Spherical elastic bearing and injecting method in forming process of spherical elastic bearing

An elastic bearing and glue injection technology, applied in the direction of flexible bearings, rigid supports of bearing components, bearings, etc., can solve problems such as deformation or lamination, insufficient rubber density, rubber and metal spacers, etc., to avoid deformation or lamination , Improve the fluidity of the glue and prevent the rubber from scorching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

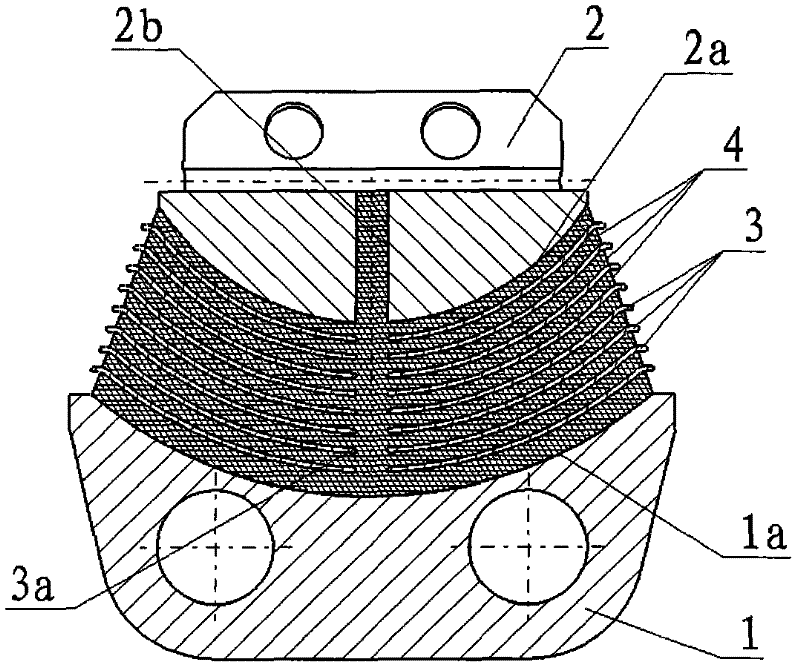

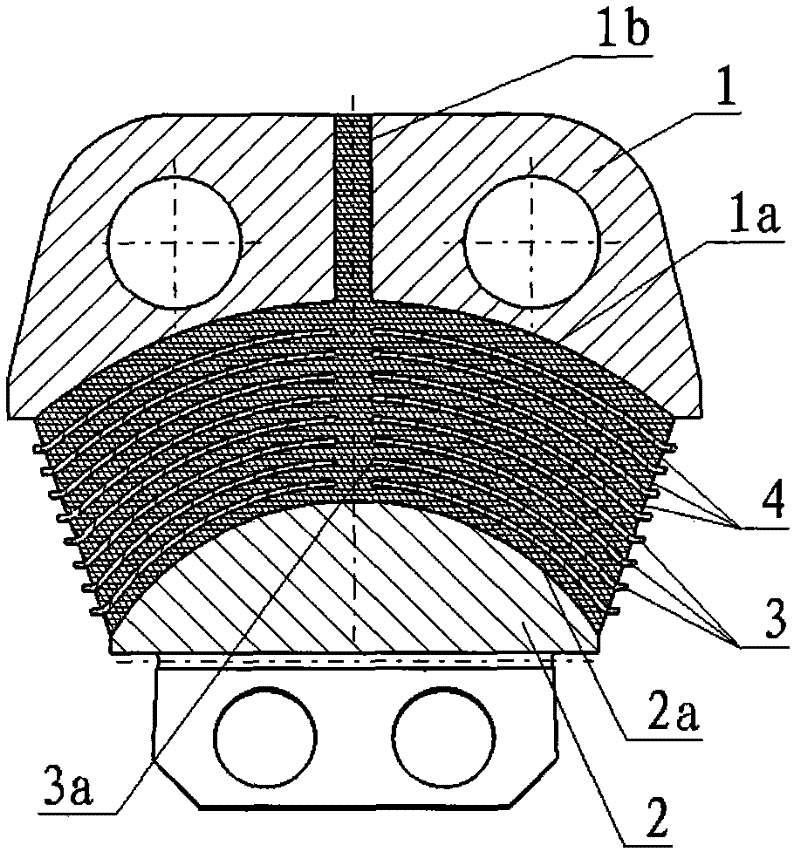

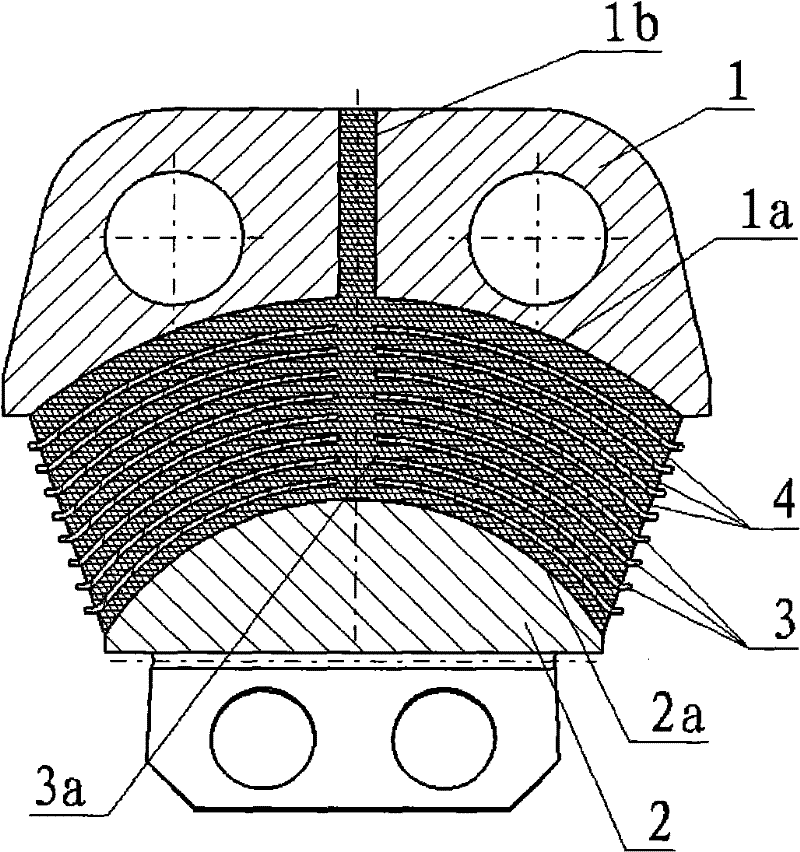

[0009] The present invention will be described in further detail below. see figure 2 , a spherical elastic bearing composed of a large joint 1, a small joint 2, 5 to 30 spherical spacers 3 and a rubber layer 4, the surface of the large joint 1 adjacent to the spherical spacer 3 is a concave concave spherical surface 1a, the small The surface of the joint 2 adjacent to the spherical spacer 3 is an upward convex convex spherical surface 2a. The spherical spacer 3 is a spherical metal sheet. All the spherical spacers 3 are stacked between the large joint 1 and the small joint 2 in sequence. The large joint 1 The concave spherical surface 1a of the spherical spacer 3 and the concave spherical surface 1a of the small joint 2 are all concentric, and there is a glue injection hole 3a in the center of the spherical spacer 3. Between the large joint 1 and the spherical spacer 3, adjacent There is a rubber layer 4 between the spherical spacer 3 and between the spherical spacer 3 and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com