Pulse modulation drive circuit of semiconductor laser unit

A technology of pulse modulation and drive circuit, which is applied in the direction of semiconductor lasers, lasers, laser components, etc., can solve problems such as failure to meet development needs, lack of versatility, complex circuits, etc., and achieve rapid pulse response, reliable performance, and pulse output powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, but not to limit the present invention. In addition, it should be noted that, for the convenience of description, only parts related to the present invention are shown in the drawings but not all content.

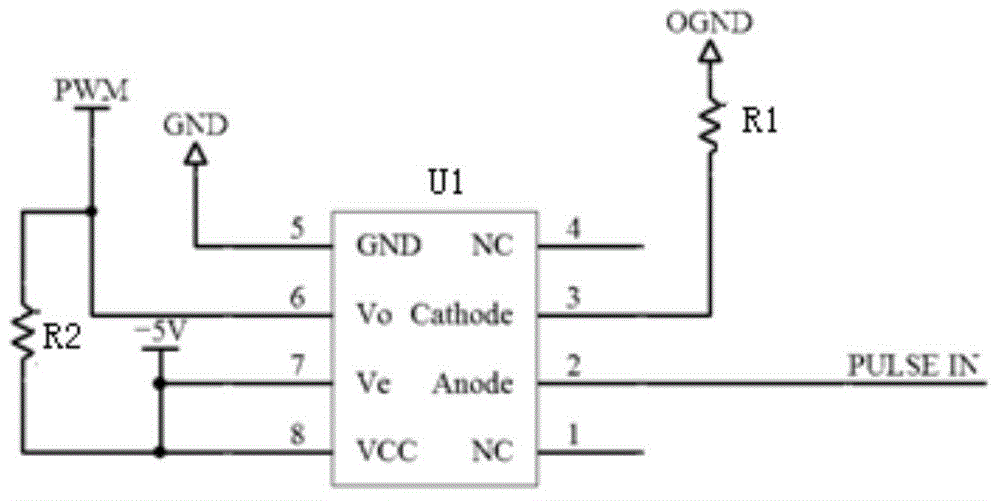

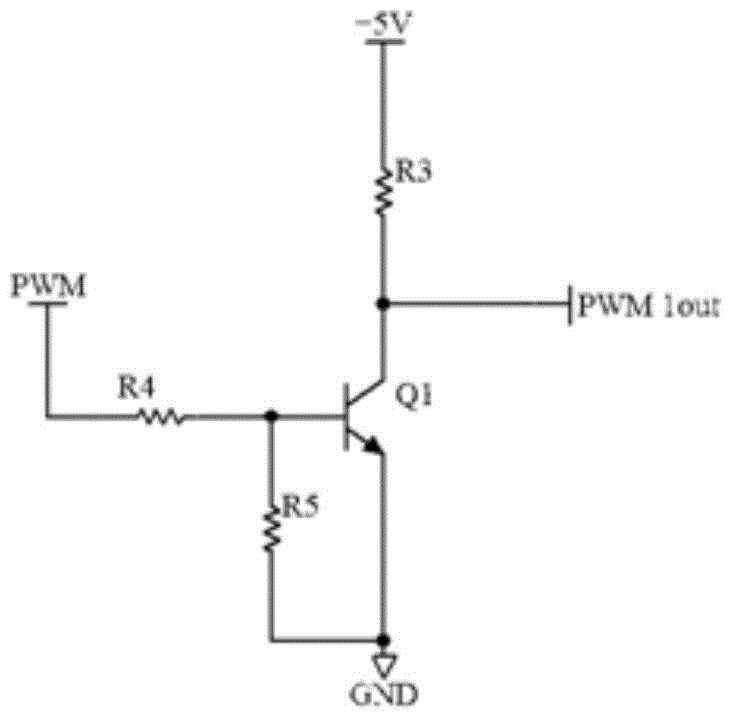

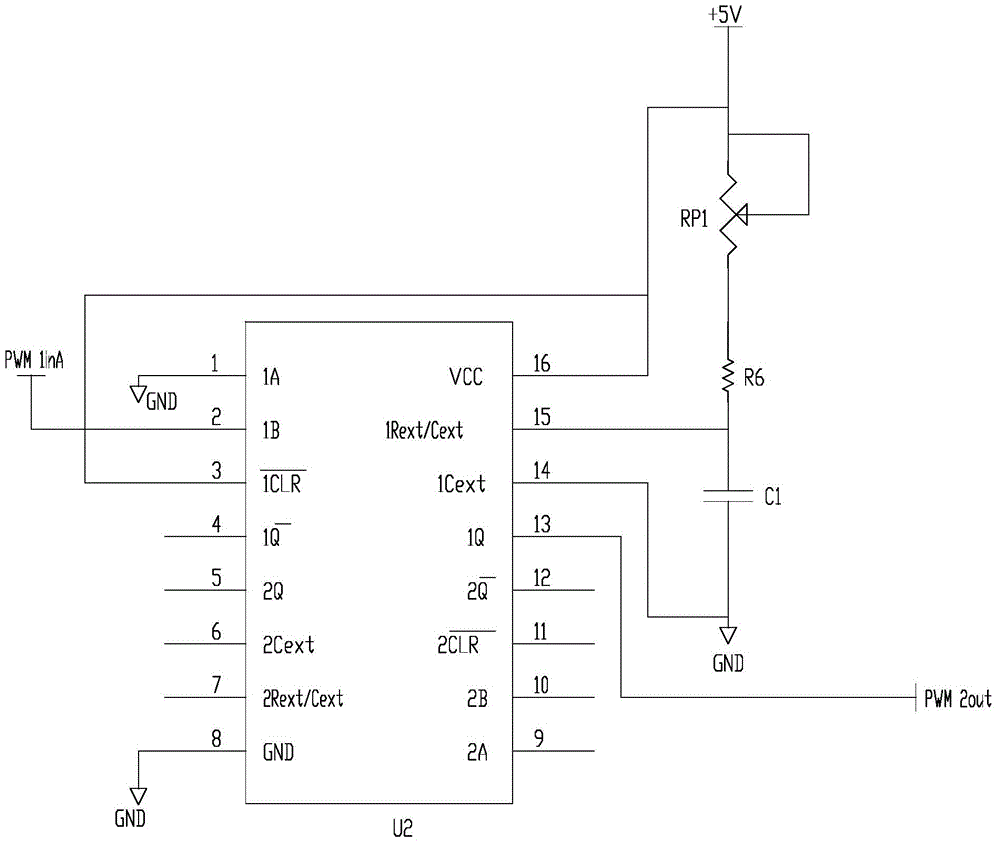

[0026] The semiconductor laser pulse modulation driving circuit in this embodiment specifically includes an isolated input circuit, an inverter circuit, a pulse width limiting circuit, a pulse signal amplification circuit, a pulse current control circuit and a laser interface matching circuit.

[0027] The isolation input circuit is used to realize external isolation by using an isolation switch, and output the isolated pulse signal to the inverter circuit.

[0028] In this embodiment, if figure 1 As shown, the isolated input circuit includes a resisto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com