High-power long-life plasma torch based on permanent magnet constraint

A plasma torch and high-power technology, applied in the field of plasma torches, can solve the problems of poor matching of power and magnetic field, inability to guarantee parameter matching, and high cost of use and maintenance, so as to increase electrode life, improve working stability and cooling efficiency. improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

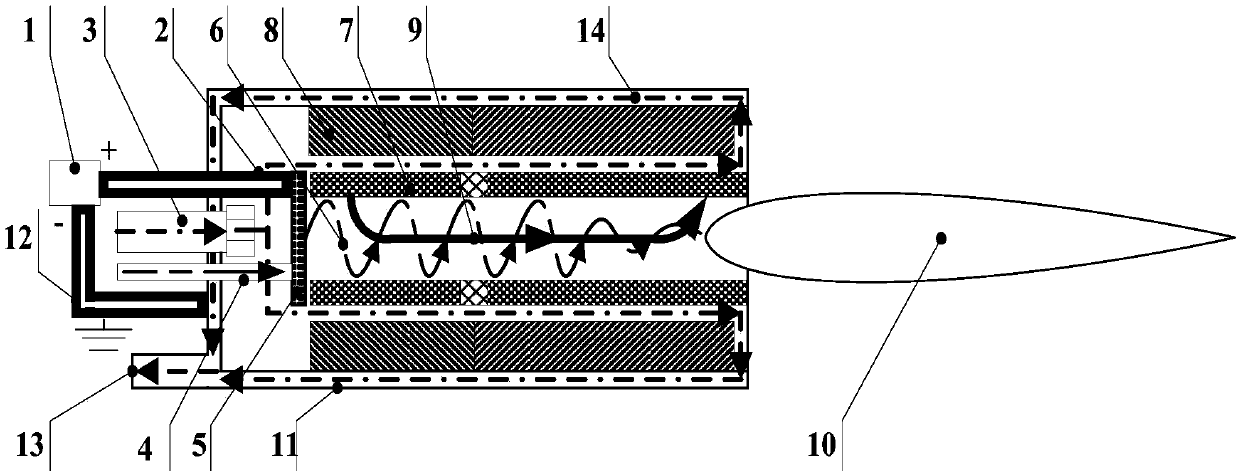

[0056] A high-power and long-life plasma torch based on permanent magnet confinement, wherein the cylindrical body used as the anode of the integrated electrode 7 has an outer diameter of 30mm, an inner diameter of 15mm, and a length of 60mm, and the material is silver-copper alloy; 7 The outer diameter of the cathode cylinder is 30mm, the inner diameter is 12mm, the length is 150mm, and the material is pure copper; the outer diameter of the insulator is 30mm, the inner diameter is 20mm, the length is 20mm, and the material is alumina ceramics.

[0057] The permanent magnet lens 8 is formed by bonding two parts. The part corresponding to the anode of the integrated electrode 7 is used as the first part of the permanent magnet lens, and the part corresponding to the cathode of the integrated electrode 7 is used as the second part of the permanent magnet lens. The two parts of the permanent magnet lens The axial polarity is opposite, the outer diameter is 50mm, the inner diameter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com