Hydroxypropyl starch empty capsule preparation device and technology

A technology of hydroxypropyl starch and hollow capsules, which is applied in capsule delivery, medical preparations of non-active ingredients, drug delivery, etc. It can solve problems such as difficult separation, glue flow, missing thickness of capsules, etc., to avoid uncertainty , Guarantee the effect of molding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

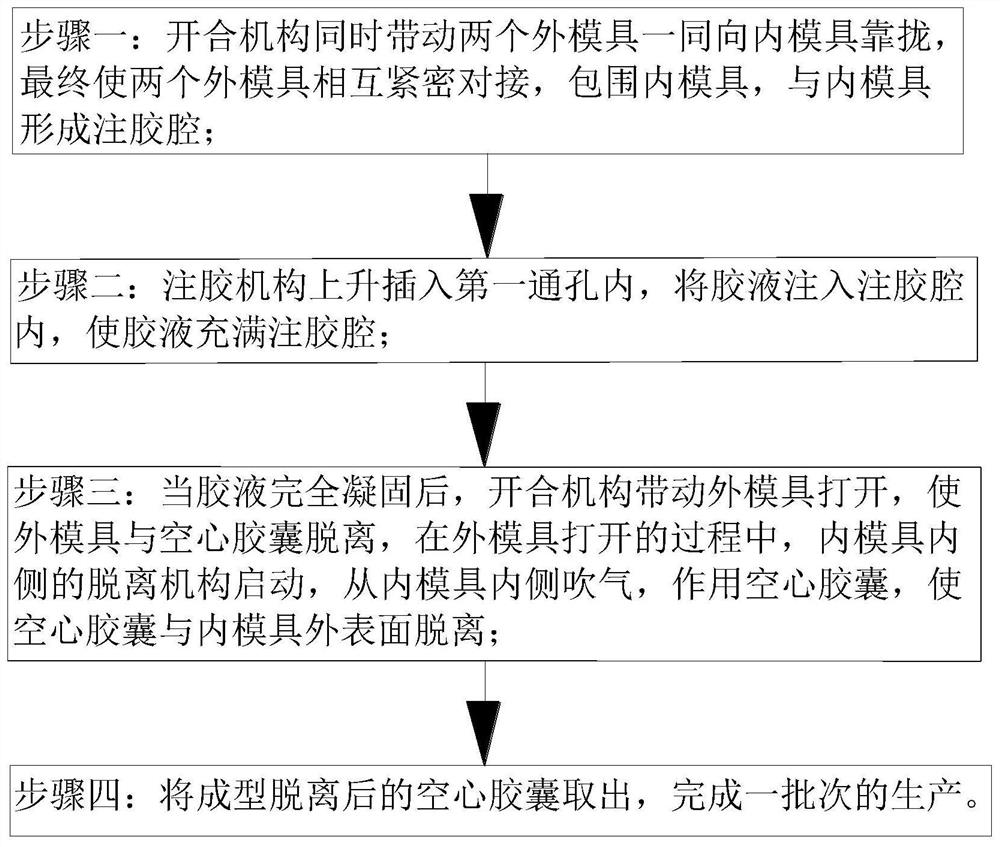

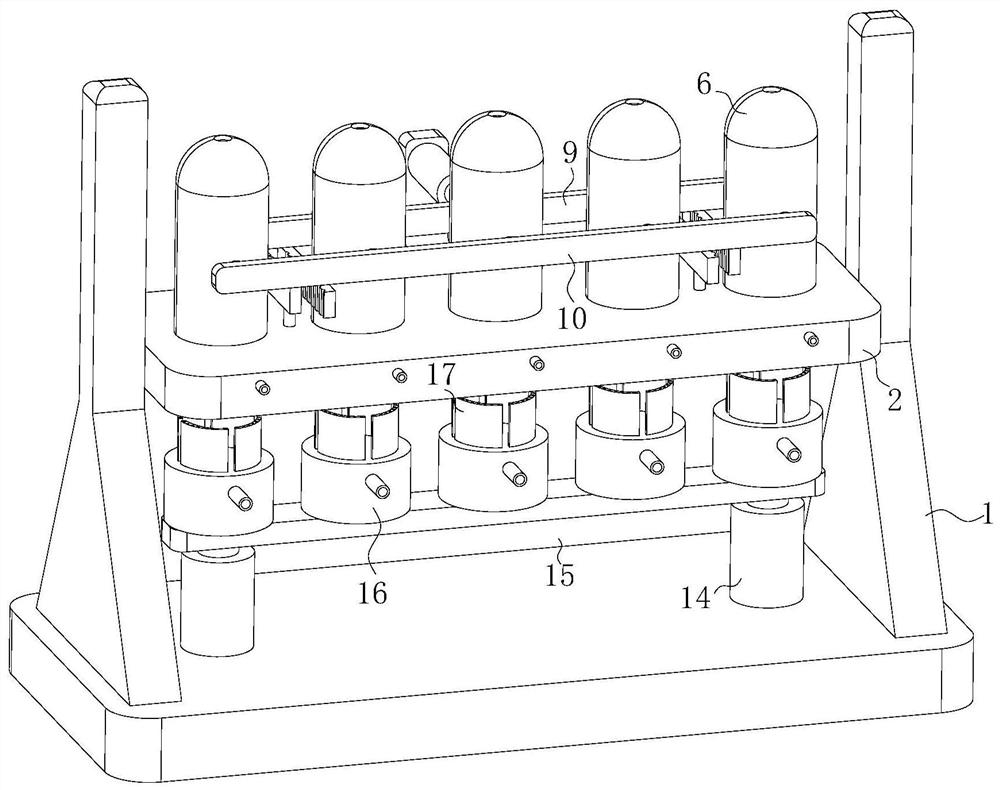

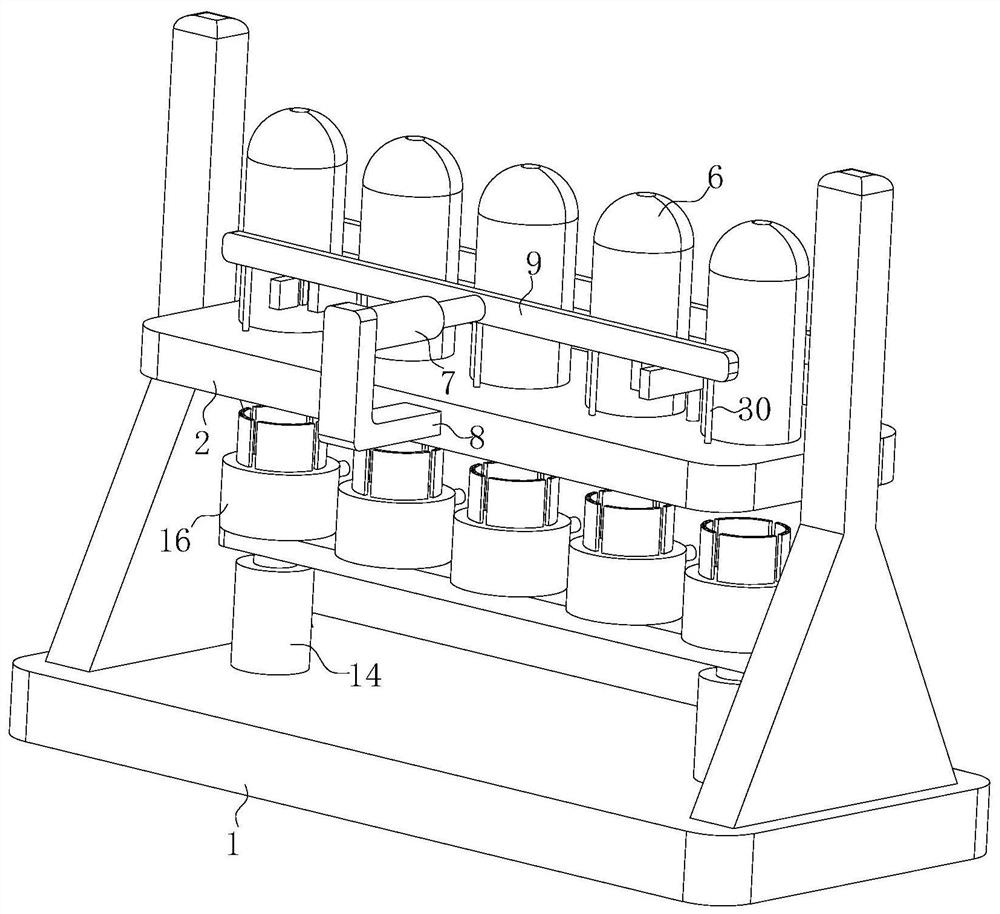

[0035] see Figure 1-11 , the present invention provides a technical solution: a hydroxypropyl starch hollow capsule preparation device, including a fixed bracket 1, a molding board 2 is fixedly connected to the inner wall of the fixing bracket 1, and several groups are connected to the top of the molding board 2 for accurate assurance Hollow capsules are uniformly molded into a capsule mold, the inside of the forming plate 2 is provided with a number of first through holes 3, the bottom of the forming plate 2 is provided with a glue injection mechanism for inserting into the first through holes 3 to inject glue into the capsule mold, and the top of the forming plate 2 is provided There is an opening and closing mechanism for driving several capsule molds to open and close at the same time, and each capsule mold is equipped with a disengagement mechanism for blowing air to the formed capsule when the opening and closing mechanism drives the capsule mold to open to make it quick...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com