Battery pack manufacturing method

A manufacturing method and battery pack technology, which is applied in secondary battery manufacturing, battery assembly, final product manufacturing, etc., can solve the problem of uneven thickness of the adhesive layer of battery modules and casings, large differences in waterproof and protective effects, and inability to Meet the use requirements and other issues, and achieve the effects of quality control, convenient glue injection, and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

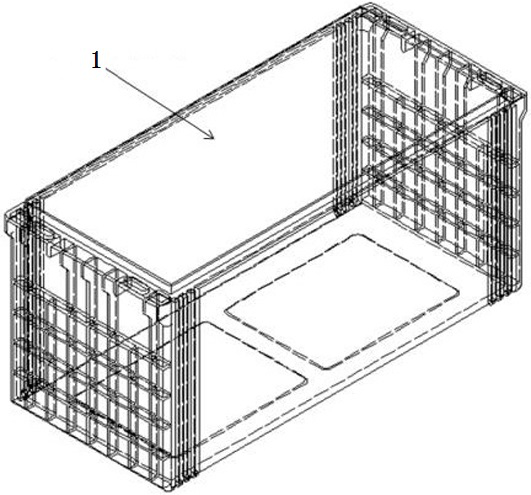

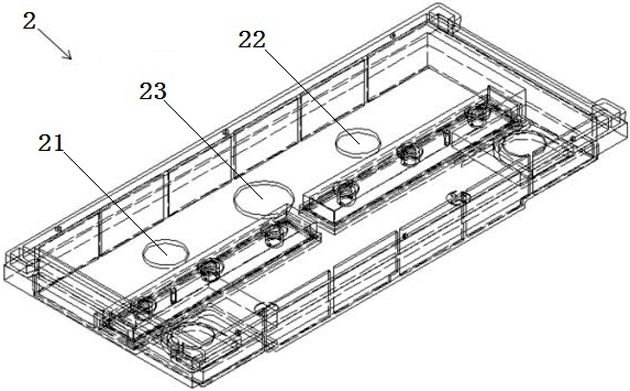

[0021] An embodiment of the battery pack manufacturing method in the present invention is: the battery pack manufacturing method is divided into two steps: the preparation of the casing and the sealing of the battery pack, wherein the preparation of the casing is as follows: figure 1 and figure 2 As shown, the upper case 2 and the lower case 1 need to be prepared, and two outlet holes for the positive lead-out wire and the negative lead-out wire of the battery pack need to be processed on the upper case 2, that is, the positive lead-out hole 21 and the Negative pole outlet hole 22. At the same time, it is also necessary to process a sampling hole 23 on the upper casing 2 for the sampling line of the battery pack to pass through. The sampling line is used to collect operating data such as voltage and temperature of the battery pack, so as to grasp the operation of the battery pack. The above-mentioned positive electrode outlet hole 21, negative electrode outlet hole 22 and sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com