Accurate axial centering device for wire harness

A centering device and axial technology, applied in the manufacture of wire harnesses, conductor/cable insulation, electrical components, etc., can solve the problems of surface glue overflow, hidden quality, waste of manpower, etc., to ensure stability and reliability, The effect of product quality improvement and convenient pick-and-place process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing.

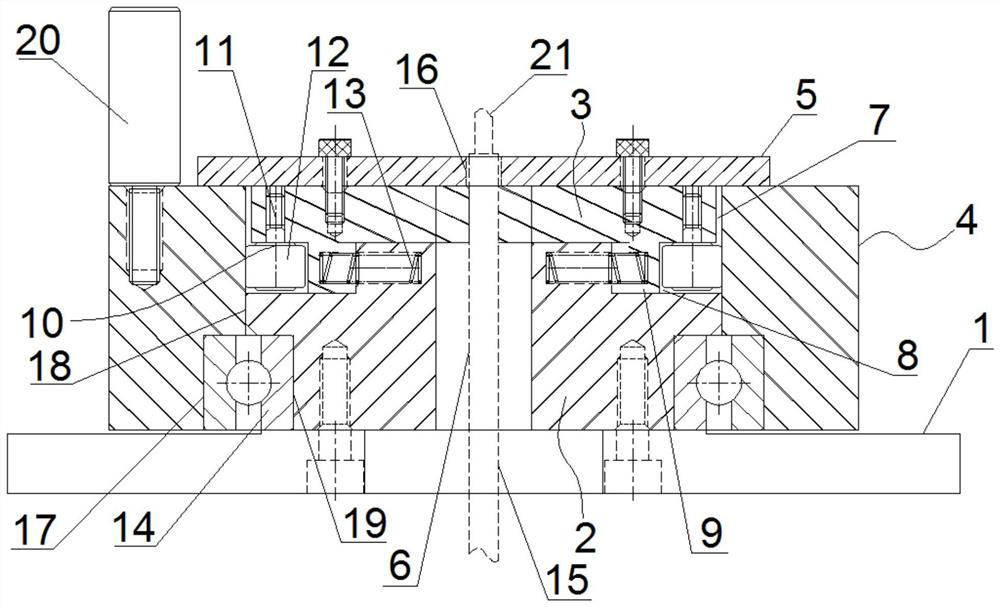

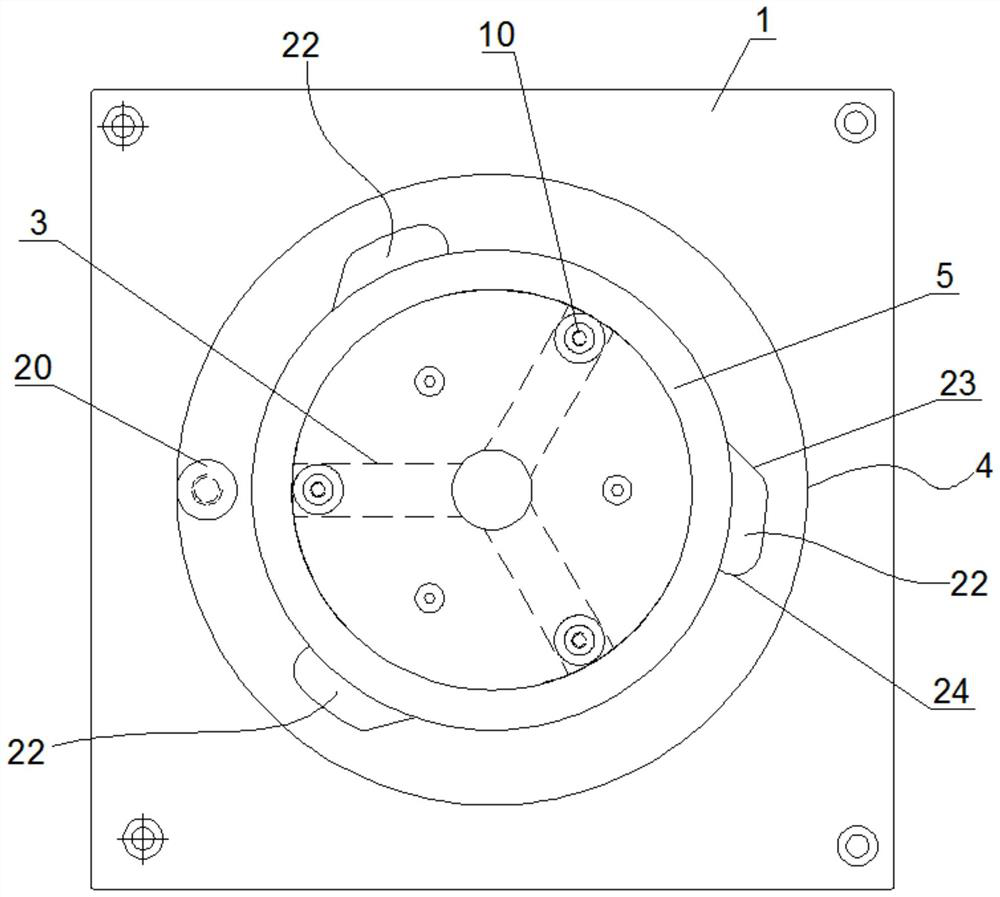

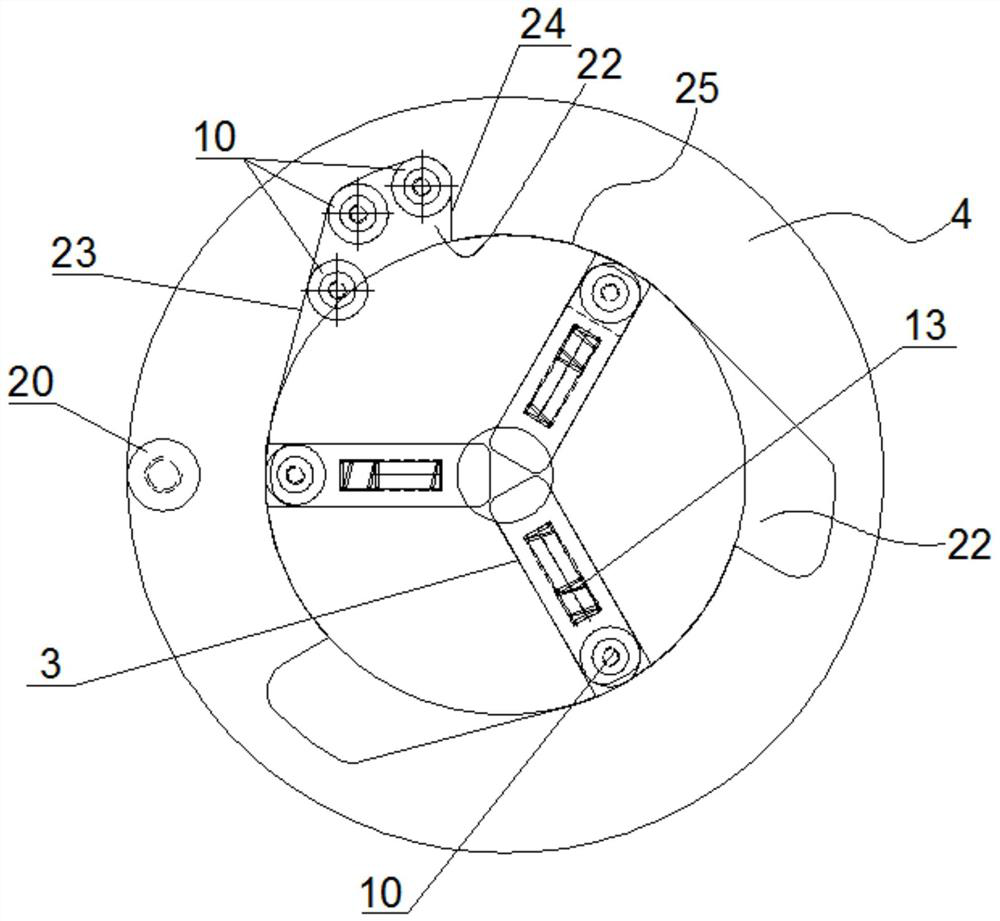

[0020] Such as Figure 1 to Figure 3 As shown, a precise axial centering device for a wire harness includes a supporting fixed plate 1, a jaw seat 2, a mechanical jaw 3, a rotating sleeve 4 and a cover plate 5;

[0021] The center of the supporting and fixing plate 1 is provided with a wire hole B15;

[0022] The jaw seat 2 is fixedly connected to the center of the upper end surface of the support fixed plate 1, and the axis of the jaw seat 2 is provided with a wire-passing hole A6, and the wire-passing hole A6 and the wire-passing hole B15 are coaxially arranged; 2 A plurality of radial chute A7 is evenly opened in the circumferential direction of the upper part, and a plurality of radial chute B8 is correspondingly opened in the lower part of the plurality of radial chute A7; the radial chute A7 is a radial through groove , its two ends are respectively connected throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com