Hinge joint reinforcing maintenance method and reinforcing and maintaining device

A technology of hinged joints and anchor plates, which is applied in bridge maintenance, bridge reinforcement, erection/assembly of bridges, etc., and can solve the problems of hinged joints that cannot be repaired again, discretization, and colloidal cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

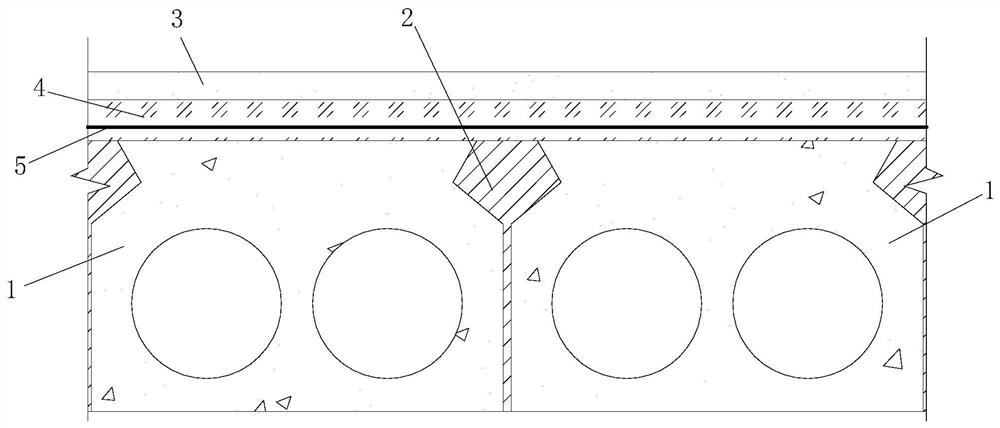

[0035] The maintenance method for joint reinforcement in this embodiment comprises the following steps:

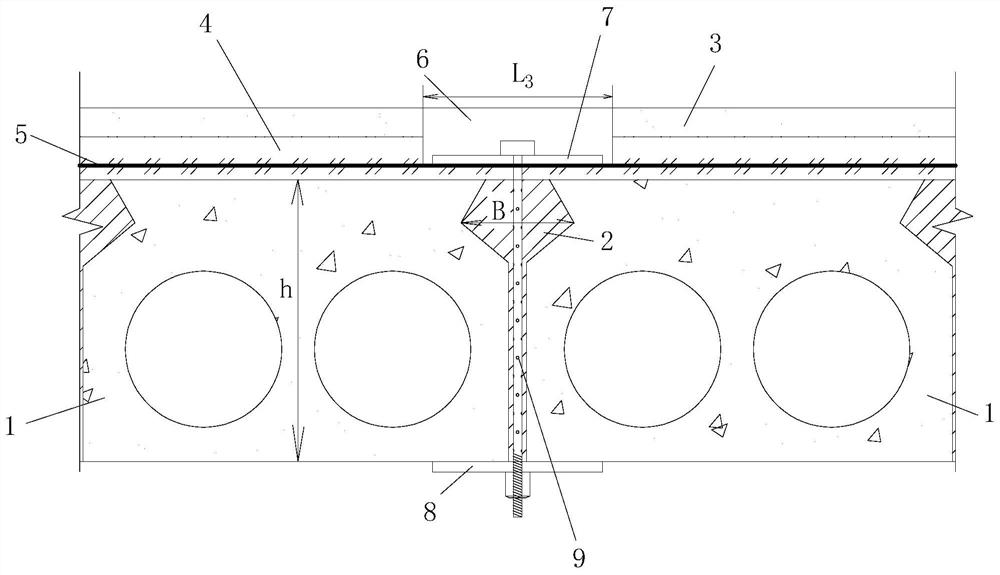

[0036] Step 1, such as figure 2 As shown, a notch 6 is made at the position of the hinge joint 2; specifically, at the top of the hinge joint 2; when opening the notch 6, part of the structure of the bridge is chiseled at the position of the hinge joint 2 until the reinforcement structure is exposed. Specifically, in this embodiment, the asphalt pavement 3 and part of the concrete pavement 4 of the bridge are chiseled at the hinge joint 2 until the steel mesh 5 in the concrete pavement 4 is exposed, that is, the concrete pavement is chiseled out. Concrete above the reinforcement mesh sheet 5 in layer 4 until the reinforcement mesh sheet 5 is exposed.

[0037] Step 2, drilling a vertical through hole in the hinged joint 2; the vertical through hole is opened in the middle of the hinged joint 2. The diameter of the vertical through hole is usually smaller than the width o...

Embodiment 2

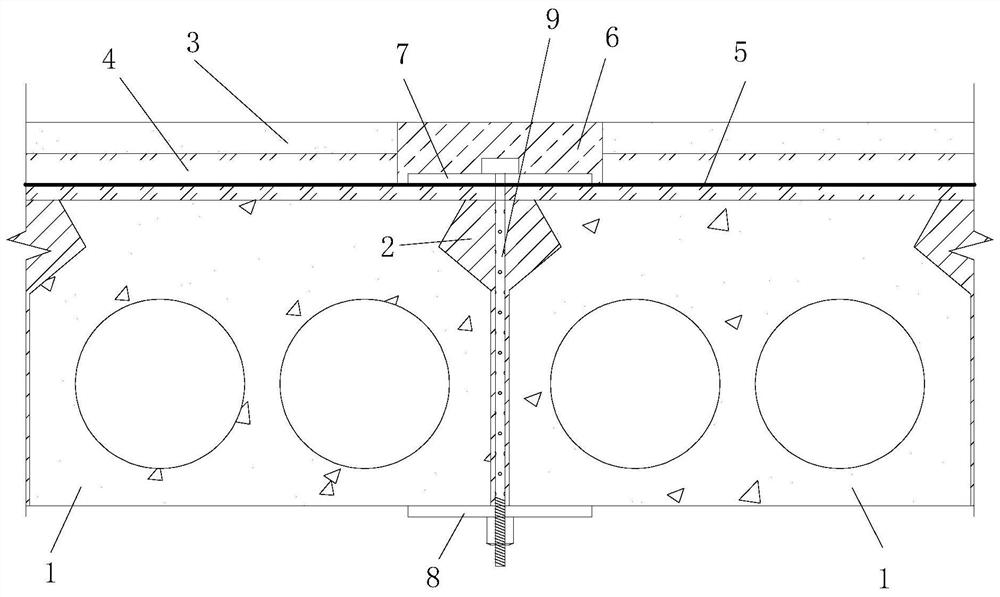

[0048] Such as Figure 4As shown, the reinforcement maintenance device of this embodiment includes: an upper anchoring plate 7; a lower anchoring plate 8, and the upper anchoring plate 7 and the lower anchoring plate 8 are arranged at intervals; A plurality of slurry outlet holes 11 are provided on the peripheral surface, and each slurry outlet hole 11 communicates with the hollow part inwardly; the upper anchor plate 7 and the lower anchor plate 8 can be arranged in cooperation with the tie rods 9 respectively.

[0049] One end of the tie rod 9 is provided with a fixed nut 12, and the fixed nut 12 can be buckled on the upper anchor plate 7 or the lower anchor plate 8; the other end of the tie rod 9 is provided with a screw thread 13 and a fastening nut 14; One end of the tie rod 9 has a communication port 10, which makes the hollow structure communicate with the outside; the slurry outlet holes 11 are located between the fixed nut 12 and the thread 13 of the tie rod 9. Each ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com