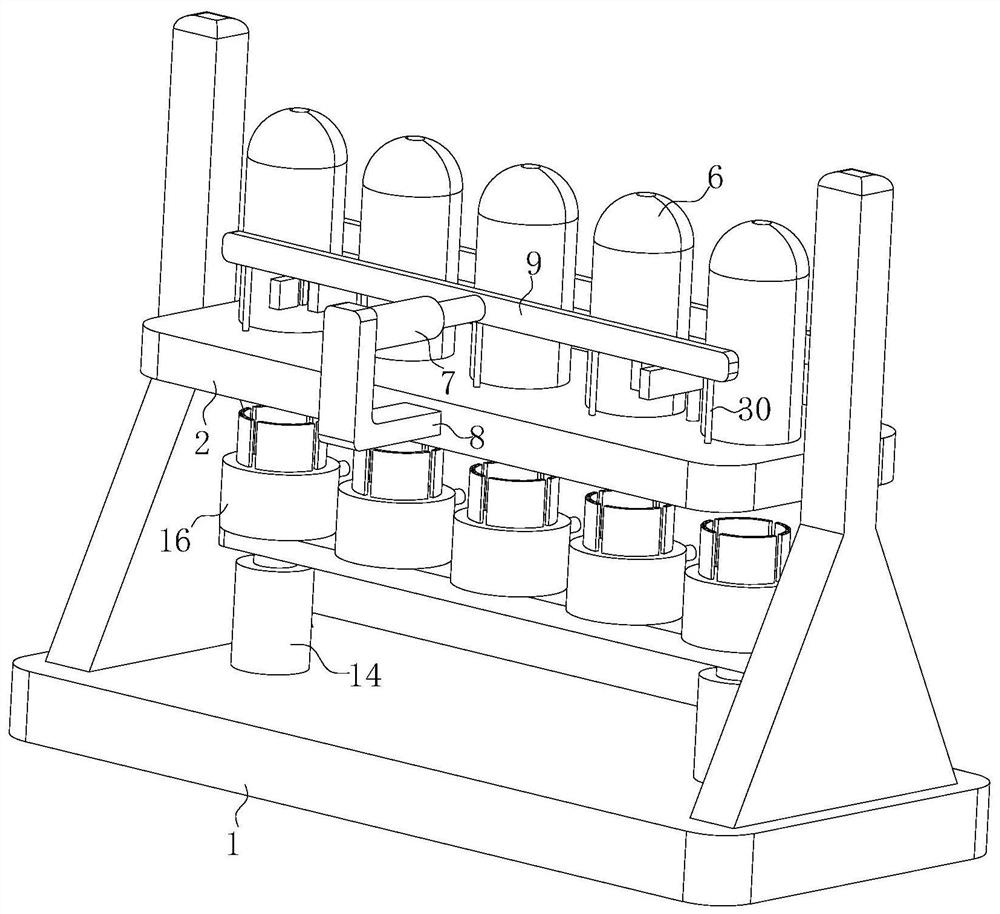

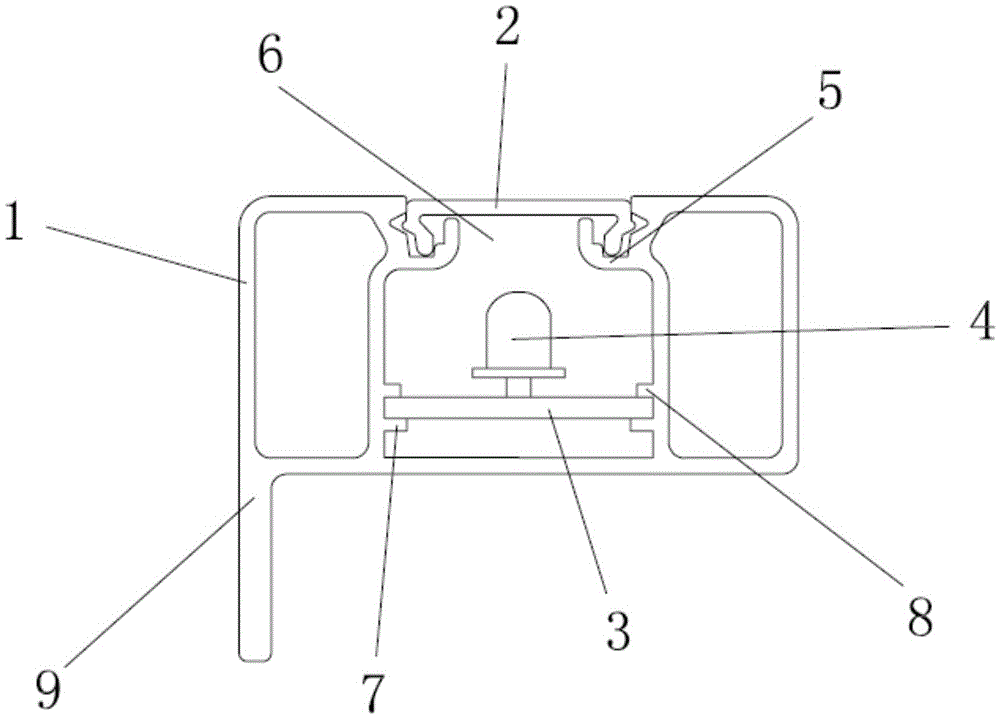

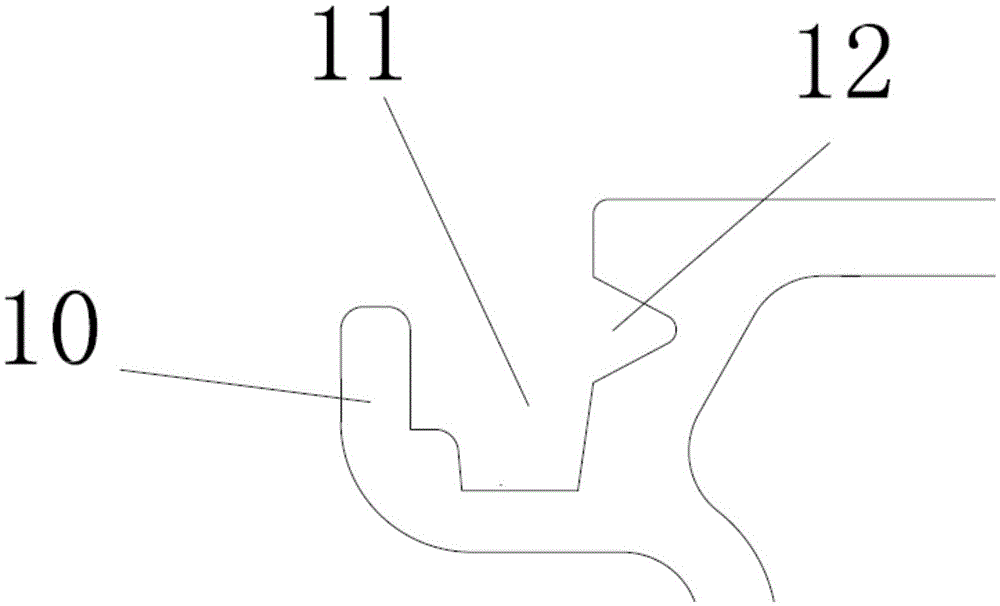

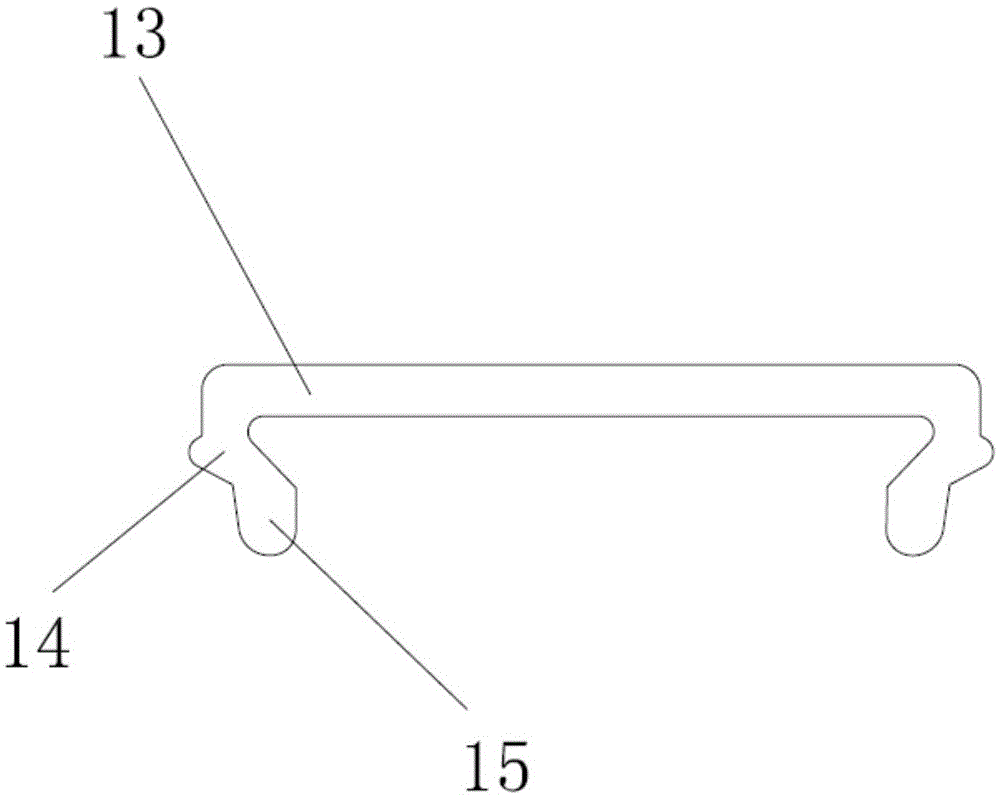

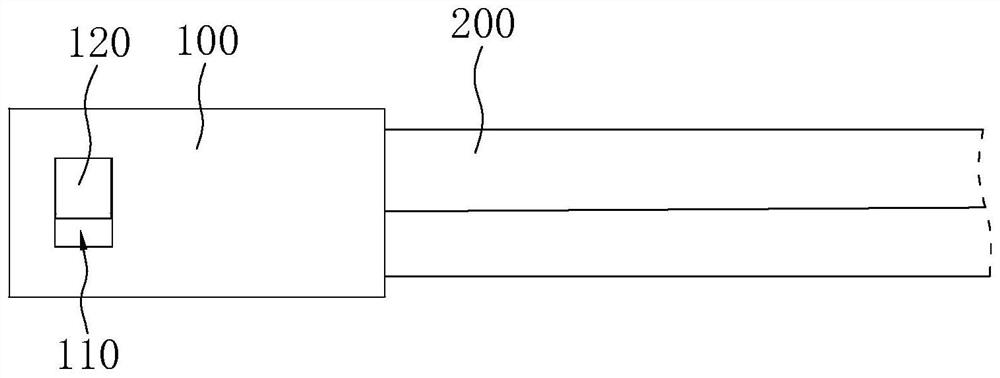

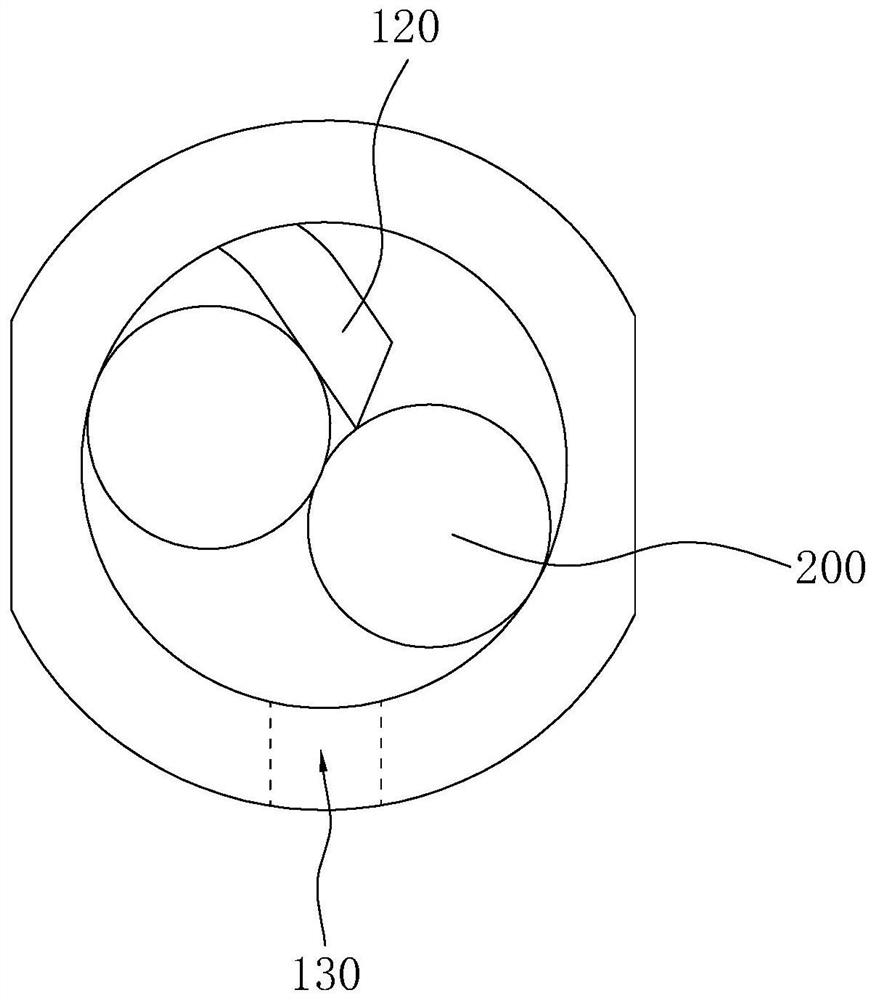

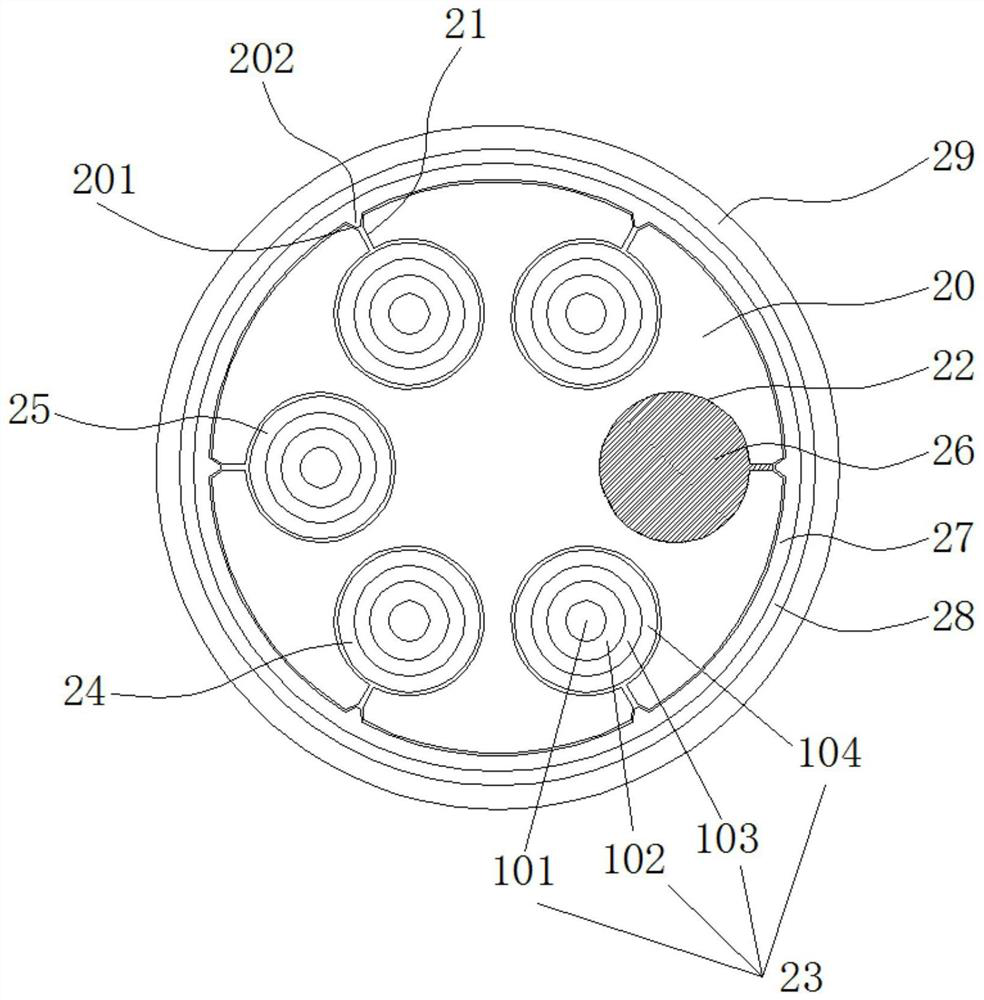

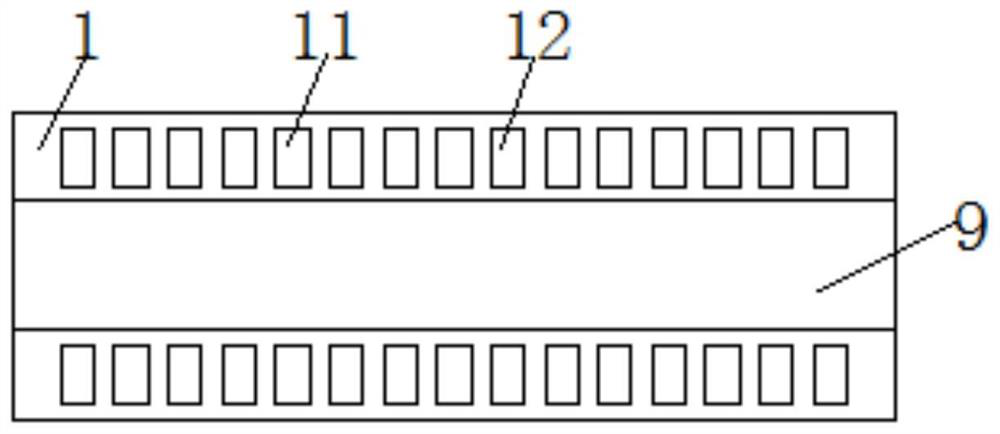

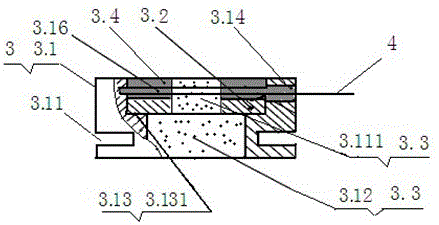

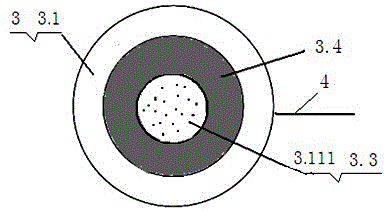

The invention relates to an EEG (Electroencephalograph) electrode cap. The EEG electrode cap comprises a cap body, electrodes and leading wires, wherein each electrode comprises a fixing ring, an electrode slice and a bonding sealant; a cavity of which two ends are opened and are communicated is formed in the middle part of each fixing ring, each cavity is internally provided with an electrode slice locating platform, and the electrode slices are arranged on the electrode slice locating platforms; one side of each electrode slice is fixed with the inner wall of the cavity of the corresponding fixing ring through the bonding sealant, and the other side of each electrode slice is combined with a conductive adhesive in a conductive adhesive chamber; fixing grooves are formed in the outer cylindrical surfaces of the fixing rings, and the fixing grooves are used for fixing the electrodes with the cap body; conductive adhesive filling holes which are communicated with the conductive adhesive chamber are formed in the bonding sealant after the bonding sealant is solidified; the electrode slices are connected with the leading wires penetrating through leading wire holes in the fixing rings. The EEG electrode cap disclosed by the invention has the advantages that the electrode slices and the fixing rings are integrally designed, and skin pretreatment, adhesive filling and adhesive supplementation can be conveniently carried out; the locating is convenient and reliable, the EEG electrode cap is tightly attached to the scalp, the wearing is comfortable, and the EEG electrode cap is particularly suitable for EEG measurement under the environment of high density, long sleep process, MEG (Magnetoencephalography) and nuclear magnetism.

