Joint cleaning and filling device

A cleaning device and seam cleaning technology, applied in the field of ceramic tile beauty seams, can solve the problems of high cost, time-consuming and laborious, and achieve the effects of avoiding pollution, reducing rotational speed and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Below in conjunction with accompanying drawing and specific embodiment, the present invention is further explained and illustrated, and it should be noted that the present invention is not limited to following specific embodiment, and all equivalent transformations done on the basis of the technical solution of the present application all fall within the scope of protection of the present invention .

[0046] Below in conjunction with accompanying drawing, structure of the present invention will be further described:

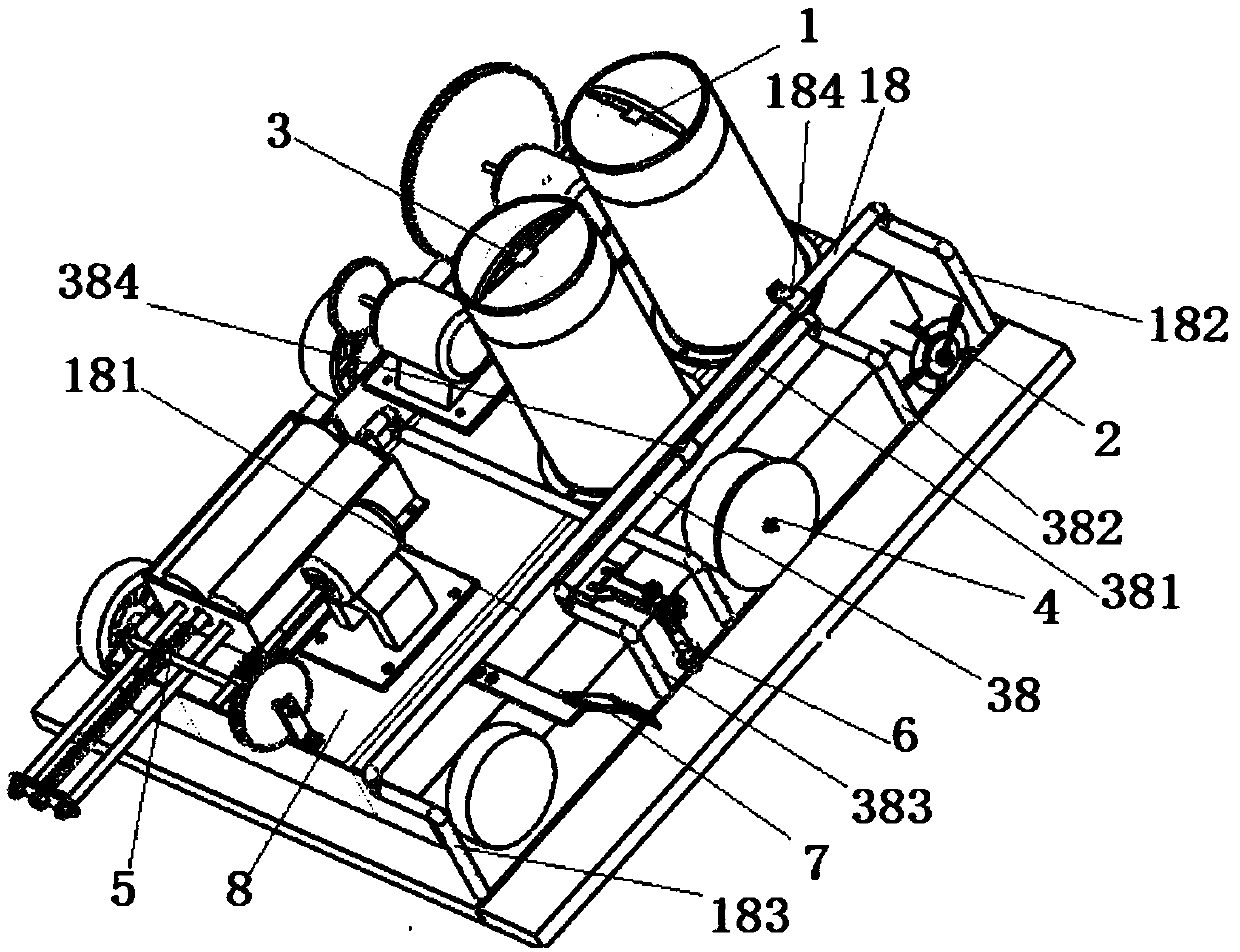

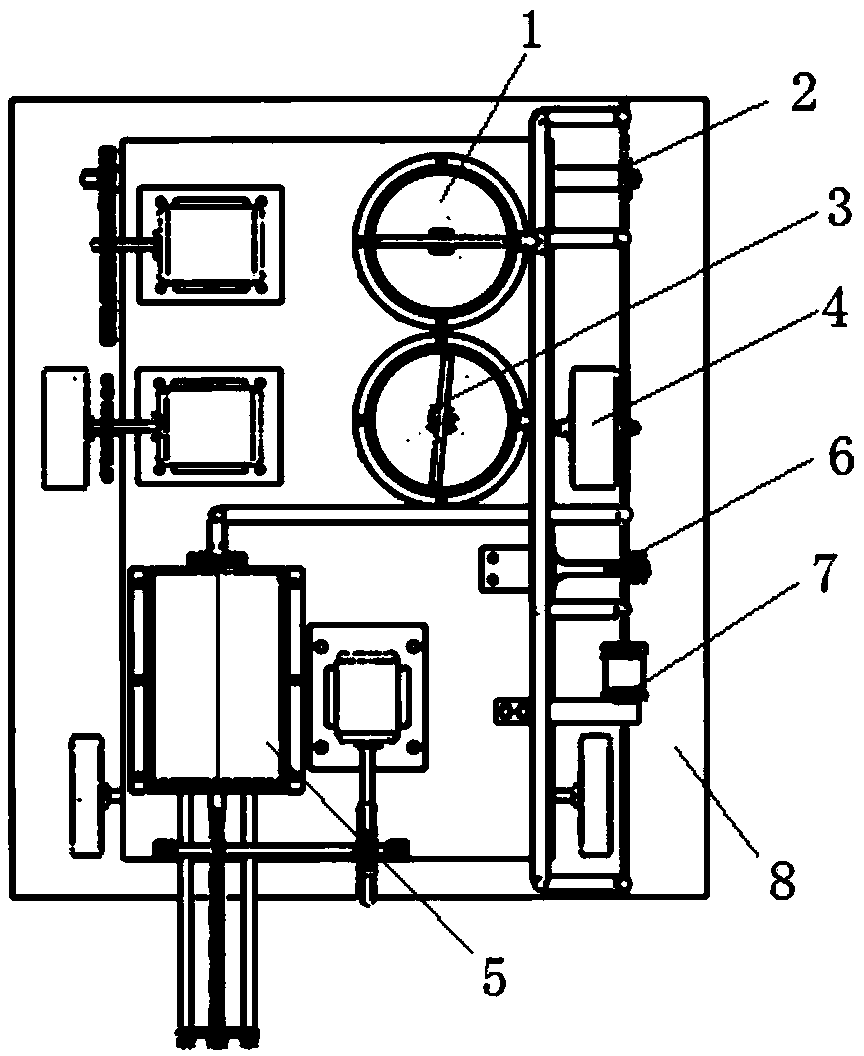

[0047] Reference attached figure 1 , 2 As shown, a seam cleaning and filling device of the present invention includes a base 8 and a dust suction device 1 installed on the base 8, a gap cleaning device 2, a hot air device 3, a guiding drive device 4, a glue injection device 5, and a groove surface compaction device. Device 6, groove surface cleaning device 7 and base 8;

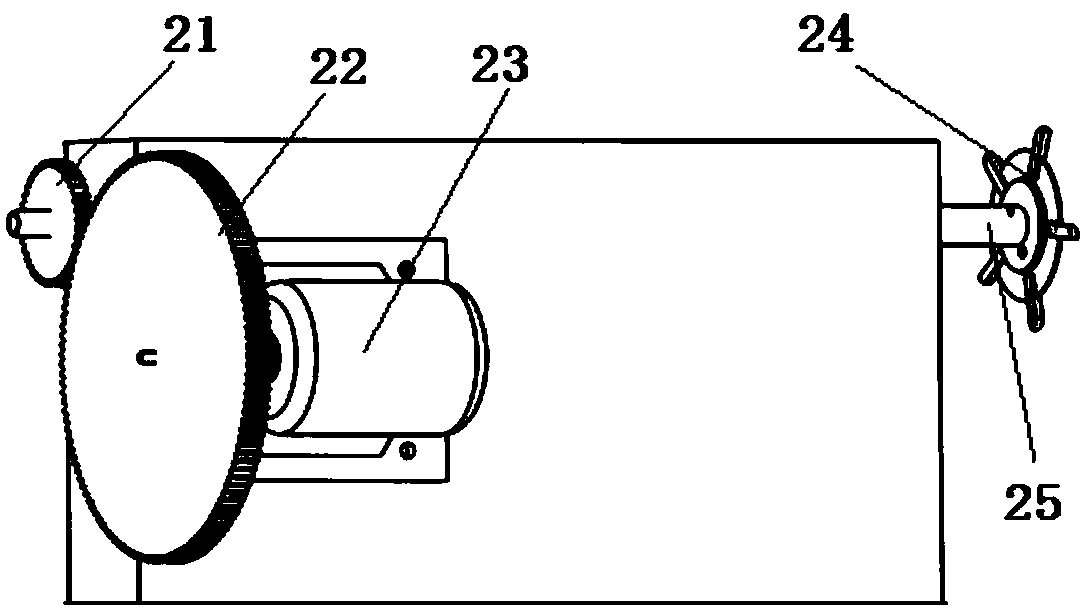

[0048] Reference attached Image 6 , 7 As shown, the ash suction device 1 inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com