Manufacturing method of heat preservation box body and heat preservation box body

A manufacturing method and technology of an incubator, which is applied in the production of incubator boxes and in the field of incubator boxes, can solve problems such as poor designability, damage, and poor user experience, and achieve simple manufacturing methods, good impact resistance, and thermal insulation effects Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

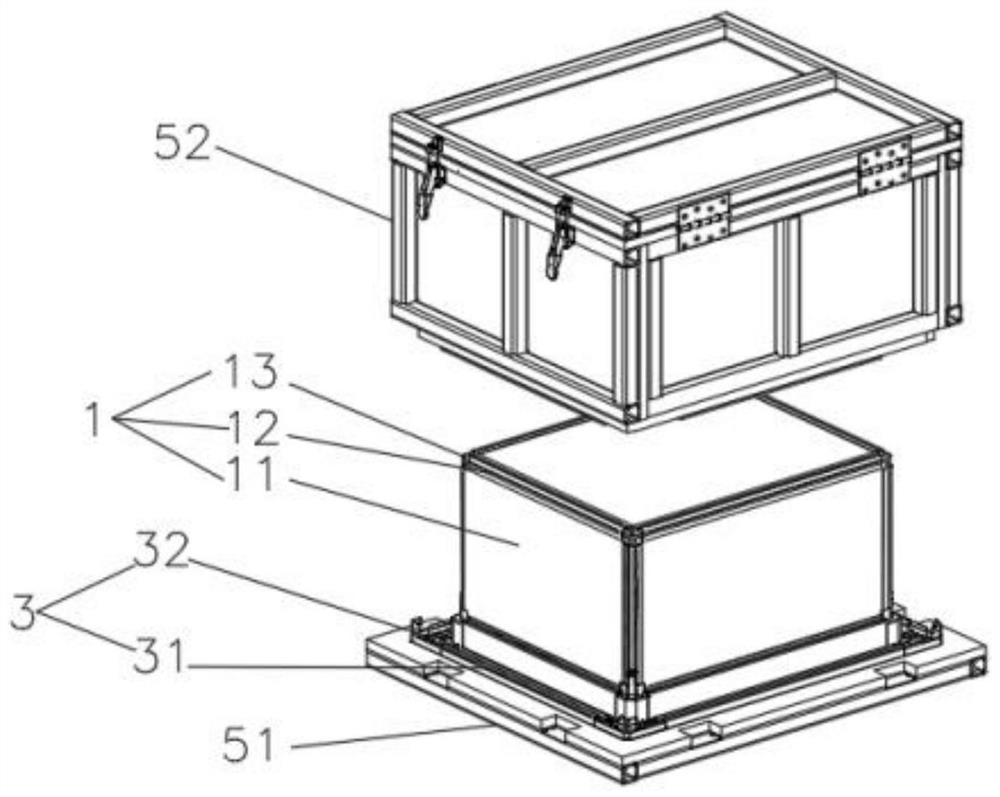

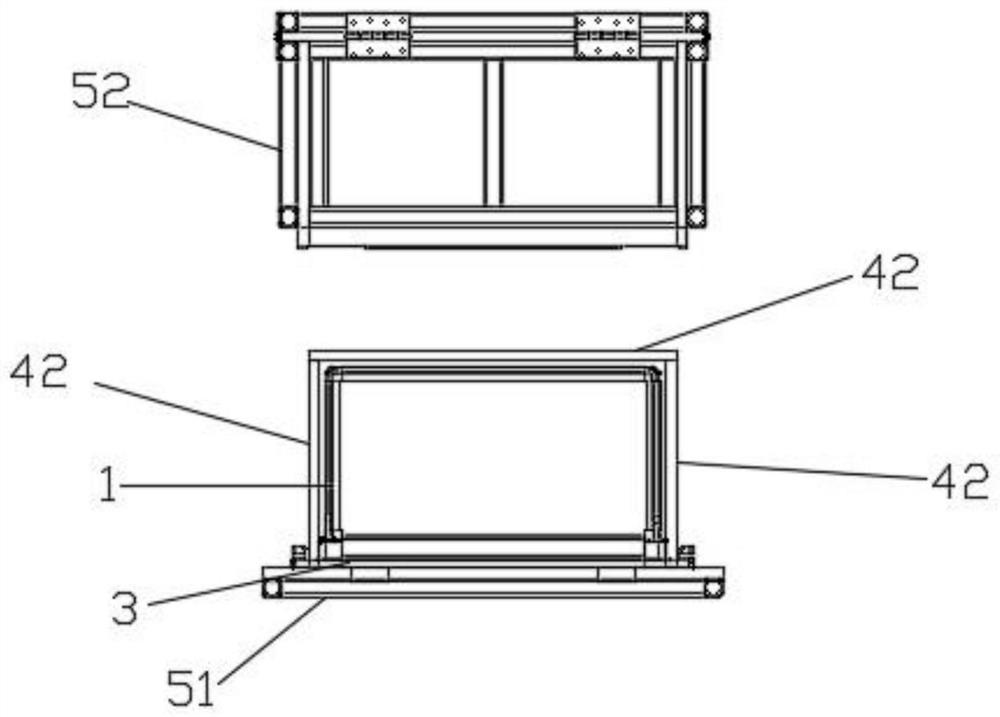

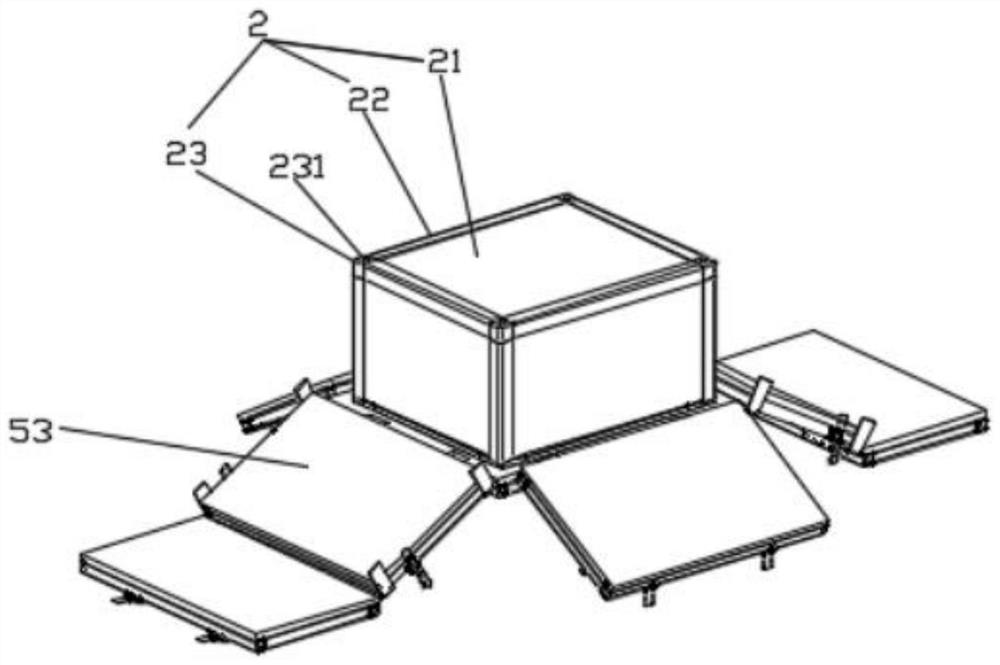

[0055] Such as Figure 1-Figure 13 As shown, the embodiment of the manufacturing method of the incubator box disclosed by the present invention includes the following steps: preparing splicing profiles and connectors: preparing inner wall panels 11, outer wall panels 21, vacuum insulation panels 42, outer box splicing edges 22, inner box Splicing rib 12, box top connecting rib 31, top connector 32, bottom inner connector 13 and bottom outer connector 23;

[0056] Cutting: according to the size of the incubator to be made, cut the inner wall panel 11, the outer wall panel 21, the outer box splicing edge 22, the inner box splicing edge 12, and the box top connecting edge 31, and cut out the required size Inner wall panel 11, outer wall panel 21, outer box splicing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com