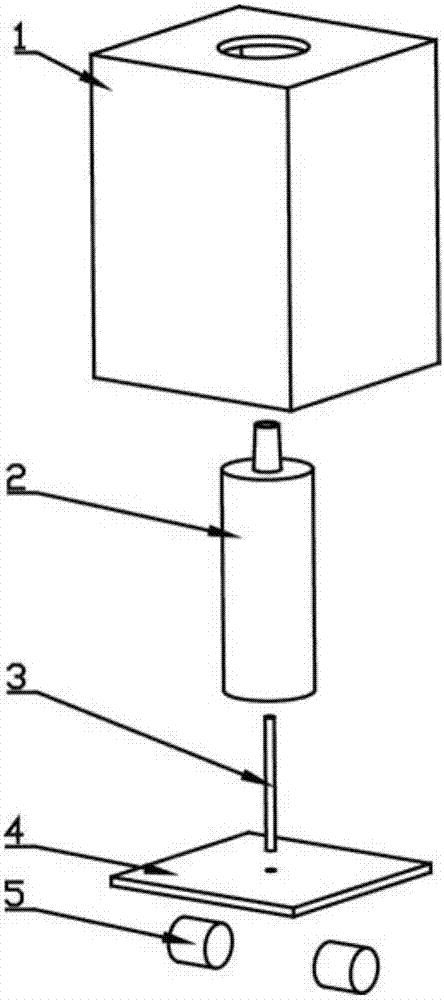

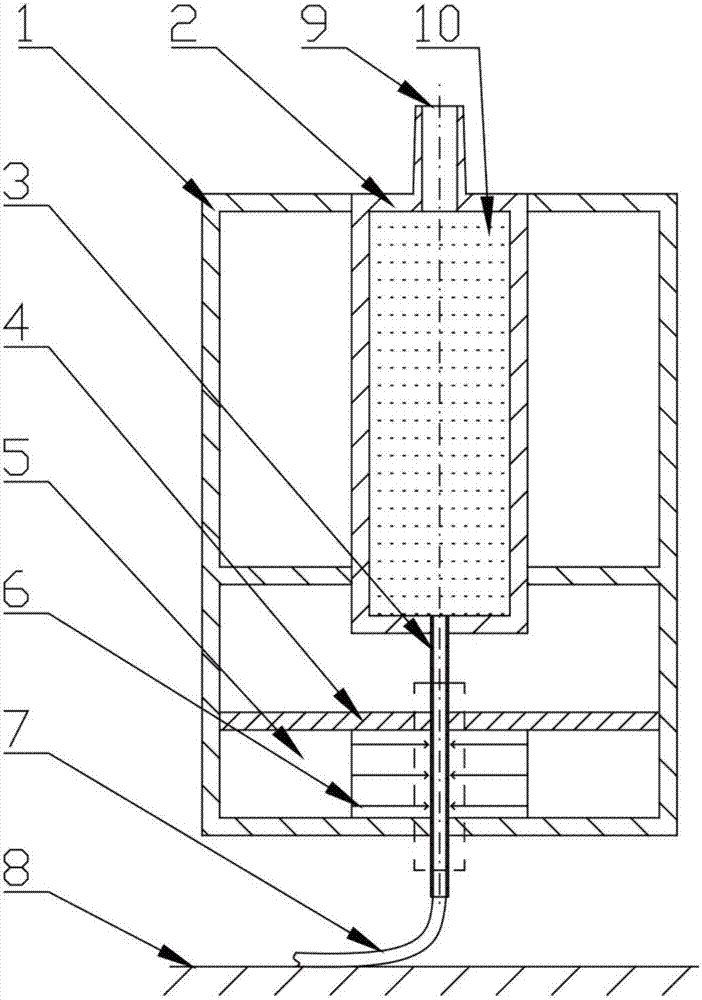

In-situ light curing extrusion nozzle

A light-curing, nozzle technology, applied in additive manufacturing, coating devices, 3D object support structures, etc., can solve problems affecting forming accuracy, etc., and achieve the effect of improving size range and printing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

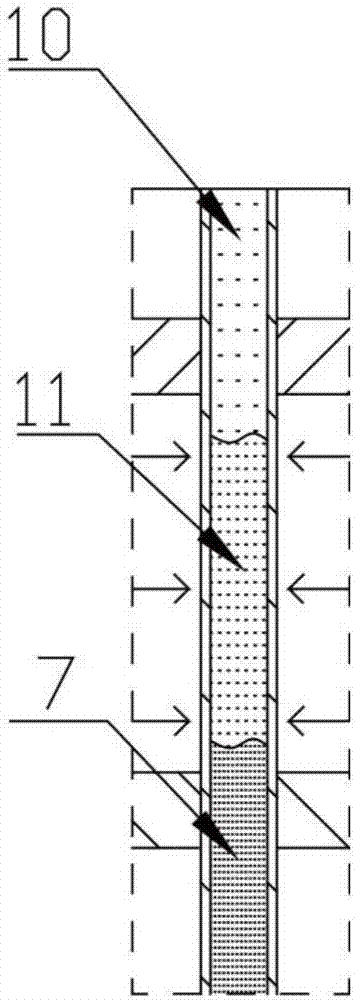

Method used

Image

Examples

Embodiment example

[0036] The material is 5% (w / v) GelMA light-curing material, the syringe pump is the feeding device, the flow rate is set to 7μL / min, and the transparent / translucent thin tube is made of translucent polytetrafluoroethylene with an inner diameter of 0.3mm and an outer diameter of 0.6mm Tube. Using dual light sources with a wavelength of 365nm, the light intensity is 100mW / cm 2 . Continuously print GelMA filaments with a diameter of 0.3mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com