A kind of high temperature heavy oil viscosity reducer and its preparation method and application

A thick oil viscosity reducer and high temperature technology, which is applied in chemical instruments and methods, earthwork drilling and production, wellbore/well components, etc., can solve the problems of low steam volume sweep coefficient, high steam injection pressure, and short thermal recovery cycle , to achieve excellent emulsifying ability, increased sweep volume, and good salt tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Example 1 Viscosity reducer 1#

[0052] Viscosity reducer 1# contains the following components by weight: 15g potassium perfluoroalkyl ether carboxylate fluorocarbon surfactant, 15g potassium perfluoroalkyl ether sulfonate fluorocarbon surfactant, 15g linear C14 fatty alcohol polyoxygen Vinyl ether, 16g nano-CaO, 4g nano-CaCO 3 , 15g polyether triol, 20g pentanediol.

[0053] The preparation method of viscosity reducer 1# comprises the following steps:

[0054] The above components are added to the stirring reaction kettle in proportion, stirred for 2 hours, and mixed evenly to obtain viscosity reducer 1#.

Embodiment 2

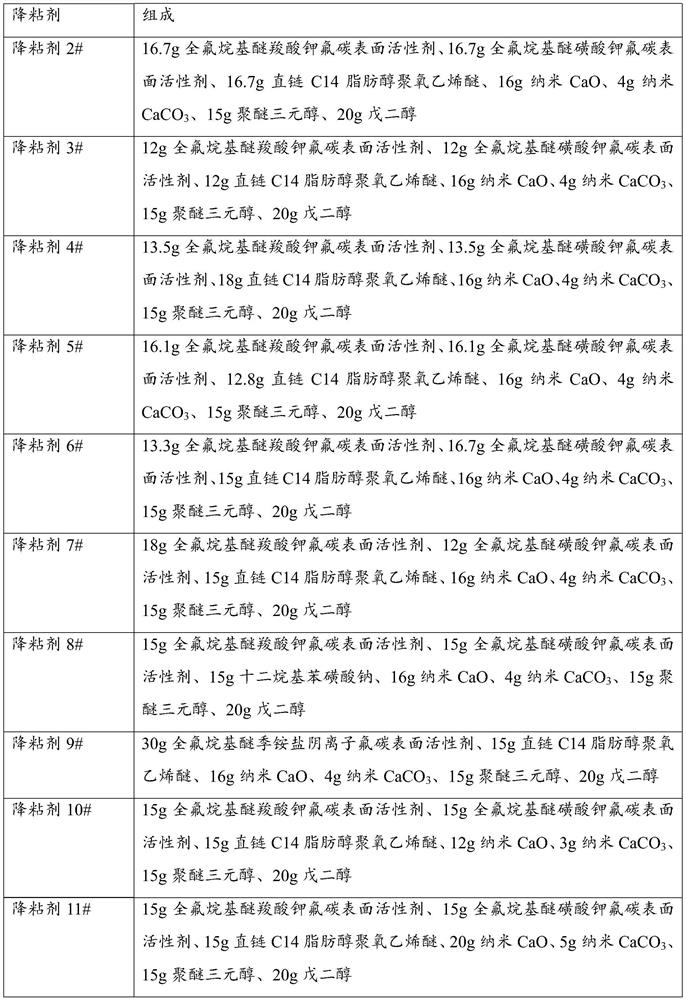

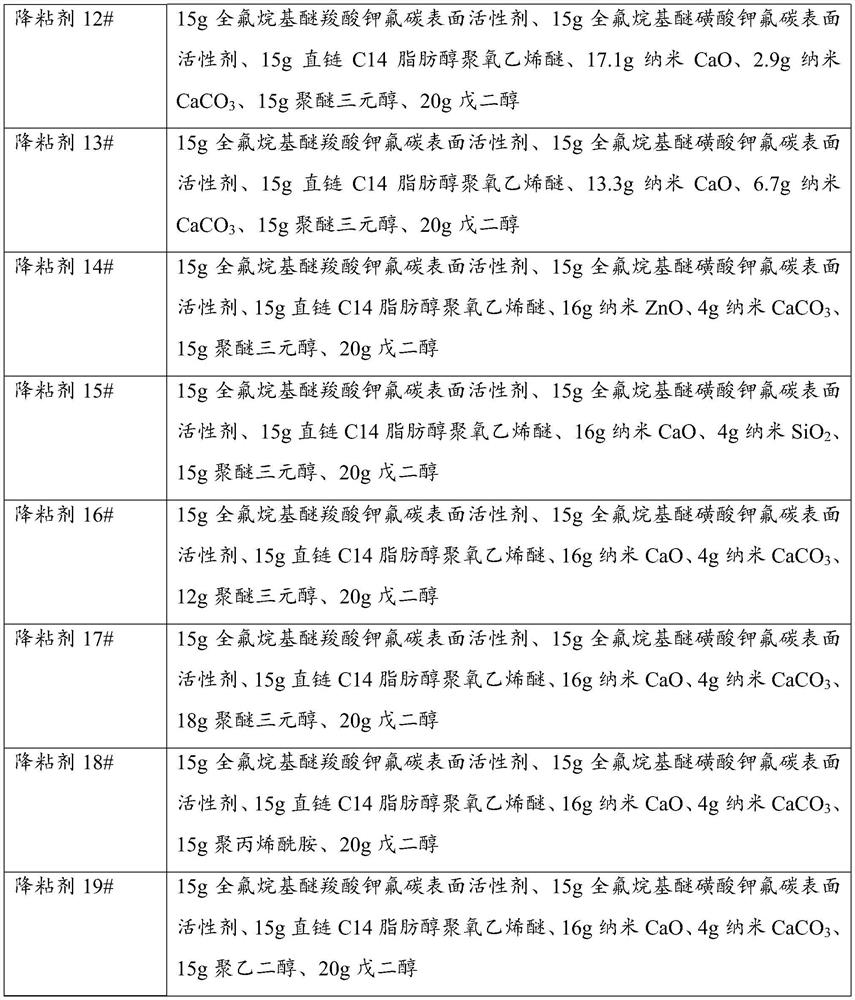

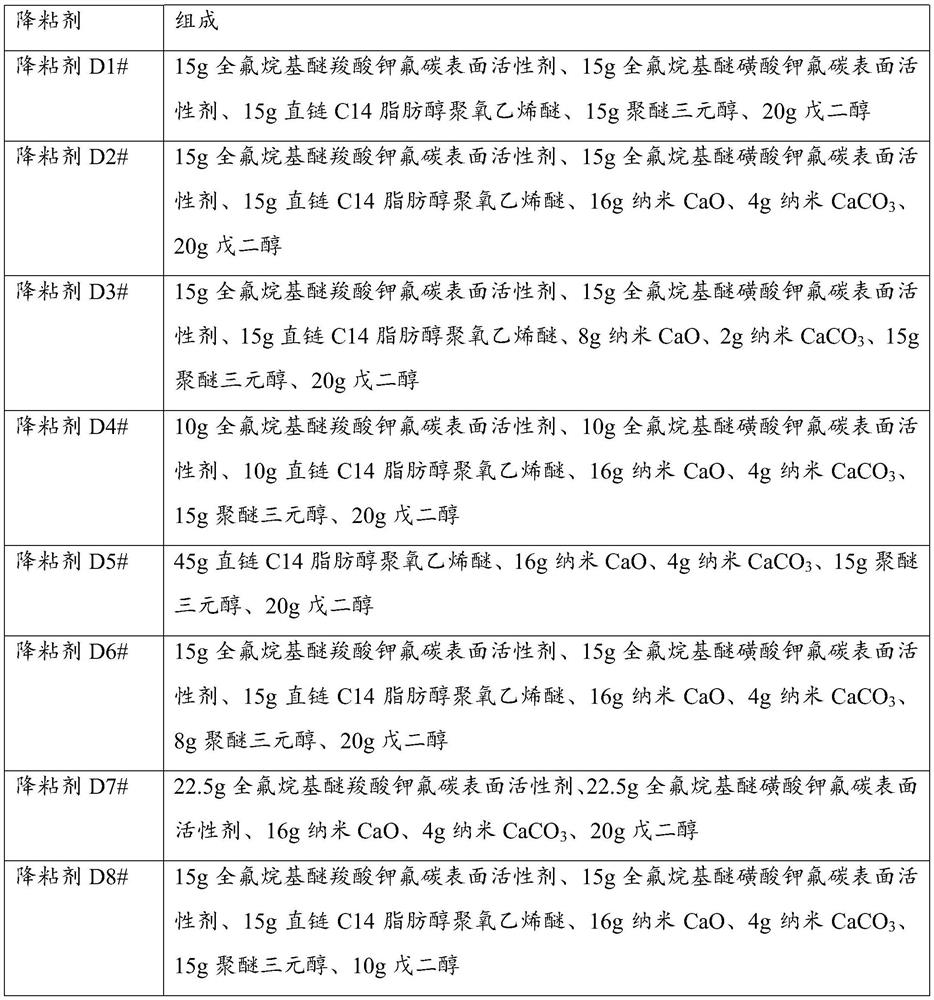

[0055] Example 2 Viscosity reducer 2#-19#

[0056] According to the preparation method of Example 1, viscosity reducers 2#-19# of different types and contents are provided, as shown in Table 1 for details.

[0057] Table 1

[0058]

[0059]

experiment example 1

[0065] The temperature resistance and salt resistance of the obtained high-temperature heavy oil viscosity reducer were tested by the following methods, and the test results are shown in Table 3:

[0066] Crude oil used for testing: crude oil from a block in Shengli Oilfield (viscosity is 16750mPa·S at 50℃, density is 0.9921g / cm) 3 ).

[0067] Determination of viscosity reduction rate at different temperatures: first use a rotational viscometer to measure the initial viscosity of the heavy oil, then add 60g of viscosity reducer to the reaction kettle, put it at a temperature of 50°C to 350°C for 24 hours, take it out, and cool it. The viscosity reducer at 50°C was added to 140 g of heavy oil, and after stirring and emulsification for 20 minutes, the viscosity of the heavy oil after the reaction was measured with a rotational viscometer, and the viscosity reduction rate of the viscosity reducer to the heavy oil was calculated.

[0068] Determination of salt resistance: in the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com