Polycarbosilane/phenolic aldehyde double-system network structure aerogel as well as composite material and preparation method thereof

A technology of polycarbosilane and network structure, which is applied in the field of polycarbosilane/phenolic dual-system network structure airgel and its composite materials and preparation, can solve problems affecting high-temperature performance, delay decomposition and carbonization temperature, and increase Good mechanical properties and anti-scouring performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] As mentioned above, the present invention provides a kind of preparation method of polycarbosilane / phenolic double-system network structure airgel in the first aspect, it is characterized in that, described method comprises the following steps:

[0030] (1) Mix and stir the phenolic resin, the first organic solvent and an optional curing agent to obtain a phenolic resin solution S1;

[0031] (2) Mix and stir the polycarbosilane, the second organic solvent and the catalyst to obtain a polycarbosilane solution S2;

[0032] (3) Mix and stir the phenolic resin solution S1 and the polycarbosilane solution S2 to obtain the polycarbosilane / phenolic resin composite solution S3;

[0033] (4) Transfer the composite solution S3 to an airtight container, and a sol-gel reaction occurs under heating conditions to obtain a polycarbosilane / phenolic dual-system network structure wet gel;

[0034] (5) Drying the wet gel with polycarbosilane / phenolic dual-system network structure to obta...

Embodiment 1

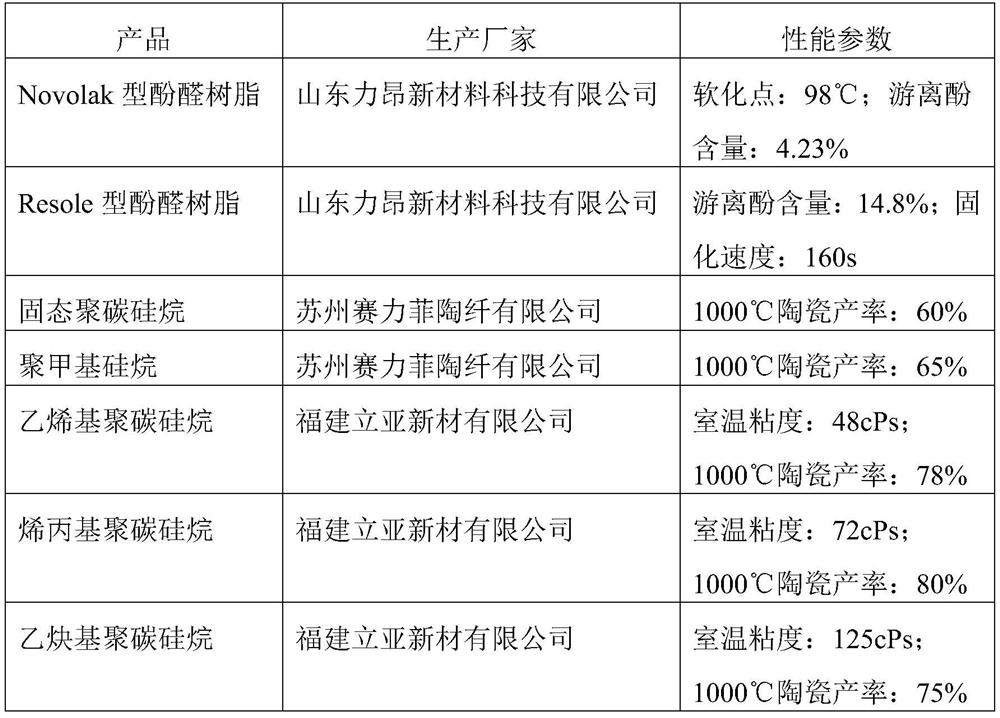

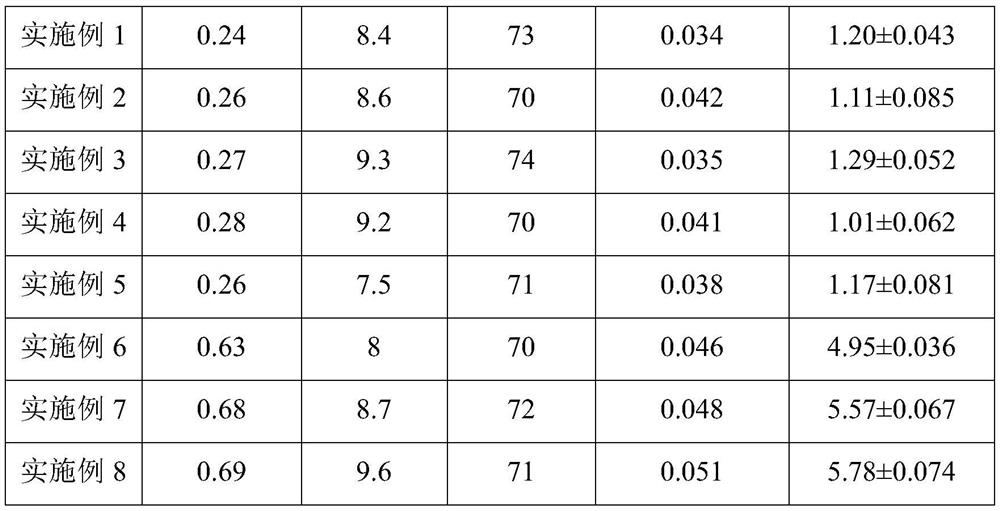

[0068] After mixing 10g of Novolak type phenolic resin and 90g of cyclohexanone, add 0.5g of hexamethylenetetramine and mix to obtain S1; after mixing 10g of solid polycarbosilane and 90g of butyl ether, add 0.001g Mix and stir the platinum catalyst to obtain S2; mix and stir S1 and S2, transfer to a hydrothermal kettle, react at 150°C for 8h, take out the wet gel and let it dry at room temperature for 24h, and then transfer it to an oven at 70°C to dry for 12h to obtain See Table 1 for the density, linear shrinkage, residual weight (900°C), thermal conductivity (room temperature) and compressive strength of polycarbosilane / phenolic dual-system network structure airgel.

Embodiment 2

[0070] After mixing 15g of Resole type phenolic resin and 85g of ethyl acetate, S1 was obtained; after mixing 1.88g of polymethylsilane and 10.65g of tetrahydrofuran, adding 0.00094g of dicumyl peroxide and mixing to obtain S2 ;Mix and stir S1 and S2, transfer them to a hydrothermal kettle, react at 80°C for 10h, take out the wet gel and let it dry at room temperature for 30h, then transfer to a 55°C oven to dry for 18h to obtain a polycarbosilane / phenolic dual-system network Structural airgel, its density, linear shrinkage, residual weight (900°C), thermal conductivity (room temperature) and compressive strength are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com