Owner:WUHAN GREENTEK

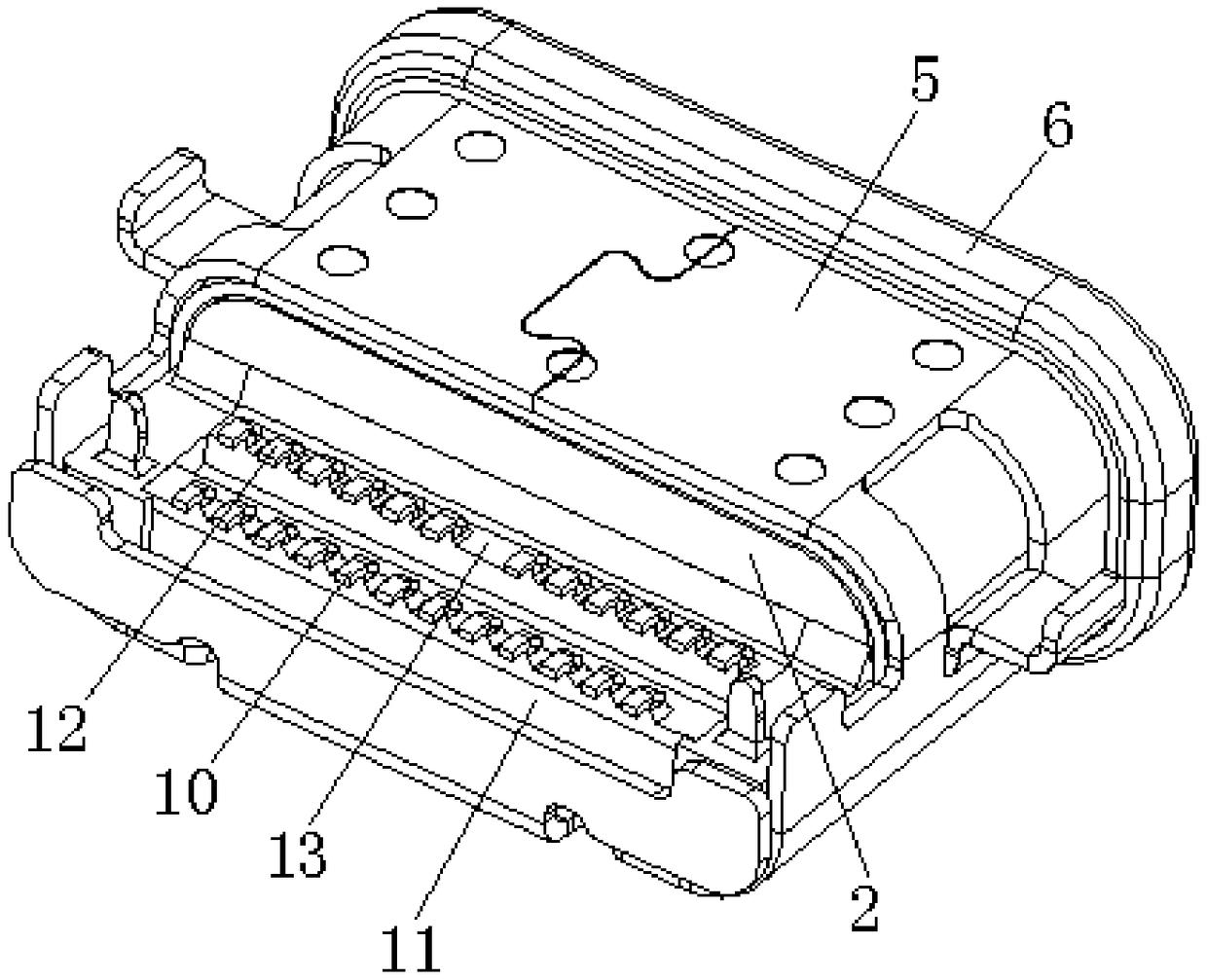

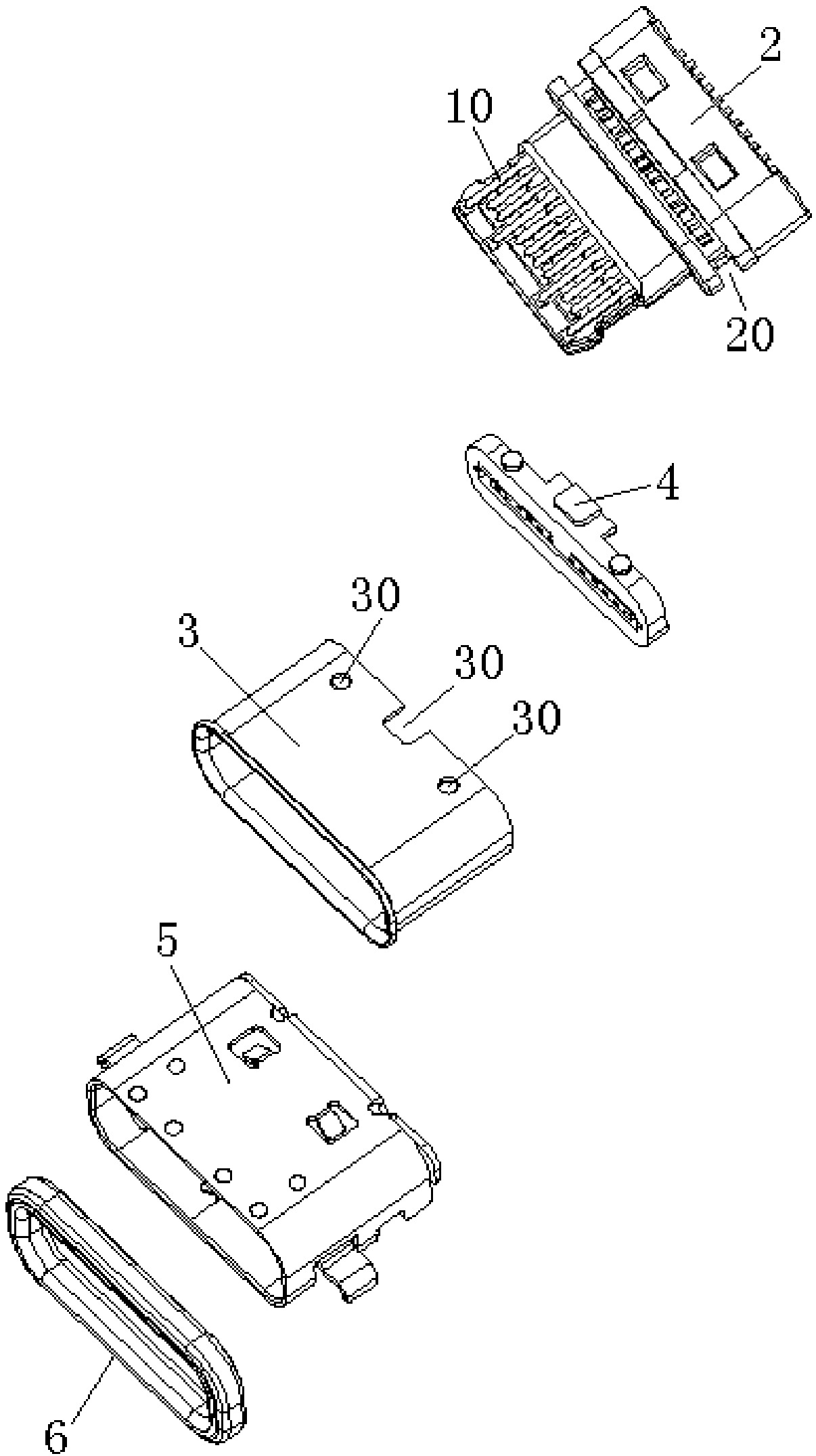

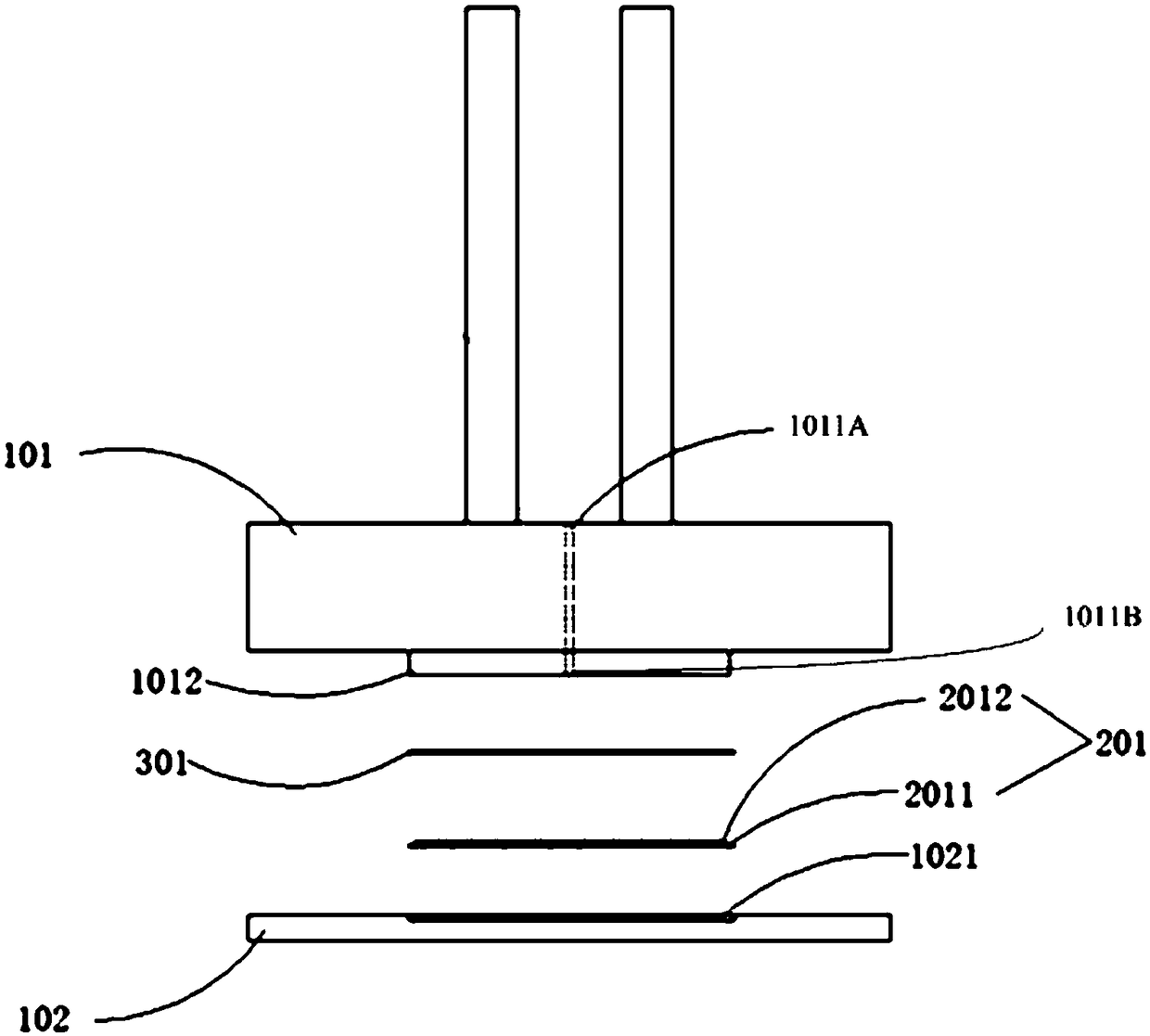

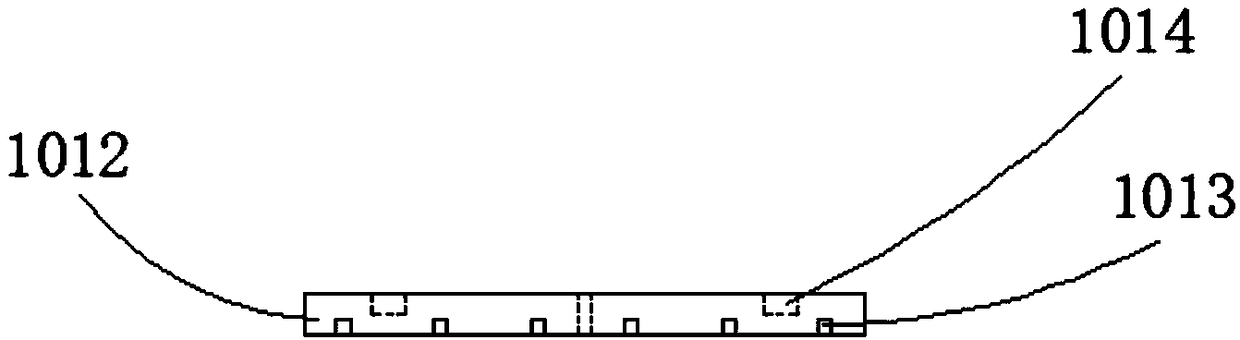

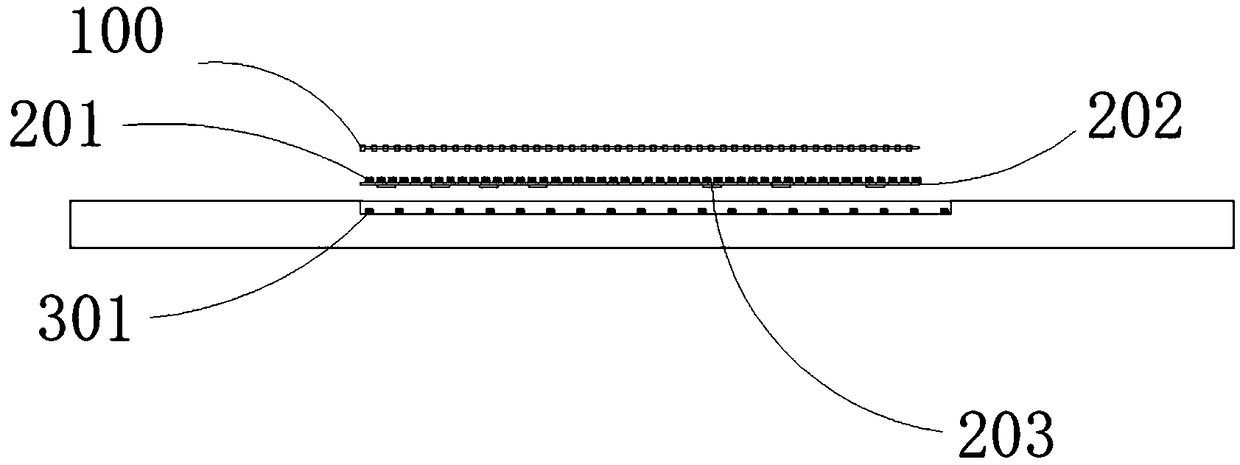

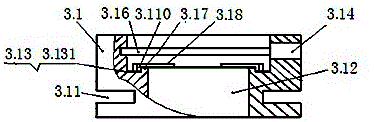

USB Type-C connector with waterproof structure

PendingCN109449634AImprove air tightnessPromote emptyingCouplings bases/casesCoupling protective earth/shielding arrangementsAir tightnessUSB

The invention discloses a USB type-C connector with a waterproof structure. An upper row of conducting terminal, an upper insulating filling body, a lower row of conducting terminal, a lower insulating filling body, and an intermediate earth plate; the main insulating filling body is molded on a terminal module to form a connector main body; a shield structure is provided with an inner metal shield shell arranged at the external of the connector main body; an upper glue flow slot is formed at a rear part of the upper insulating filling body, a lower glue flow slot is formed at the rear part ofthe lower insulating filling body, a circle of glue flow ring slot is formed at the rear part of the main insulating filling body; at least two glue openings are formed on the inner metal shield shell; at least two glue openings, the glue flow ring slot, the lower glue flow slot and the upper glue flow slot are mutually communicated to construct a glue injection channel; the waterproof glue is filled in the glue-injection channel; the waterproof glue can seal the back part of the terminal module, and seal a gap between the back part of the connector main body and an insulating shell, therebyimproving the airtightness of the connector product, and a waterproof effect is good.

Owner:KUNSHAN HONGZE ELECTRONICS

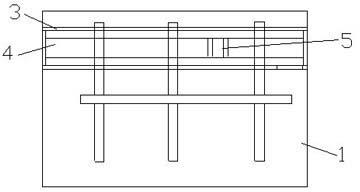

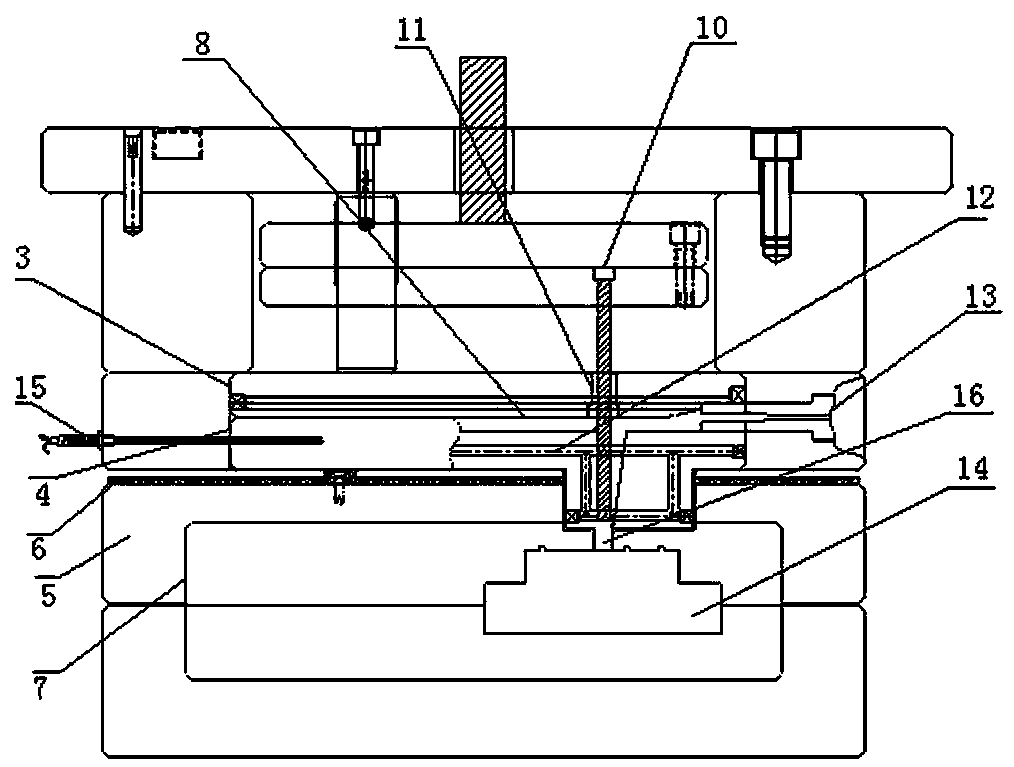

Plastic encapsulating die of LED light source

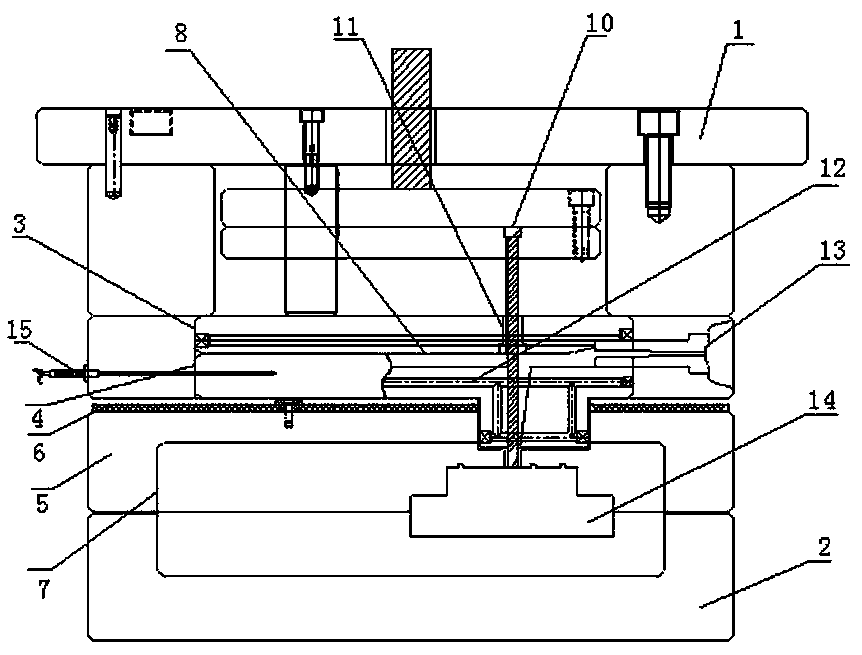

PendingCN108417699AThickness is easy to controlEvenly distributedSemiconductor/solid-state device manufacturingSemiconductor devicesEngineeringColloid

The invention discloses a plastic encapsulating die of a LED light source. An upper die and a lower die are buckled during glue injection to form a closed space which is used for containing the LED light source and a film fixed on the lower die. A first air extraction reserved hole is formed in the middle of the upper die, a press block is arranged at the lower end of the upper die, and a second air extraction reserved hole is formed in a position, opposite to the first air extraction reserved hole, of the press block. The first and second air extraction reserved holes are used for vacuumizingthe closed space, and the press block is heated to melt the film so as to plastically encapsulating a LED module in the closed space. By the plastic encapsulating die, air bubbles in the process of glue encapsulating can be avoided effectively, and encapsulating yield is increased.

Owner:SHENZHEN DICOLOR OPTOELECTRONICS

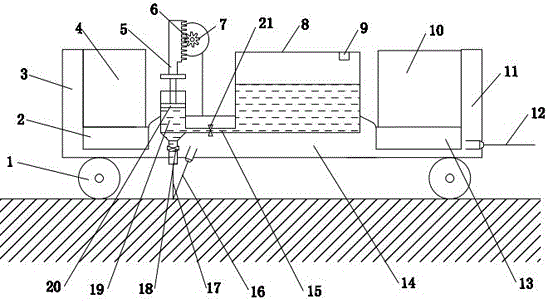

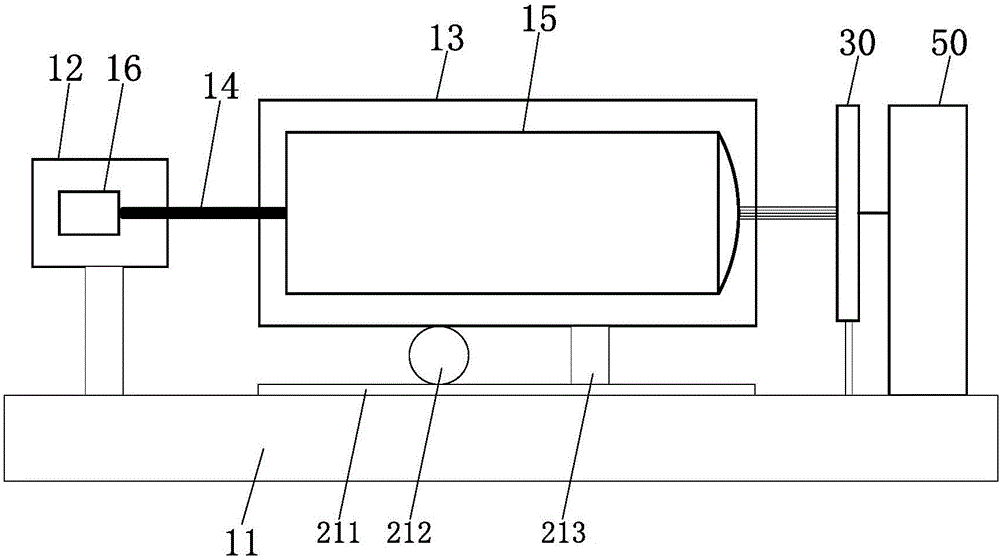

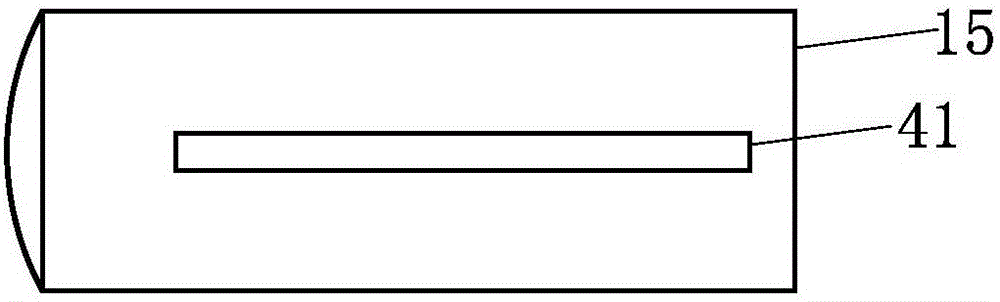

Laser guide type ground glue-injection machine

ActiveCN105484482ASave glueGuarantee product qualityBuilding constructionsLaser transmitterEngineering

The invention relates to a laser guide type ground glue-injection machine which comprises a rack and a rolling wheel. Bases are arranged in the rack and comprise a left base, a middle base and a right base. The left base is adjacent to the left side wall of the rack. The right base is adjacent to the right side wall of the rack. A motor is arranged on the left side wall of the rack. A controller is arranged on the right base. A glue-injection device is arranged in the middle of the middle base in a penetrating mode and comprises a glue storing chamber and a glue-injection device. A laser transmitter is arranged on the right side wall. A depth probing device is arranged at the bottom of the middle base and located at one side of a glue-injection needle head of the bottom of the glue-injection deice. The controller is connected with the motor, the laser transmitter and the depth probing device. The glue-injection machine is simple in structure, glue feeding and injecting are convenient, and controllability is good; after the finite glue-injection device is adopted for injecting glue on the ground, natural stones such as marble and granite can be directly bonded to the glue base plane, industrial production of construction is achieved, construction speed is greatly increased, economic cost is greatly saved, and the construction period is shortened.

