Method for vacuum reinforced desulfurization of high sulfur petroleum coke

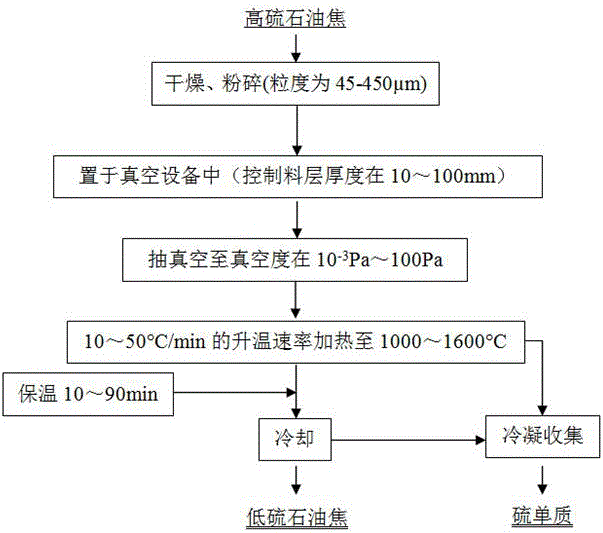

A petroleum coke and high-sulfur technology, applied in the petroleum industry, carbon preparation/purification, solid fuel, etc., can solve the problems of complex production process, low gas content, complex technical operation, etc., and achieve short production process and high desulfurization rate , The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] The specific steps of the vacuum-enhanced petroleum coke desulfurization method are as follows: First, grind and sieve high-sulfur petroleum coke (from a silicon company in Yunnan, with a petroleum coke sulfur content of 8.21wt%) to a particle size of 350-450µm, and control the thickness to 10mm , under the condition of a vacuum degree of 100Pa, the temperature was raised to 1600°C at a heating rate of 10°C / min and kept for 10 minutes to prepare desulfurized petroleum coke, and at the same time, elemental sulfur with a purity of more than 90% was collected in the condensing equipment at the top.

[0016] The desulfurization rate of the above-mentioned desulfurized petroleum coke is 80.02%.

Embodiment 2

[0018] The specific steps of the vacuum-enhanced desulfurization method for high-sulfur petroleum coke are as follows: firstly, high-sulfur petroleum coke (from a silicon company in Yunnan, with a petroleum coke sulfur content of 8.21wt%) is ground and screened to a particle size of 250-350µm, and the thickness is controlled. 30mm, and under the condition of vacuum degree of 1.0Pa, the temperature was raised to 1400°C at a heating rate of 20°C / min and kept for 30min to prepare desulfurized petroleum coke. sulfur.

[0019] The desulfurization rate of the above-mentioned desulfurized petroleum coke is 75.3%.

Embodiment 3

[0021] The specific steps of the vacuum-enhanced desulfurization method for high-sulfur petroleum coke are as follows: firstly, high-sulfur petroleum coke (from a silicon company in Yunnan, with a sulfur content of 8.21wt%) is ground and screened to a particle size of 150-250µm, and the thickness is controlled. 50mm, in a vacuum of 10 -1 Under Pa conditions, the temperature was raised to 1300°C at a heating rate of 30°C / min and kept for 50 minutes to prepare desulfurized petroleum coke. At the same time, elemental sulfur with a purity of more than 91.2% was collected in the condensing equipment at the top.

[0022] The desulfurization rate of the above-mentioned desulfurized petroleum coke is 76.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com