Clean hatch structure

An incubator and clean technology, applied in the incubation field of biomedical products, can solve the problems of inability to achieve a clean incubation room with uniform air temperature and humidity, insufficient air disturbance in the incubation area, limited wind pressure, etc., and achieve overall structural strength. Guaranteed, the effect of reducing the temperature difference of the supply air and uniform air volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

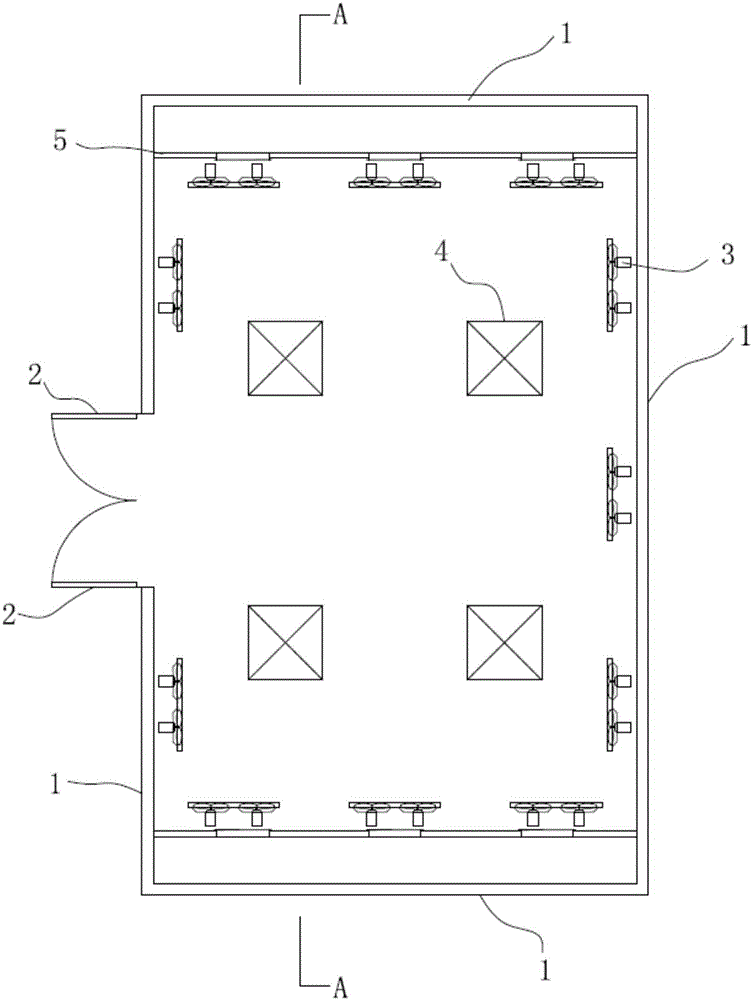

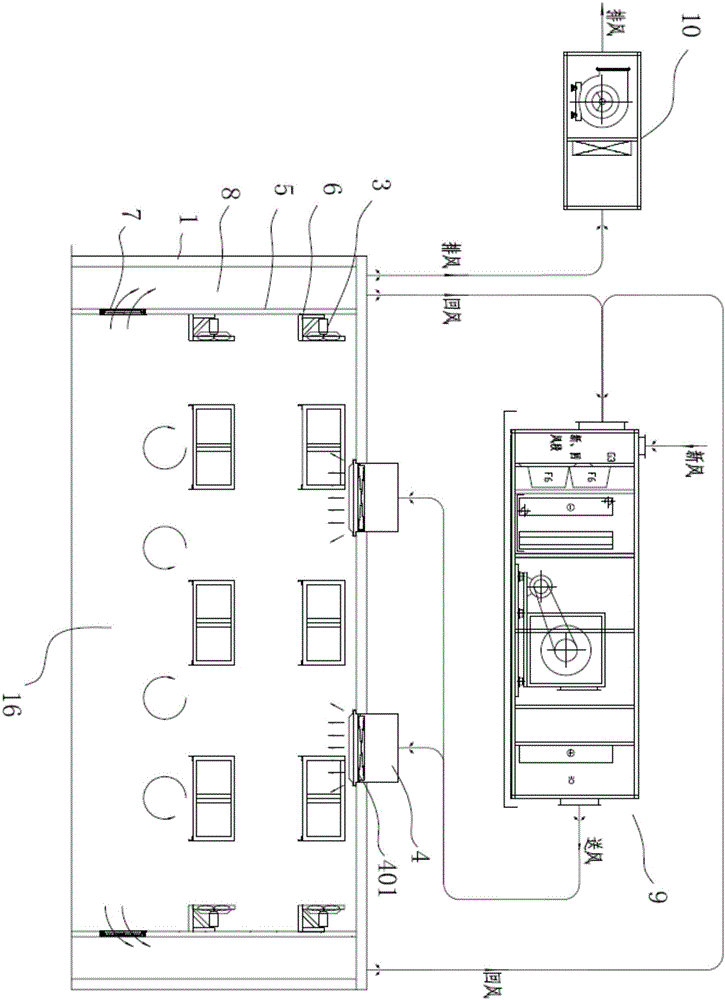

[0037] Refer to attached figure 1 , attached figure 2 , the first clean hatching room structure provided by the embodiment of the present invention is surrounded by a plurality of composite panels 1 to form a hatching room body, at least one composite panel 1 is provided with a thermal insulation door 2, and at least one partition 5 is installed in the hatching room Inside, the interior of the hatching room is separated to form a return air passage and an incubation area; on the partition 5, a plurality of spoiler axial flow fans 3 controlled by time relays are installed, and the spoiler axial flow fans 3 are installed on the fan On the frame 6, the fan frame 6 is fixedly connected to the partition plate 5, and the air inside the hatching area is forced to convect through the spoiler axial flow fan 3, in order to improve the uniformity of the air temperature and humidity in the hatching area.

