Ablation-resistant organosilicon composite, and preparation method and application thereof

An organosilicon and composite technology, applied in cables, insulated conductors, conductors, etc., can solve the problems of elasticity, strength, elongation at break mechanical properties not improved, complex preparation process, complex raw materials, etc., and achieve ceramic yield. Increase, high pyrolysis temperature, good ablation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

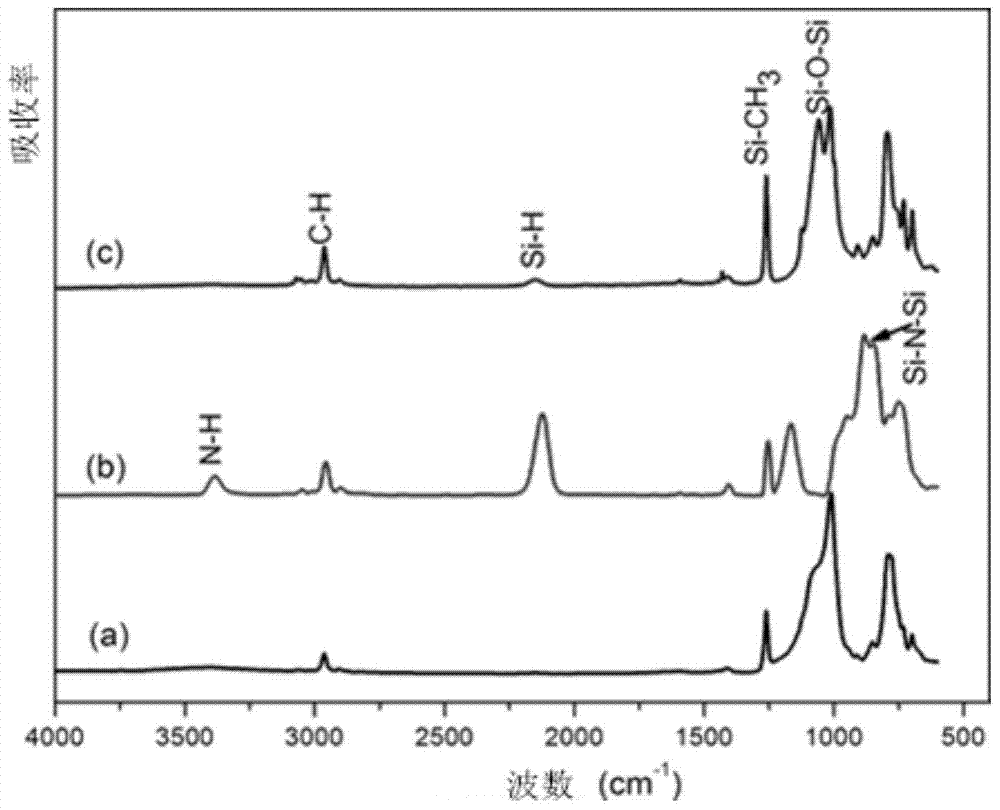

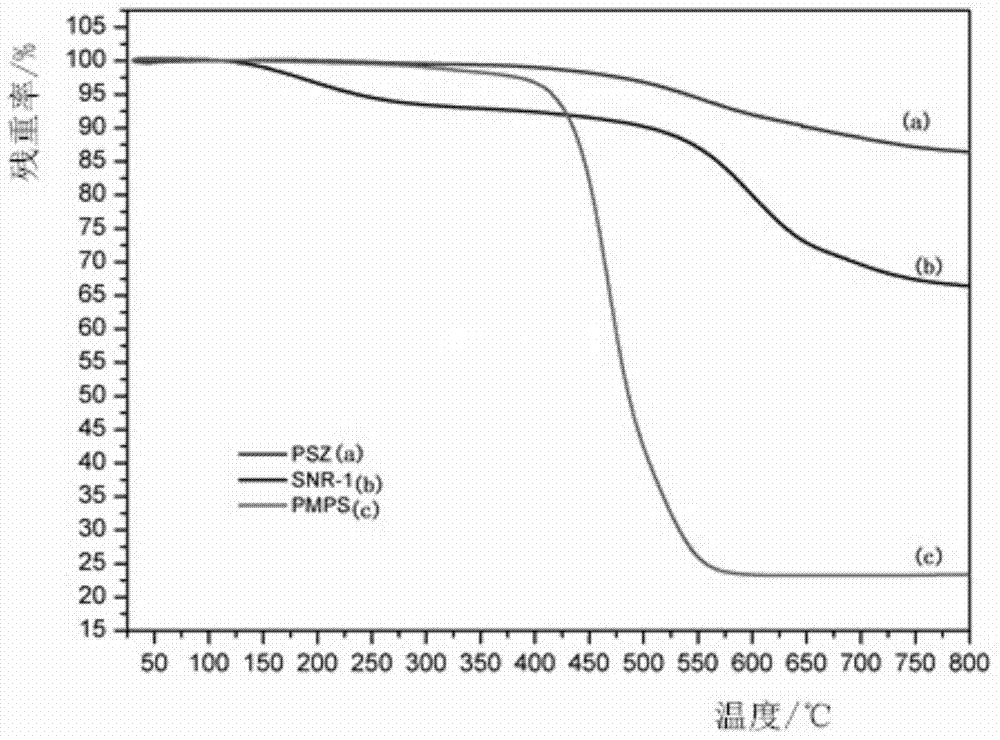

[0064] Raw material component formula: 100 parts of PMPS and PSN with a mass ratio of 4:1 as the base rubber, 30 parts of fumed silica TS530, and 2 parts of bis-2,5 vulcanizing agent to prepare SNR-1. The preparation steps are as follows:

[0065] Weigh 40.0g of PMPS, 10.0g of PSN and put them together on the open mixer for mixing, and slowly add 15.0g of fumed silica TS530 at the same time; stop for 20 minutes after mixing evenly; add 1.0g of bis-2,5 vulcanizing agent, and mix evenly Finally, remove the silica gel and place it on a flat vulcanizer for 25 minutes at 150°C. The resulting product number was SNR-1.

