Full-automatic lens glue injection machine capable of realizing multi-body combination

A fully automatic glue injection machine technology, which is applied to household appliances, optical components, and other household appliances. It can solve problems such as easy outflow of glue, excessive tearing tape, and uneven tape application, so as to improve product quality and production. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings.

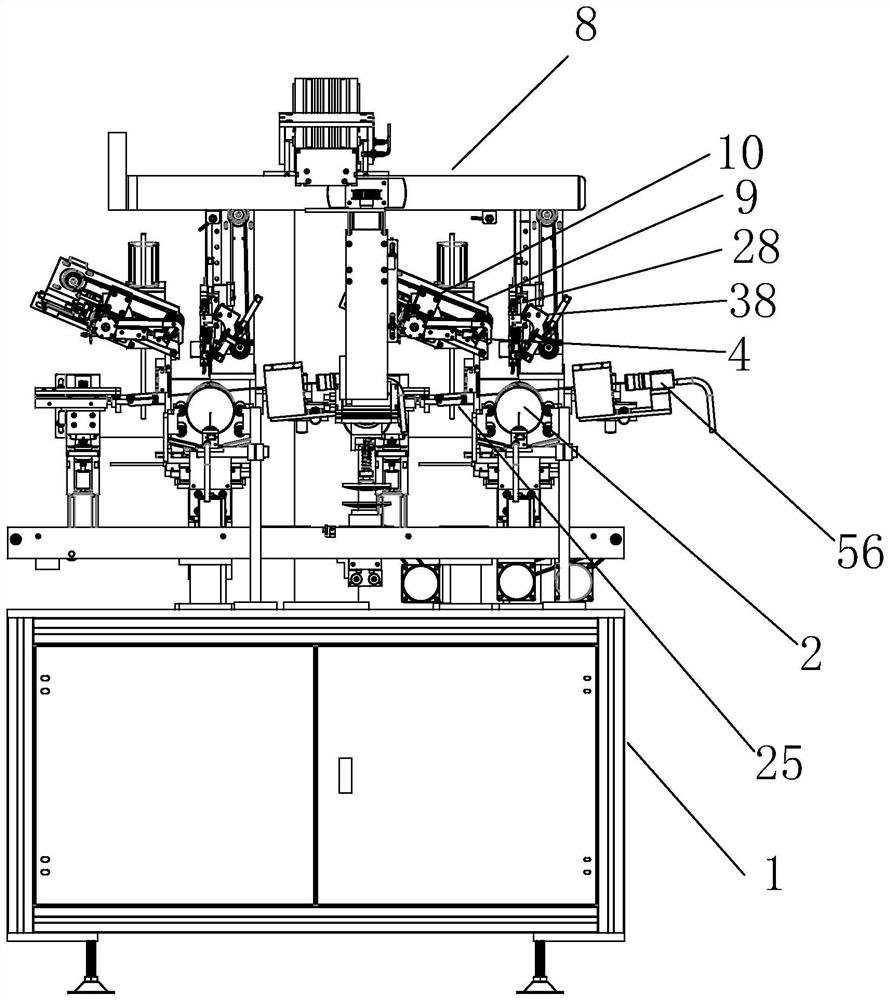

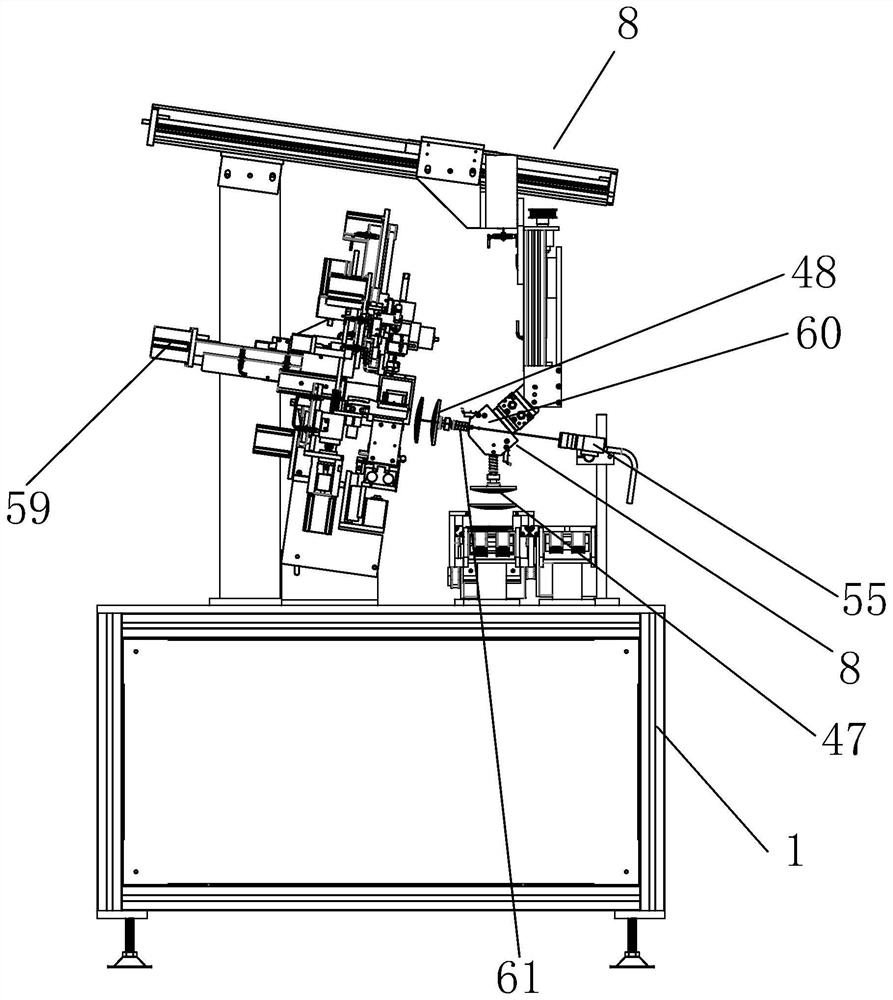

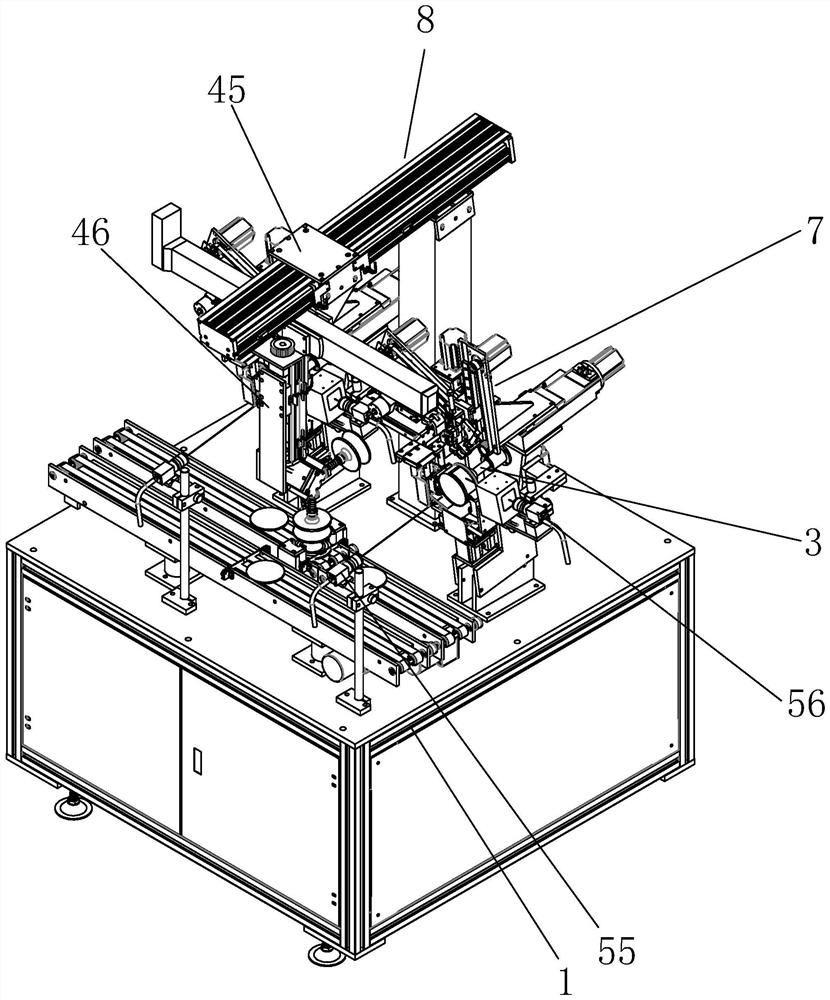

[0029] Such as Figure 1 to Figure 5The shown multi-body combined automatic lens glue injection machine includes a frame 1 and a PLC control unit arranged on the frame 1, and an automatic glue injection device 7 for automatically pouring lenses is set on the frame 1, automatically Glue injection device 7 comprises the main shaft 3 that is used for fixing lens mold 2, and the front end of main shaft 3 is provided with sucker, is provided with the motor 59 that drives main shaft 3 to rotate on frame 1, and the front of main shaft 3 is provided with first vision sensor 55 and front projection. For the light source, a second visual sensor 56 and a side-projection light source are provided on one side of the main shaft 3, and more accurate visual production can be realized by using the visual sensor with the PLC control unit. The lens mold 2 on the suction cup of the main ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com