[0038] Such as figure 1 , figure 2As shown, the louver air return port 7 is al...

Embodiment 2

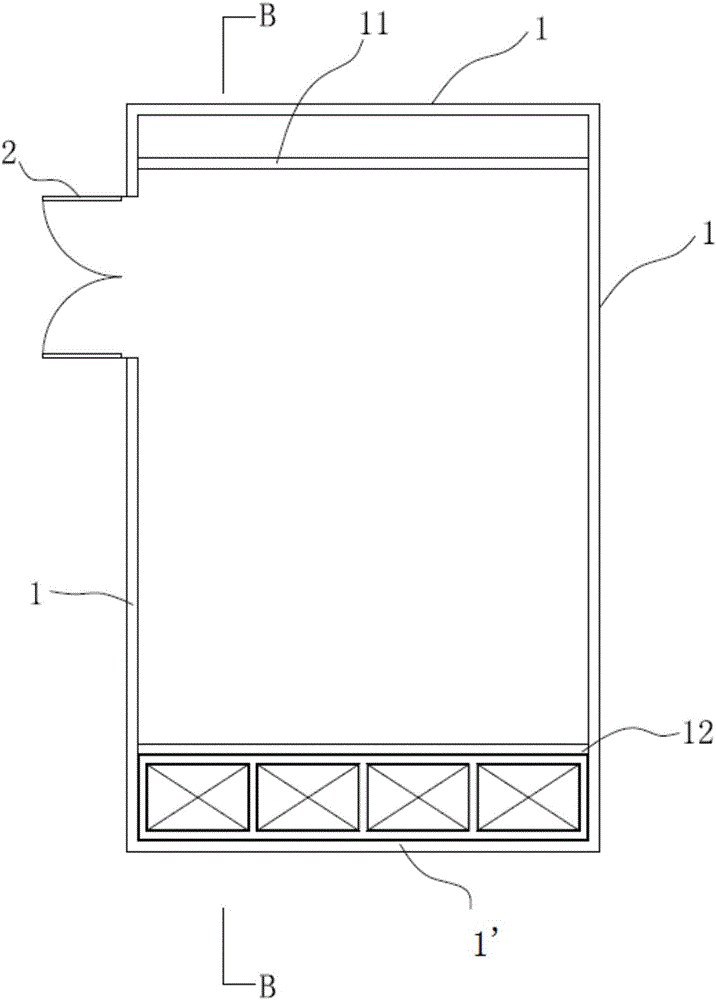

[0043] In order to solve the practical problems of the first clean hatch structure provided by Embodiment 1, the embodiment of the present invention also provides an improved clean hatch structure, which is called the second clean hatch structure, such as image 3 , Figure 4 , Figure 5 , Figure 6 As shown, the second clean hatching room structure is a hatching room body formed by a plurality of composite boards 1. The composite boards 1 are made of stainless steel and polyurethane materials. The thickness of the composite board 1 can be 50mm to 150mm. In a preferred In the scheme, the thickness of the composite board 1 can be 100mm, and at least one composite board 1 is provided with a thermal insulation door 2, and the thermal insulation door 2 is also made of stainless steel polyurethane material, and its thickness is also 50mm to 150mm. In a preferred In the scheme, the thickness of the thermal insulation door 2 can be 100mm. In another preferred solution of the embod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com