Owner:ZHEJIANG YASHA DECORATION

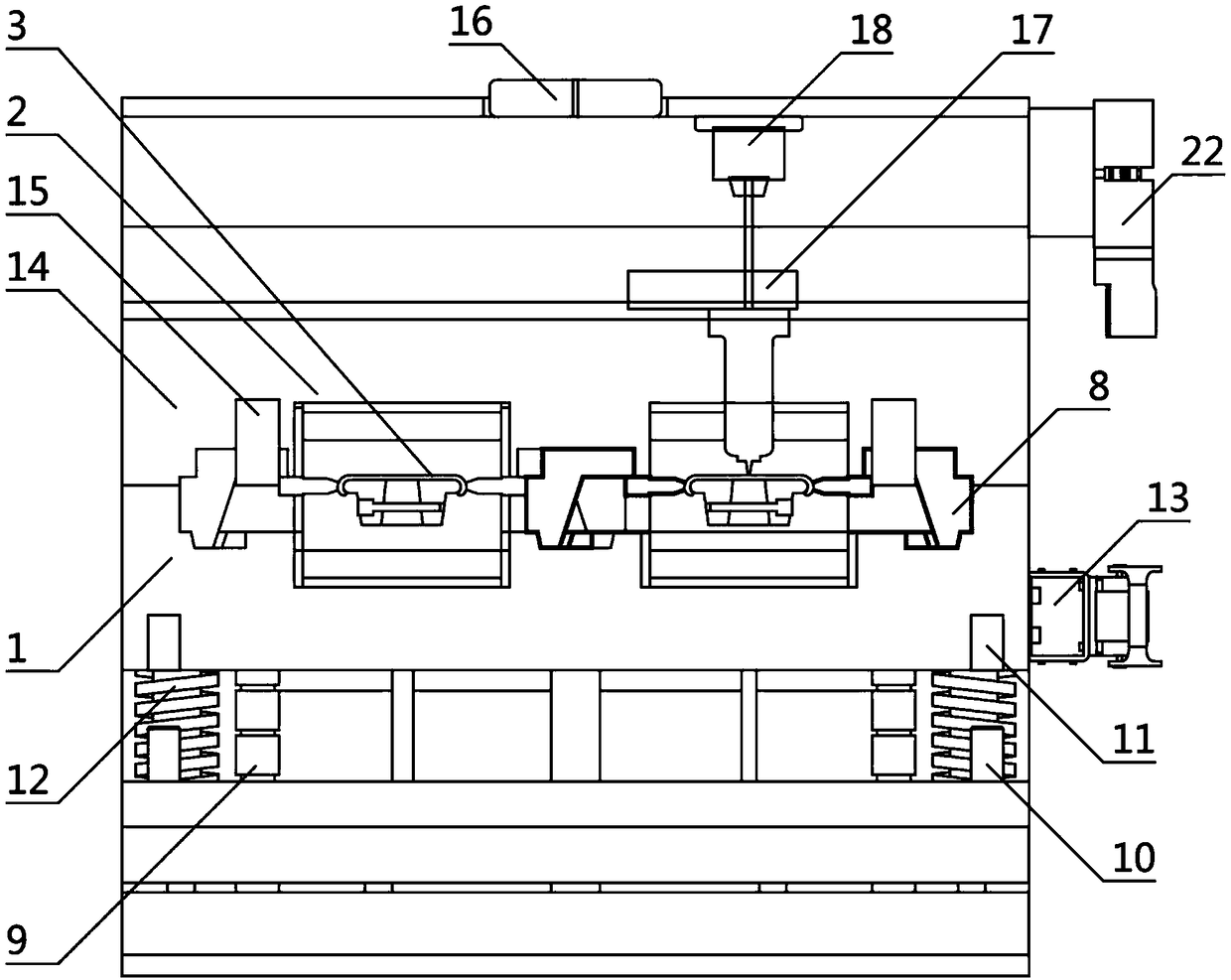

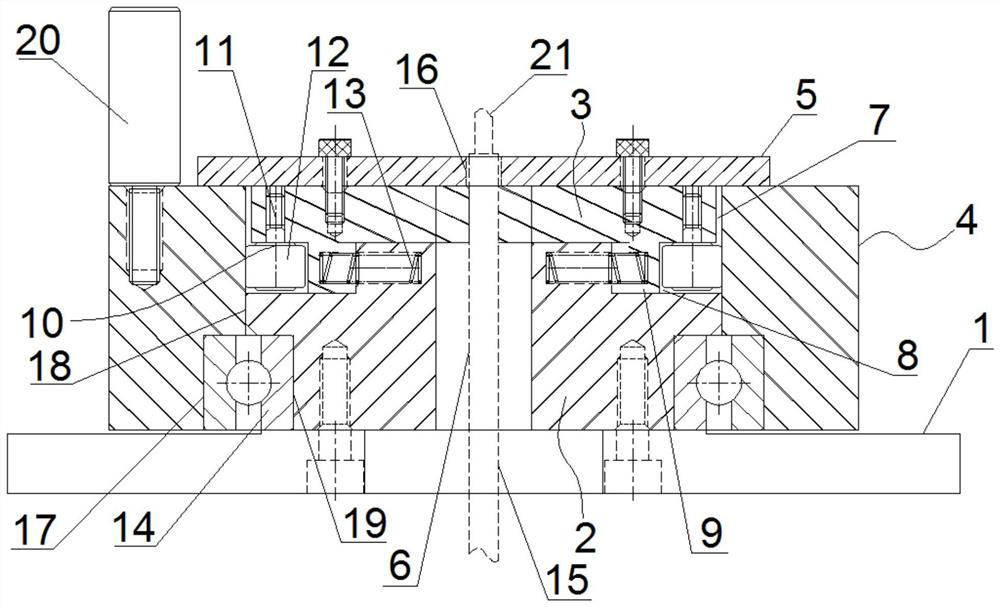

Epoxy resin pressure gel forming machine

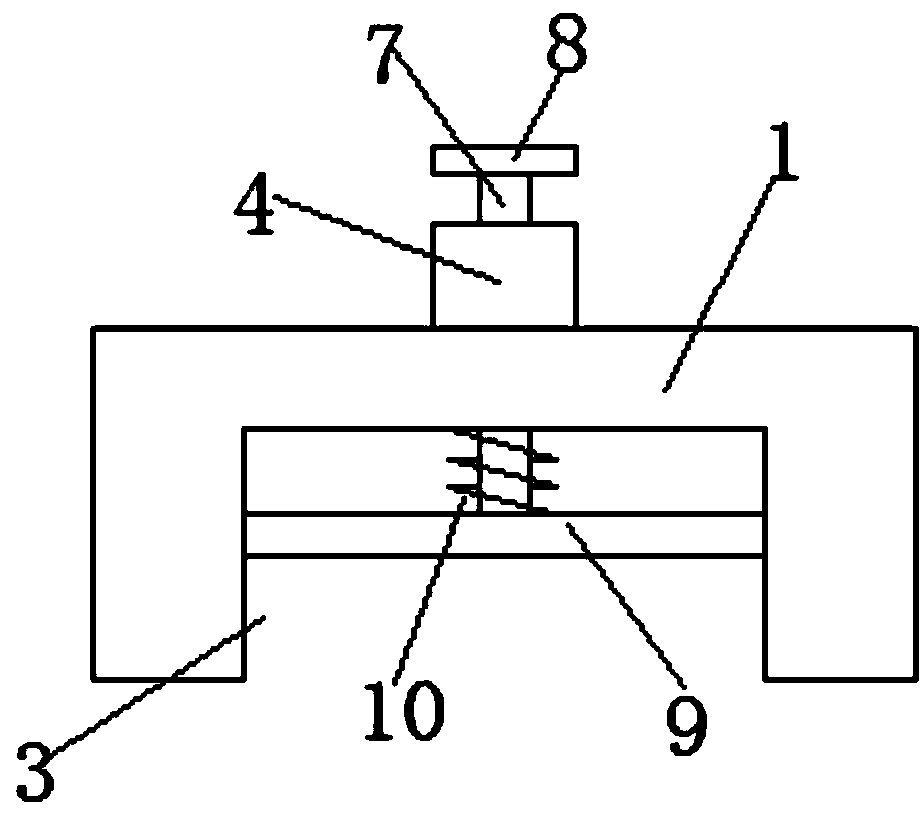

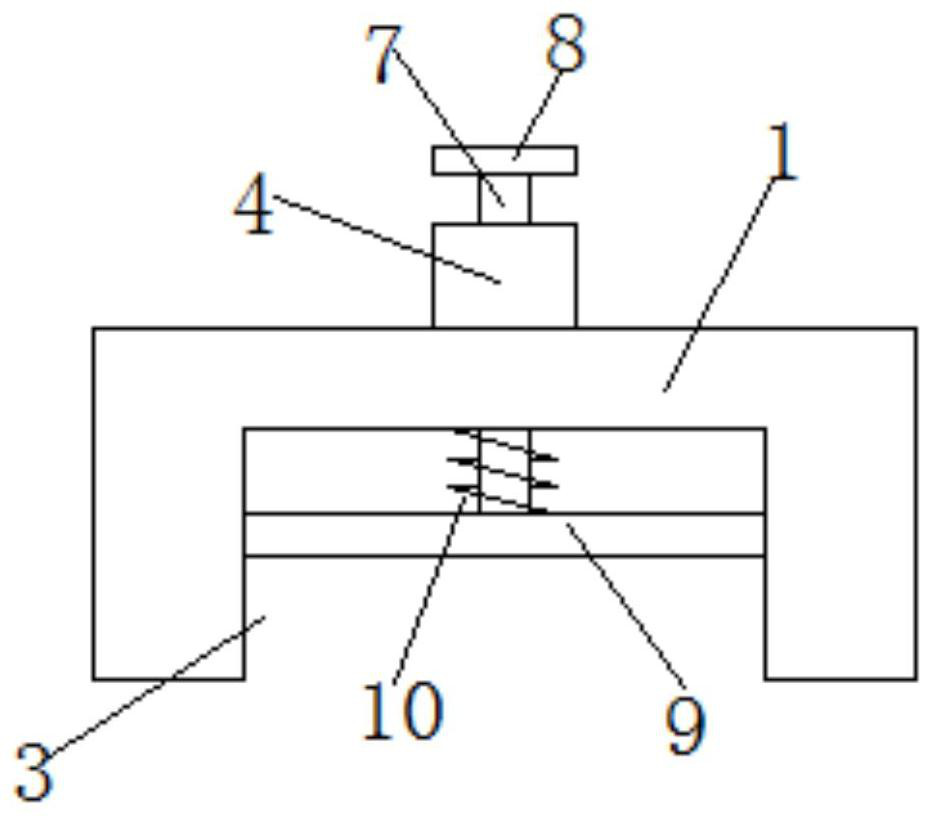

InactiveCN103144232AReduce manufacturing costsCompact structureCoils manufactureEpoxyVacuum pressure

The invention discloses an epoxy resin pressure gel forming machine which comprises a movable rack, a heating plate (4) assembled on the rack and an open-close type mould (8) assembled on the heating plate, wherein an ejecting mechanism capable of withdrawing a voltage transformer blank body (9) in the mould is arranged on the rack, the mould is connected with a vacuum stirring tank (6) through a gel injecting hole (5) and a gel injecting pipe (7), and gel is injected into the mould by the vacuum stirring tank when the vacuum pressure is 8kg / cm<3> (about 0.8MPa). Compared with an existing epoxy resin pressure gel forming device, the epoxy resin pressure gel forming machine disclosed by the invention has the advantages that the machine is compact in structure, small in floor space, and convenient to operate; the machine is quick to heat, short in heating time, and short in curing time, so that the manufacture efficiency can be improved; a set of mould can be recycled, so that the manufacture cost of the mould can be saved, and the cost can be reduced; and the gel is convenient to inject, and the mould is convenient to open, so that the machine is small in labor intensity, and environment-friendly in working environment.

Owner:林小平 +1

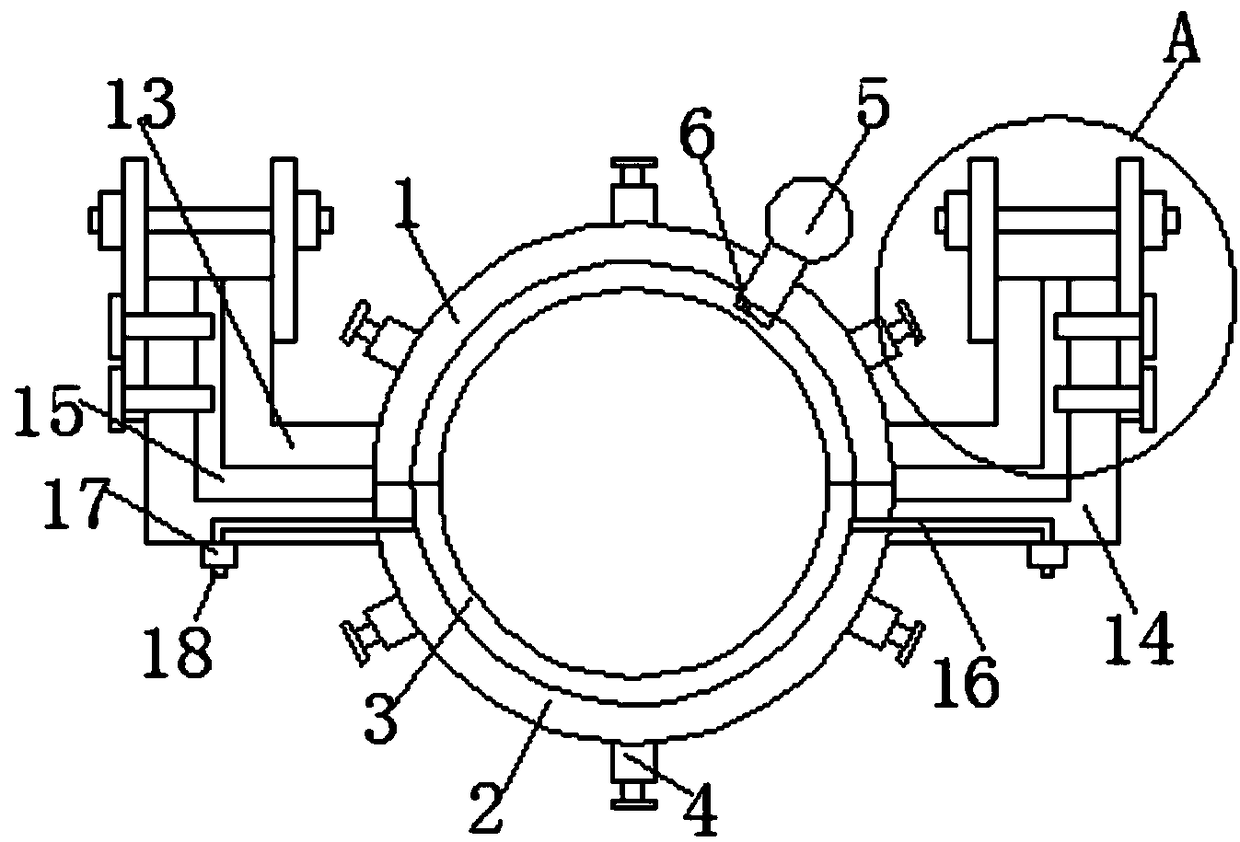

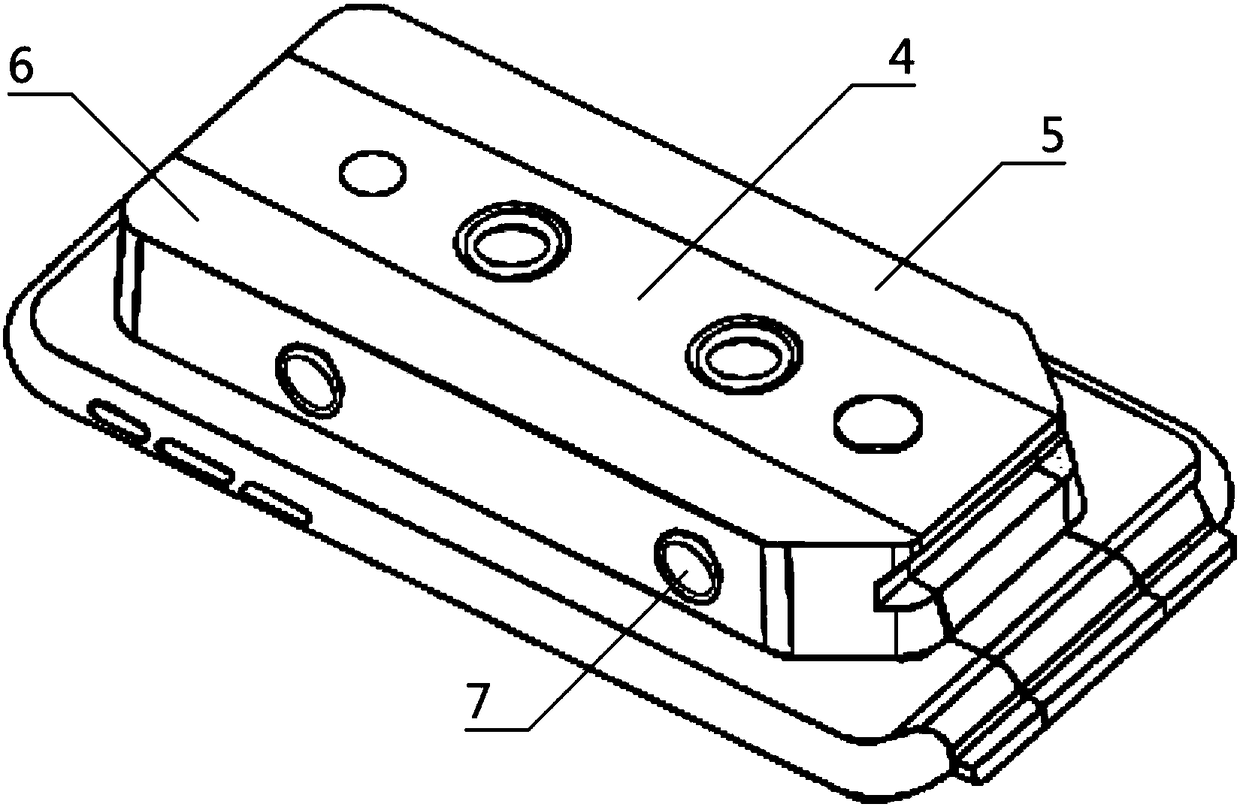

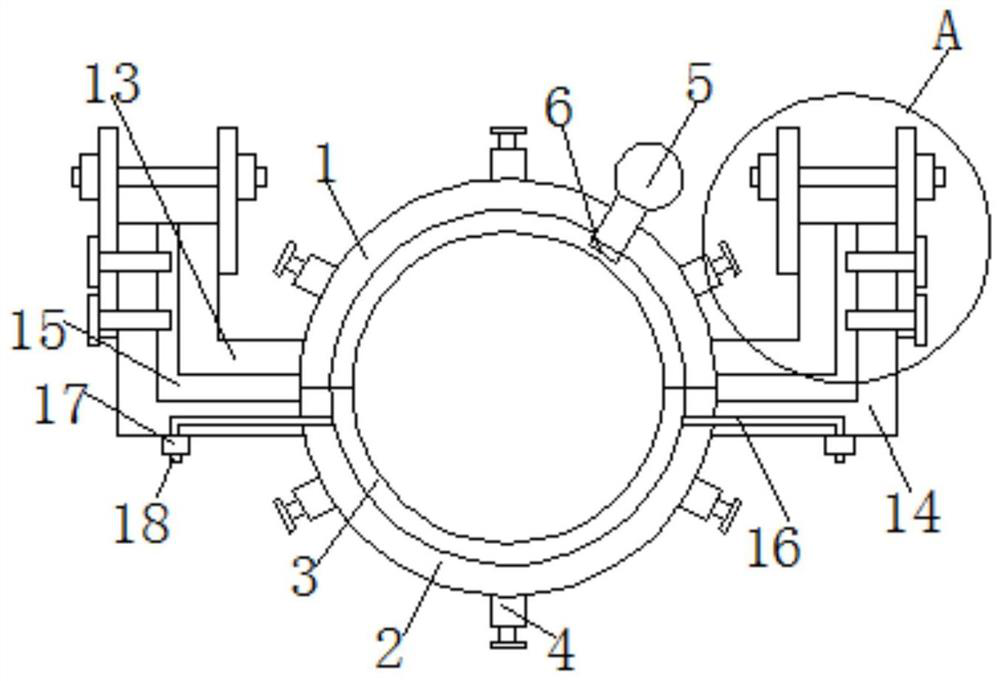

Universal fixture for fluid pipeline belt pressure leaking stoppage

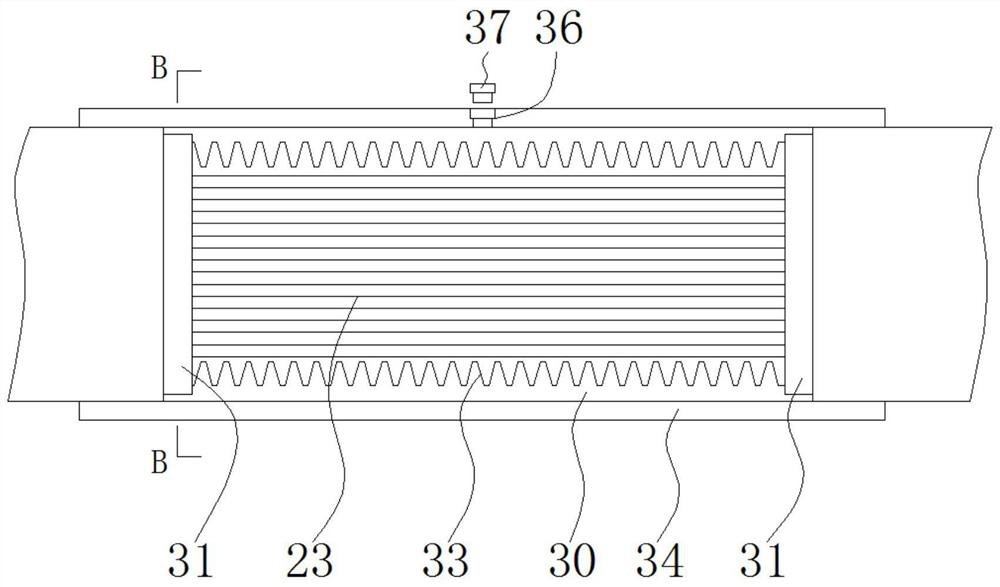

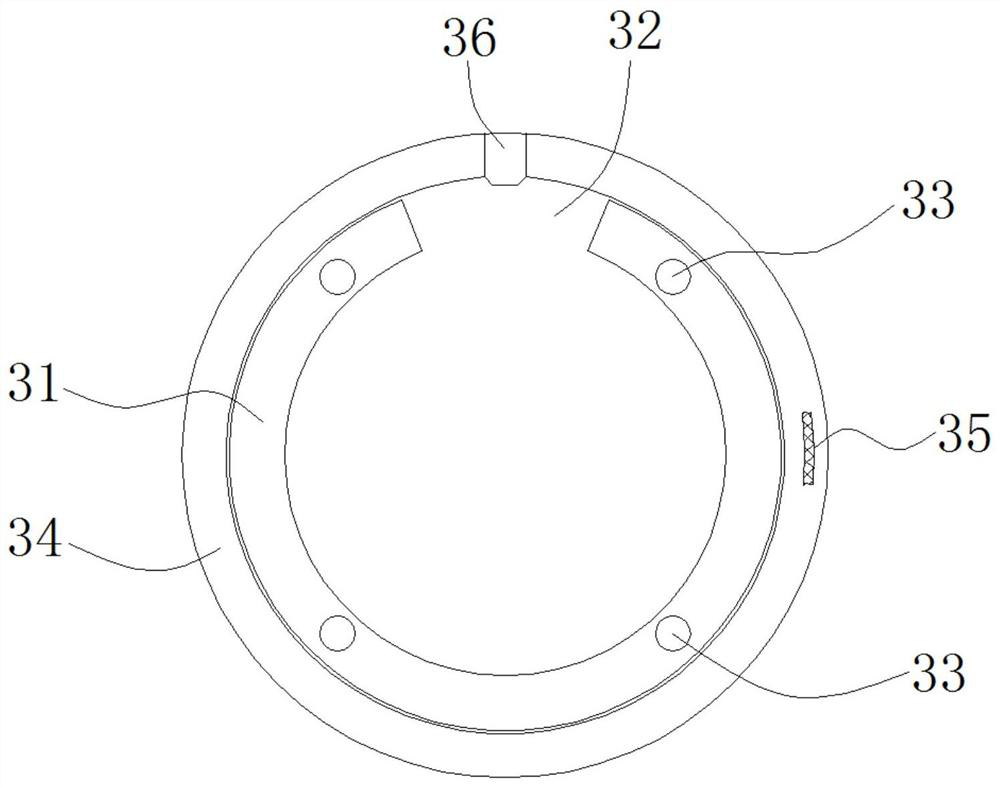

ActiveCN108612954AHigh tensile strengthImprove structural stabilityPipe elementsStructural stabilityMechanical engineering

The invention discloses a universal fixture for fluid pipeline belt pressure leaking stoppage and relates to the technical field of fluid pipelines. The universal fixture for the fluid pipeline belt pressure leaking stoppage comprises an upper clamping collar and a lower clamping collar; sleeves distributed in a circumferential array are fixedly installed on the outer surface of the upper clampingcollar; sleeves distributed in a circumferential array are fixedly installed on the outer surface of the lower clamping collar; a pressure detection meter is fixedly inserted into the right side of the upper clamping collar; the interiors of the sleeves are in threaded insertion with adjusting screw rods; rotary knobs are fixedly installed at the top ends of the adjusting screw rods; and antiskidgrooves laid uniformly are formed in each of the upper side and the lower sider of the front of the upper clamping collar. The universal fixture for the fluid pipeline belt pressure leaking stoppageis high in tensile strength and good in structural stability; enough and lasting radial pressure can be exerted after the clamping collars are tightly hooped so as to allow the fixture to be compressed on the excircle surface of a pipeline, so that the sealability is improved, the leaking stoppage effect is improved, and the potential safety hazard is eliminated; and pressure on the inner side ofthe fixture can be detected in real time, so that a user conveniently judges whether the problem of oil leakage or gas leakage happens according to the pressure on the inner side, and disconnecting detection is avoided.

