Multi-component complex phase nano boride, corresponding ultra-high temperature oxidation-resistant coating and preparation method thereof

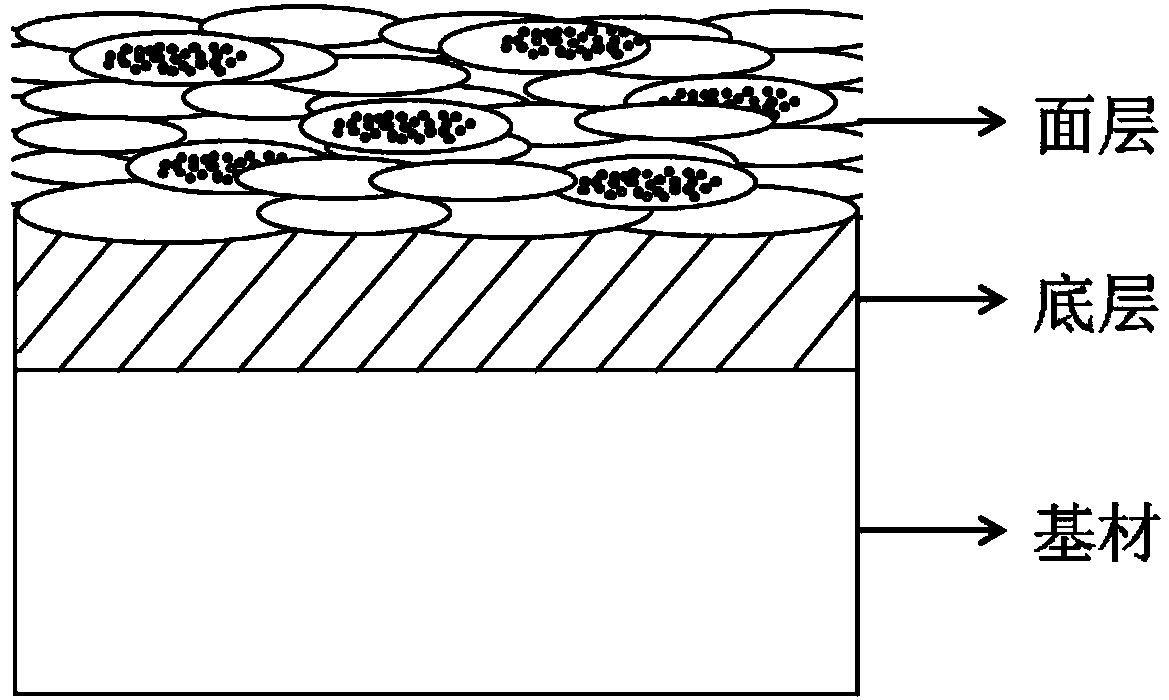

A nano-boride and anti-oxidation coating technology is applied in the field of high toughness and ultra-high temperature anti-oxidation coating and its preparation, and in the field of new multi-phase complex nano-borides, which can solve the problem of insufficient high-temperature oxidation and ablation resistance of the coating, silicon carbide Whiskers or carbon fibers break, destroy the integrity of whiskers and carbon fibers, etc., to improve the high temperature oxidation resistance, accurately control the thickness and uniformity of the coating, and improve the effect of cracking failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Example 1: Deposition of HfB on C / C composites 2 -SiC-TiB 2 coating.

[0029] The first step: preparation of nano-spray powder

[0030] 1) Preparation of slurry: high-purity HfB with an average particle diameter of 30nm 2 , SiC and TiB 2 The powder is mixed, the content of SiC in the powder is 10wt%, TiB 2 The content is 5wt%, the balance is HfB 2 . Then add binder and distilled water for preparation, and after adding balls, use a ball mill for ball milling to obtain slurry.

[0031] Described binder is polyvinyl alcohol (PVA), and the add-on of binder is 5% of mixed powder mass, and dispersant is lauryl ether and polyethylene glycol (PEG), and the add-on of dispersant is mixed powder 2% of the mass, the addition of distilled water is 40% of the mass of the mixed powder, the mass of the ball is twice that of the mixed powder, and the ball milling time is 12h;

[0032] 2) Spray drying and agglomeration granulation: transfer the slurry obtained in step 1) to a spr...

Embodiment 2

[0038] Example 2: Deposition of HfB on C / C composites 2 -SiC-TiB 2 coating.

[0039] The first step: preparation of nano-spray powder

[0040] 1) Preparation of slurry: the average particle diameter is 40nm high-purity HfB 2 , SiC and TiB 2 The powder is mixed, the SiC content in the powder is 20wt%, TiB 2 The content is 8wt%, the balance is HfB 2 . Then add binder and distilled water for preparation, and after adding balls, use a ball mill for ball milling to obtain slurry.

[0041] Described binder is polyvinyl alcohol (PVA), and the add-on of binder is 8% of mixed powder quality, and dispersant is lauryl ether and polyethylene glycol (PEG), and the add-on of dispersant is mixed powder 2% of the mass, the addition of distilled water is 60% of the mass of the mixed powder, the mass of the grinding ball is 3 times that of the mixed powder, and the ball milling time is 15h;

[0042] 2) Spray drying and agglomeration granulation: transport the slurry obtained in step 1) ...

Embodiment 3

[0048] Example 3: Deposition of HfB on C / SiC composite 2 -SiC-TiB 2 coating.

[0049] The first step: preparation of nano-spray powder

[0050] 1) Preparation of slurry: the average particle diameter is 50nm high-purity HfB 2 , SiC and TiB 2 The powder is mixed, the SiC content in the powder is 20wt%, TiB 2 The content is 10wt%, the balance is HfB 2 . Then add binder and distilled water for preparation, and after adding balls, use a ball mill for ball milling to obtain slurry.

[0051] Described binder is polyvinyl alcohol (PVA), and the add-on of binder is 6% of mixed powder quality, and dispersant is lauryl ether and polyethylene glycol (PEG), and the add-on of dispersant is mixed powder 2% of the mass, the addition of distilled water is 60% of the mass of the mixed powder, the mass of the ball is twice the mass of the mixed powder, and the ball milling time is 20h;

[0052] 2) Spray drying and agglomeration granulation: transport the slurry obtained in step 1) to a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com