A method and system for intelligent glue injection and feeding on an automated shoemaking production line

A technology of feeding system and production line, which is applied in the direction of shoe-making machinery, footwear, bonding shoe parts, etc. Increase or decrease the flow rate of glue injection, the effect of maintaining uniform glue injection volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the object, technical solution and advantages of the present invention more clear and definite, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

[0034] In the shoemaking process, glue injection is a very important process, especially the common cloth shoes with polyurethane foam soles. Due to the defects of existing manual glue injection, the present invention provides an intelligent system to solve the problem of automatic glue injection, especially the uniformity and accuracy of glue injection.

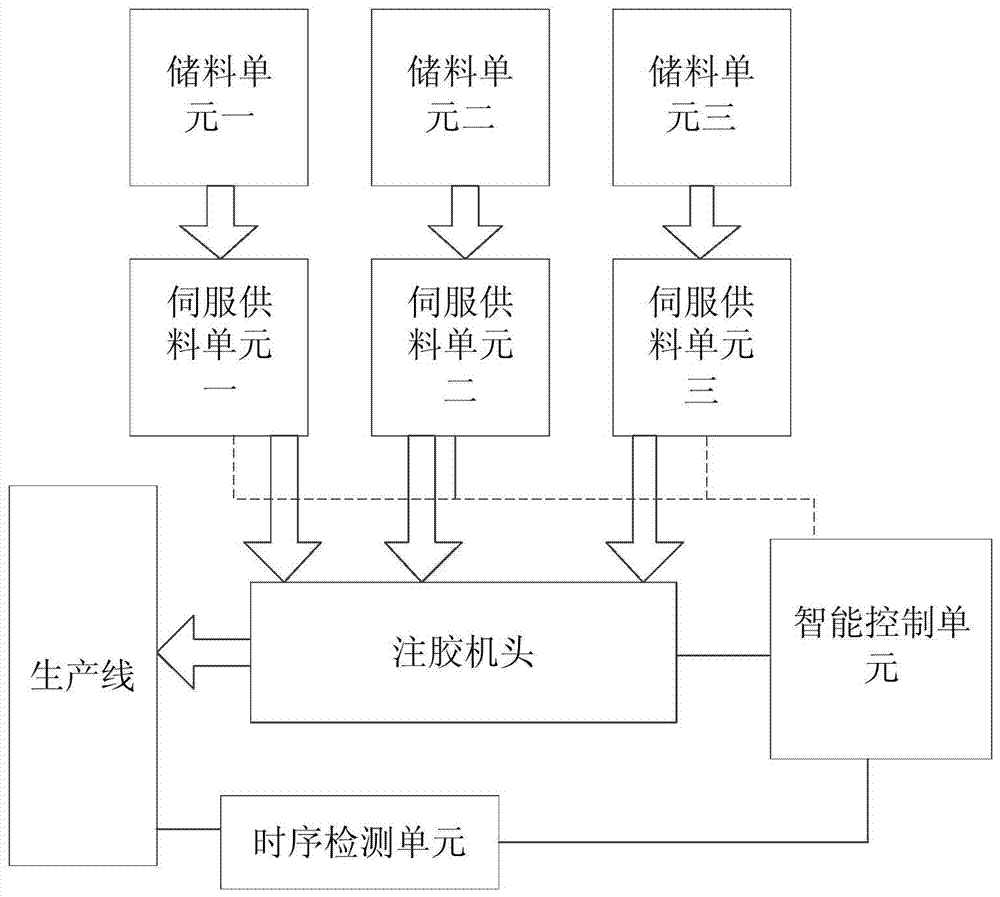

[0035] see figure 1 , the system provided by the present invention includes an intelligent control unit, a timing detection unit, a storage unit, a servo supply unit and a glue injection machine head, and the storage unit is used for mixing and storing the glue injected. There are multiple feeding units, which can provide pumping of various rubber materials; the servo feeding unit is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com