Glue injection packaging machine

A technology of glue injection bag and packaging machine, which is applied to the device and coating of the surface coating liquid, which can solve the problems of high technical requirements for workers, low production efficiency, and tiredness of workers, and achieve low technical level requirements. The injection amount is flexible and controllable, and the effect of uniform injection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Embodiments of the present invention are described in detail below.

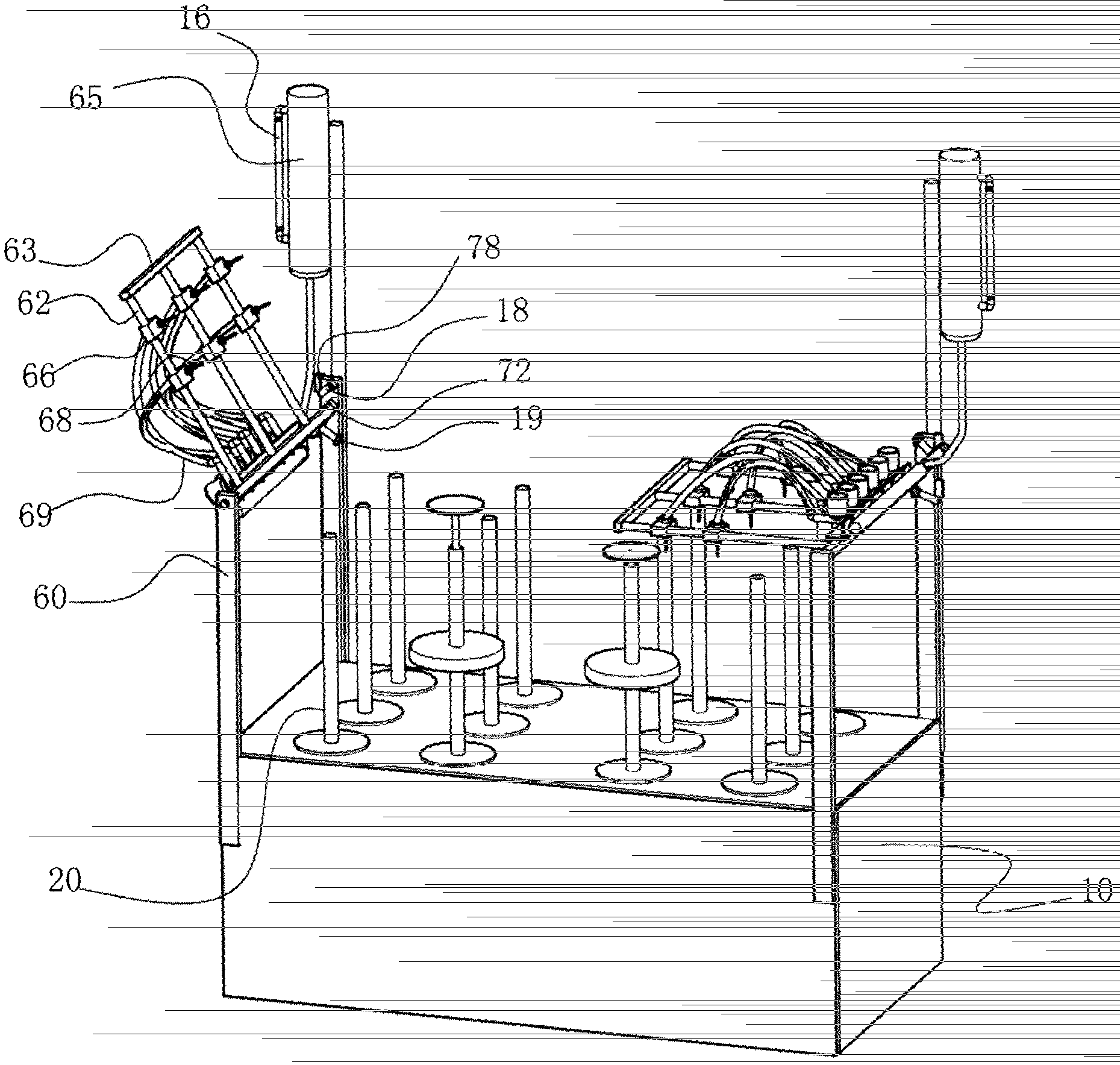

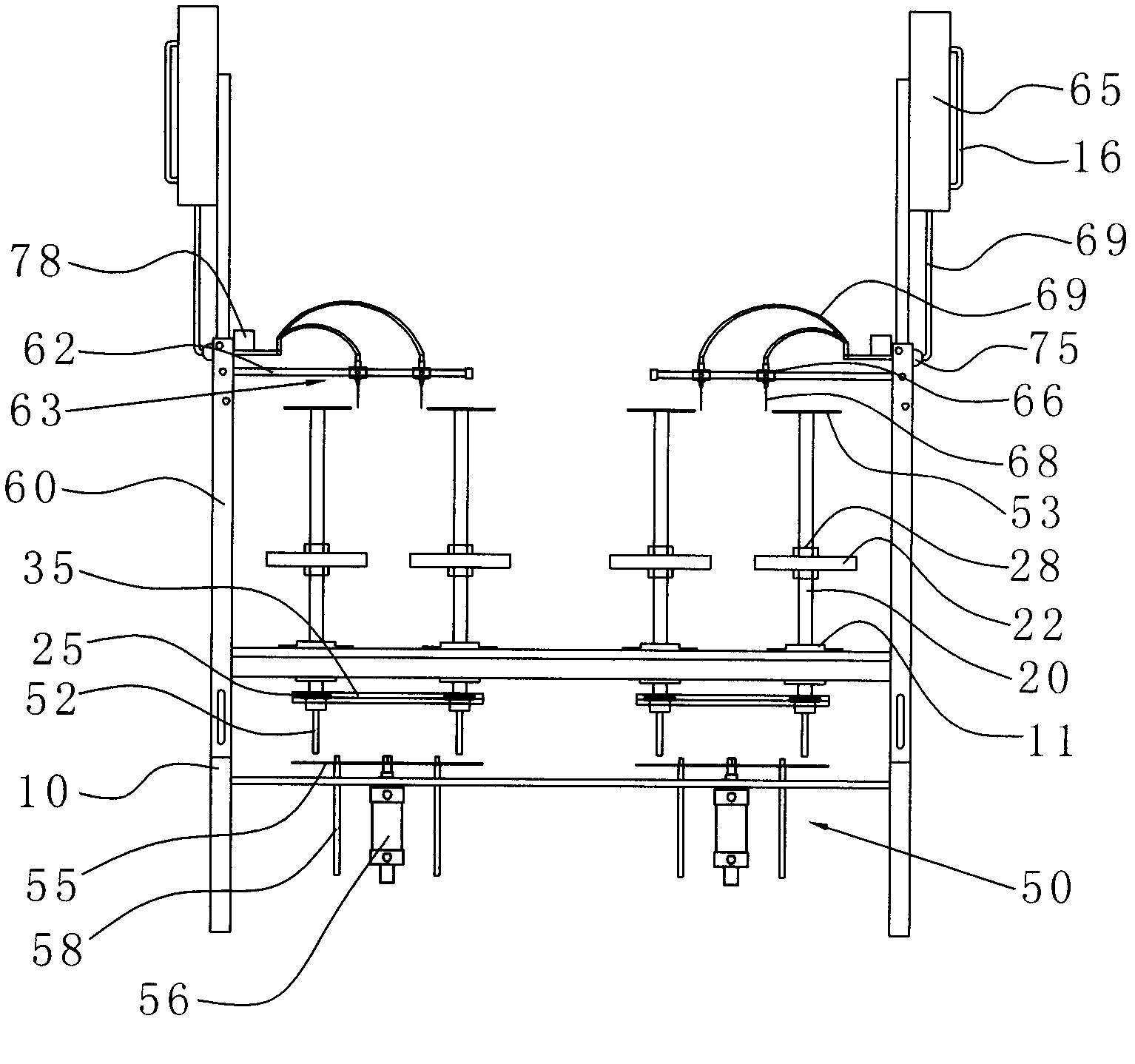

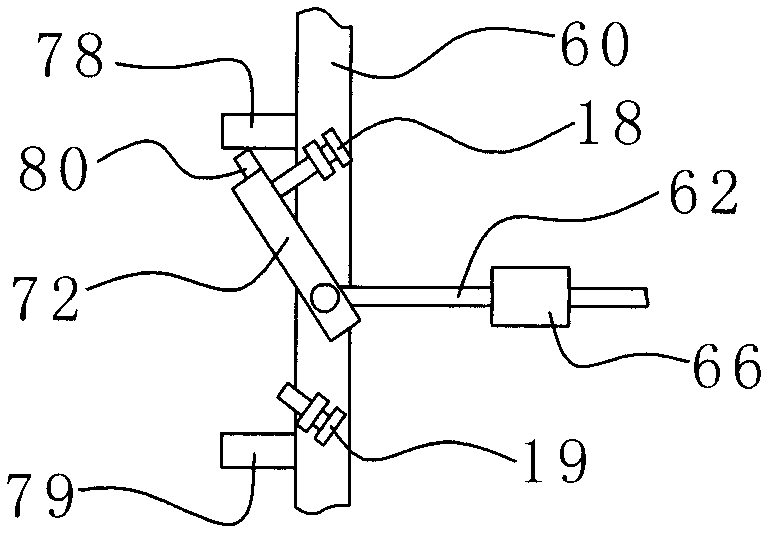

[0021] refer to Figure 1 to Figure 5 As shown, a glue injection packaging machine of the present invention is used to make cylindrical packages. The glue injection packaging machine includes a machine base 10 and a hollow tubular mold that is rotatably mounted on the machine base 10 through a bearing seat 11. Shaft 20, a mold 22 screwed to the mold shaft 20, a transmission wheel 25 fixedly connected to the mold shaft 20, a driving device 30 fixedly connected to the base 10 and connected to the transmission wheel 25, fixed The ejector demoulding device 50 connected to the support 10, the support 60 fixedly connected to the support 10, the dial 63 with the supporting rod 62 hinged to the support 60, the support 60 fixedly connected to the support 60 The glue tank 65 , the sleeve head 66 slidably sleeved on the supporting rod 62 , the needle nozzle 68 connected to the sleeve head 66 , the glue guide tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com