Metal key forming equipment with multi-layer die plate structure

A molding equipment and template technology, applied in the direction of coating, etc., can solve the problems of poor product quality, uniform dispersion of glue, laborious operation, etc., and achieve the effect of beautiful products, accurate mold closing, and prevention of mold falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

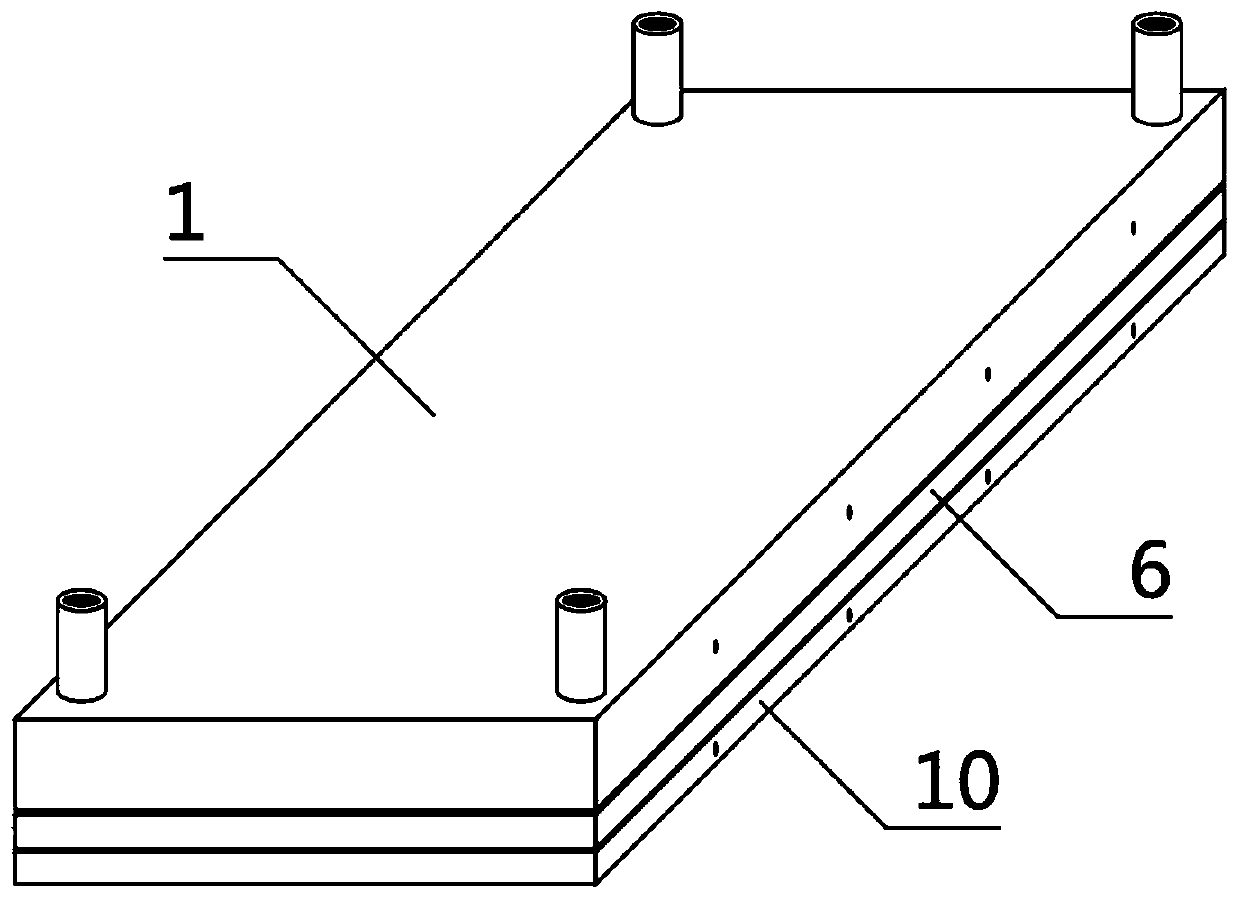

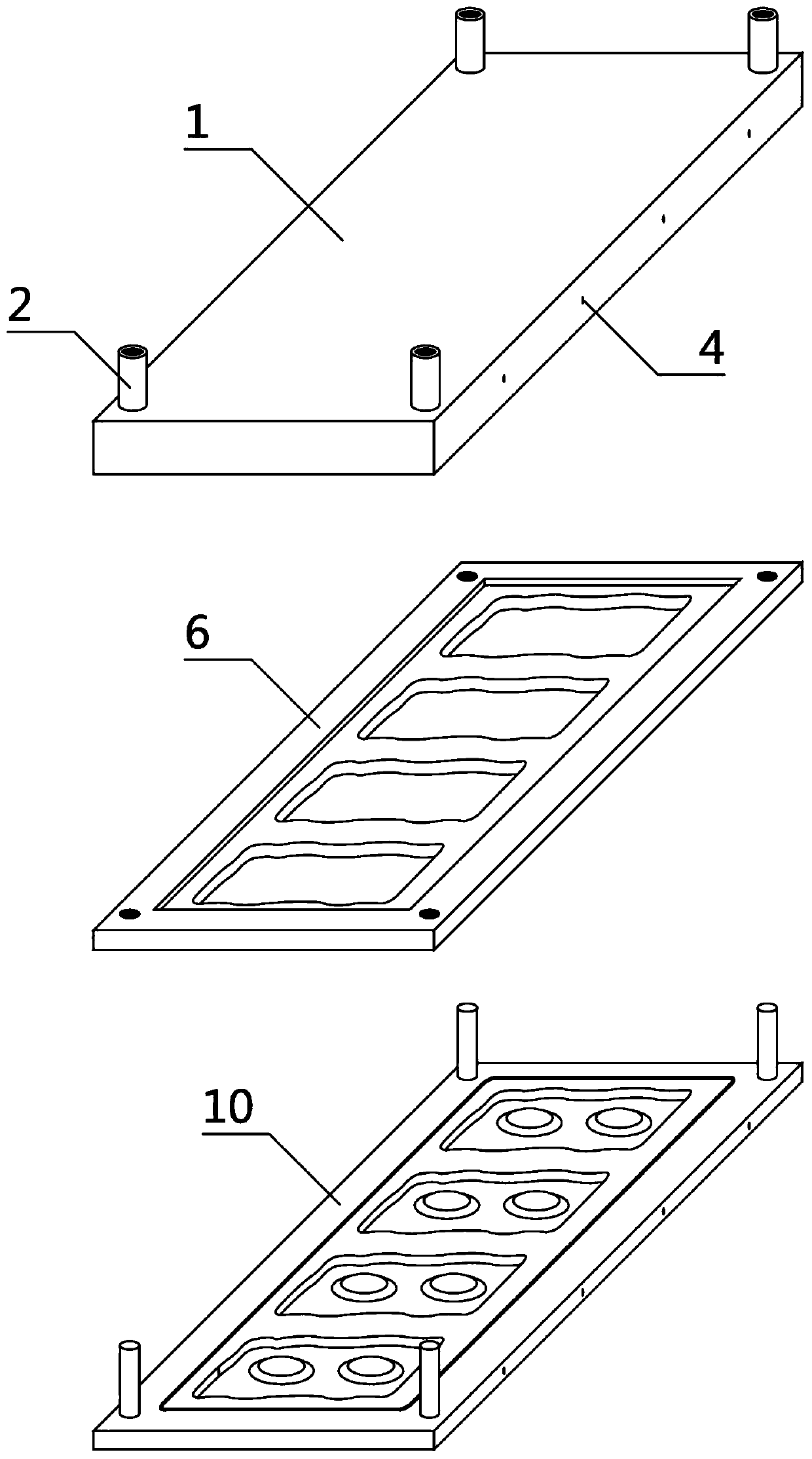

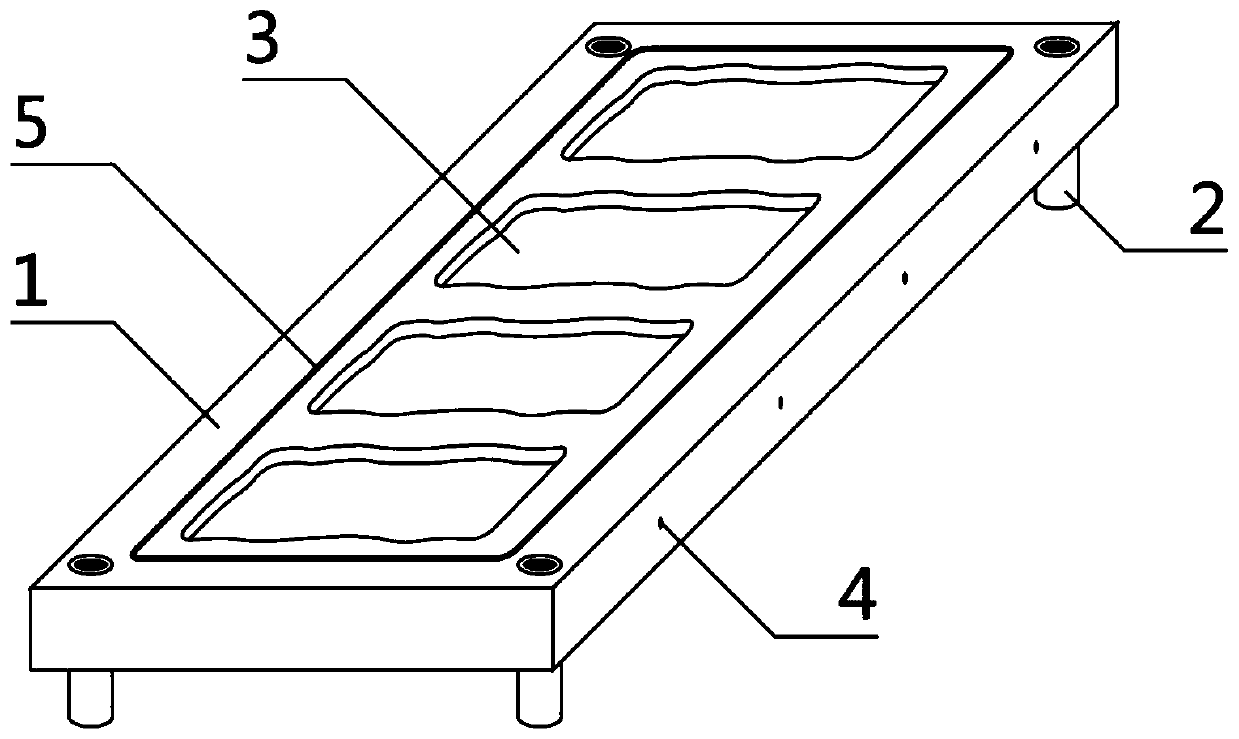

[0026] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5A metal button molding device with a multi-layer template structure is shown, which is characterized in that it is composed of an upper template 1 for injection molding, a molding structure template 6 and a lower template 10 for injection molding, and the upper template 1 for injection molding is also provided with There are four mold-closing registration extension hole columns 2, multiple upper template forming structural frames 3 and upper template overflow glue partition grooves 5, and the four mold-closing registration extension hole columns 2 are respectively located at the four corners of the injection molding upper template 1 position, the four mold-closing registration extension hole columns 2 are fixedly connected with the injection molding upper formwork 1, and the plurality of upper formwork forming structural frames 3 are arranged horizontally and horizontally on the injection molding In the ...

Embodiment 2

[0029] Such as figure 1 , image 3 , Figure 6 , Figure 7 A metal button molding device with a multi-layer template structure is shown, which is characterized in that it is composed of an upper template 1 for injection molding, a molding structure template 6 and a lower template 10 for injection molding, and the upper template 1 for injection molding is also provided with There are four mold-closing registration extension hole columns 2, multiple upper template single-button forming frames 15 and upper template overflow glue partition grooves 5, and the four mold-closing registration extension hole columns 2 are respectively located on the injection molding upper template 1 At the positions of the four corners, the four clamping and register extension hole columns 2 are all fixedly connected with the injection molding upper template 1, and the plurality of upper template single-button forming frames 15 are equidistant and horizontally arranged in groups of two. The charact...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com