Multi-sprayer glue injector

A glue injection machine and multi-nozzle technology, which is applied in the field of glue injection machines, can solve problems such as uneven product thickness, difficult quality assurance, and low safety, and achieve a stable glue injection mixing ratio and output, reduced energy consumption, and safety The effect of sexual security

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The specific structure of the present invention will be further described below in conjunction with the accompanying drawings.

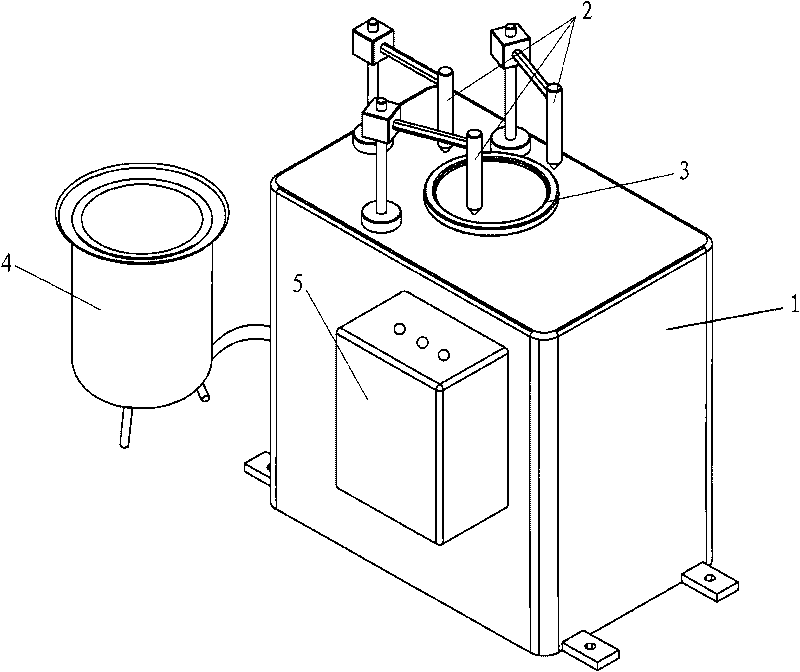

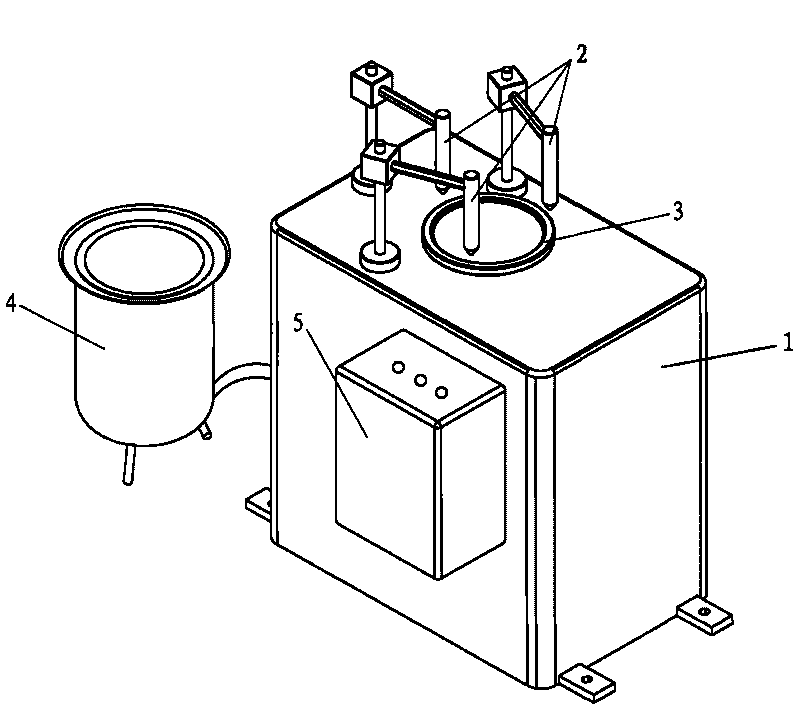

[0010] as attached figure 1 As shown, a multi-nozzle glue injection machine includes a body 1, a nozzle 2 fixed on the body 1 for glue injection, a rotatable tray 3 placed under the nozzle 2, and a rotatable tray 3 for providing glue. The glue tank 4 of the material, the nozzle 2 and the glue tank 4 are connected by pipelines, the number of the nozzle 2 is three, and the nozzle 2 is facing the edge of the pallet 3, so The above-mentioned spray heads 2 are evenly distributed on the same circle, and this circle is concentric with the above-mentioned tray 3, so that the distances between the three spray heads 2 and the edge of the tray 3 are equal. The multi-nozzle glue injection machine also includes a PLC control electric box 5, and the said spray head 2 and the said tray 3 are electrically connected with the said PLC control electric box 5. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com