Belt conveyor speed detecting system based on radio-frequency identification

A belt conveyor and speed detection technology, which is applied in the direction of conveyors, conveyor objects, conveyor control devices, etc., can solve the problems of large measurement errors, low precision, and easy wear and tear of equipment, and achieve fast and accurate scanning Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The following will be described in detail in conjunction with the embodiments of the present invention with reference to the accompanying drawings.

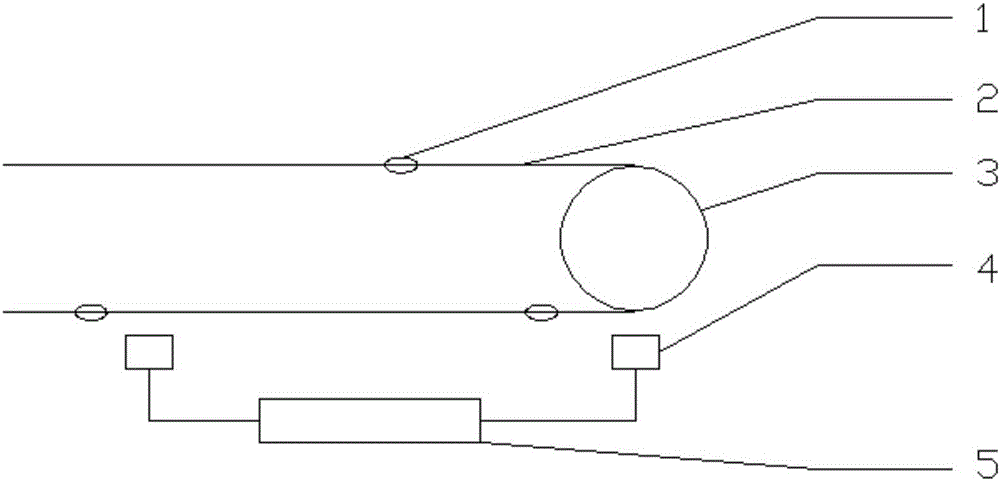

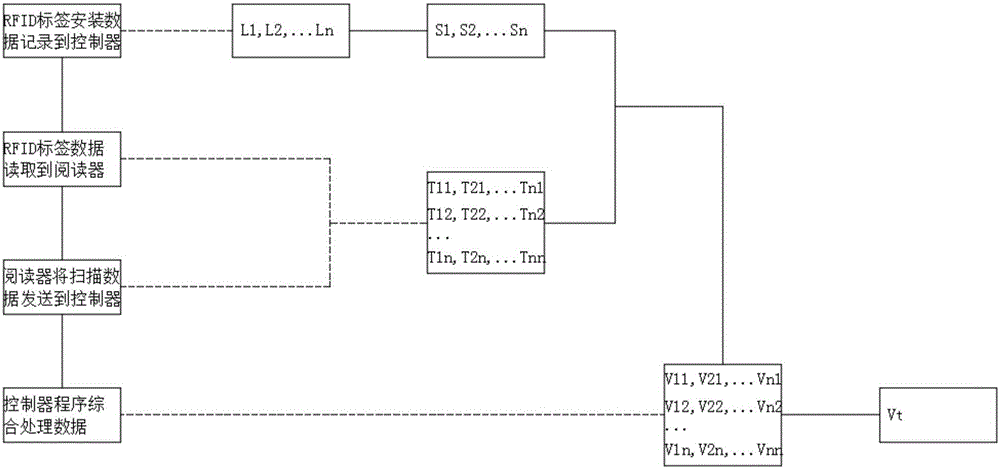

[0011] A belt conveyor speed detection system based on radio frequency identification, including two or more radio frequency identification tags 1, a belt 2, a roller 3, two or more readers 4, and a controller 5; the radio frequency identification tags 1 are embedded On the belt 2, the position of the radio frequency identification tag 1 relative to the belt 2 is fixed and can be identified by different readers; the belt 2 moves with the drum 3; The distance is fixed, and the reader 4 identifies the RFID tag 1 and sends a signal to the controller 5; the controller 5 calculates the speed of the belt conveyor according to the identified tag signal.

[0012] Described controller 5 is PLC controller.

[0013] The principle of a belt conveyor speed detection system based on radio frequency identification is the definition of s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com