Safety pressure cooker

A safe pressure and pressure cooker technology, applied in the direction of pressure cooker, etc., to achieve the effect of simple structure, elimination of safety hazards, and easy production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

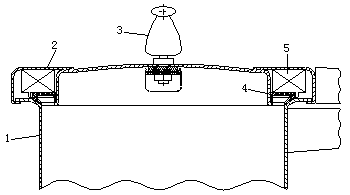

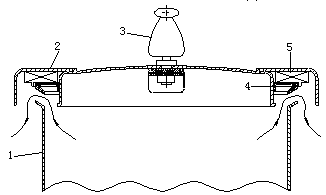

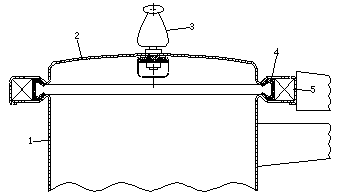

Embodiment 1

[0047] Figure 5 , Figure 6 The sealing ring can be moved up, and the elastic body adopts the embodiment of gradual cylinder and conical helical compression elasticity.

[0048] The top of the sealing ring 4 is equipped with a sealing ring holder 6, and some spring supports 7 are fixed on the sealing ring holder 6. The spring support 7 can be stretched up and down, and the spring support 7 is equipped with a compression spring 8. Of course, the spring 8 can adopt other suitable spring.

[0049] Figure 7 It is a schematic diagram of an installation method and a normal state of a helical compression spring;

[0050] Figure 8 It is a schematic diagram of the maximum deformation of the compression spring when it is above the safe steam pressure;

[0051] Figure 9 It is another kind of spring supporting type that embodiment 1 adopts, and there are many kinds of supporting members of the spring, which cannot be listed one by one.

[0052] The spring deformation characteri...

Embodiment 2

[0055] Figure 10 and Figure 11For sealing ring can move up, elastic body adopts the embodiment of abrupt type torsion spring.

[0056] A sealing ring holder 6 is disposed above the sealing ring 4, and a plurality of torsion springs 10 and balance rings 9 are arranged on the sealing ring holder 6. The mandrel of the torsion spring 10 is fixed on the sealing ring holder 6 . The balance ring 9 is drilled with a hole corresponding to the end hole of the torsion spring 10, and a bolt is fixed in the hole, and the bolt passes through the end hole of the torsion spring 10.

[0057] Figure 12 It is a schematic diagram of the mutation type torsion spring of embodiment 2 in a normal state;

[0058] Figure 13 for Figure 12 A view from direction A.

[0059] The torsion spring 10 has a preset torque and a preset torsion angle. When the steam pressure in the pot is set as a safe pressure (for example, 100KPa), the steam pressure that each torsion spring bears is P, then the pre...

Embodiment 3

[0066] Figure 18 and Figure 19 It is an embodiment that the sealing ring can move outward (move toward the pot body), and the elastic body adopts a gradual tension spring.

[0067] The sealing ring 4 is placed on the edge of the pot body 1 and the lid 2, and a number of tension spring rings 11 are arranged on the outside (the spring ring can also be placed in the sealing ring). Before the two ends of the spring ring are connected, an appropriate amount of A short cylinder (other supports can also be used) to prop up the spring coil, so that the stretched spring coil produces a preset internal tension. The internal pressure generated by this tension is equal to the steam pressure in the pot as a safe pressure (for example, 100KPa ), the pressure of the steam on the sealing ring. Because of the supporting function of the supporting part in the spring ring, when there is no steam pressure, the spring ring has no pressure on the sealing ring, and the sealing ring and the sprin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com