Double-core tail fiber and auxiliary gluing tool thereof

A core tail and glue technology, which is applied to the surface coating liquid device, optical waveguide coupling, coating, etc., can solve the problems of low production efficiency of pigtails, achieve the effect of facilitating glue injection and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

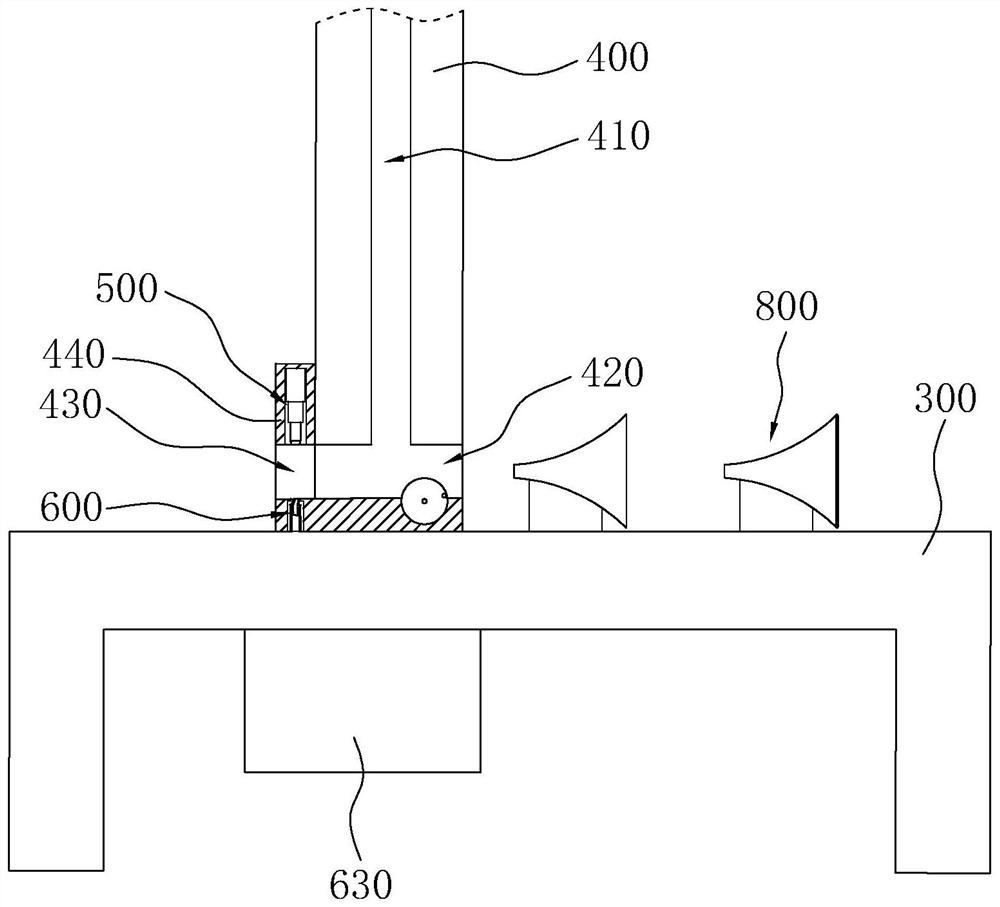

[0040] The following is attached Figure 1-6 The application is described in further detail.

[0041]The embodiment of the present application discloses a dual-core pigtail.

