Independent negative-pressure exhaust gas dust removal device

A dust removal device and independent technology, applied in the direction of dust removal, cleaning methods and appliances, chemical instruments and methods, etc., can solve the problems of limited dust removal area and high energy consumption, achieve improved dust removal effect, high dust removal efficiency, and reduce dust removal area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

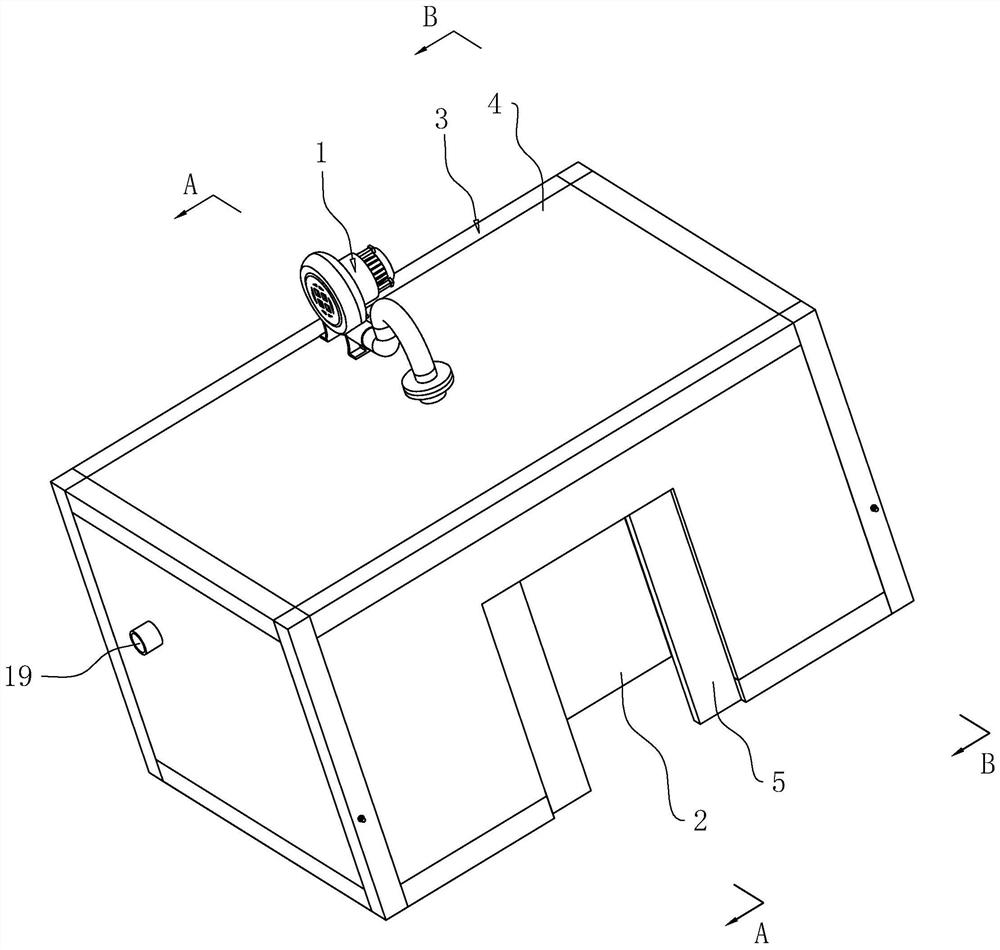

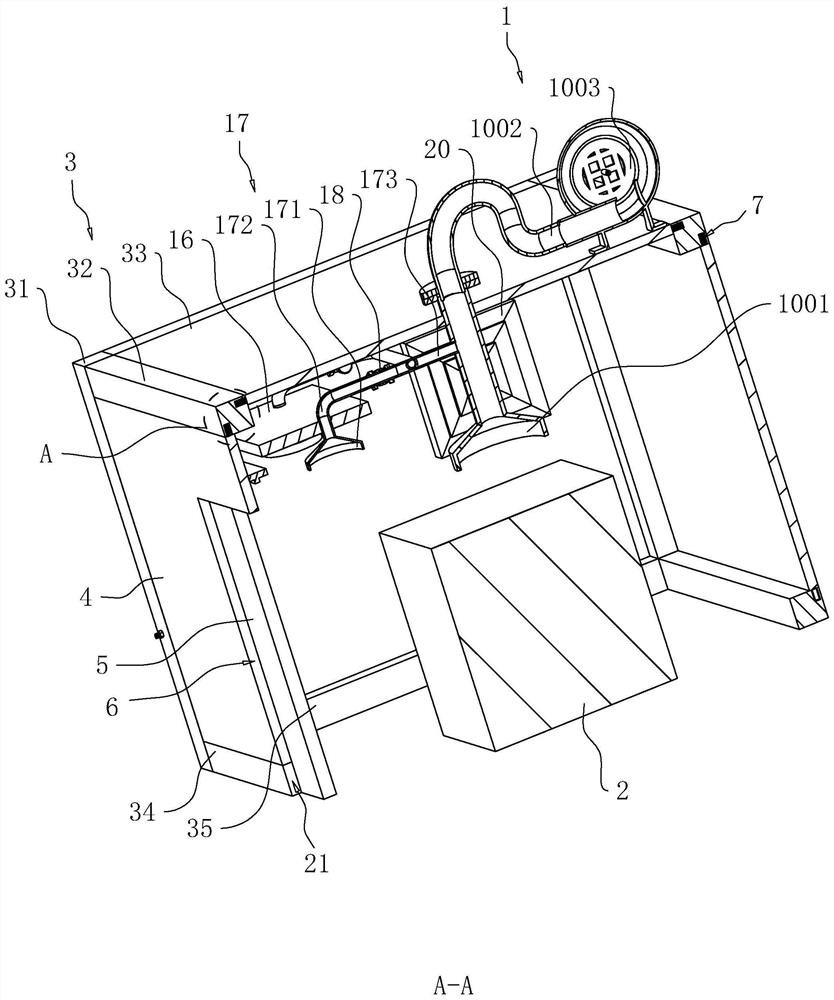

[0047] The embodiment of the present application discloses a self-contained negative pressure exhaust dust removal device, referring to figure 1 The dust removal device includes an equipment body 2 and a supporting steel frame 3 placed on the ground. The equipment body 2 