Controllable discharge switch of high-energy impulse in three electrodes under vacuum environment

A high-energy pulse and vacuum environment technology, applied in electric switches, high-voltage/high-current switches, circuits, etc., can solve problems such as electrode ablation, difficult to meet requirements, and narrow switching range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

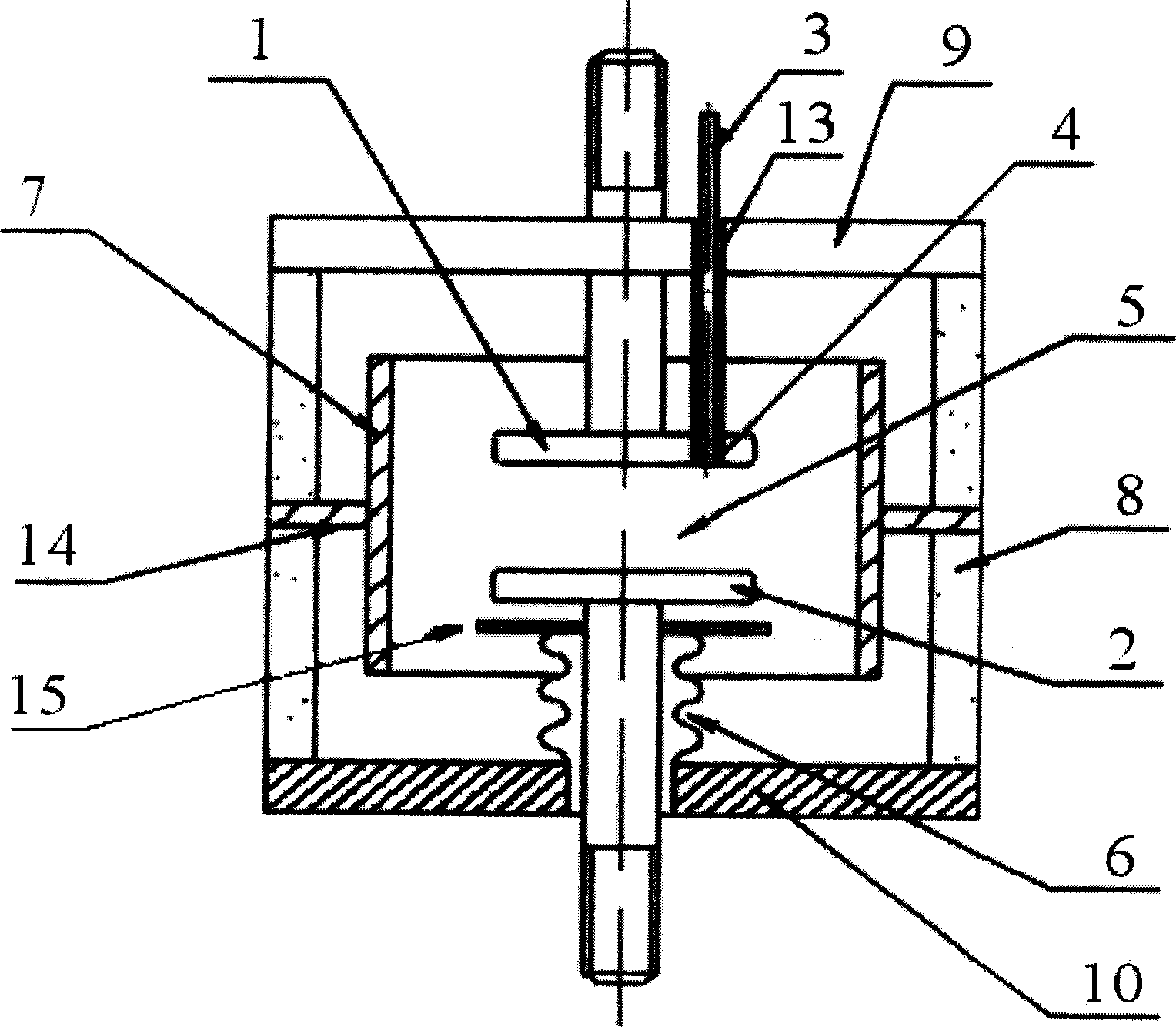

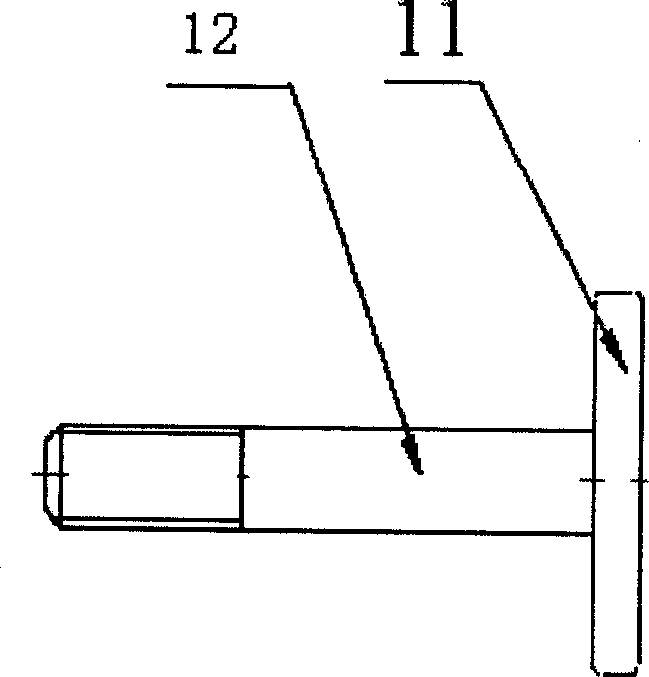

[0015] Example 1, see figure 1 , 2, this embodiment includes an insulating shell 8 and an upper electrode 1 and a lower electrode 2 composed of a contact 11 and a conduction part 12 arranged in the insulating shell 8, and the upper electrode 1 and the lower electrode 2 pass through the end flange 9 and the The end flange 10 is arranged in the insulating shell 8, and the pressure in the airtight housing formed by the insulating shell 8 and the end flanges 9 and 10 arranged at both ends of the insulating shell 8 is 10 -3 ~10 -4 Pa, the upper electrode 1 is a fixed electrode, and an insulating tube 13 inlaid with a columnar trigger electrode 3 is opened in the upper electrode 1. A discharge gap 4 is formed between the columnar trigger electrode 3 and the insulating sleeve 13, and the lower electrode 2 is a movable electrode. The lower electrode 2 is connected to the end flange 10 through the bellows 6, the upper end of the bellows 6 is also provided with a bellows shield 15, the...

