Structure and method for reinforcing transverse linkage of highway hollow slab bridge

A horizontal connection, hollow slab technology, applied in bridges, bridge construction, bridge parts, etc., can solve the problems of weak horizontal overall connection, shedding of hinge joints of hollow slab bridges, long longitudinal cracks, etc., so as to reduce maintenance costs and strengthen horizontal connections. , good synergistic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

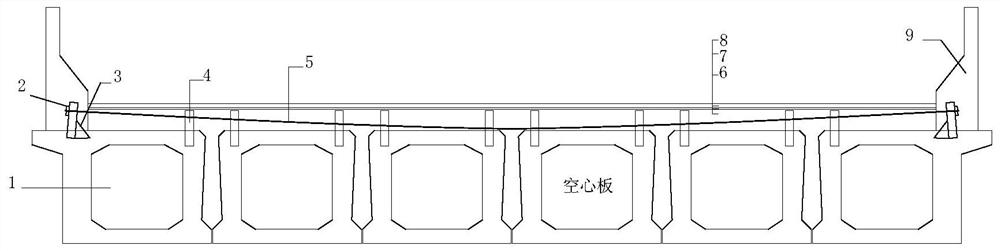

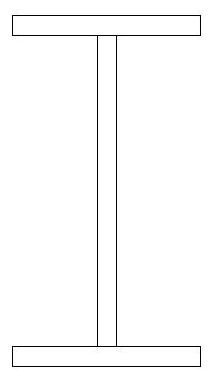

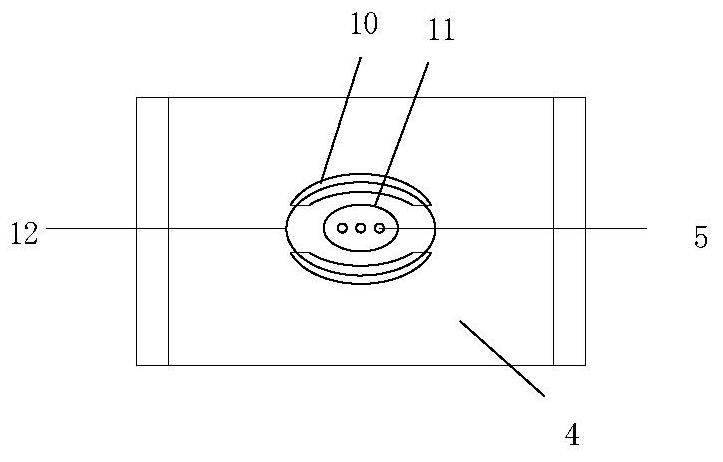

[0019] A structure for strengthening lateral connection of a highway hollow plate bridge, comprising a plurality of structural units; each structural unit includes a hollow plate 1 provided with more than one section steel 4; section steel openings 12 are provided in the section steel 4; U-shaped bellows protection The sleeve 10 is set at the position of the section steel opening 12; the bellows 11 passes through the section steel opening 12; the steel strand 5 passes through the bellows 11; the steel strand 5 is anchored on the anchorage 2; A reinforced concrete pavement layer 6, a waterproof layer 7, and a bridge deck asphalt pavement layer 8 are laid; multiple structural units are spliced horizontally, and guardrails 9 are provided on the sides of the hollow slabs 1 at both ends; anchorages are provided inside the guardrails 9 2 and anchoring device stiffening steel plate 3.

[0020] The method for strengthening the lateral connection of the highway hollow slab bridge bas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com