Owner:HUZHOU BEIDE FLUID EQUIP CO LTD

SC-type rubber-insulated optical fiber connector

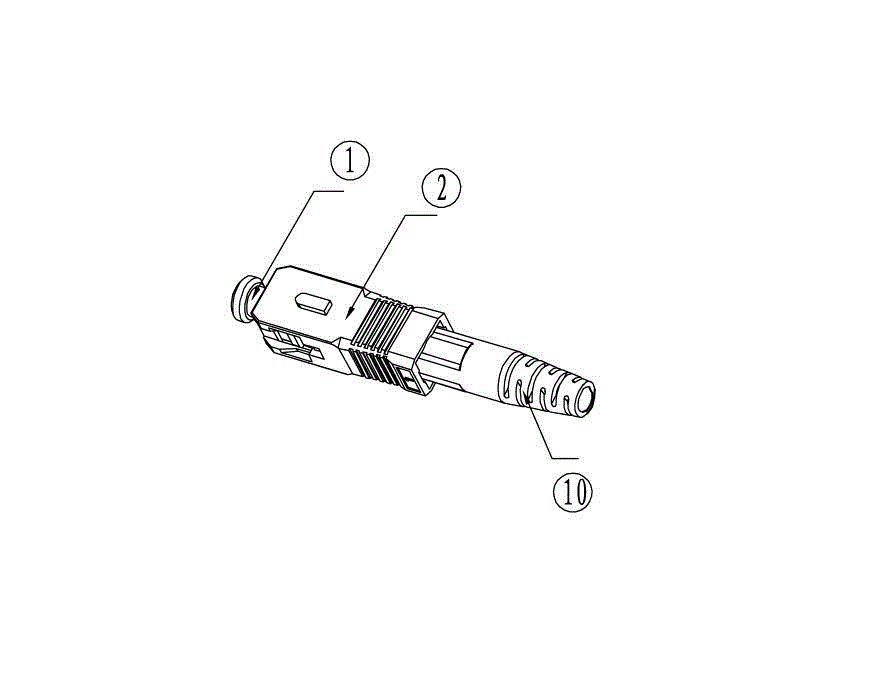

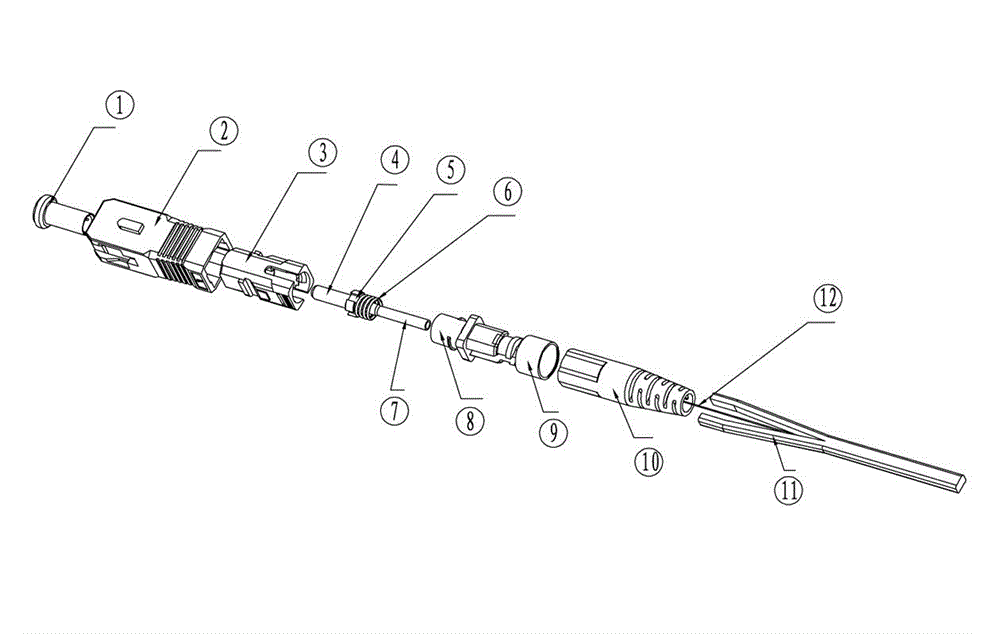

InactiveCN102981220AImprove connection strengthImprove tensile propertiesCoupling light guidesFibre mechanical structuresClamp connectionEngineering

The utility model relates to an SC-type rubber-insulated optical fiber connector. The SC-type rubber-insulated optical fiber connector is characterized by comprising a shell, a front sleeve, an inserting core, a tail handle, a glue injecting tube and a tail sleeve, wherein the front sleeve is blocked inside the shell; the inserting core is embedded in the front sleeve; the tail handle is positioned at the back end of the inserting core; one end of the glue injecting tube is connected with the tail handle; the tail sleeve is in a clamp connection with the front sleeve; the SC-type rubber-insulated optical fiber connector further comprises a riveting and pressing base and a compression joint tube for riveting and pressing the riveting and pressing base; the riveting and pressing base is internally provided with a through hole for an optical fiber to pass through; the front end of the riveting and pressing base is in a tubular structure in joint with the front sleeve, and the back end of the riveting and pressing base is provided with an extending section; two rubber-insulated grooves for accommodating rubber-insulated wires are formed in the extending section; the compression joint tube is sleeved on the rubber-insulated grooves; and the glue injecting tube is positioned inside the riveting and pressing base. The SC-type rubber-insulated optical fiber connector provided by the invention is high in connection strength and high in reliability.

Owner:NINGBO MINGRI COMM EQUIP

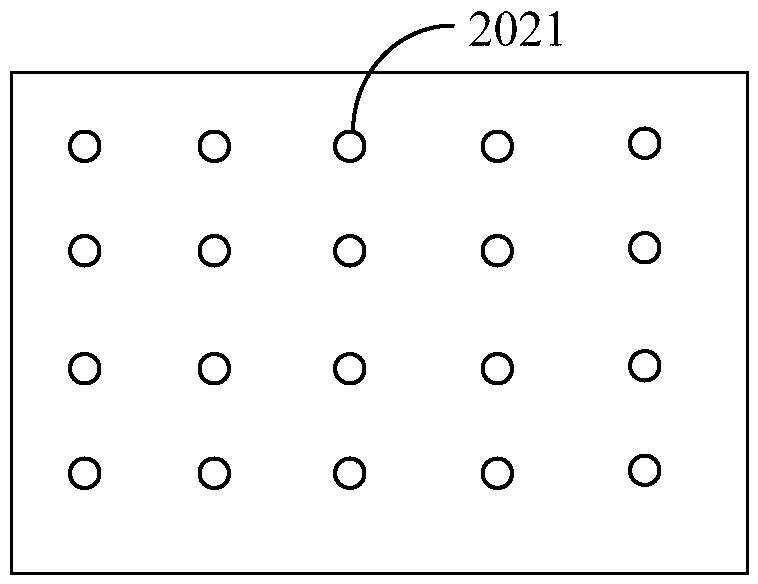

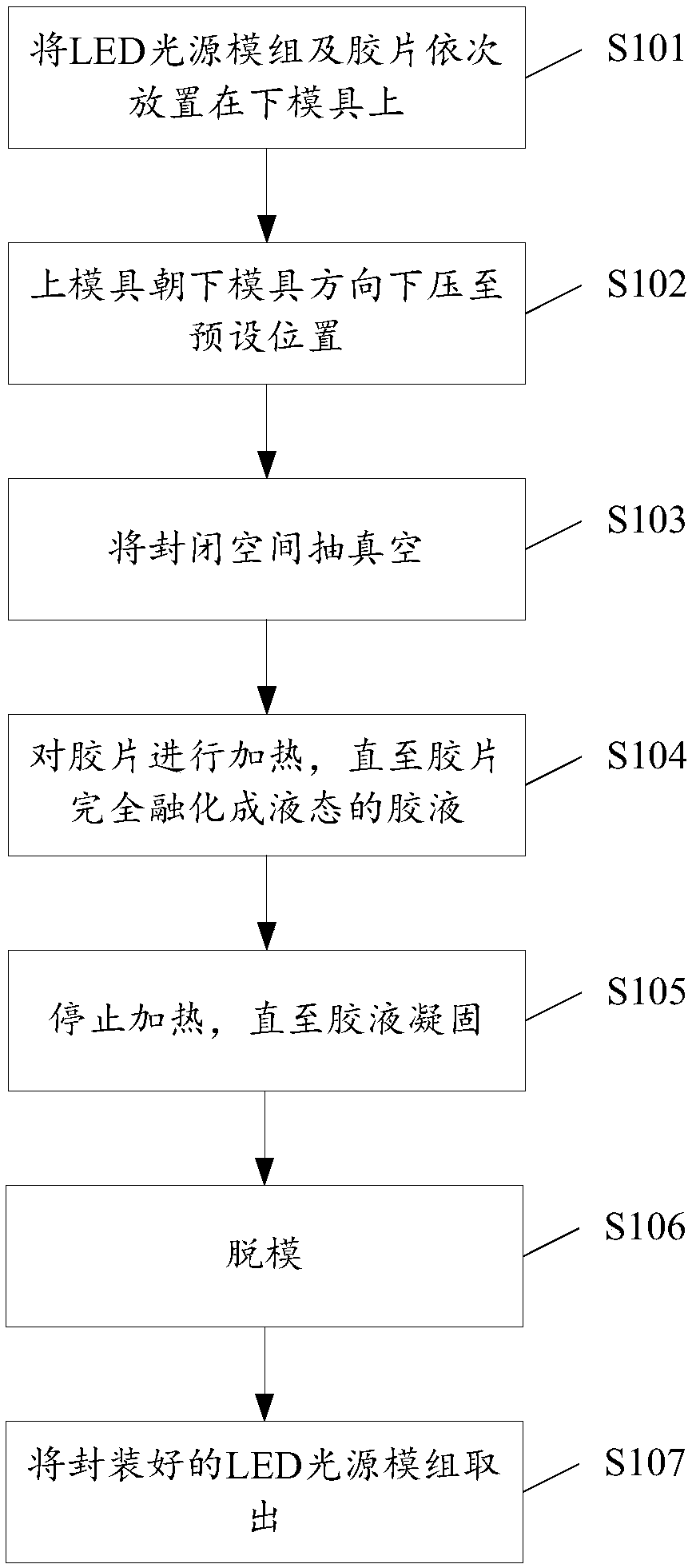

LED light source glue filling die and method

The invention discloses an LED light source glue filling die and method. During glue injection, an upper die and a lower die are at least partially completely buckled to form a closed space for containing an LED light source fixed to the lower die. Exhaust through holes and through hole covers are arranged on the two sides of the upper die, wherein the exhaust through holes and the through hole covers are consistent in size and number, the exhaust through holes are used for vacuum pumping of the closed space, and the through hole covers are used for sealing the exhaust through holes after vacuum pumping. Glue injection holes are formed between the exhaust through holes in the two sides of the upper die and used for fully filling packaging glue into the closed space. Air bubbles can be effectively prevented from appearing in the glue packaging process, and the packaging yield is improved.

Owner:SHENZHEN DICOLOR OPTOELECTRONICS

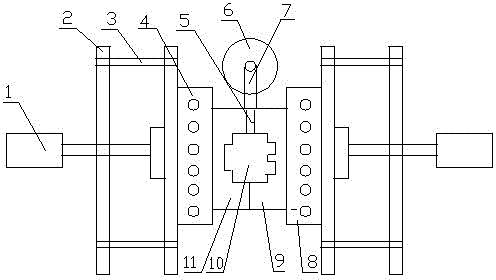

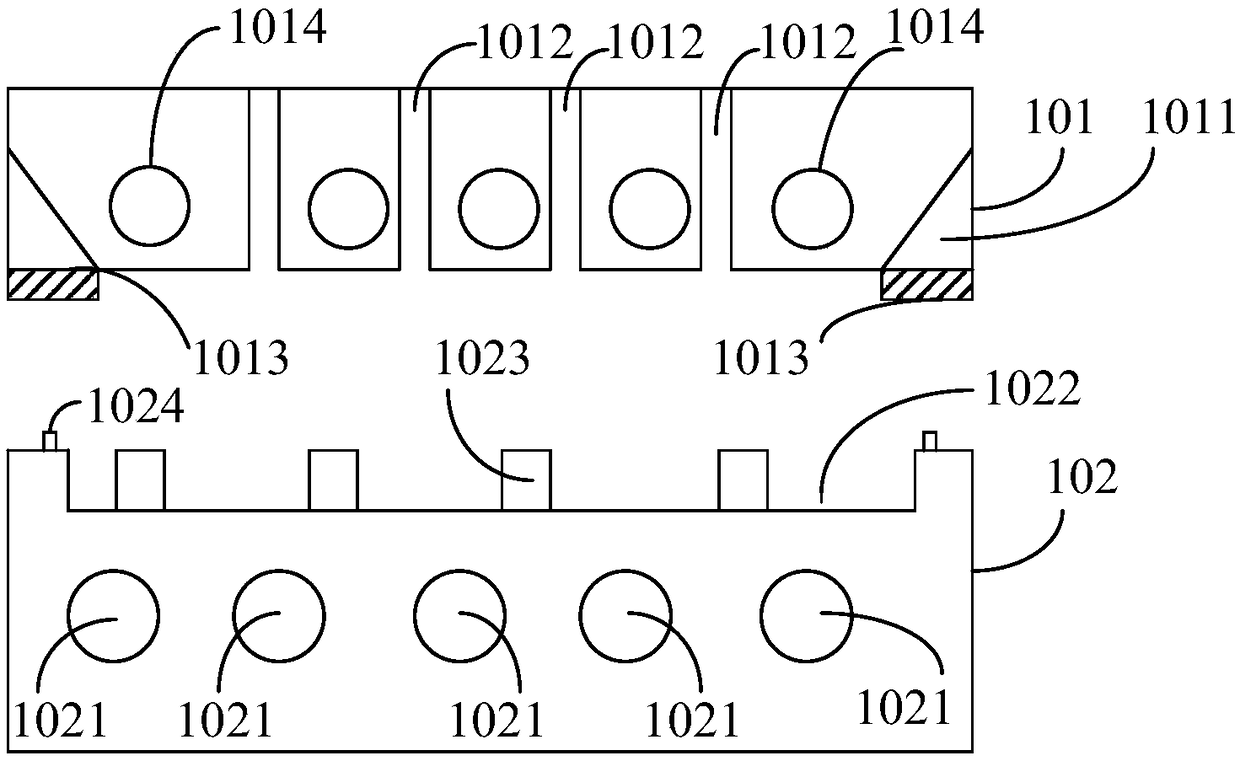

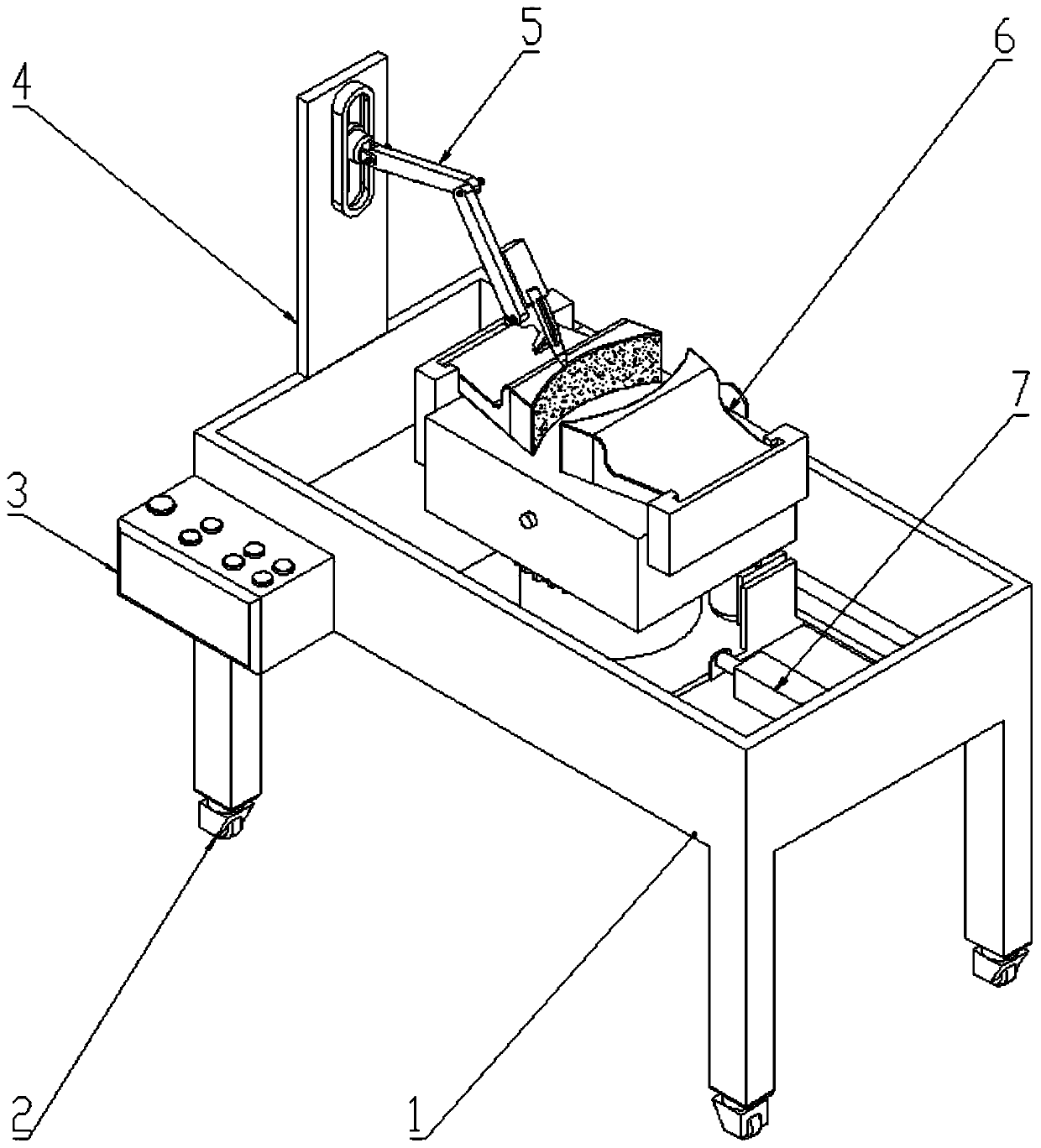

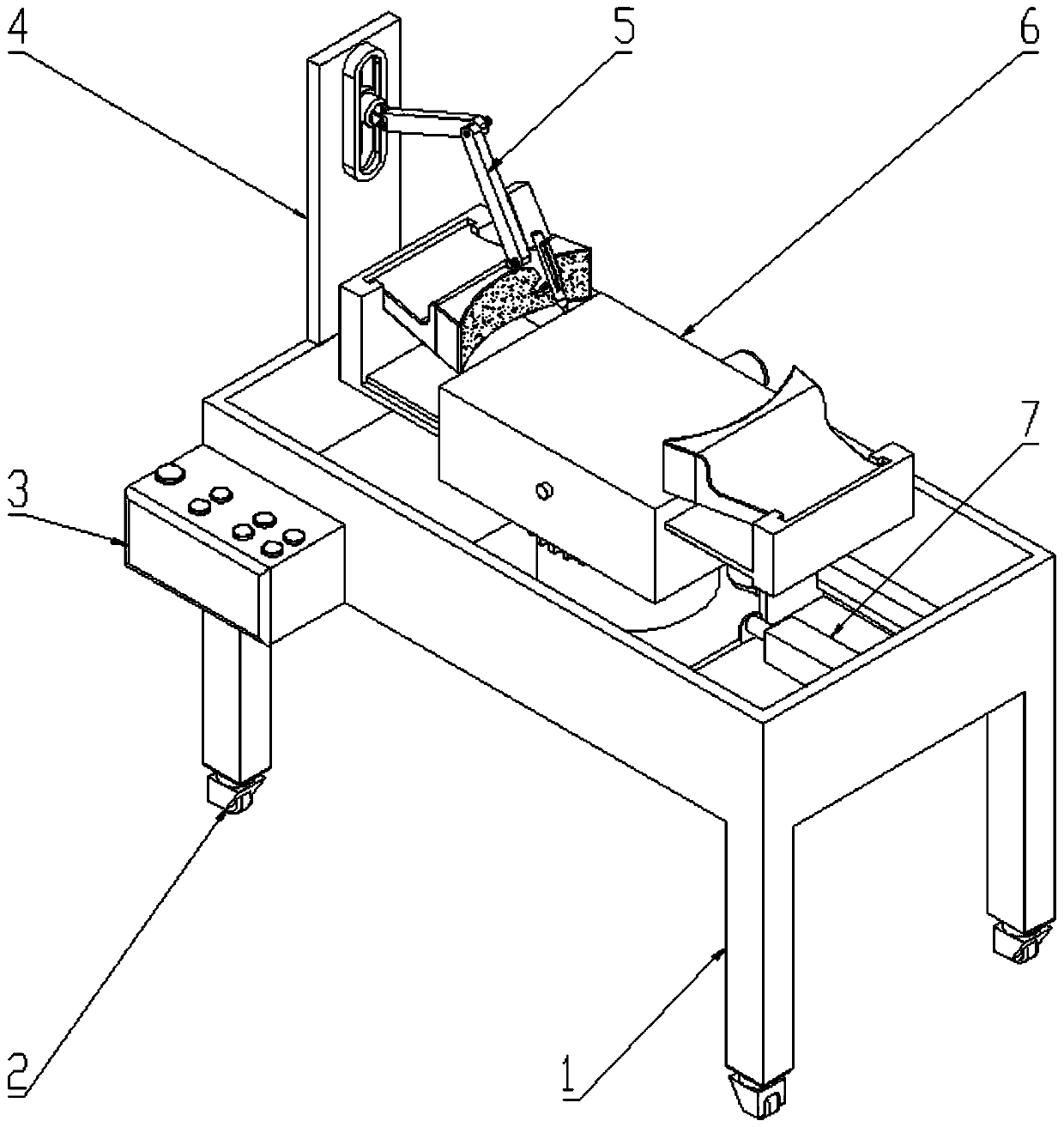

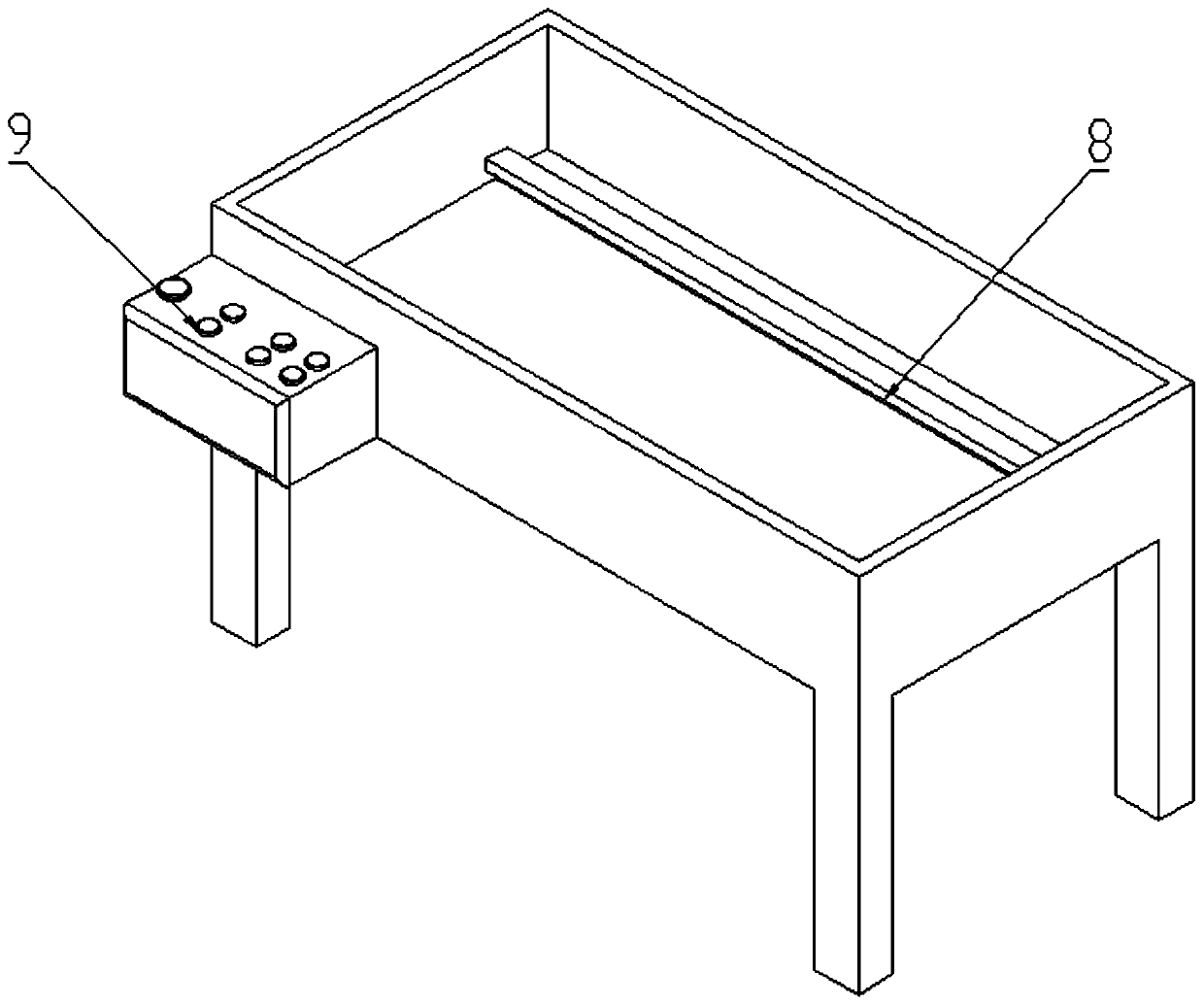

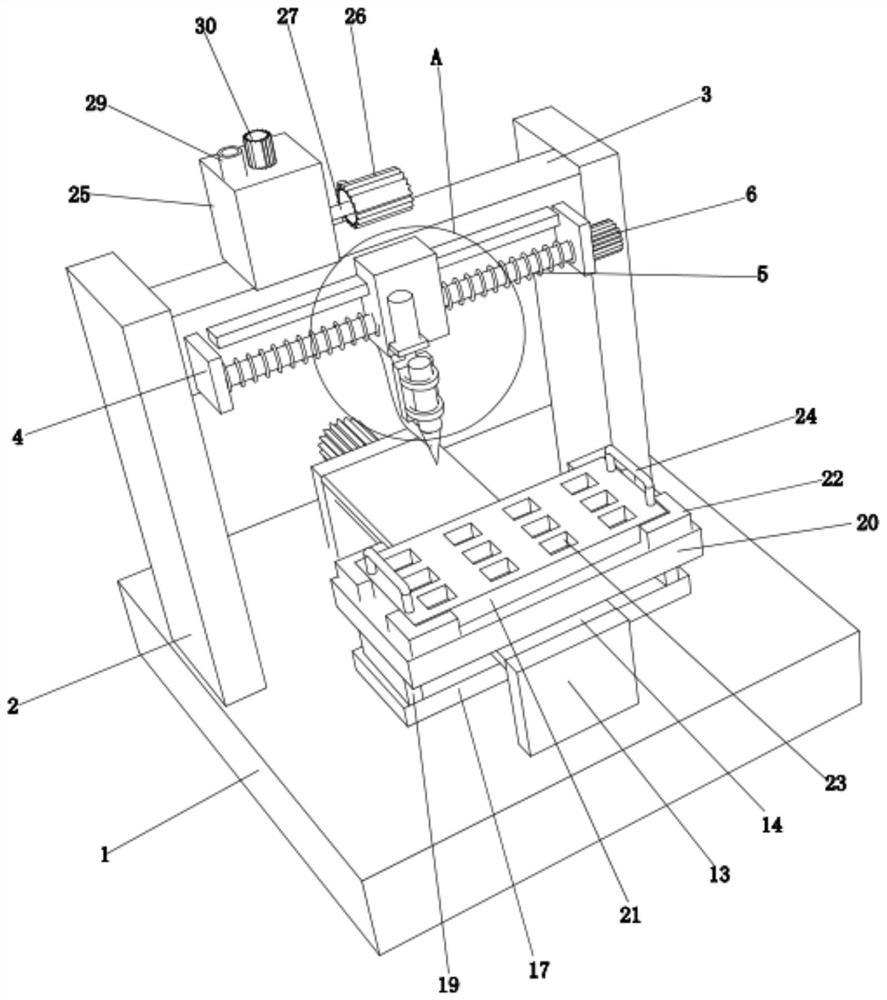

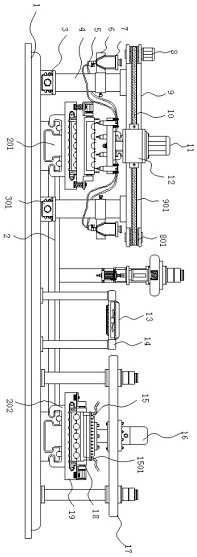

X-Y axis bidirectional glue injection machine

InactiveCN102303000AEasy to inject glueWon't wear outLiquid surface applicatorsCoatingsEngineeringMechanical engineering