Embodiment 2

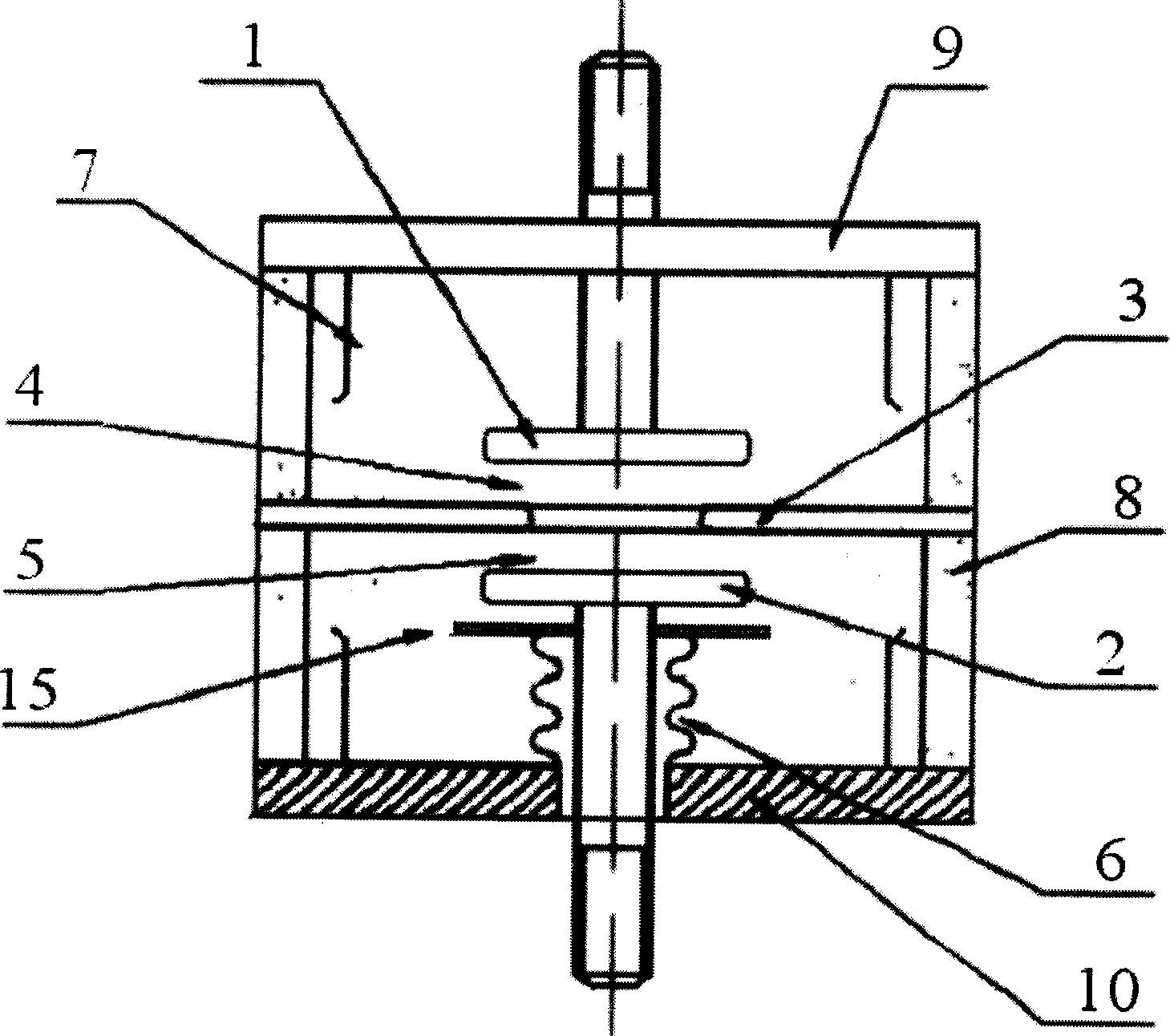

[0017] Example 2, see image 3 , this embodiment includes an insulating shell 8 and an upper electrode 1 and a lower electrode 2 composed of a contact 11 and a conduction part 12 arranged in the insulating shell 8, and the upper electrode 1 and the lower electrode 2 pass through the end flange 9 and the end method The flange 10 is arranged in the insulating shell 8, and the pressure in the airtight shell formed by the insulating shell 8 and the end flanges 9 and 10 arranged at both ends of the insulating shell 8 is 10 -3 ~10 -4 Pa, the upper electrode 1 is a fixed electrode, the lower electrode 2 is a movable electrode, the lower electrode 2 is connected to the end flange 10 through the bellows 6, the upper end of the bellows 6 is also provided with a bellows shield 15, and the bellows shield 15 It can prevent metal vapor from depositing on the bellows 6, affecting the characteristics and life of the bellows 6. An annular trigger electrode 3 is arranged between the discharge ...

Embodiment 3

[0019] Embodiment 3: see Figure 4 , this embodiment includes an insulating shell 8 and an upper electrode 1 and a lower electrode 2 composed of a contact 11 and a conduction part 12 arranged in the insulating shell 8, and the upper electrode 1 and the lower electrode 2 pass through the end flange 9 and the end method The flange 10 is arranged in the insulating shell 8, and the pressure in the airtight shell formed by the insulating shell 8 and the end flanges 9 and 10 arranged at both ends of the insulating shell 8 is 10 -3 ~10 -4 Pa, the upper electrode 1 and the lower electrode 2 are movable electrodes, which are respectively connected to the end flanges 9 and 10 through the bellows 6. The upper end of the bellows 6 is also provided with a bellows shield 15, which can prevent metal Vapor is deposited on the bellows 6, which affects the characteristics and life of the bellows 6. Around the upper electrode 1, the lower electrode 2 and the trigger electrode 3, a shielding cov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com