Prestressed concrete slab girder bridge type and construction method thereof

A prefabricated concrete slab and construction method technology, applied in bridges, bridge materials, bridge construction, etc., can solve problems such as affecting the normal operation of bridges, existing safety hazards, and poor economic benefits, reducing the amount of formwork and concrete, and improving construction. Efficiency, improved safety and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further introduced below in conjunction with the accompanying drawings and specific embodiments.

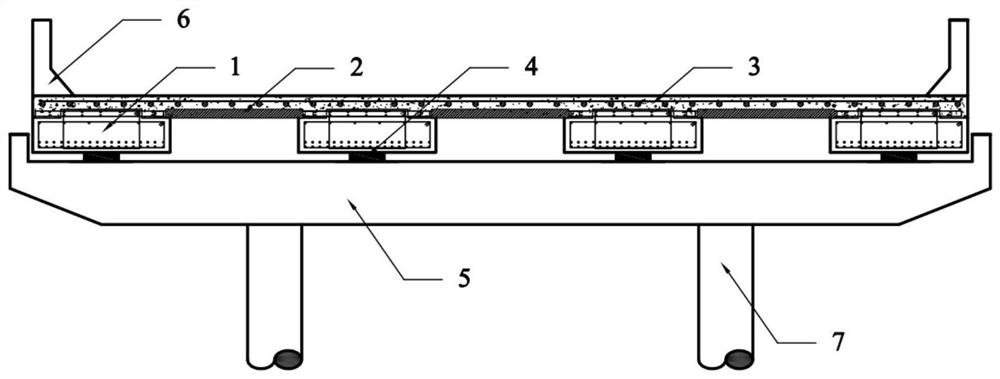

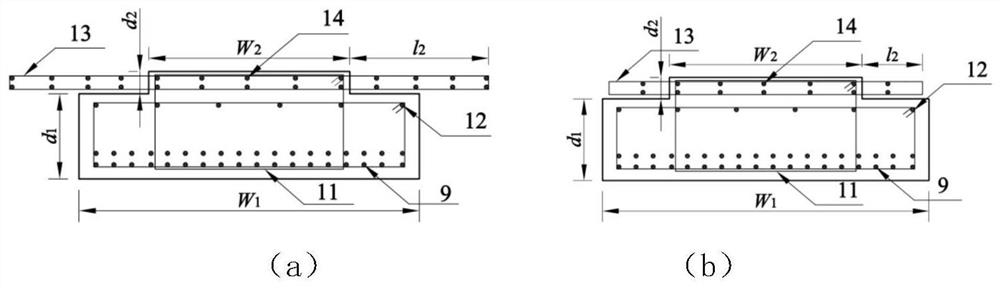

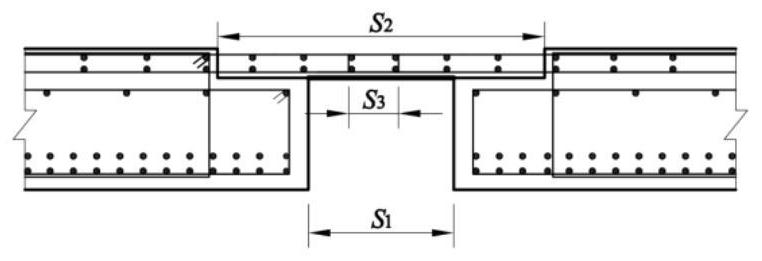

[0032] combine Figure 1-Figure 10 , a prestressed concrete slab girder bridge suitable for rapid construction, which has two main girder construction connection methods, that is, according to the size of the clear distance between adjacent main girders, the pre-embedded connection steel bars can be selected to overlap or the precast concrete slab connection can be selected , the former is suitable for smaller girder spacing, and the latter is used for larger girder spacing. The main components include inverted T-shaped main girder 1, prefabricated concrete slab 2, and cast-in-place reinforced concrete deck 3; main girder 1 is the key structural component to bear the load, and the on-site formwork or shelving is selected according to the net distance of the main girder in the actual bridge example The prefabricated concrete slab 2 is used to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com