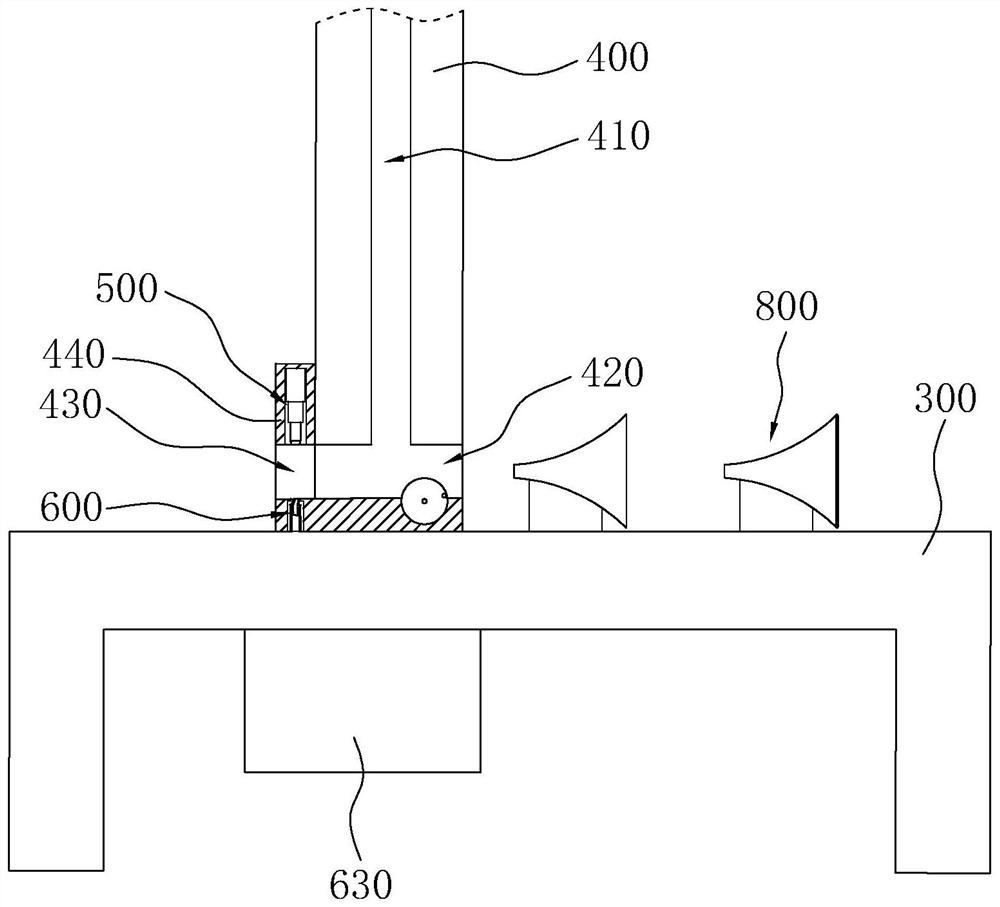

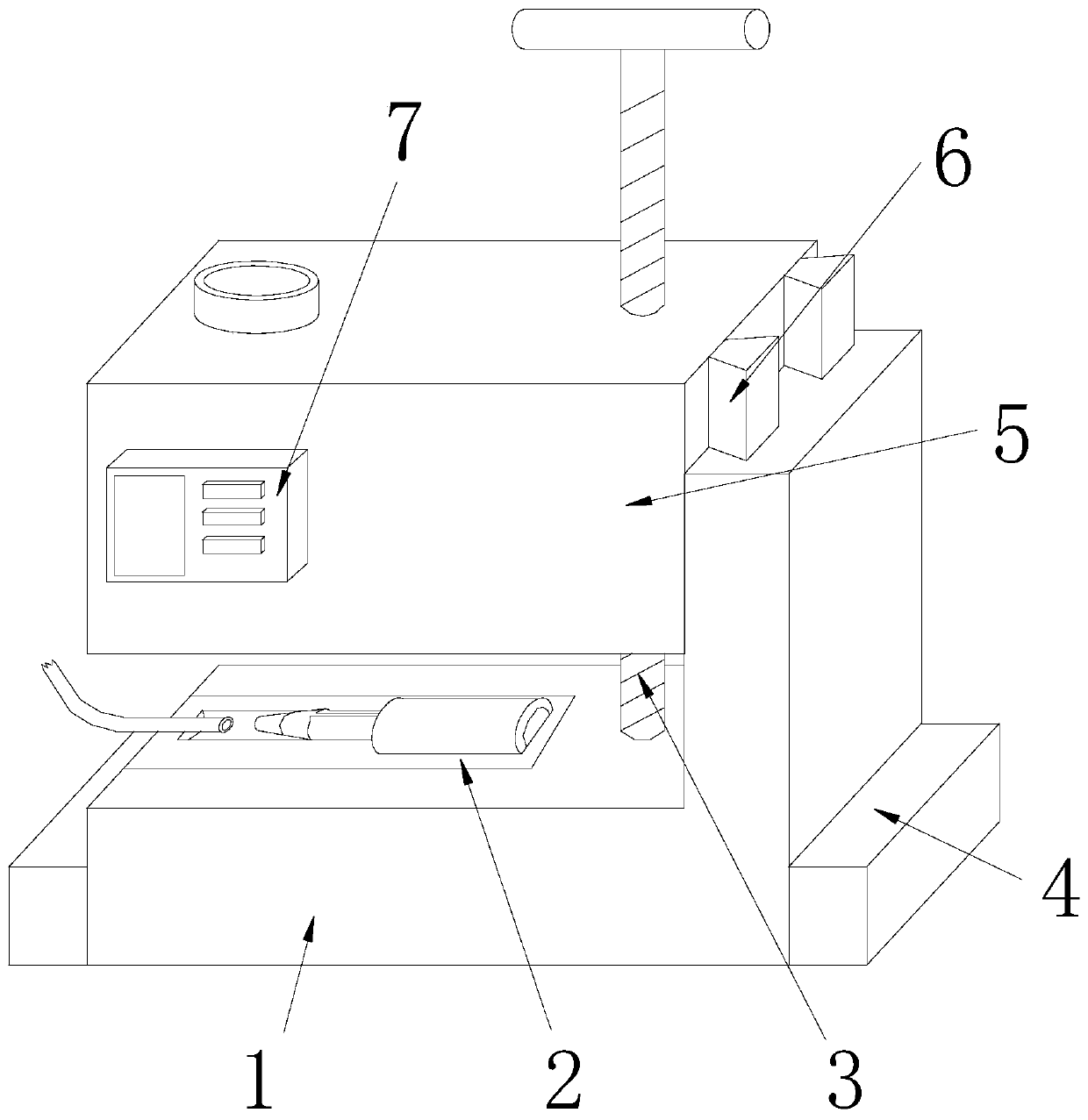

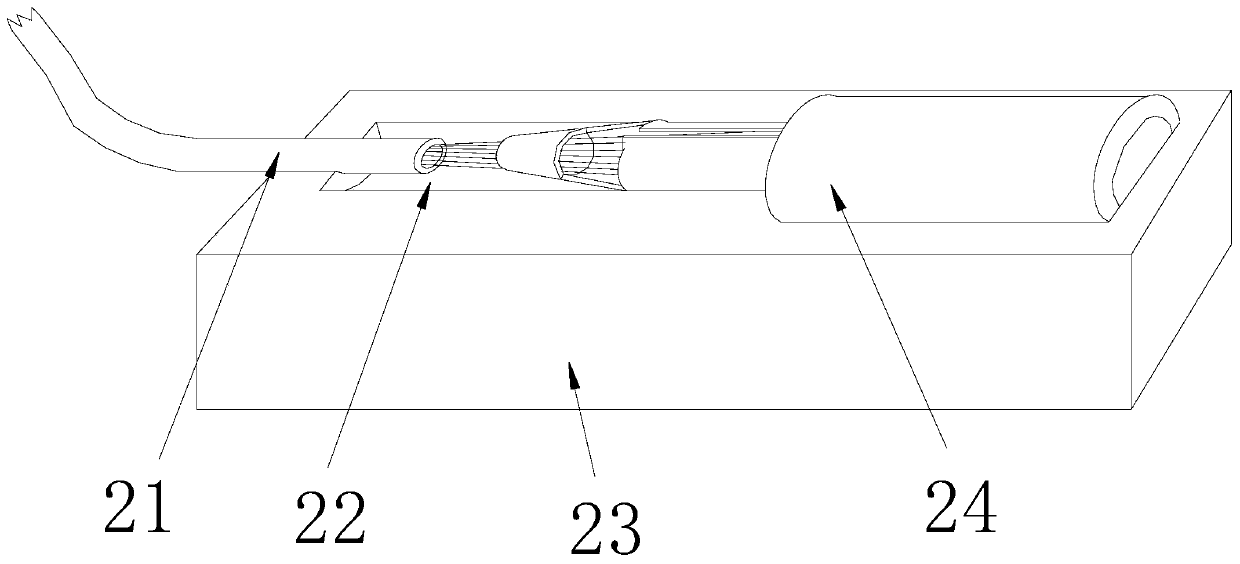

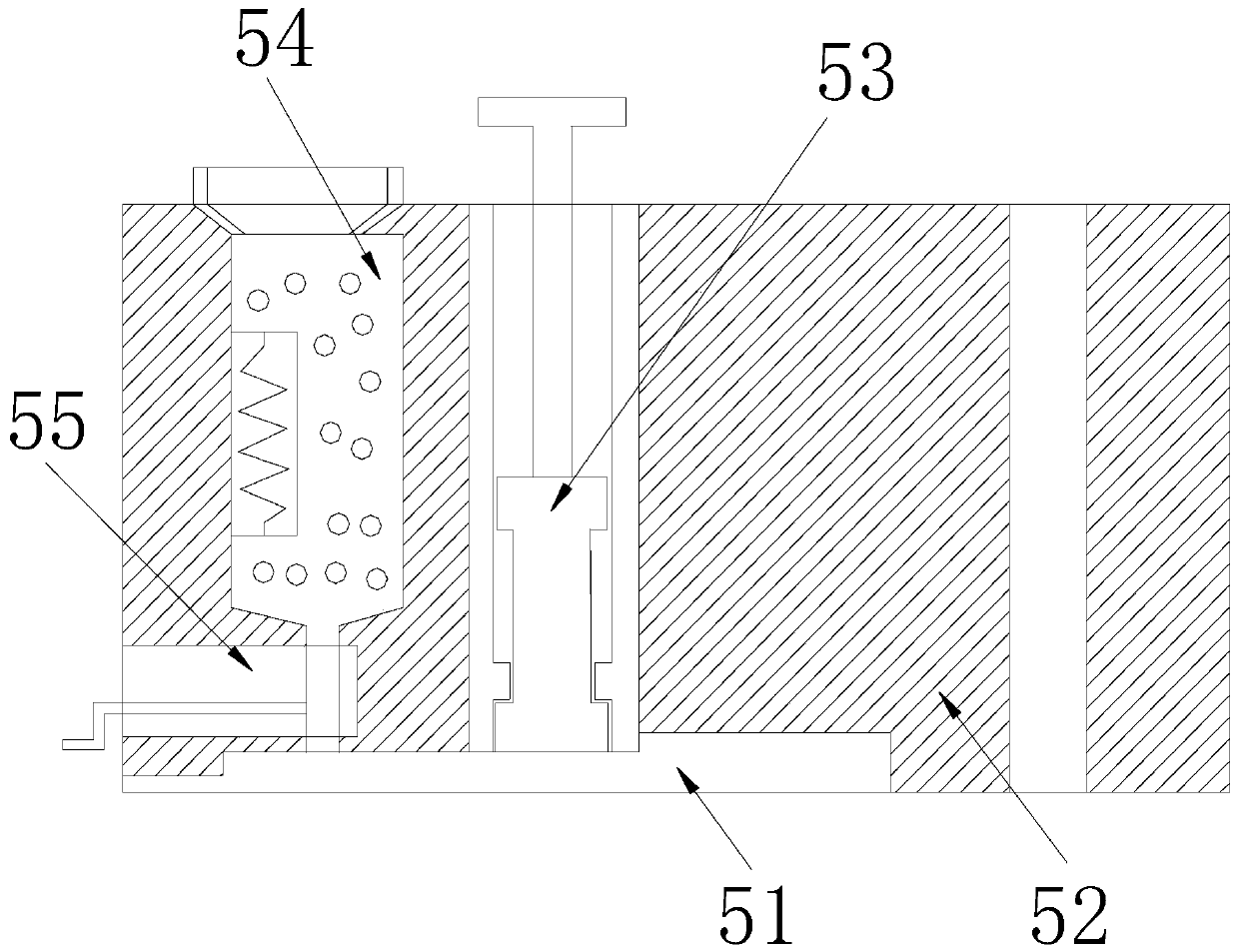

The invention relates to an X-Y axis bidirectional glue injection machine. The X-Y axis bidirectional glue injection machine comprises a workbench, a horizontal lifting support, a glue injection support, a glue injection nozzle and a controller, wherein the horizontal lifting support is arranged below the workbench, the glue injection support is arranged above the workbench, the glue injection nozzle is arranged on the glue injection support, the controller is fixed on the glue injection support, the glue injection support is provided with a sliding rail in a horizontal direction (the X-axis direction), and the glue injection nozzle is arranged on the sliding rail. Through using bidirectional glue injection, glue injection can be carried out on a product conveniently; and the product is fixed through the up-down movement of the horizontal lifting support, so that the product is not abraded in the process of fixing, thereby greatly ensuring the attractive appearance of the product.

Owner:SUZHOU KONIG ELECTRONICS TECH CO LTD

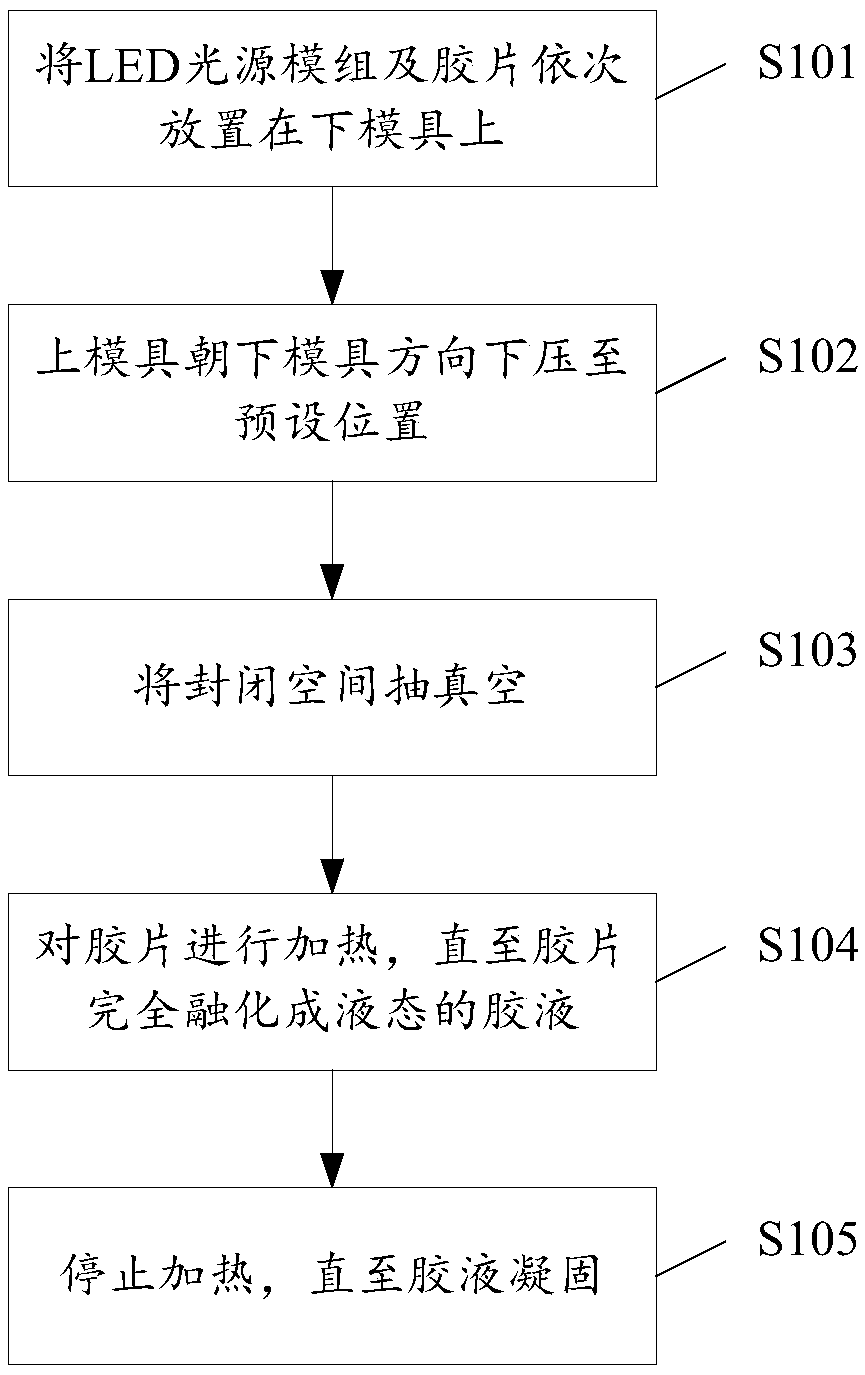

Plastic packaging method for LED light source

ActiveCN108807649AEasy to inject glueImprove product qualitySemiconductor devicesVacuum pumpingPlastic packaging

The invention provides a plastic packaging method for an LED light source. The method comprises the steps as follows: a plastic packaging mold is provided, wherein the plastic packaging mold comprisesan upper mold and a lower mold corresponding to the upper mold; a pressing block is arranged at the lower end of the upper mold; and the pressing block can be heated. An LED light source module is put into a cavity of the lower mold; a film is put on the LED light source module; and the upper mold descends to a preset position of the lower mold to form a closed cavity. Vacuum pumping treatment iscarried out on the closed cavity through a first air-pumping hole in the upper mold and a second air-pumping hole in the pressing block; the pressing block is heated to melt the film; and solidifyingtreatment is finally carried out to obtain the plastic-packaged LED light source module. According to the plastic packaging method, a packaging technology of laying the film and heating the pressingblock in sequence and then applying a laminating process to the LED light source module is adopted, so that the LED light source module which is higher in reliability, smaller in thickness, lighter inweight, lower in cost and more flexible in applicability can be obtained; air bubbles in the colloid packaging process can be effectively avoided through packaging in a vacuum confined space; and thepackaging yield is improved.

Owner:SHENZHEN DICOLOR OPTOELECTRONICS

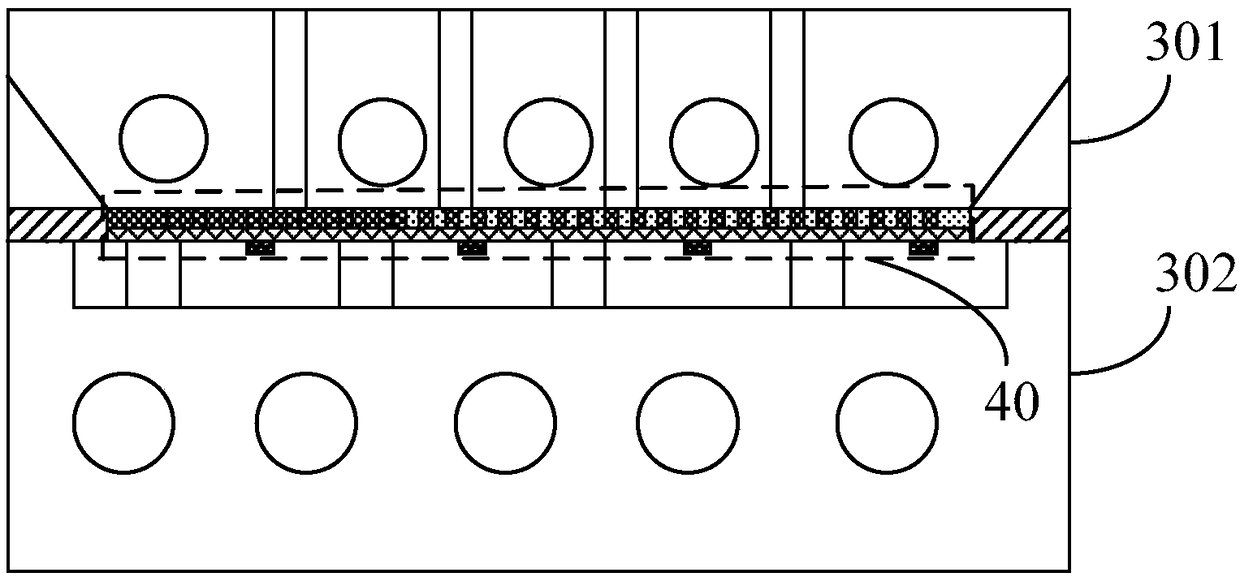

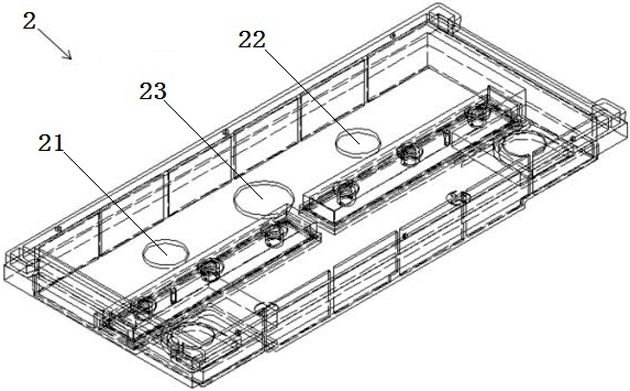

Battery pack manufacturing method

InactiveCN112421088AEasy to inject glueIncrease productivityAssembling battery machinesFinal product manufactureProcess engineeringElectrical and Electronics engineering

The invention provides a battery pack manufacturing method, and the method comprises the following steps: 1, putting an assembled battery module into a lower shell, and keeping a certain gap between the battery module and the peripheral side wall of the lower shell; 2, injecting a pouring sealant into a gap between the battery module and the lower shell, performing standing for a period of time, solidifying the pouring sealant, and achieving the pre-fixing of the battery module; 3, connecting the upper shell to the lower shell in a sealing manner to form a complete battery shell; 4, injectingthe pouring sealant into the battery shell from the sealant pouring hole in the upper shell until the pouring sealant fills the remaining space in the battery shell, and then performing standing for aperiod of time, so that the pouring sealant is cured. The battery module has the beneficial effects that after the battery module is placed in the lower shell, glue is injected firstly to realize pre-fixation, and the upper opening of the whole lower shell can be used as a glue injection hole, so that the glue injection is very convenient, and the production efficiency can be greatly improved; inaddition, the whole process is visible, quality control is facilitated, and the uniformity of the thickness of the peripheral adhesive layer is guaranteed.

Owner:HENAN BENMA +1

Automatic bonding device for full mold casting

The invention provides an automatic bonding device for a full mold casting, and belongs to the technical field of full mold casting bonding. The problem that irregular full mold casting bonding facesare difficult to be rapidly coated with hot glue for bonding is solved. The device comprises a base, universal brake trundles are fixed to the lower ends of four supporting legs of the base, a controlbox is fixed to the front end of the base, the side end of the base is fixedly provided with a glue injection mounting plate, a second adjusting sliding rail is fixed to the glue injection mounting plate, a glue injection mechanism is arranged on the second adjusting sliding rail, two first adjusting sliding rails are fixed to a bottom plate in the base, and are symmetrically distributed, rotating clamping mechanisms are arranged in the first adjusting sliding rails in a sliding manner, and adjusting push rods are arranged between the rotating clamping mechanisms and the base. Through cooperation of the rotating clamping mechanisms and the adjusting push rods, the full mold casting is clamped and driven to move, the irregular bonding face moves at the lower end of a glue outlet of a hot melt adhesive gun, the bonding face can be rapidly coated with the hot glue fully, and the application range is wide.

