PCBA automatic glue injection equipment

A technology of glue injection and equipment, which is applied in the direction of coating, liquid coating device on the surface, etc., can solve the problems of single mobile glue injection, poor glue fluidity, hidden quality hazards, etc., achieve uniform glue injection, improve efficiency, and reduce replacement cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

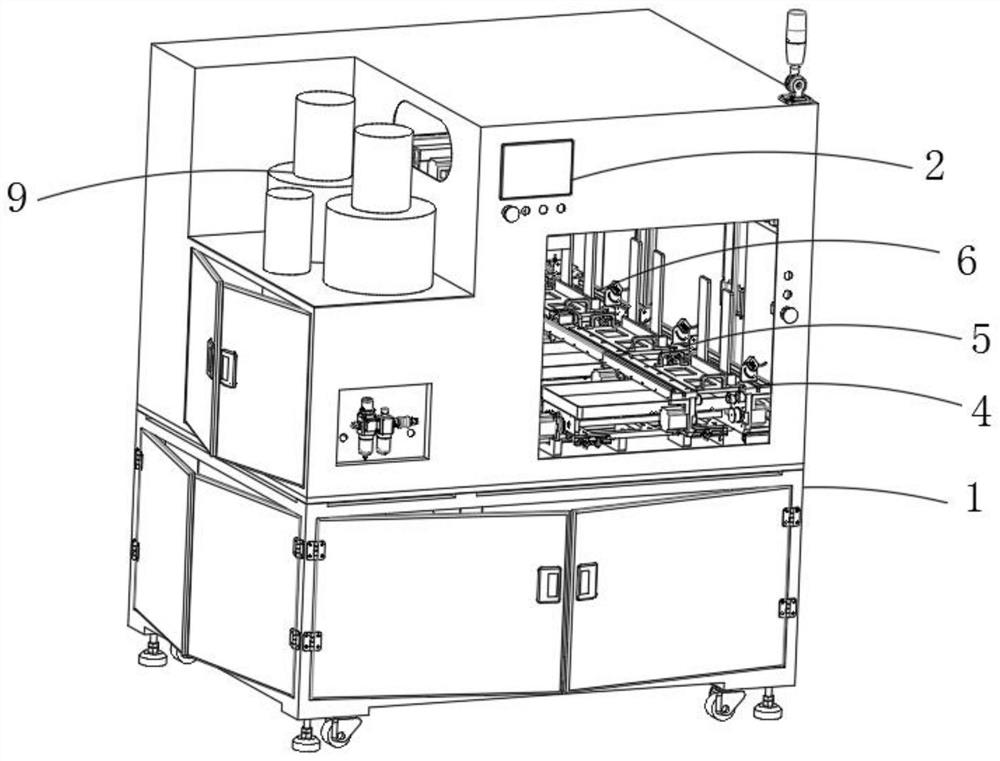

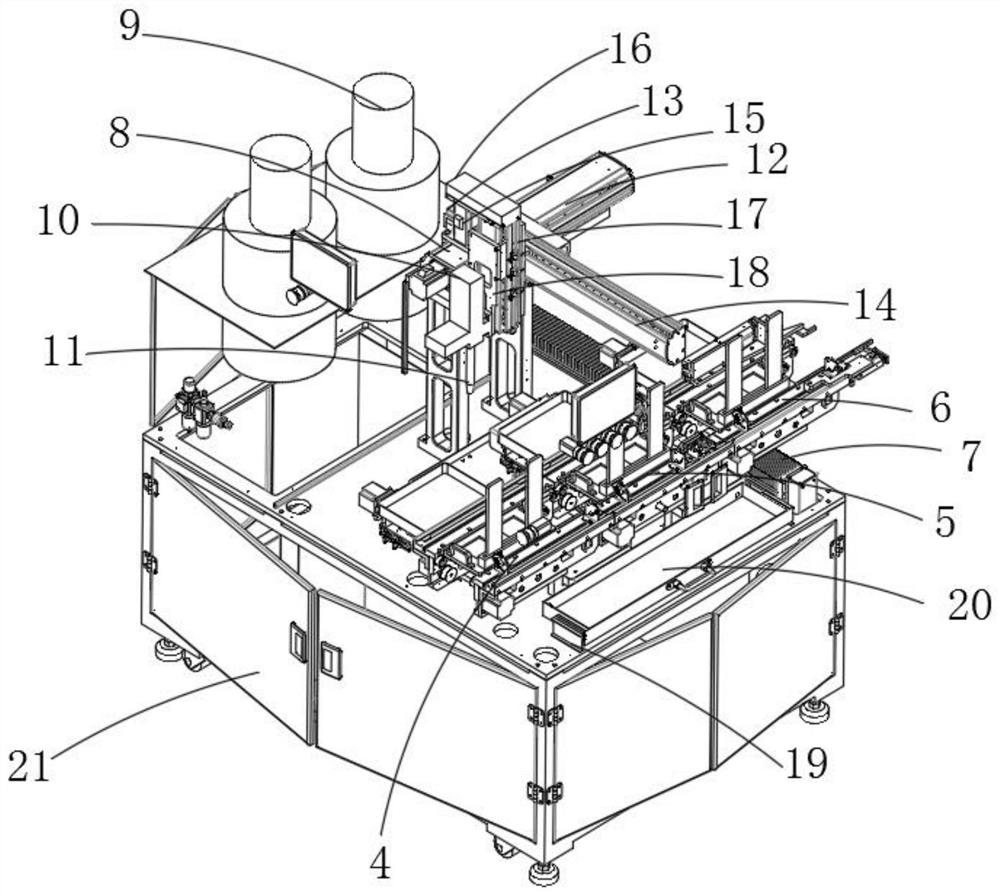

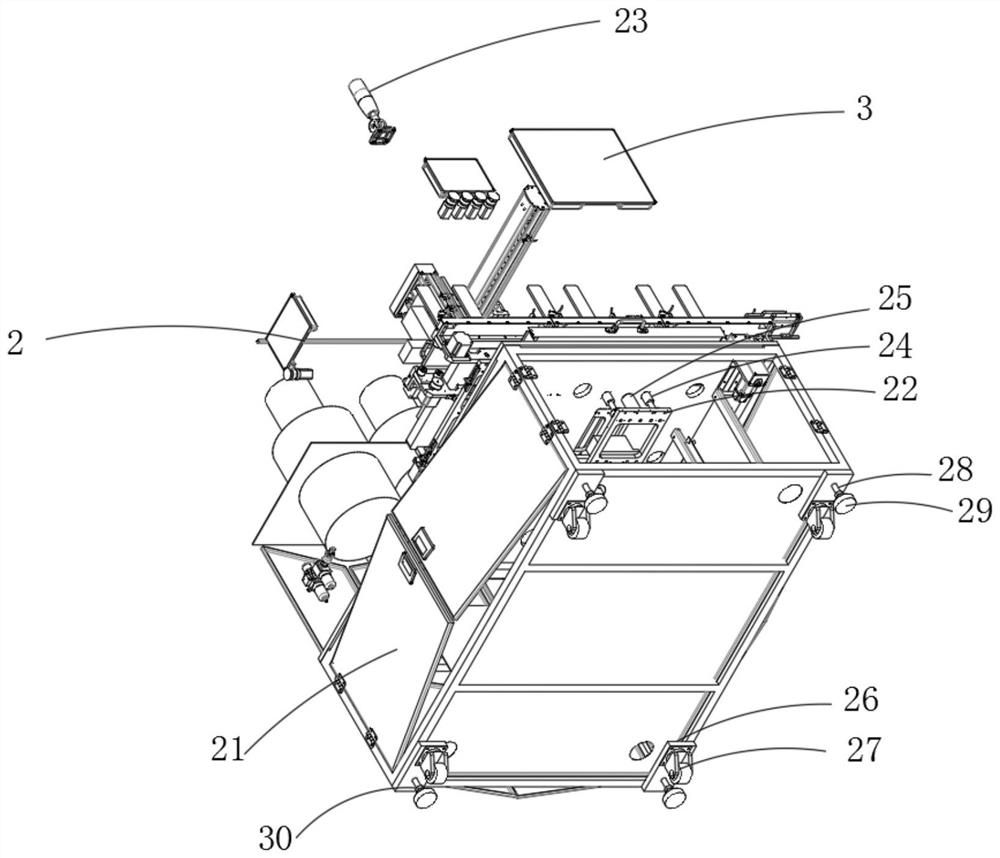

[0031] Example 1: as Figure 1-5The use method of the described PCBA automatic glue injection equipment is as follows: when using the present invention, firstly, the equipment is moved to a corresponding position, and the PCBA is started to be driven into by the feed flow channel mechanism 4, and the vibration flow channel mechanism 5 vibrates the PCBA, The glue injection moving module 8 moves the glue injection, the placement flow channel mechanism 6 drives the PCBA, the swing plate module 7 selects and places the PCBA, and the placement flow channel mechanism 6 moves the PCBA to complete the glue injection and enter the next process. The material flow channel mechanism 4 senses the PCBA to enter and circulate in sequence, the transmission flow channel drives the PCBA flow, the module mechanism drives the glue injection mechanism to inject glue, the vibration mechanism vibrates the PCBA to improve the fluidity of the glue, and the flow channel swing plate mechanism places the ...

Embodiment 2

[0032] Example 2: Structural design of PCBA automatic glue injection machine: 2mm thick iron sheet material is used to make the outer frame and electric control board, and 16mm thick 45# material is used to make the bottom plate; the appearance size of the overall platform is 1400*1100*1650mm; PLC / Industrial computer controls the overall circuit; cylinder and motor / servo motor transmission mechanism; glue injection mechanism; use touch screen / display for parameter setting, data statistics and management.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com