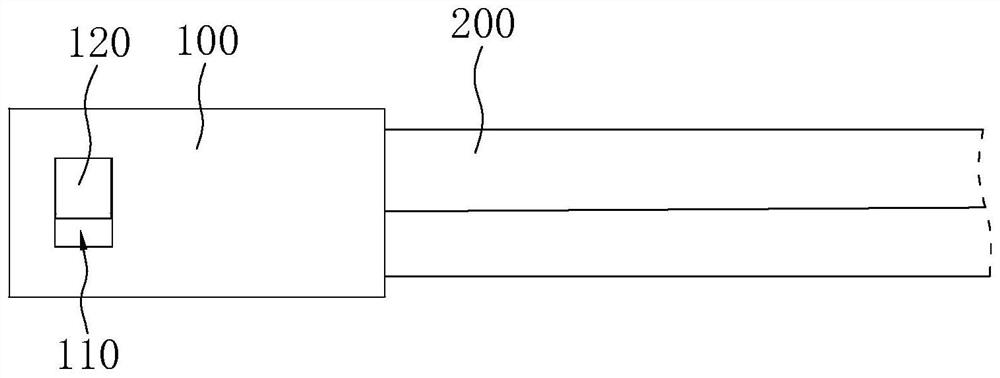

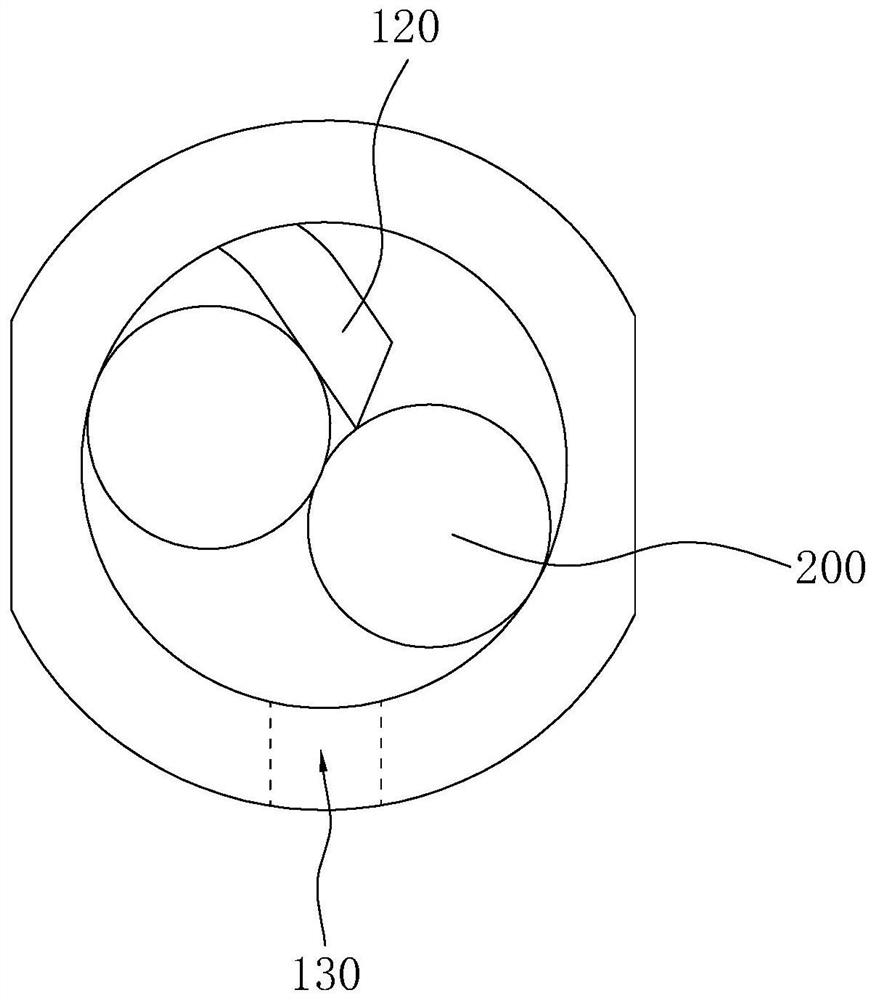

[0042] refer to figure 1 , a dual-core pigtail includes a connector 100 and two optical fibers 200, wherein the connector 100 itself has a central hole, and the connector 100 is provided with a pretensioning component. One end of the two optical fibers 200 is inserted into the central hole of the connector 100, and the pretensioning assembly is used to pre-fix one end of the optical fiber 200 inserted into the connector 100, and the connector 100 and the optical fiber 200 are fixedly connected by injecting glue into the central hole together. By pre-fixing the optical fiber 200 with a pre-tightening component, it is possible to reduce the relative movement between the connector 100 and the optical fiber 200 when injecting glue into the connector 100, thereby reducing the need for workers to make relat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com