Glue injection device of temperature detection blind hole

A technology of glue injection device and blind hole, which is applied to measurement devices, thermometer parts, thermometers, etc., can solve the problems of affecting heat conduction efficiency, large resistance in the glue injection process, waste of thermal conductive glue, etc., so as to avoid contamination of the surrounding environment, Reduce glue injection resistance, simple and practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings.

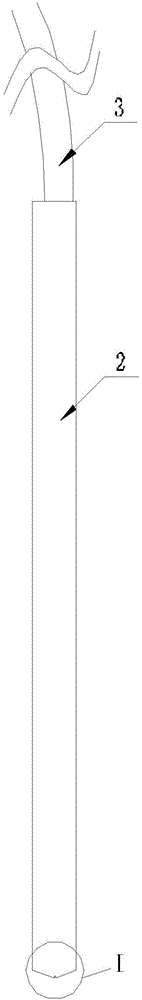

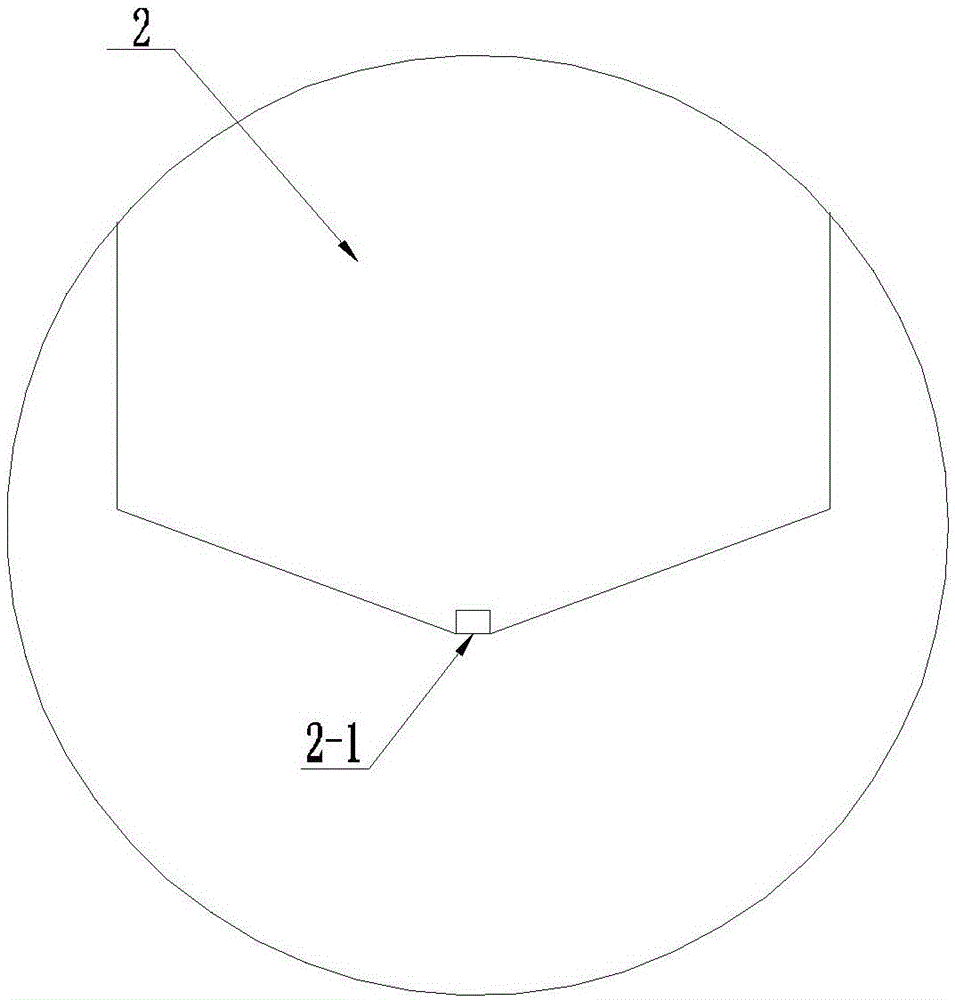

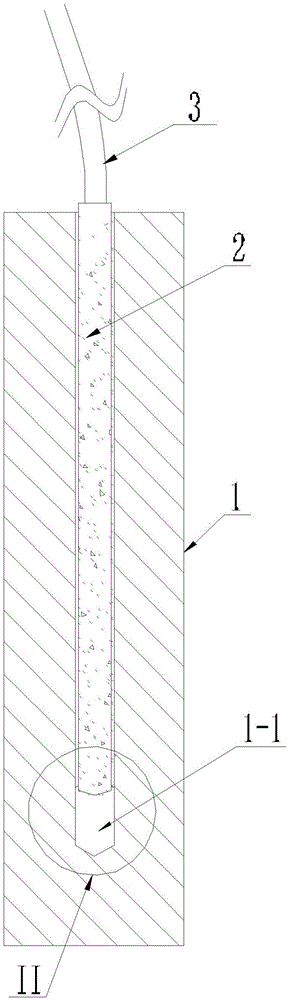

[0017] Such as Figure 1 to Figure 2 As shown, the glue injection device of temperature detection blind hole of the present invention comprises injection head 2, flexible pipe 3 and the conventional syringe 5 without needle, and the outer diameter of injection head 2 is less than the internal diameter of temperature detection blind hole 1, and the inner diameter of injection head 2 The front end is provided with a conical injection port 2-1, and the end of the injection head 2 is fixedly connected with the hose 3 and runs through it. The other end of the hose 3 is connected with a conventional syringe 4 without a needle and runs through it.

[0018] The injection head 2 is a rigid circular tube with a total length greater than or equal to 50 mm.

[0019] The outer diameter of the injection head 2 is smaller than the inner diameter of the temperature detecti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com