Differential pressure type high sensitivity liquid level flow measuring device

A flow measurement device and high-sensitivity technology, applied in the direction of displaying liquid level indicator by pressure measurement, detecting fluid flow by measuring differential pressure, volume/mass flow generated by mechanical effect, etc. , can not work for a long time and other problems, to achieve good compatibility and adaptability, small error, reliable sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific embodiment of the present invention will be further described in conjunction with the accompanying drawings.

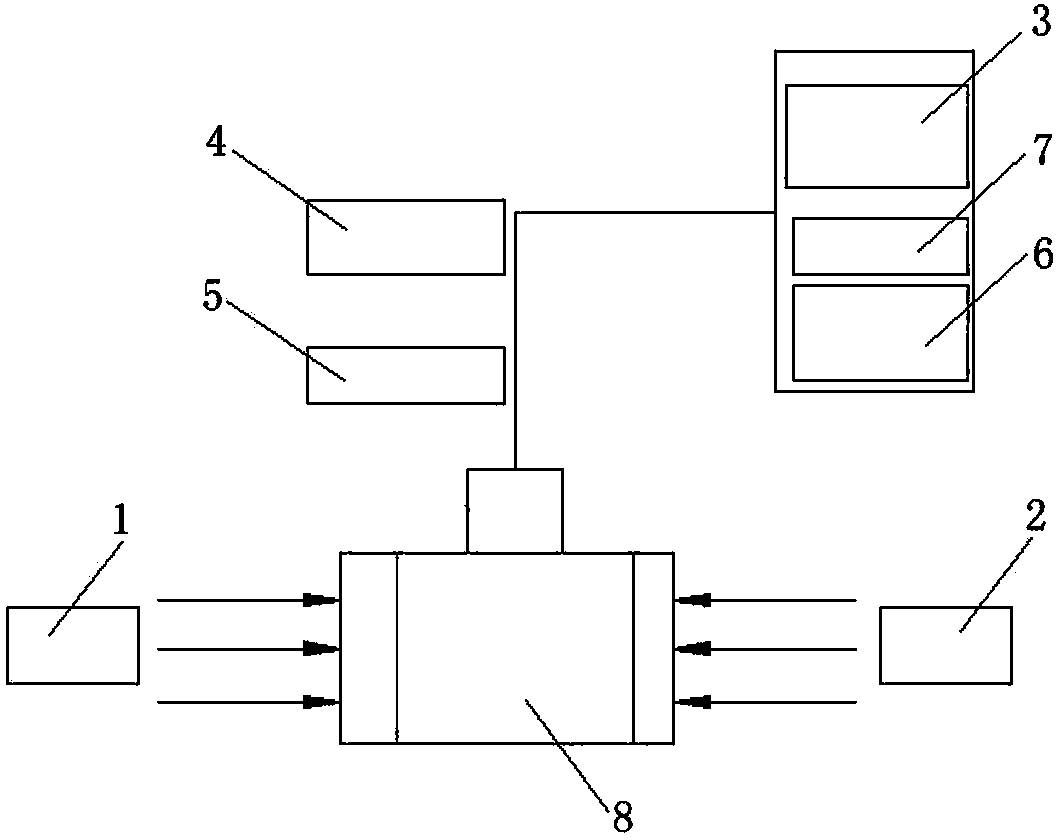

[0015] Such as figure 1 As shown, the differential pressure type high-sensitivity liquid level flow measuring device is characterized in that it includes a pressure probe 8 immersed under the liquid level, and also includes a reference pressure compensation module 3 far away from the liquid level, a flow rate conversion module 4 and a signal amplification processing module 5. The pressure probe 8 is equipped with a total pressure measurement module 1 and a static pressure measurement module 2;

[0016] The static pressure measurement module 1 is connected to the signal amplification processing module 5 through the reference pressure compensation module 3, and the reference pressure compensation module 3 is provided with an air guiding device that transmits the atmospheric pressure to the static pressure measurement module, the static pressure measu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com