is located inside the supporting steel frame 3. When installing the equipment body 2 and the supporting steel frame 3, it is necessary to ensure the flatness of the ground.

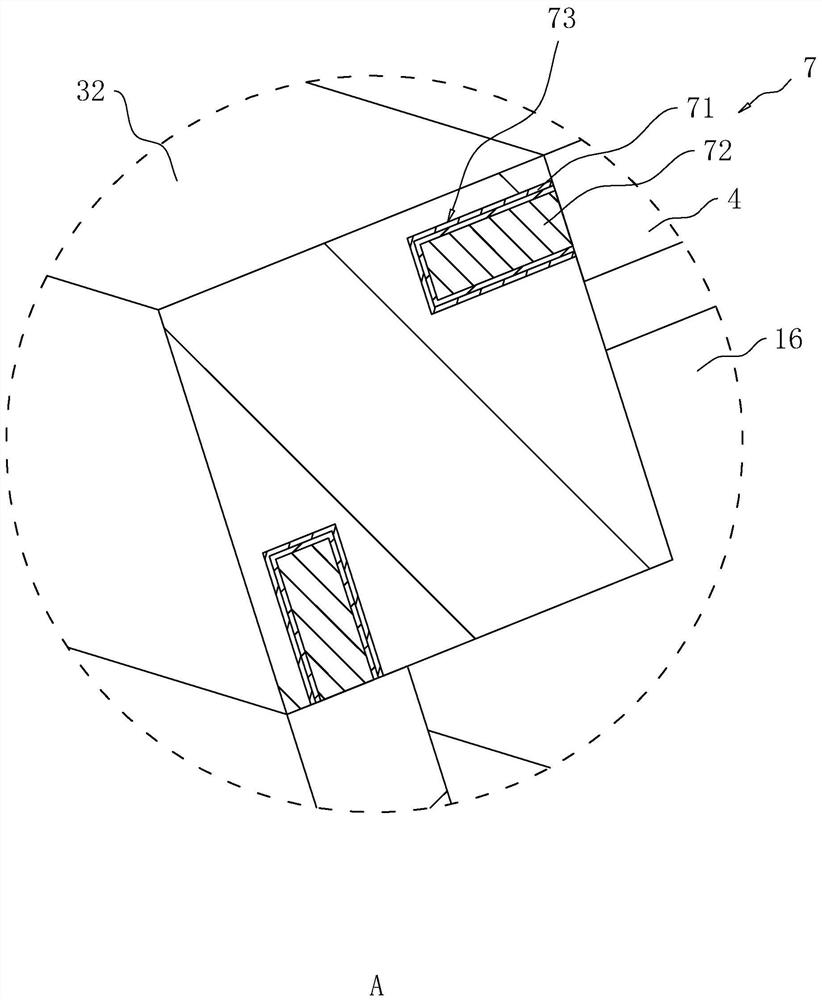

[0048] In this embodiment, the equipment body 2 is a fully automatic processing equipment without manual operation and processing. The supporting steel frame 3 is arranged in a rectangular shape. Combined with the dust shield 4 to form a dust shield, the dust shield is used to cover the equipment body 2, and the side wall of one of the dust shields 4 is provided with an inspection port 6, and the dust shield 4 is located on the inner wall of the inspection port 6 to slide Two opposite airtight doors 5 are provided, and when the airtight d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com