Washing machine control method and washing machine

A control method and washing machine technology, which is applied in the field of washing machines, can solve the problems of sensor signal drift, noise, and can not meet the user's low noise requirements, and achieve the effect of accurate load judgment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

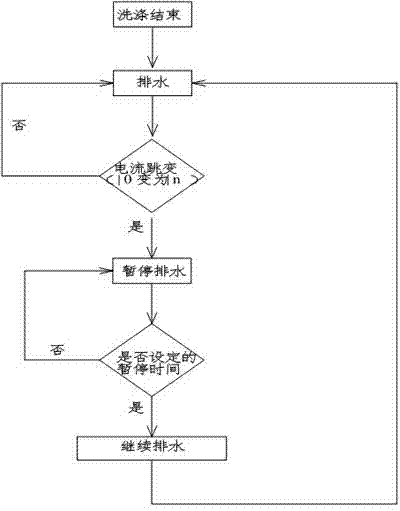

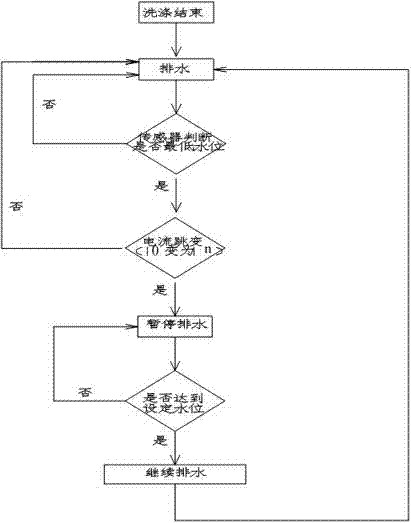

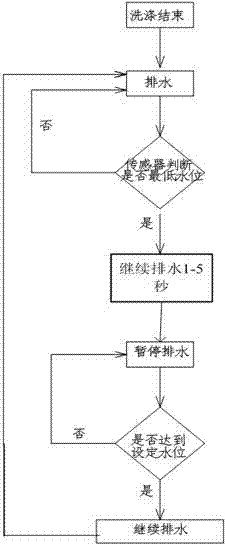

[0033] See figure 1 Shows the first embodiment of the present invention, a drainage control method when a washing machine uses a water level pressure switch. The working process of the water level pressure switch controlling the water level: When the washing machine barrel has a lot of water, the drain pump works at full load, and the noise is not large. At this time, the current is large, and the main controller reads the current value I0 at this time as the drain pump The current value at full load is recorded in the main controller MCU. When the water in the cylinder is emptied, the drain pump load suddenly disappears, the main controller MCU will detect a jump from I0 to In in the current of the pump motor, and after software processing, the main controller MCU stops the drain pump after confirming that the signal is correct. At this time, a small amount of residual water in the drain pipe can flow back into the cylinder without impacting the pump blades, avoiding the "buzz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com