Owner:安徽兰翔纺机科技有限公司

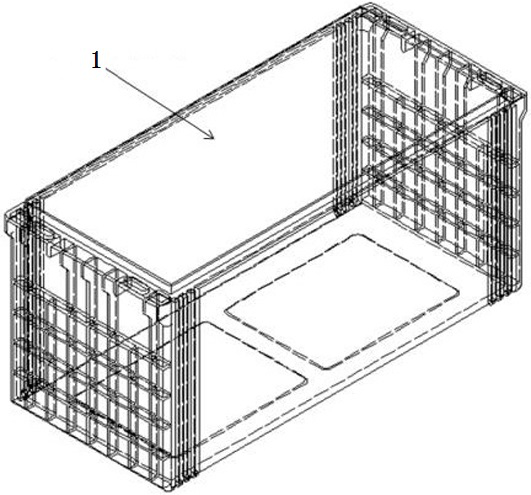

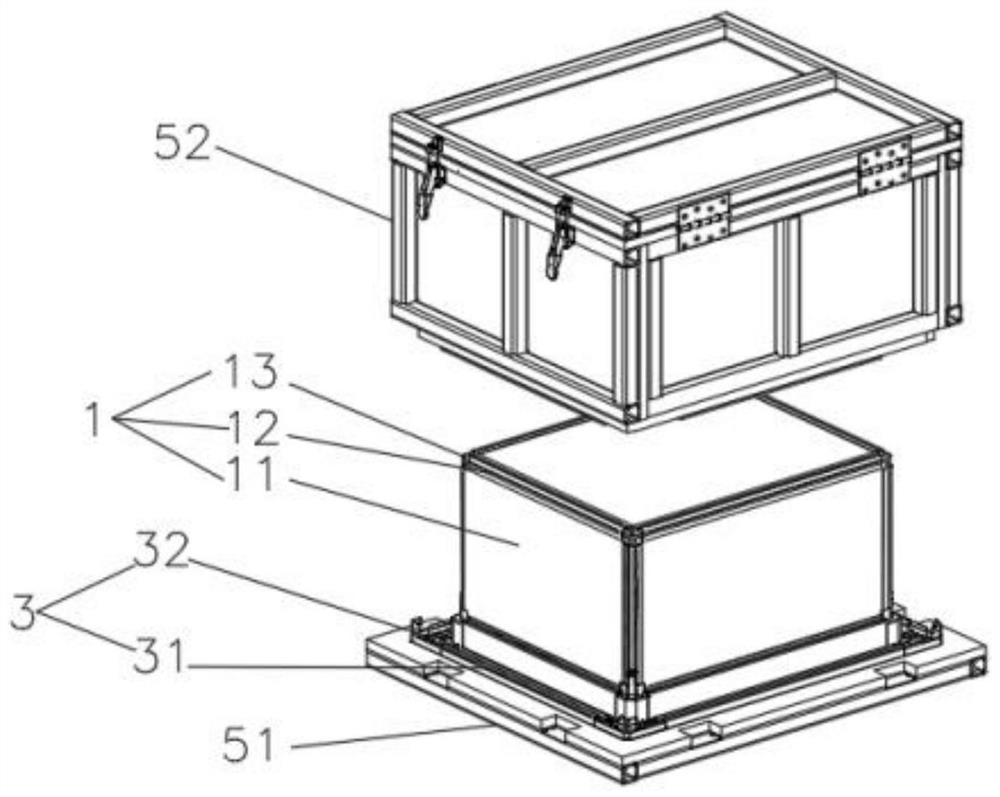

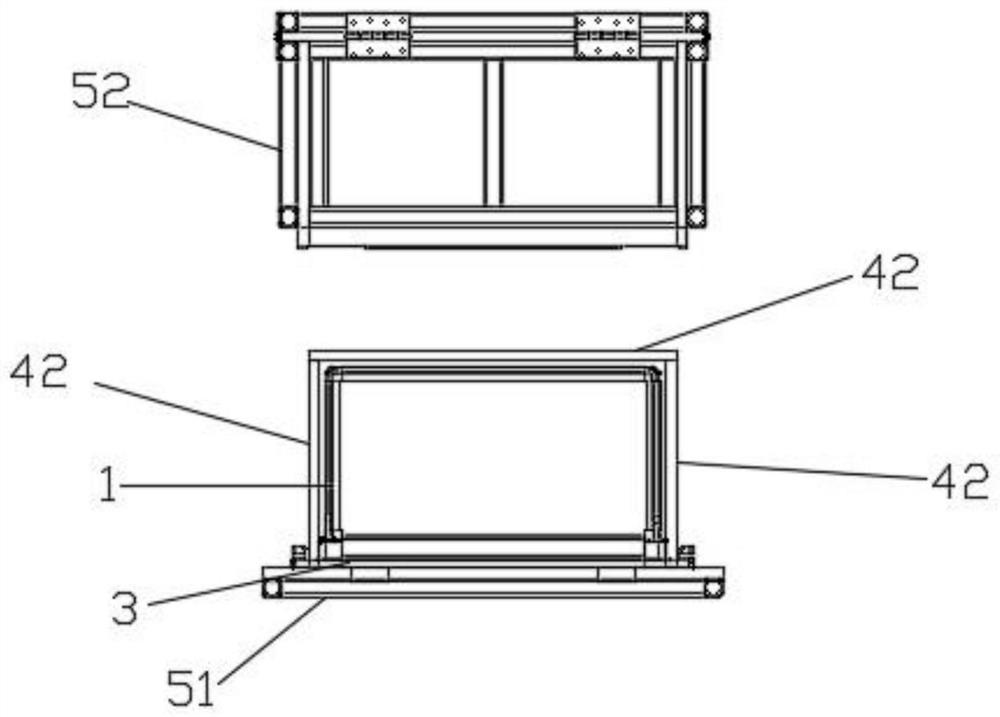

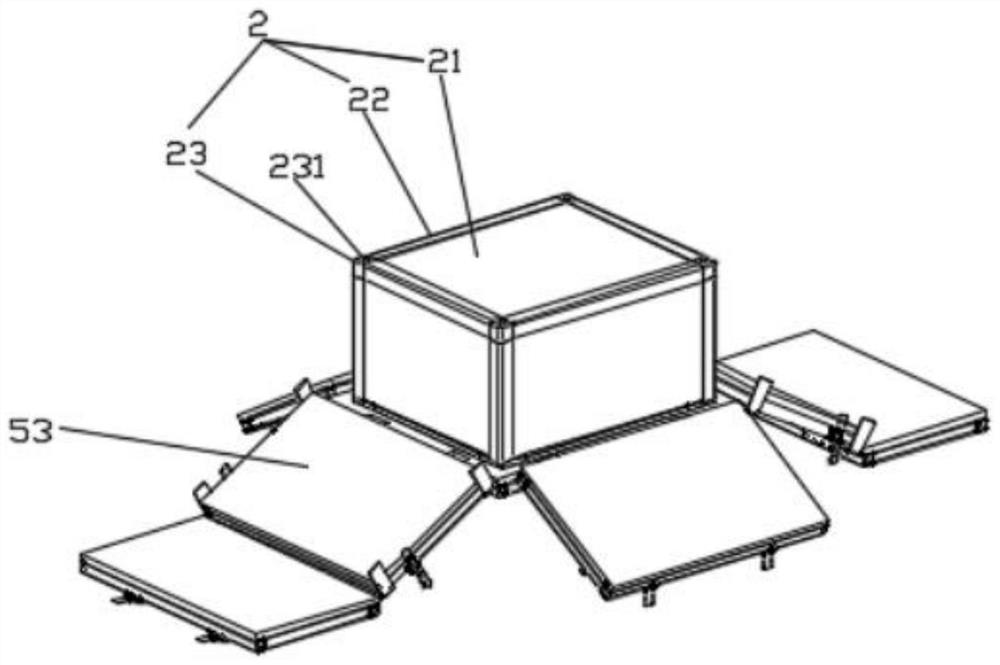

Manufacturing method of heat preservation box body and heat preservation box body

InactiveCN111688244AImprove impact resistanceThe cost of customization is not highDomestic cooling apparatusLighting and heating apparatusProcess engineeringHeat conservation

The invention discloses a manufacturing method of a heat preservation box body. The manufacturing method comprises the steps of preparation of splicing sectional materials and connecting pieces, cutting, splicing of a box body inner container, first-time foaming, splicing of a box body shell and second-time foaming. The invention further discloses the heat preservation box body manufactured through the manufacturing method of the heat preservation box body. According to the manufacturing method of the heat preservation box body and the heat preservation box body, the heat preservation box is good in heat preservation effect and impact resistance, the personalized customization cost of different sizes is low, and the manufacturing method is simple and efficient.

Owner:SHANDONG ANLENG NEW MATERIAL TECH CO LTD

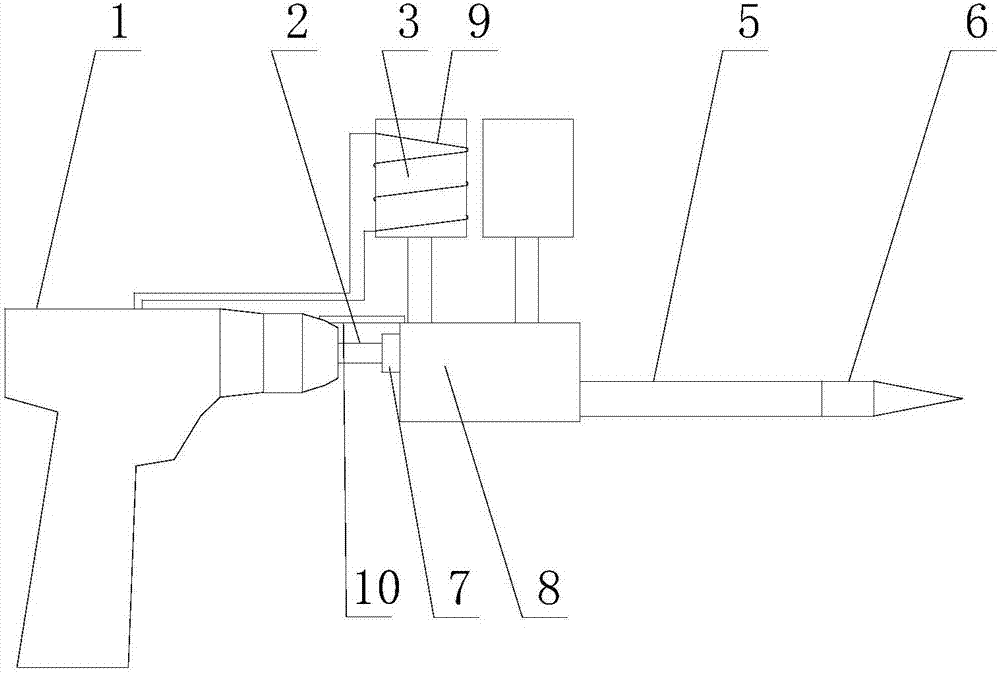

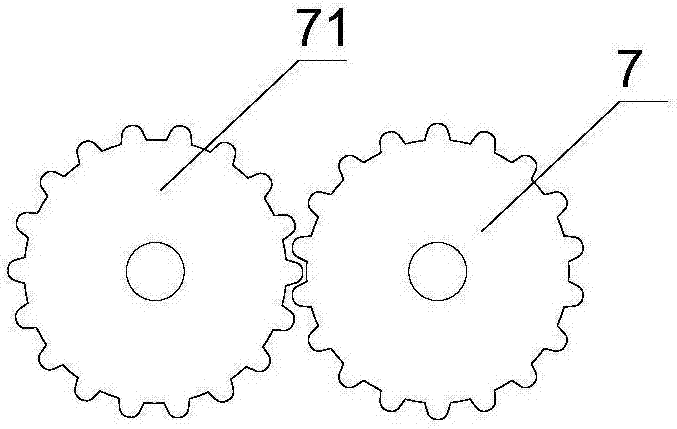

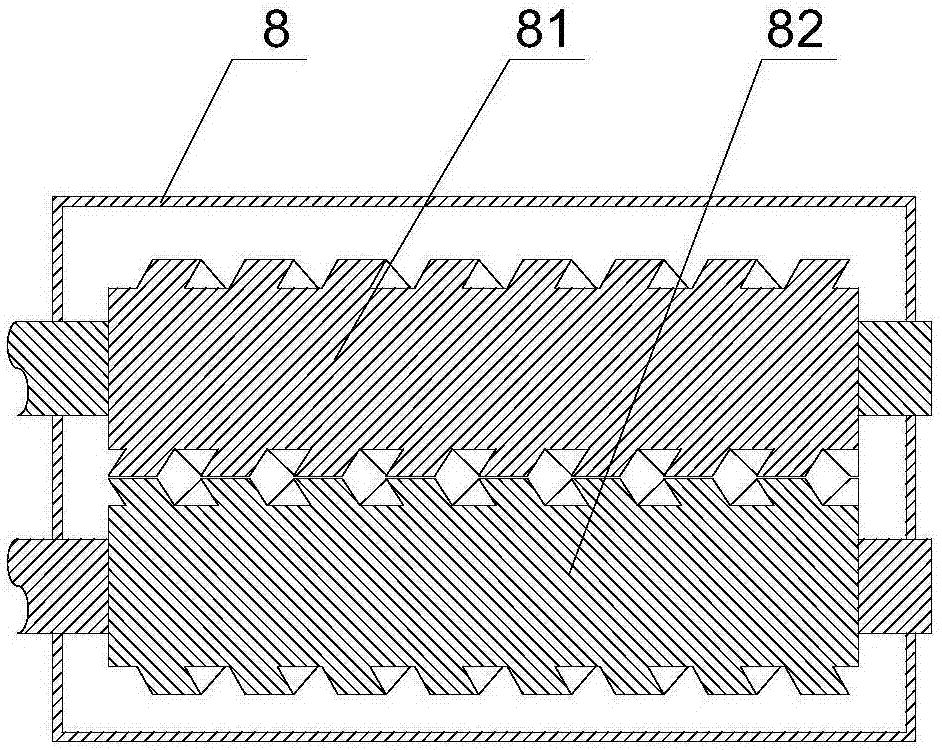

Handheld double-component high-pressure glue-injection machine

InactiveCN107199152AImprove construction efficiencyGuarantee the construction qualityLiquid surface applicatorsCoatingsHigh pressureInjection molding machine

The invention relates to the field of glue-injection devices, in particular to a handheld double-component high-pressure glue-injection machine. The handheld double-component high-pressure glue-injection machine comprises a material screw-in drive device, wherein an output shaft of the material screw-in drive device and one end of a material mixing screw-in bin are arranged in a penetration manner, a screw-in threaded rod is arranged in the material mixing screw-in bin and connected with the output shaft, the other end of the material mixing screw-in bin communicates with a glue-injection pipe, and the material mixing screw-in bin communicates with at least one feeding barrel. The handheld double double-component high-pressure glue-injection machine is provided and solves the problems that when an existing glue-injection machine injects glue, insufficient glue injection and non-uniform mixing occur easily.

Owner:东方雨虹民用建材有限责任公司

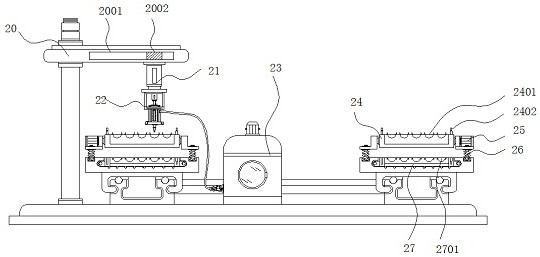

Glue pouring method and device

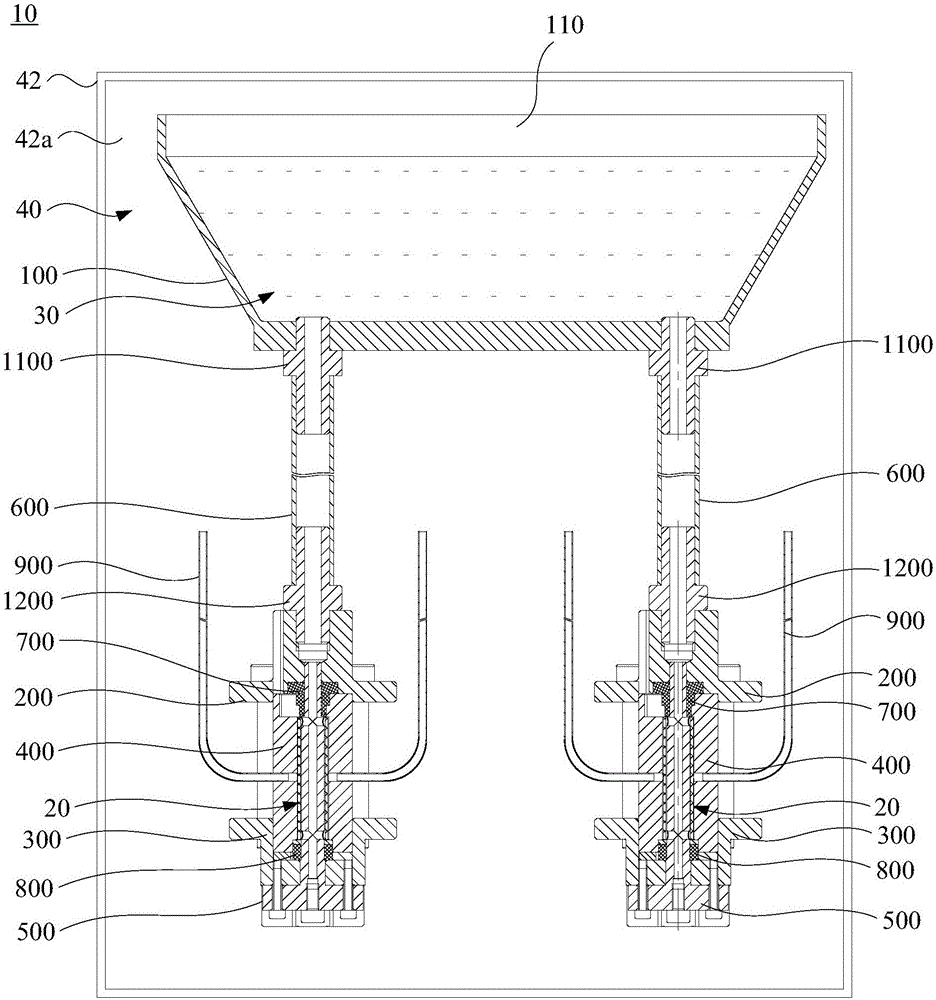

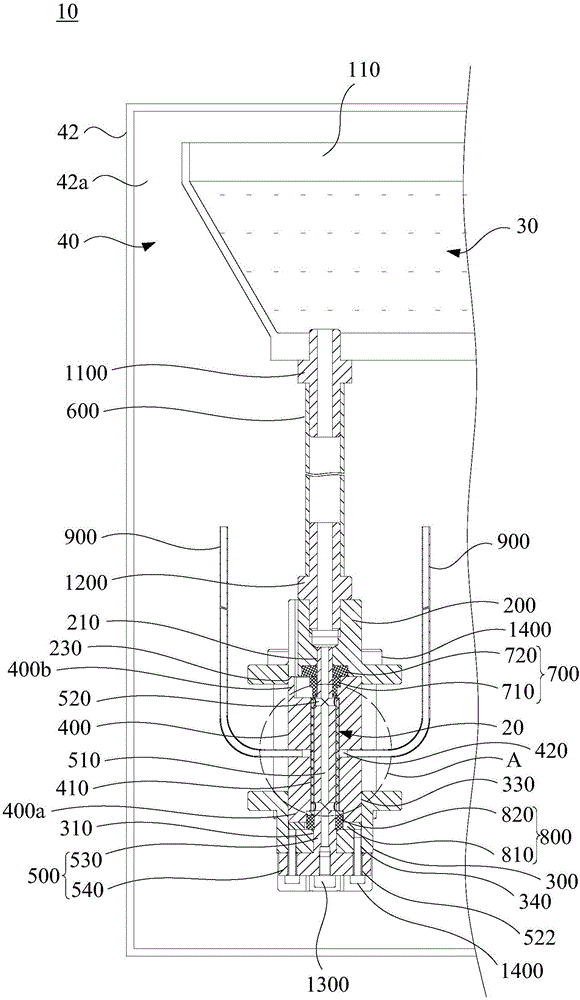

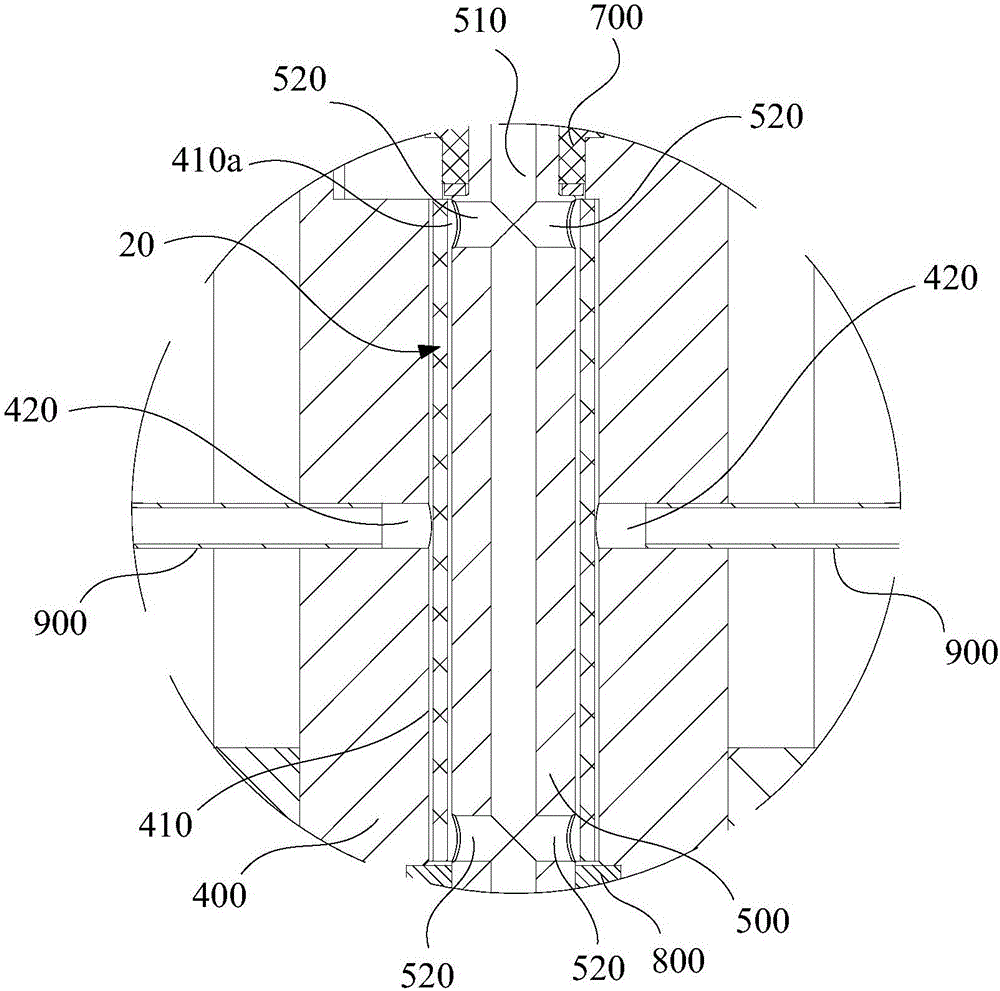

ActiveCN106533086AFit clearance is smallLess precisionManufacturing dynamo-electric machinesEngineeringLiquid tank

The invention relates to a glue pouring method and device. The device is used for the glue pouring of a coil, and comprises a hopper, a first seat body, a second seat body, a coil sleeve, a central spindle, a first connection pipe, and a second connection pipe. The hopper is provided with a liquid tank for storing glue. The first seat body is provided with a first through hole. The second seat body is provided with a second through hole. Two ends of the coil sleeve are respectively connected with the first seat body and the second seat body, and the coil sleeve is provided with an accommodation cavity and a third through hole. The accommodation cavity is communicated with the first through hole, the second through hole and the third through hole. The central spindle is disposed in the accommodation cavity in a passing-through manner, and two ends of the central spindle respectively stretch into the first and second through holes. There is a gap between the central spindle and the coil sleeve for accommodating a coil. The central spindle is provided with a pipe and a fourth through hole, and the fourth through hole is communicated with the pipe and the accommodation cavity. According to the invention, because there is no need to carry out debonding operation of the coil after glue pouring, the method and device can solve problems that the operation precision of a motor is lower and the service life of the motor is shorter.

