Optical fiber collimator assembling and adjusting device

An optical fiber collimator and optical fiber technology, which is applied in the field of optical communication, can solve the problems of increasing production cost, optical fiber damage, and reducing installation and adjustment efficiency, and achieves the effects of improving consistency, high alignment accuracy, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

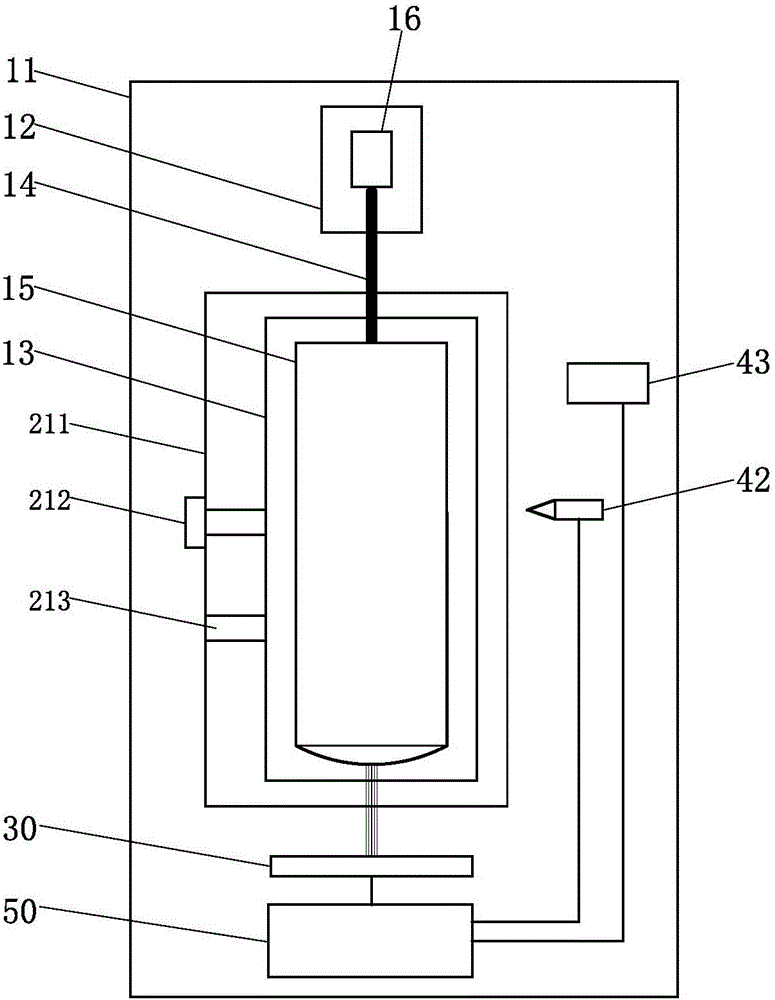

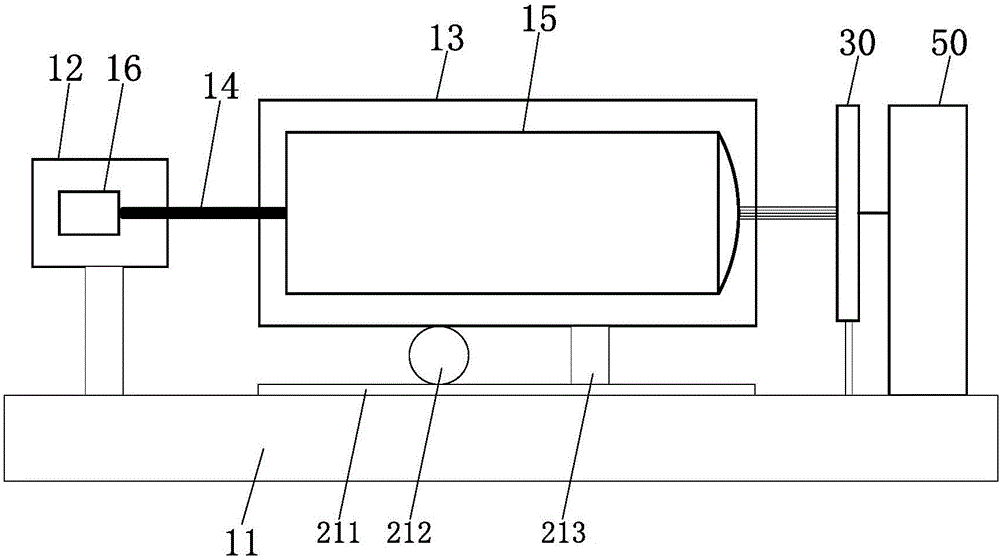

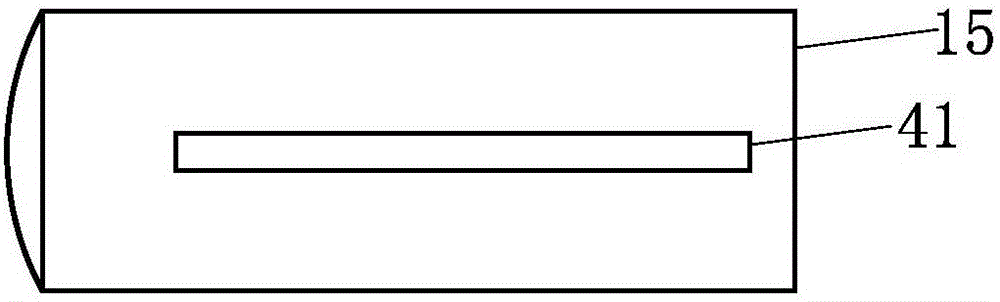

[0032] As another specific embodiment of the present invention, the optical fiber collimator installation and adjustment device also includes a controller 50, which is connected to the first displacement adjustment assembly 21, the spot imaging device 30, the second displacement adjustment assembly 22 and the third displacement adjustment assembly 21 respectively. The displacement adjustment assembly 23; the spot imaging device 30 sends the real-time spot information output by the fiber collimator 15 to the controller 50, and the controller 50 processes and analyzes the real-time spot information. image effect, the controller 50 sends drive information to drive the first displacement adjustment assembly 21 so that the second fixed assembly 13 moves relative to the base 11 to adjust the relative position between the fiber collimator 15 and the optical fiber 14; if the real-time spot information meets the control If the spot image effect pre-stored in the controller 50 is used, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com