Multi-mortise uniform glue injection device

A glue injection device and tongue and groove technology, which is applied in the field of glue injection machines, can solve problems such as glue not being scattered and bonding is not firm, and achieve the effects of improving docking efficiency, improving operating efficiency, and enhancing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

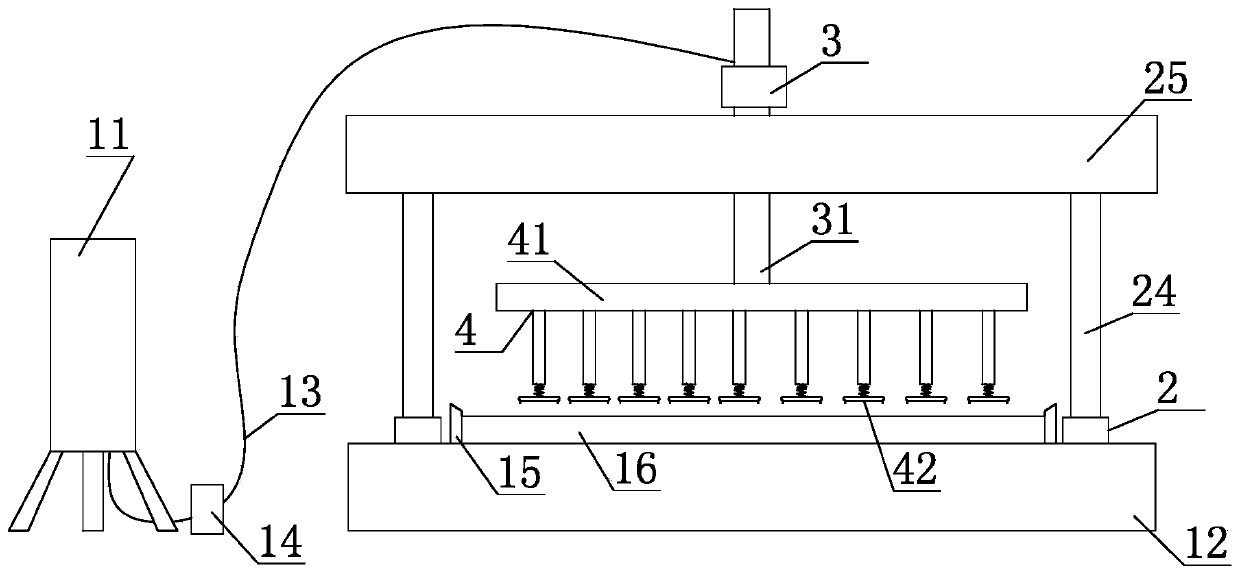

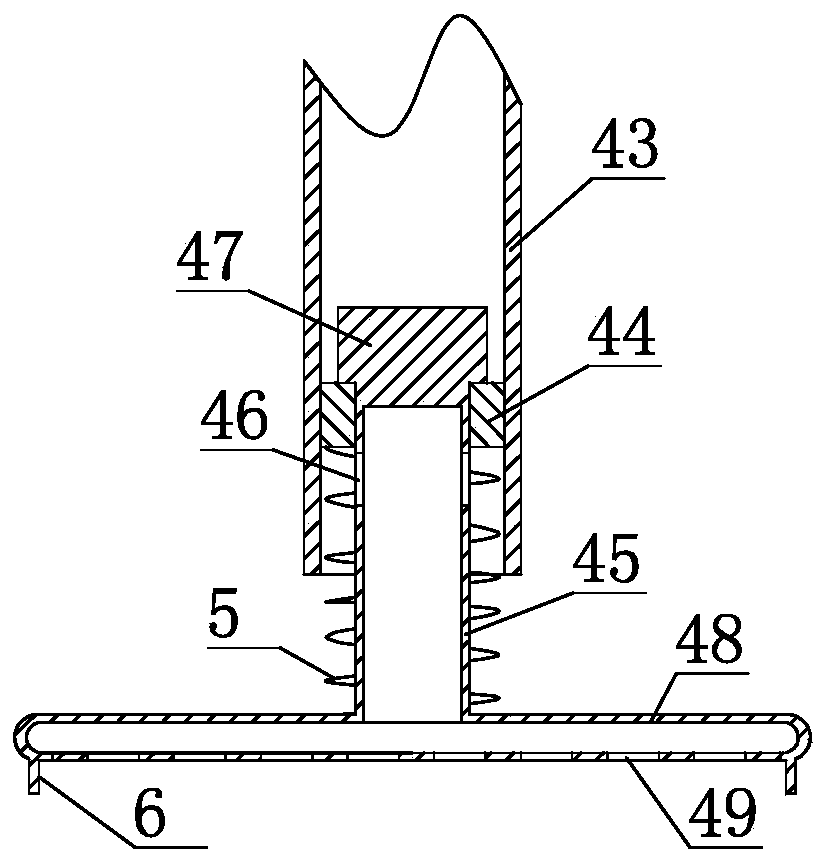

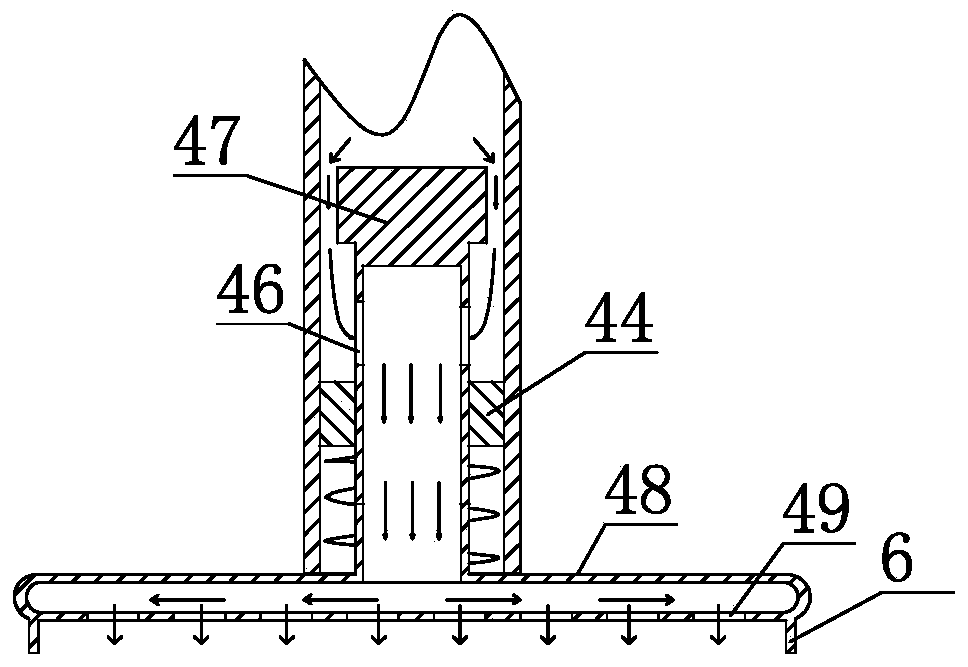

[0032] The present invention is a multi-mortise uniform glue injection device, including a glue storage tank 11 and a base 12, both of which are located on the ground, and a delivery pipe 13 is provided on the glue storage tank 11 , the middle of the delivery pipe 13 is provided with a glue supply pump 14, and the glue supply pump 14 pumps the glue in the glue storage tank 11 to the glue injection mechanism 4, and the base 12 is provided with a clamping plate 15, and the clamping plate 15 The board 15 is provided with a multi-tenon-groove wood 18, the multi-tenon-groove wood 18 is provided with a tenon groove 17, and the two sides of the base 12 are provided with a moving mechanism 2, and the moving mechanism 2 is used to push the glue injection mechanism 4 back and forth Moving, the moving mechanism 2 includes a cylinder 21 and a slideway 22, the slideway 22 is provided with a slider 23, the slider 23 is connected to the output end of the cylinder 21, and the expansion and con...

Embodiment 2

[0037] The present invention is a multi-tenon groove uniform glue injection device. On the basis of Embodiment 1, in order to improve the docking efficiency between the glue injection head 42 and the tenon groove 17, the lifting mechanism 3 includes a lifting rod 31, and the lifting mechanism 3 includes a lifting rod 31. A rack 32 is provided on the side wall of the rod 31, a motor 33 is provided on the top of the connecting plate 41, and a gear 34 is provided at the output end of the motor 33, and the gear 34 is meshed with the rack 32, and the lifting mechanism 3. It can realize the stable lifting of the glue injection mechanism 4, and improve the docking efficiency of the glue injection head 42 and the tongue and groove 17.

[0038] In order to further improve the operating efficiency of the whole device, the lifting rod 31 is provided with a slide groove 35, and the inside of the connecting plate 41 is provided with a slide rail 36, and the slide rail 36 is matched with the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com