Owner:HANS LASER TECH IND GRP CO LTD +1

Optical fiber collimator assembling and adjusting device

The invention discloses an optical fiber collimator assembling and adjusting device. The optical fiber collimator assembling and adjusting device comprises a fixing unit, the fixing unit comprises a pedestal, a first fixing assembly and a second fixing assembly which are arranged on the pedestal, an optical fiber which is horizontally arranged is fixed on the first fixing assembly, and an optical fiber collimator which is horizontally arranged is fixed on the second fixing assembly; the optical fiber collimator assembling and adjusting device also comprises a displacement adjusting device comprising a first displacement adjusting assembly arranged between the second fixing assembly and the pedestal, and the first displacement adjusting assembly drives the second fixing assembly to move relative to the pedestal; the optical fiber collimator assembling and adjusting device also comprises a light spot imaging unit which horizontally aligns to the light emitting terminal of the optical fiber collimator; the optical fiber is coupled with a laser light source; and the optical fiber can be movably inserted into the axle center of the optical fiber collimator. With respect to the optical fiber collimator assembling and adjusting device, under the imaging aid of the light spot imaging unit, and the first displacement adjusting assembly drives the second fixing assembly to move relative to the pedestal in order to adjust the relative plug-in position of the optical fiber collimator and the optical fiber, the optical fiber collimator assembling and adjusting device is simple in structure and high in aligning precision, and the imaging consistency is improved.

Owner:SUZHOU INST OF BIOMEDICAL ENG & TECH CHINESE ACADEMY OF SCI

Liquid state silica gel sizing device

The invention aims to provide a liquid state silica gel sizing device. According to the technical scheme, the liquid state silica gel sizing device is composed of a lower mold plate, product implanting grooves, product position clamping blocks, a lower-position silica gel releasing device, an upper mold plate, a silica gel injecting port, a cold runner silica gel dispensing device and a high-position silica gel releasing device; a product fixer is arranged in each product implanting groove, and is composed of a center inserting block, a first edge inserting block, a second edge inserting blockand two fixing bolts; the lower mold plate is provided with positioning columns, auxiliary positioning columns, auxiliary positioning grooves and pressure springs; and the cold rubber silica gel dispensing device is composed of a supporting table, a silica gel entering storing disk, a silica gel injecting rotating disk and a silica gel injecting pipe. The whole mold structure is clear in train ofthought, and operation is convenient; the structural design of the cold runner silica gel injecting type and the structural design of raw material recycling are adopted, the overall machining stability is improved, the shape attractiveness and the production efficiency are improved, raw materials for use are greatly reduced, cost is reduced, the mold is also well protected, and pollution is reduced.

Owner:SYNERGY HANIL PRECISION POLYMER TECH CO LTD

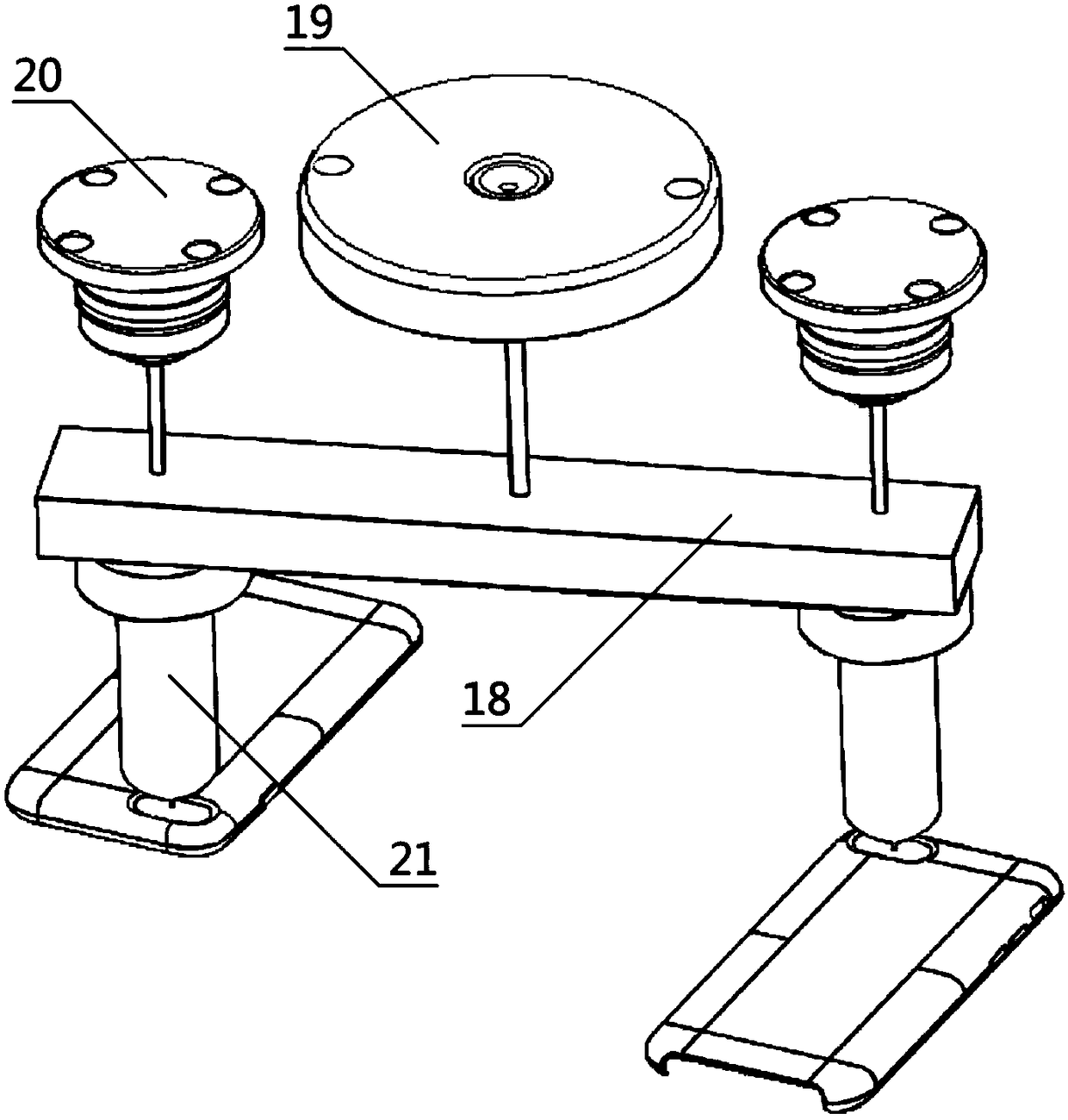

Accurate axial centering device for wire harness

ActiveCN111696725AGuaranteed stabilityGuaranteed reliabilityManufacturing wire harnessesInsulating conductors/cablesStructural engineeringCam

The invention discloses an accurate axial centering device for a wire harness. The accurate axial centering device is characterized in that a wire passing hole B is formed in the center of a supporting fixing plate; a clamping jaw seat is fixedly connected to the supporting fixing plate, a wire passing hole A is formed in the axis of the clamping jaw seat, and a plurality of radial sliding groovesA and a plurality of radial sliding grooves B are evenly formed in the upper portion of the clamping jaw seat in the circumferential direction; mechanical clamping jaws are slidably assembled in theradial sliding grooves A, and the middle portion and the left portion of the lower end of the mechanical clamping jaw are respectively connected with a longitudinal stop arm and a cam bearing follower; the longitudinal stop arm is connected with the inner end of the radial sliding groove B through a spring; a rotary sleeve is sleeved outside the clamping jaw seat through an axial cavity, and the inner side of the upper portion of the rotary sleeve is in rolling fit with the roller of a cam follower; a plurality of lift sliding grooves for allowing the roller to roll in and roll out are formedin the rotary sleeve in the circumferential direction; one end of the anticlockwise side of the lift sliding groove is provided with a guide inclined edge, and one end of the clockwise side of the lift sliding groove is provided with a limiting concave edge; and a cover plate is fixedly connected with the upper end of the clamping jaw seat through a connecting bolt. The accurate axial centering device can accurately position the axis of the wire harness, and can effectively reduce the labor cost.

Owner:XUZHOU HUAXIA ELECTRONICS

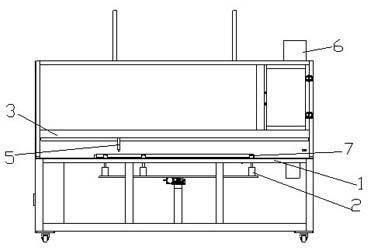

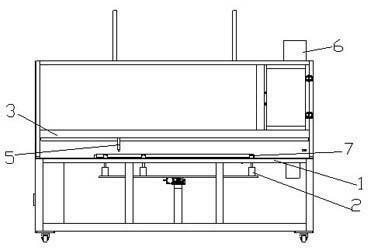

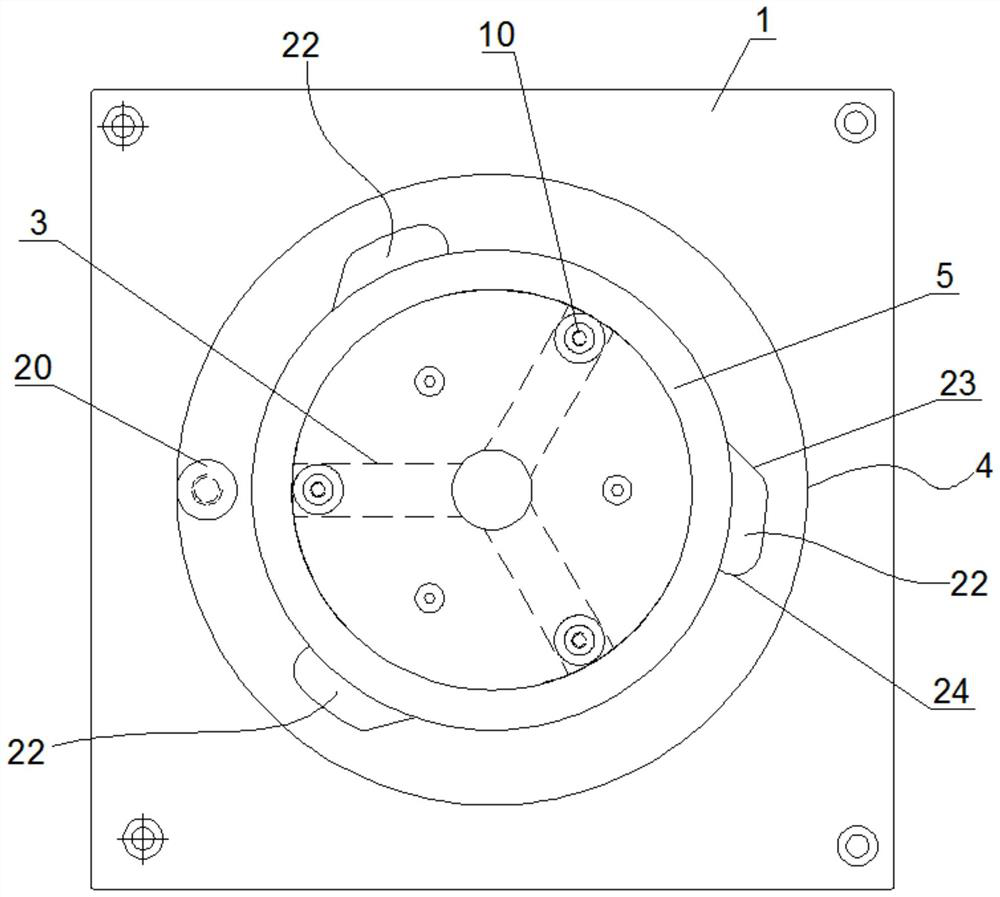

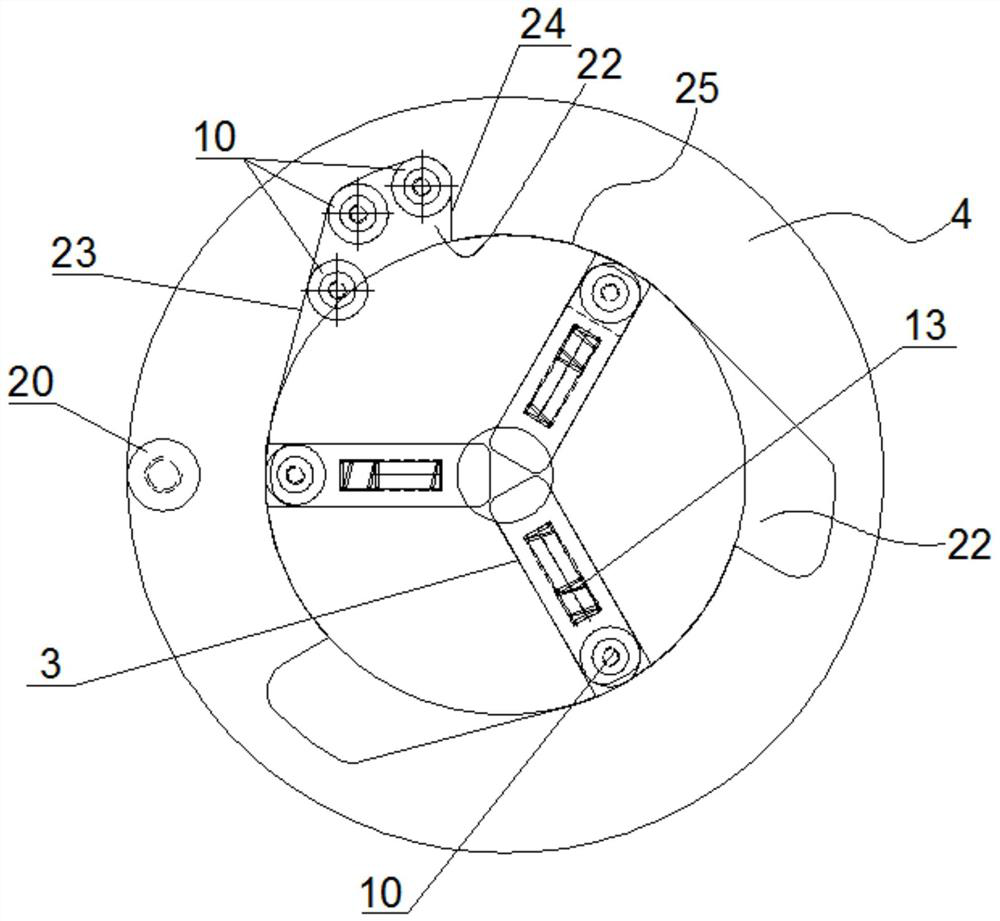

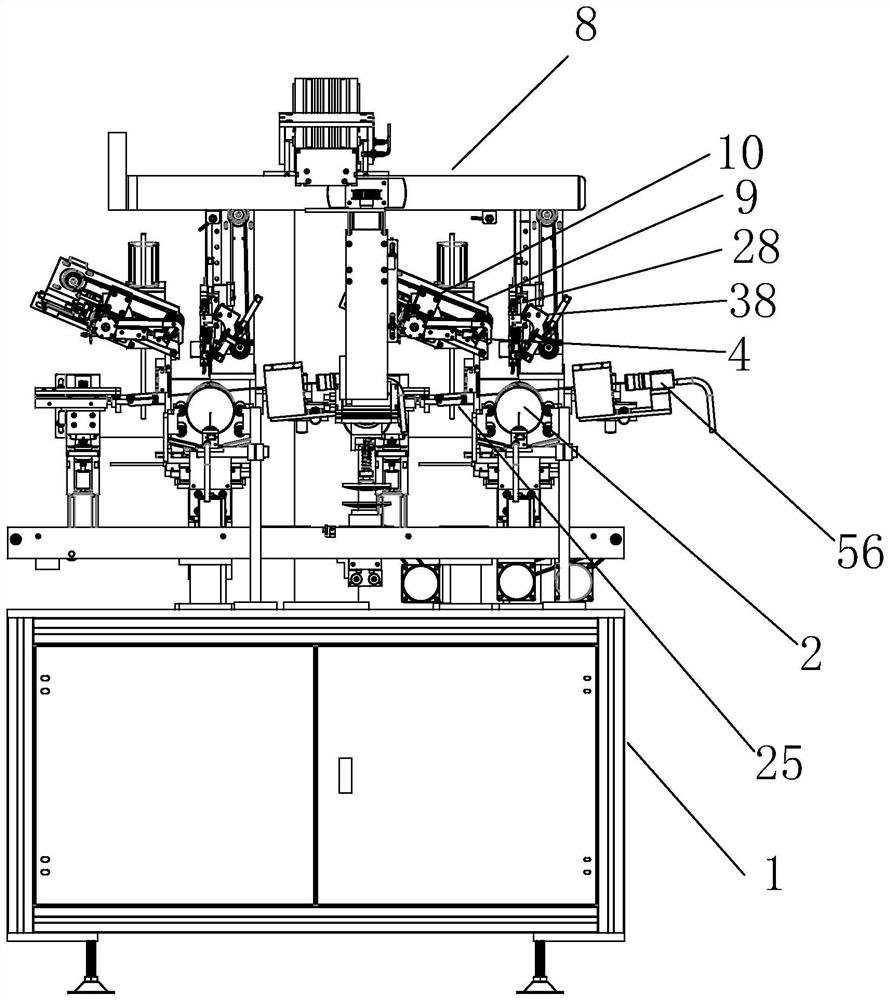

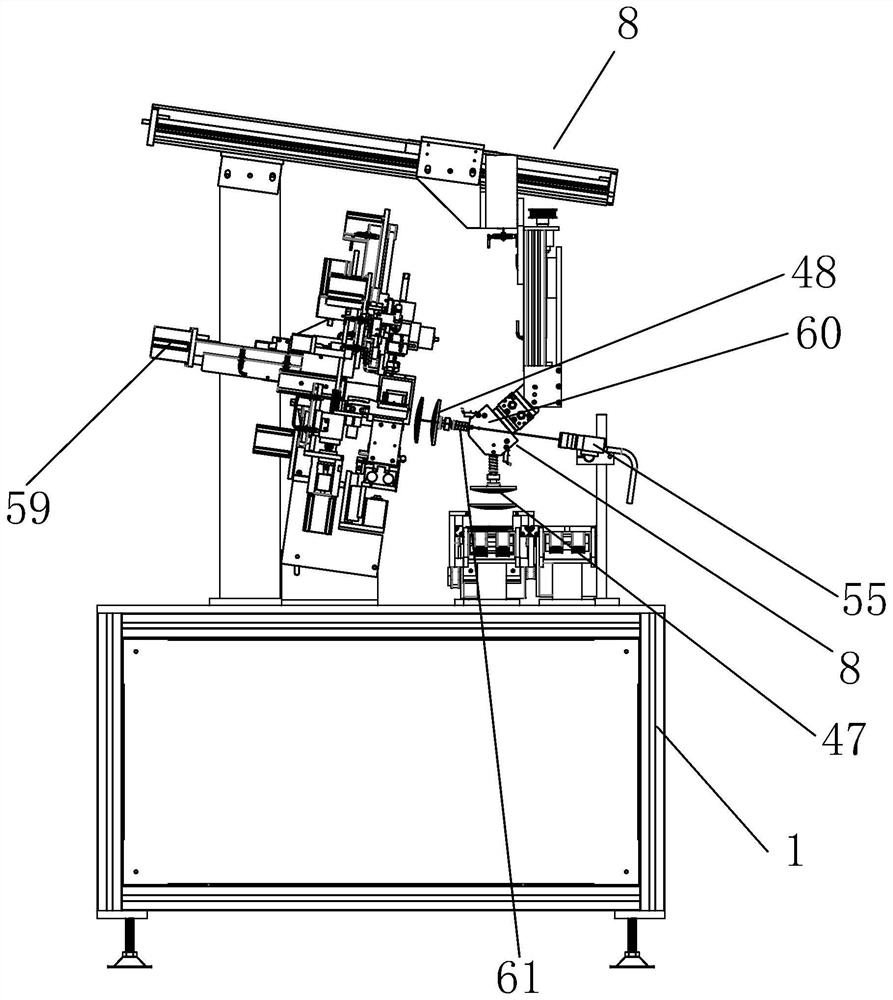

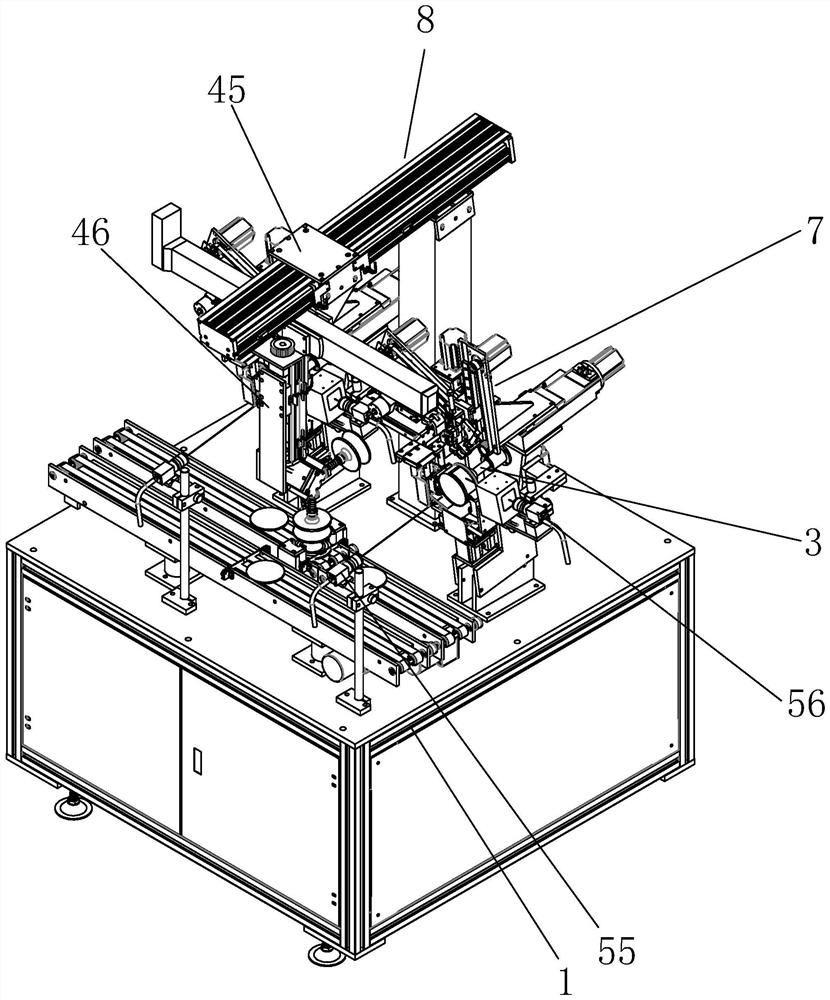

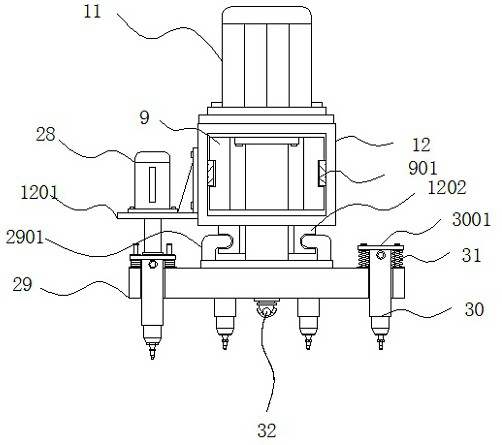

Full-automatic lens glue injection machine capable of realizing multi-body combination

The invention discloses a full-automatic lens glue injection machine capable of realizing multi-body combination, and belongs to the technical field of lens manufacturing. The full-automatic lens glueinjection machine comprises a rack (1), wherein an automatic glue injection device (7) is arranged on the rack (1), a first visual sensor (55) and a front projection light source are arranged right in front of a main shaft (3), a second visual sensor (56) and a side projection light source are arranged on one side of the main shaft (3), a glue injection mechanism (28) is arranged above the main shaft (3), a conveying belt feeding and discharging mechanism (8) is arranged on the rack (1), an adhesive tape tearing and pasting device (9) with a positioning function is arranged on one side of themain shaft (3), and a locking piece (10) is arranged on the adhesive tape tearing and pasting device (9). According to the full-automatic lens glue injection machine, an adhesive tape of a lens moldcan be better torn and pasted, the length of the torn adhesive tape can be accurately determined, and the full-automatic lens glue injection machine can combine a plurality of glue injection machine bodies, so that the product quality is improved, and the production efficiency is improved.

