Hard anode oxidation method for aluminum and aluminum alloy

A hard anodizing, aluminum alloy technology, applied in electrolytic coatings, surface reaction electrolytic coatings, coatings, etc., can solve problems affecting product quality and other issues, achieve high yield, high hardness, and good promotion and application value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Example 1: Turn on the tank liquid cooling and stirring device, lower the tank temperature to about 0°C, lower the hanger with an appropriate amount of aluminum and aluminum alloy parts into the tank, conduct electricity, and turn on the power supply according to the calculated minimum current, every 3~ Adjust the current once every 5 minutes, adjust it 5-6 times to the specified value, and keep the current constant until the oxidation ends.

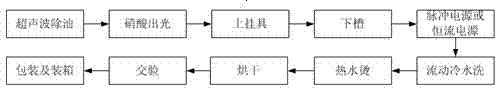

[0032] For the process flow of hard anodizing of aluminum and aluminum alloy, see image 3 , and its flow sequence is:

[0033] Ultrasonic degreasing→nitric acid light→upper hanger→lower tank→pulse power supply or constant current power supply→flowing cold water washing→hot water scalding→drying→delivery inspection→packing and packing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com