Activated carbon and preparation method thereof

A technology of activated carbon and wood charcoal, applied in the field of activated carbon, can solve the problems of reduced adsorption capacity of activated carbon, excessive VOCs pollution, etc., and achieve the effects of improving processing performance, improving molding effect, and reducing cracks and burrs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

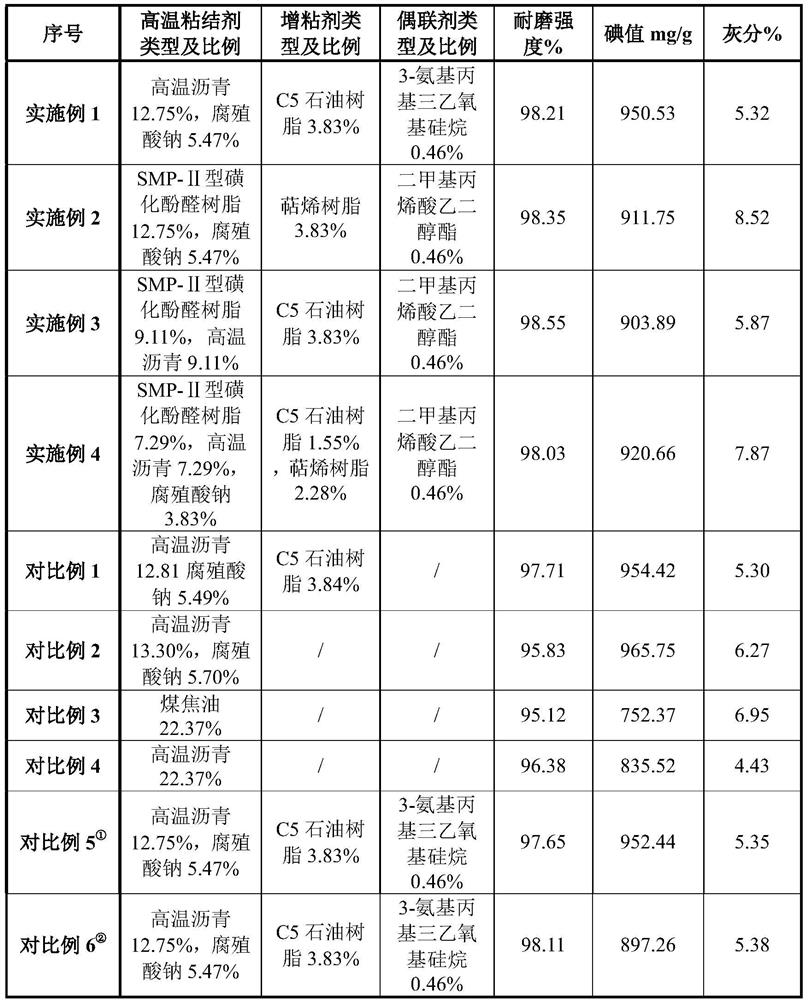

Examples

Embodiment 1

[0034] 200g of wood activated carbon powder, 5g of yellow dextrin, 5g of polyvinyl alcohol, 35g of high-temperature asphalt, 15g of sodium humate and 10.5g of C5 petroleum resin were pulverized by a pulverizer at a speed of 24000rpm / min, and then sieved with a 200-mesh vibrating sieve. The pass rate requirement is higher than 90%;

[0035] After crushing and screening, woody activated carbon powder larger than 200 meshes, yellow dextrin, polyvinyl alcohol, high-temperature asphalt, sodium humate and C5 petroleum resin powder are put into a kneader for pre-mixing. During the mixing process, the speed of the kneader is 60rpm / min, mixing time 15min;

[0036] Add 2.7g of lactic acid, 1.25g of 3-aminopropyltriethoxysilane and 105g of deionized water to the mixed powder, and then knead it into a billet through a kneader at room temperature. The kneader speed is 60rpm / min, and the kneading time is 2h ;

[0037] After the kneading is completed, the resulting billet is collected in ...

Embodiment 2

[0043] 200g of woody activated carbon powder, 5g of yellow dextrin, 5g of polyvinyl alcohol, 35g of SMP-II sulfonated phenolic resin, 15g of sodium humate and 10.5g of terpene resin were pulverized by a pulverizer at a speed of 24000rpm / min, and then 200-mesh vibrating sieve screening, the pass rate is required to be higher than 90%;

[0044] Put the crushed and screened woody activated carbon powder, yellow dextrin, polyvinyl alcohol, SMP-II sulfonated phenolic resin, sodium humate and terpene resin powder into the kneader for pre-mixing. The mixing process, Kneader speed 60rpm / min, kneading time 15min;

[0045] Add 2.7g of lactic acid, 1.25g of ethylene glycol dimethacrylate and 112g of deionized water to the mixed powder, and then knead it into a billet through a kneader at room temperature. The kneader speed is 60rpm / min, and the kneading time is 2h;

[0046] After the kneading is completed, the resulting blank is collected in a ziplock bag and stale for 12 hours;

[004...

Embodiment 3

[0052] 200g of woody activated carbon powder, 5g of yellow dextrin, 5g of polyvinyl alcohol, 25g of SMP-II sulfonated phenolic resin, 25g of high-temperature asphalt and 10.5g of C5 petroleum resin were pulverized by a pulverizer at a speed of 24000rpm / min, and then 200 mesh Screening by vibrating sieve, the pass rate is required to be higher than 90%;

[0053] Put the crushed and screened wood activated carbon powder, yellow dextrin, polyvinyl alcohol, SMP-II sulfonated phenolic resin, high-temperature asphalt and C5 petroleum resin powder into the kneader for pre-mixing, the mixing process, the kneader Rotation speed 60rpm / min, kneading time 15min;

[0054] Add 2.7g of lactic acid, 1.25g of ethylene glycol dimethacrylate and 110g of deionized water to the mixed powder, and then knead it into a billet through a kneader at room temperature. The kneader speed is 60rpm / min, and the kneading time is 2h;

[0055] After the kneading is completed, the resulting blank is collected i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| Ash content | aaaaa | aaaaa |

| abrasion resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com