Owner:LINHAI JINZHENG MACHINERY

Glue injection equipment special for electronic product production

InactiveCN113042320AEasy to inject glueImprove injection effectLiquid surface applicatorsRotary stirring mixersHydraulic cylinderInjection equipment

The invention discloses glue injection equipment special for electronic product production. The equipment comprises a base, wherein two first vertical plates are oppositely arranged above the base, a transverse plate is connected between the two first vertical plates, two side plates are oppositely arranged at the front end of the transverse plate, a first lead screw is rotatably arranged between the two side plates, a first motor used for driving the first lead screw to rotate is arranged on the outer side of one side plate, a first moving base is in threaded connection with the first lead screw, a guide plate is arranged on the front side face of the transverse plate, the first moving base is in sliding connection with the guide plate, a mounting plate is arranged at the front end of the first moving base, a hydraulic cylinder is arranged on the mounting plate, a fixing plate is arranged at the bottom of a piston rod of the hydraulic cylinder, a glue injection pipe is fixed to the fixing plate, a glue injection head is arranged at the bottom of the glue injection pipe, and a feeding assembly is arranged on the base. Compared with the prior art, the glue injection equipment has the advantages of being high in glue injection efficiency and good in glue injection effect.

Owner:长兴锐宏电子有限公司

Hydroxypropyl starch empty capsule preparation device and technology

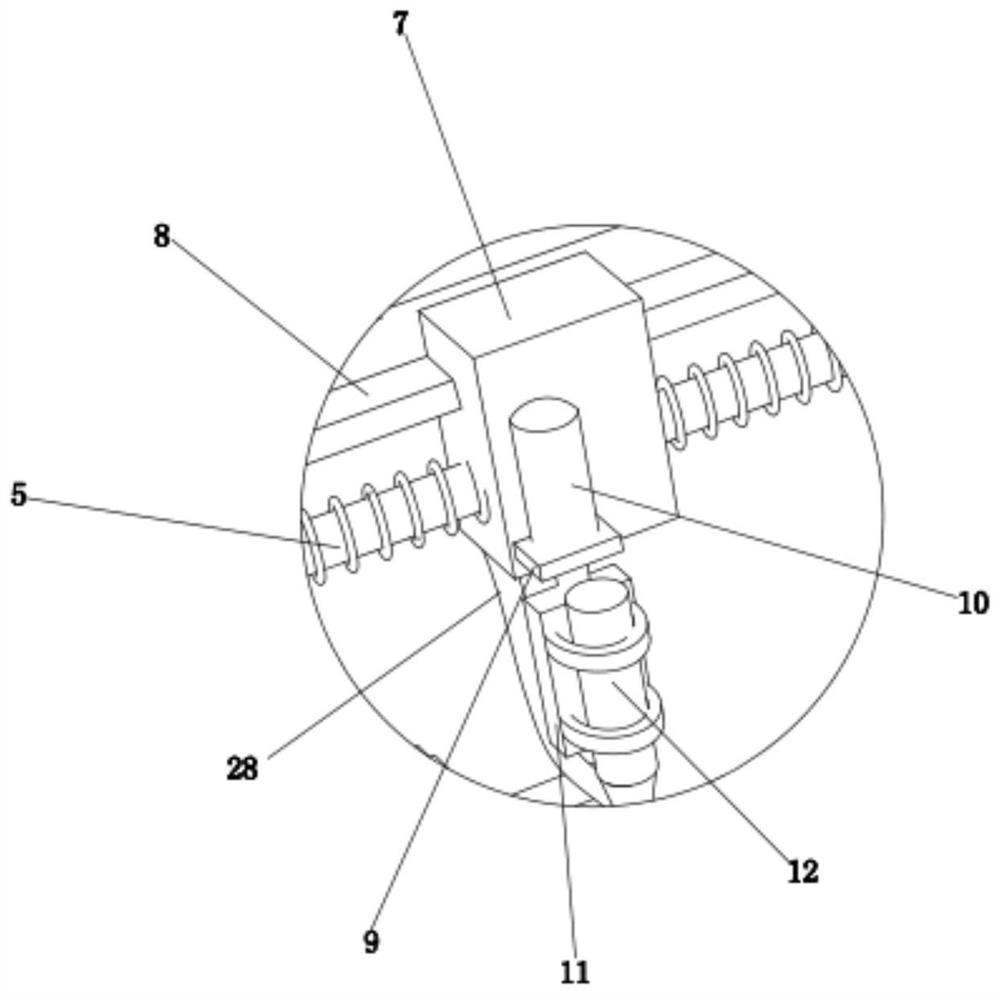

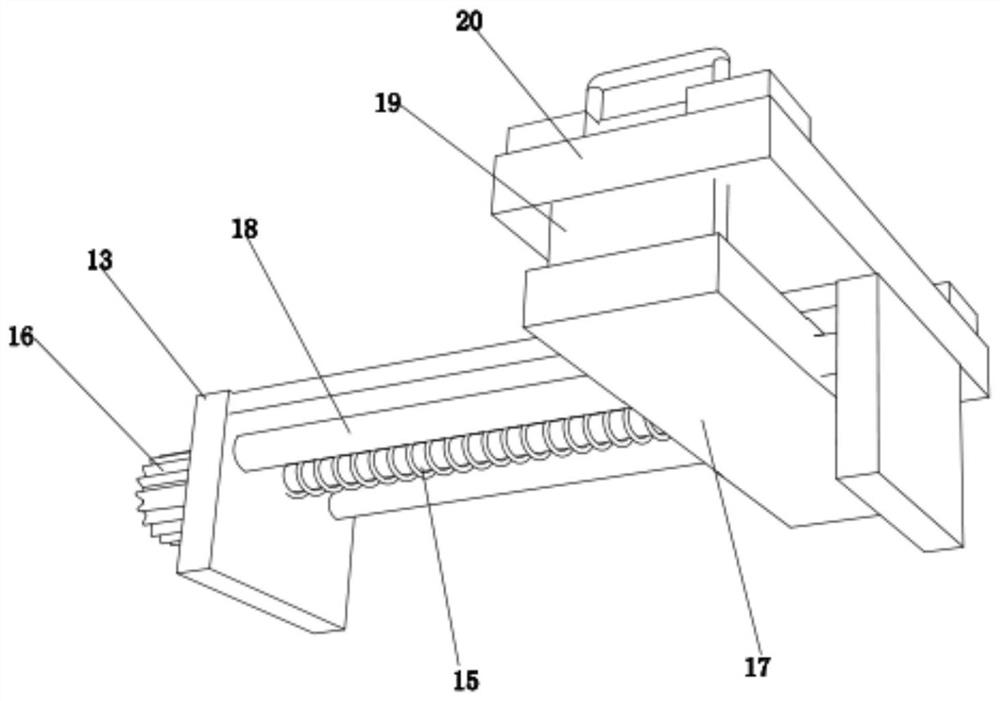

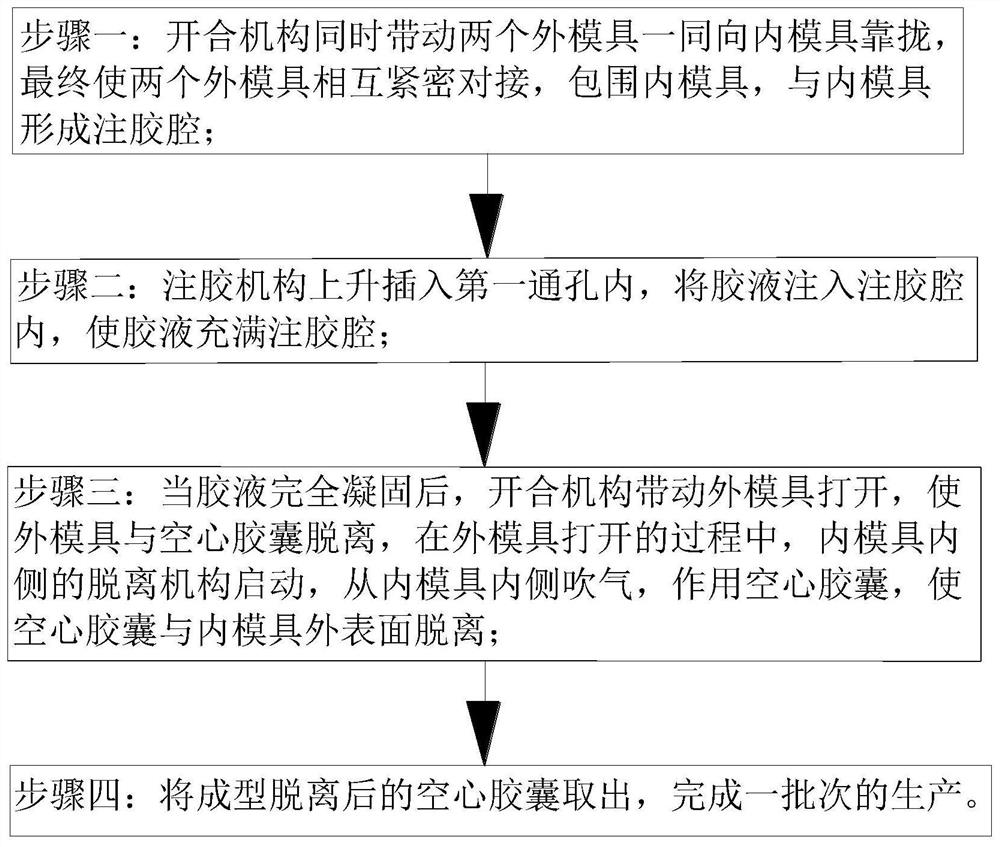

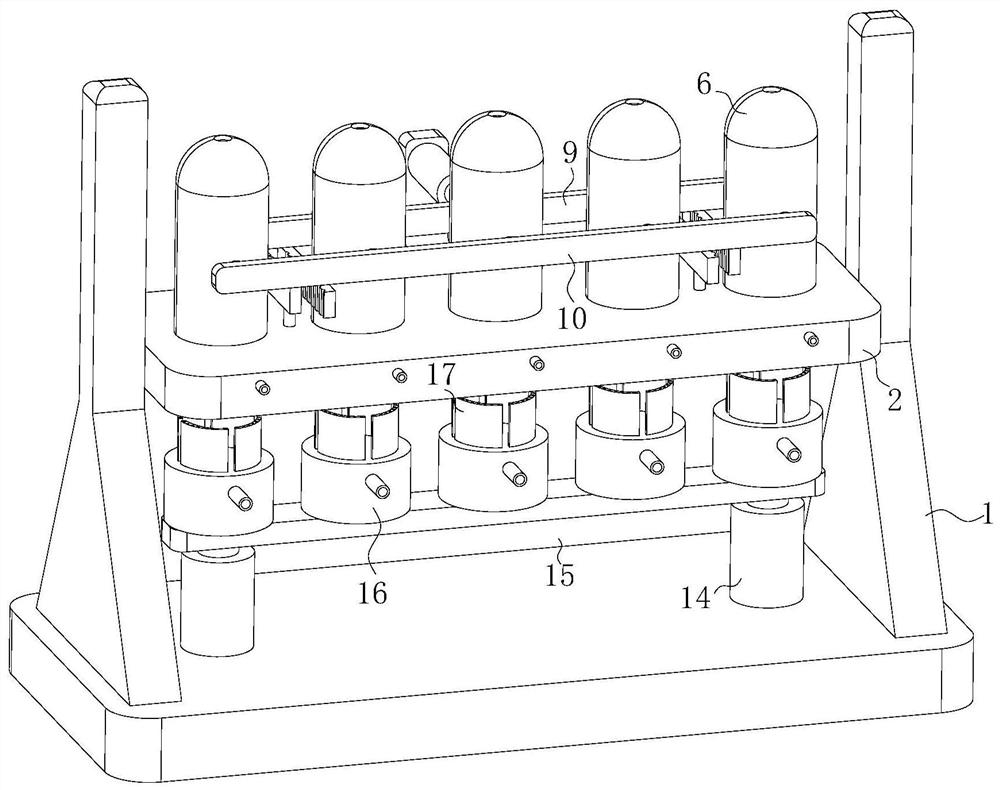

PendingCN113768790AQuick breakGuarantee molding qualityPharmaceutical non-active ingredientsCapsule deliveryPolymer scienceBiomedical engineering

The invention discloses a hydroxypropyl starch empty capsule preparation device and process in the technical field of empty capsule preparation. The hydroxypropyl starch empty capsule preparation device comprises a fixed support, the inner side wall of the fixed support is fixedly connected with a forming plate, and the top of the forming plate is connected with a plurality of groups of capsule molds used for accurately ensuring uniform forming of empty capsules. In each empty capsule production process, outer molds, inner molds and separation mechanisms are matched to form sealed capsule glue injection cavities, and all parts of gaps between the inner molds and the outer molds are consistent, so that all parts of the empty capsules can be filled with the same thickness after the glue injection cavities are filled with glue subsequently, many uncertainties in the glue dipping process are avoided, the forming quality of the empty capsules every time is guaranteed, after glue injection is completed, an opening and closing mechanism is matched with the separation mechanisms to conduct inflation and gas extrusion on the empty capsules from the inner sides of the empty capsules, the empty capsules are made to be rapidly separated from the capsule molds, and production of the empty capsules is facilitated.

Owner:ANHUI UNIVERSITY

Dispensing structure bringing convenience to connection of filtering strip and proximate matter

ActiveCN105521919ABig gapEasy to installLiquid surface applicatorsCoatingsProximateMechanical engineering

The invention relates to a dispensing structure bringing convenience to connection of a filtering strip and proximate matter. The proximate matter is hollowed, an opening part communicated with a hollowed part is arranged at the upper end of the proximate matter, and two dispensing structure bodies are symmetrically installed on two side walls of the opening part; each dispensing structure body comprises a positioning protrusion, a positioning slot and a buckling slot, the vertically-upward positioning protrusions are distributed at the positions, close to the side walls, of the opening part, the lower ends of the positioning protrusions extend to the side wall of the proximate matter and are integrally connected with the inner side wall of the proximate matter, and the positioning slots are distributed in one sides, close to the proximate matter, of the positioning protrusions; and the buckling slots communicated with the positioning slots are transversely formed in the middle portion of the side wall of the proximate matter, and the filtering strip with the two ends matched with the dispensing structure bodies is installed on the opening part. The dispensing structure has the beneficial effects that the structure is simple, and installation is convenient; original insertion installation is changed into buckle installation, so that gaps of the dispensing structure bodies are increased, and the glue injection amount is conveniently controlled; and meanwhile, the convenience is brought to glue injection of a glue injection structure.

Owner:WECO OPTOELECTRONICS

Double-core tail fiber and auxiliary gluing tool thereof

ActiveCN114273159AReduced relative motionImprove work efficiencyLiquid surface applicatorsCoupling light guidesFiberEngineering

The invention relates to the technical field of tail fibers and discloses a double-core tail fiber and an auxiliary gluing tool thereof, the double-core tail fiber comprises a connector, a wire body and a pre-tightening assembly, one end of an optical fiber is inserted into the connector, and the pre-tightening assembly is used for pre-fixing the end, inserted into the connector, of the optical fiber, so that the phenomenon that the optical fiber is damaged when glue is injected into the connector is reduced; the condition that the connector and the optical fiber move relatively is avoided; the auxiliary gluing tool comprises a workbench, a clamping pipe, an impact assembly and a glue injection assembly, the clamping pipe clamps the connector, the impact assembly is used for impacting the pre-tightening piece, the glue injection assembly is used for injecting glue into the connector, and then the effect of improving the production efficiency of a factory on the double-core tail fiber is achieved.

Owner:JIANGSU ETERN OPTOELECTRONICS TECH CO LTD

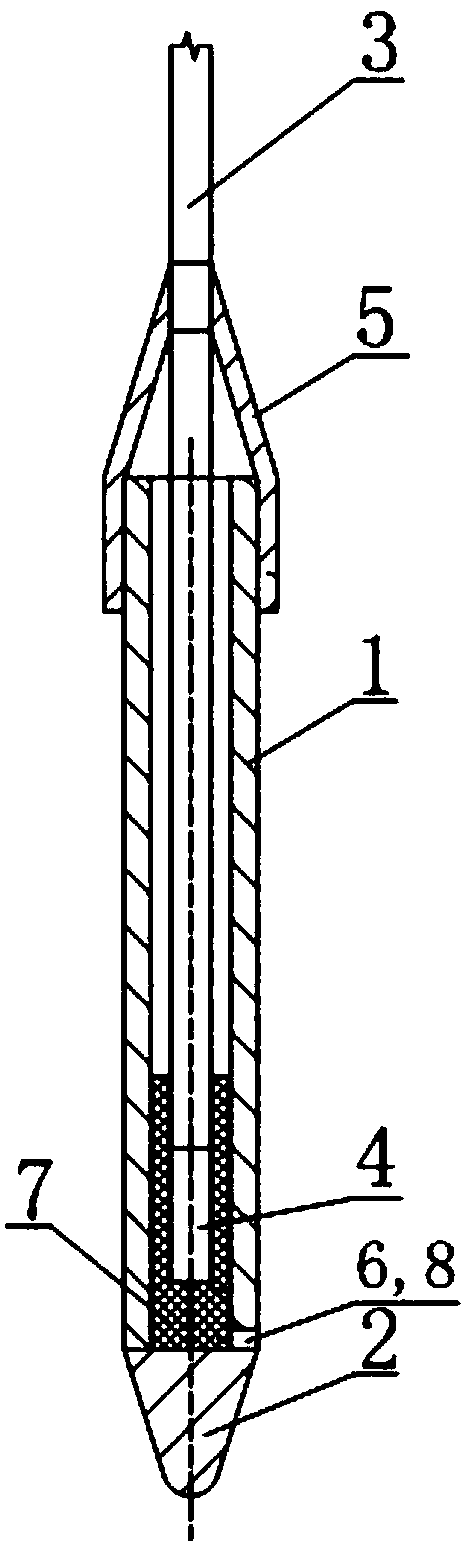

Temperature measurement probe and packaging method

PendingCN107764421AEasy to inject glueGuaranteed to be fully submergedThermometer detailsSyringeThermal conductivity

The invention provides a temperature measurement probe and a packaging method and belongs to the technical field of temperature measurement devices. According to the invention, heat conducting seal glue is injected into a housing via an injection hole arranged on one side, adjacent to a plug, of the housing. An injector or other aid tools can be used for injection. The glue injection process is convenient and quick. According to the invention, the heat conducting seal glue is injected into the housing and then a sensor part provided with a cable is inserted into the heat conducting seal glue.Air extruded during the sensor insertion process runs from the upper part. Then the heat conducting seal glue is injected into the housing via the injection hole again and total immersion of the sensor is ensured and bubble cavities are avoided. Therefore, a problem of measurement precision decrease due to heat conducting glue injection difficulties and internal cavity formation is solved.

Owner:承德兴春和农业股份有限公司

Environment-friendly waterproof cable for underwater decontamination equipment

ActiveCN112071488AImprove waterproof performanceBlock flowSubmarine cablesInsulated conductorsStructural engineeringMechanical engineering

The invention discloses an environment-friendly waterproof cable for underwater decontamination equipment, and the cable comprises a waterproof environment-friendly skeleton located at the innermost layer, and the whole waterproof environment-friendly skeleton is of a cylindrical structure; wherein the surface of the waterproof environment-friendly skeleton is provided with a plurality of caulkingseams which are uniformly spaced and extend towards the inner side, each caulking seam correspondingly points to the circle center of the waterproof environment-friendly skeleton, each caulking seamextends inwards to form a cable core mounting groove, and the cable core mounting grooves are correspondingly and uniformly formed in the waterproof environment-friendly skeleton at intervals, and a power supply cable core, a control cable core and a communication cable core are correspondingly arranged in a cable core mounting groove. The cable is mainly used for underwater decontamination equipment, and the whole operation process of the equipment is carried out underwater, so that the cable needs to have good waterproof performance, and circulation of water and air in gaps of cable cores inthe cable can be blocked.

Owner:黑龙江津达线缆有限公司

Cold-runner mould for thermosetting plastic

Owner:张家港市卓普精密模具有限公司

Automatic production device capable of injecting glue at fixed point for flexible glue dripping doll

InactiveCN112497608AQuality improvementRealize automatic processingMechanical engineeringIndustrial engineering

The invention discloses an automatic production device capable of injecting glue at a fixed point for a flexible glue dripping doll. The automatic production device specifically comprises a bottom plate, a concentric-square-shaped sliding rail, a movable sleeve, a functional base and a rotating disc, wherein the concentric-square-shaped sliding rail is installed in the middle of the top of the bottom plate, sliding blocks are evenly arranged in the concentric-square-shaped sliding rail, the top end of the concentric-square-shaped sliding rail is evenly sleeved with installation sleeves, and the installation sleeves are all connected with the sliding blocks. According to the automatic production device capable of injecting glue at the fixed point for the flexible glue dripping doll, throughthe arrangement of the functional base, a lower die holder is movably connected to the bottom end of the interior of the functional base, and when glue dispensing or glue injection is conducted on the lower die holder, the lower die holder and an upper die holder are staggered in position, so that glue dispensing is conducted on the lower die holder and the upper die holder conveniently, after glue injection is completed, the upper die holder can be turned over by 180 degrees, then the lower die holder returns to the position below the upper die holder to be aligned with the upper die holder,the upper die holder does not need to be turned over manually or an upper die and a lower die do not need to be spliced manually, and use is more convenient and safer.

Owner:重庆数智源智能装备科技有限公司

Hot-melt adhesive type aluminum alloy terminal pressing mold for wire harness fixing

ActiveCN110071407AImprove the fixing strengthFlexible rotationLiquid surface applicatorsDustproof/splashproof/drip-proof/waterproof/flameproof connectionCopper wireAlloy

The invention discloses a hot-melt adhesive type aluminum alloy terminal pressing mold for wire harness fixing. The structure comprises a worktable, a lower pressing mechanism, a rotating rod, a sidefixing plate, an upper stable pressing mechanism, a trapezoidal limit column and a control panel, wherein the lower pressing mechanism is embedded on the upper surface of the worktable. In the hot-melt adhesive type aluminum alloy terminal pressing mold for wire harness fixing provided by the invention, the sealing groove and the sol pressing groove seal and fix the wire harness and the aluminum alloy terminal by providing the upper stable pressing mechanism, which facilitates the injection and pressing at the joint of the wire harness and the aluminum alloy terminal; the conical teeth and thepressing cylinder cooperate with each other to firstly press the aluminum foil and then extrude the surface of the aluminum foil to form a pit, thereby improving the fixing of the aluminum foil to the copper wire and improving the tensile strength with closer contact of the two and better power-on performance; and the multi-page runner and the rebound rod cooperate to control the falling speed and the amount of falling of the size such that the size just wraps the bare copper wire at the joint and the equipment can also be used normally in a humid environment while increasing tensile strength.

Owner:浙江凯思特科技有限公司

A universal fixture for plugging fluid pipelines under pressure

ActiveCN108612954BHigh tensile strengthImprove structural stabilityPipe elementsScrew threadRadial pressure

The invention discloses a universal fixture for fluid pipeline belt pressure leaking stoppage and relates to the technical field of fluid pipelines. The universal fixture for the fluid pipeline belt pressure leaking stoppage comprises an upper clamping collar and a lower clamping collar; sleeves distributed in a circumferential array are fixedly installed on the outer surface of the upper clampingcollar; sleeves distributed in a circumferential array are fixedly installed on the outer surface of the lower clamping collar; a pressure detection meter is fixedly inserted into the right side of the upper clamping collar; the interiors of the sleeves are in threaded insertion with adjusting screw rods; rotary knobs are fixedly installed at the top ends of the adjusting screw rods; and antiskidgrooves laid uniformly are formed in each of the upper side and the lower sider of the front of the upper clamping collar. The universal fixture for the fluid pipeline belt pressure leaking stoppageis high in tensile strength and good in structural stability; enough and lasting radial pressure can be exerted after the clamping collars are tightly hooped so as to allow the fixture to be compressed on the excircle surface of a pipeline, so that the sealability is improved, the leaking stoppage effect is improved, and the potential safety hazard is eliminated; and pressure on the inner side ofthe fixture can be detected in real time, so that a user conveniently judges whether the problem of oil leakage or gas leakage happens according to the pressure on the inner side, and disconnecting detection is avoided.

Owner:HUZHOU BEIDE FLUID EQUIP CO LTD

EEG electrode cap

ActiveCN104382594BEasy to fixExtended service lifeDiagnostic recording/measuringSensorsHigh densityScalp

The invention relates to an EEG electrode cap, comprising a cap body, an electrode and a lead wire; the electrode includes a fixing ring, an electrode sheet and a bonding sealant; the middle part of the fixing ring has a cavity with both ends open and connected, and the electrode is arranged in the cavity Sheet positioning table, the electrode sheet is placed on the electrode sheet positioning table; one side of the electrode sheet is fixed with the inner wall of the fixed ring cavity by bonding sealant, and the other side is combined with the conductive adhesive in the conductive adhesive chamber; the outer cylindrical surface of the fixed ring There are fixed grooves for fixing the electrode and the cap body; after the adhesive sealant is cured, there is a conductive glue hole connected to the conductive glue chamber; the electrode sheet and the lead wire passing through the lead wire hole on the fixing ring line connection. The advantages of the present invention are: the integrated design of the electrode sheet and the fixing ring is convenient for skin pretreatment, glue injection and glue replenishment; convenient and reliable positioning, close fit with the scalp, comfortable to wear, especially suitable for high density, long-term sleep, brain magnetism Figure and EEG measurement in MRI environment.

Owner:WUHAN GREENTEK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com