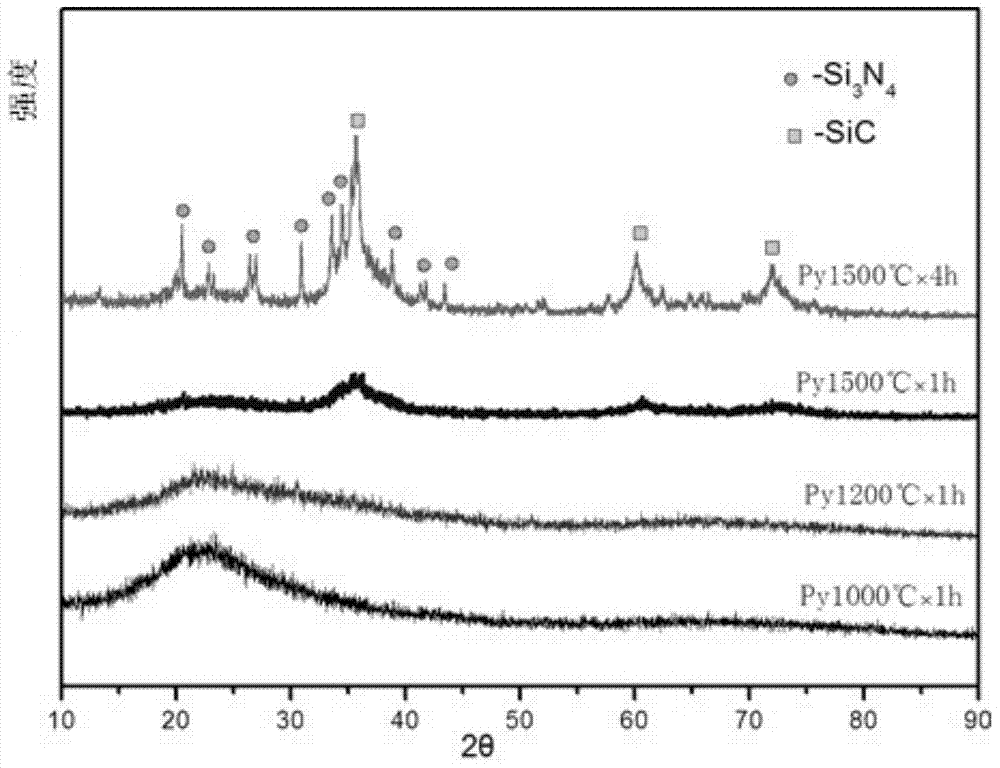

[0066] The tensile strength of the prepared product is 8.1MPa, and the elongation at break is 357%. Under the protection of high-purity argon atmosphere, the speed is raised to 800°C at a rate of 10°C / min. The initial degradation temperature is 524°C, and the ceramic yield is 59.26 %. Taking the national military GJB323A-96 as the standard, the mass ablation rate ...

Embodiment 2

[0071] Raw material component formula: 100 parts of PMPS and PSN with a mass ratio of 3:1 as the base rubber, 30 parts of fumed silica TS530, and 2 parts of bis-2,5 to prepare SNR-2. The preparation steps are as follows:

[0072] Weigh 30.0g PMPS, 10.0g PSN and put them together on the open mixer for mixing, at the same time slowly add 12.0g fumed silica (TS-530); stop for 20 minutes after mixing evenly; add 0.8g bis-2,5 vulcanizing agent After mixing evenly, remove the silica gel and place it on a flat vulcanizer for 25 minutes at 150°C. The resulting product number was SNR-2.

[0073] The tensile strength of the prepared product is 8.2MPa, and the elongation at break is 360%. When it is heated from room temperature to 800°C at a rate of 10°C / min and stays for 1hr for cracking, the initial degradation temperature of the co-cured product is 535°C. Ceramic products The rate is 67.74%. Taking the national military GJB323A-96 as the standard, the mass ablation rate of the samp...

Embodiment 3

[0076] Raw material composition formula: 100 parts of PMPS and PSN with a mass ratio of 3:1 as the base rubber, 30 parts of fumed silica TS530, and 2 parts of chloroplatinic acid catalyst to prepare SNR-3. The preparation steps are as follows:

[0077] Weigh 30.0gPMPS, 10.0gPSN and put them together on the open mill for mixing, and slowly add 12.0g fumed silica (TS-530); 20 minutes after mixing evenly; add 0.8g chloroplatinic acid, and mix evenly , Remove the silica gel and place it on a flat vulcanizer for 25 minutes at 150°C. The resulting product number was SNR-3.

[0078] The tensile strength of the prepared product is 7.6MPa, and the elongation at break is 363%. When it is heated from room temperature to 800°C at a speed of 10°C / min and stays for 1hr for cracking, the initial degradation temperature of the co-cured product is 535°C. Ceramic products The rate is 65.99%. Taking the national military GJB323A-96 as the standard, the mass ablation rate of the sample after a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com