High-current multi-channel metal cathode

A metal cathode, multi-channel technology, applied in circuits, electrical components, discharge tube electron guns, etc., can solve the problems of unsuitable magnetic plasma thrusters, complex cathode structure, difficult system control, etc., so as to reduce the material ablation rate. , the structure and control are simple, the effect of improving the emission current capability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

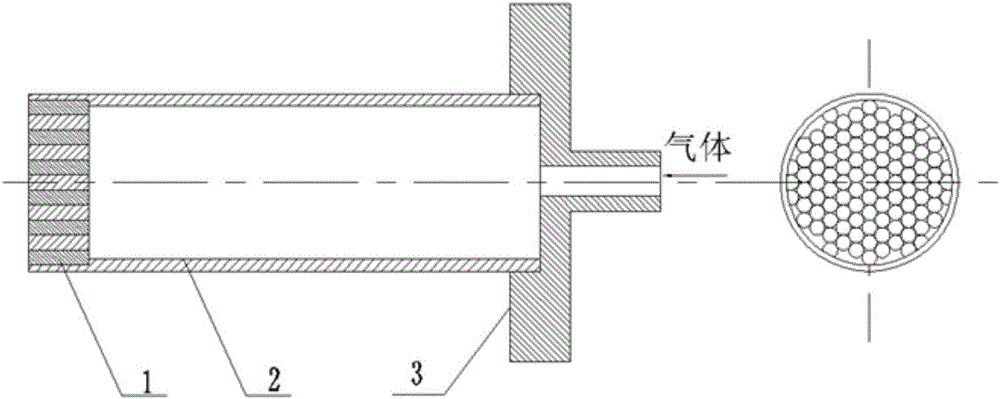

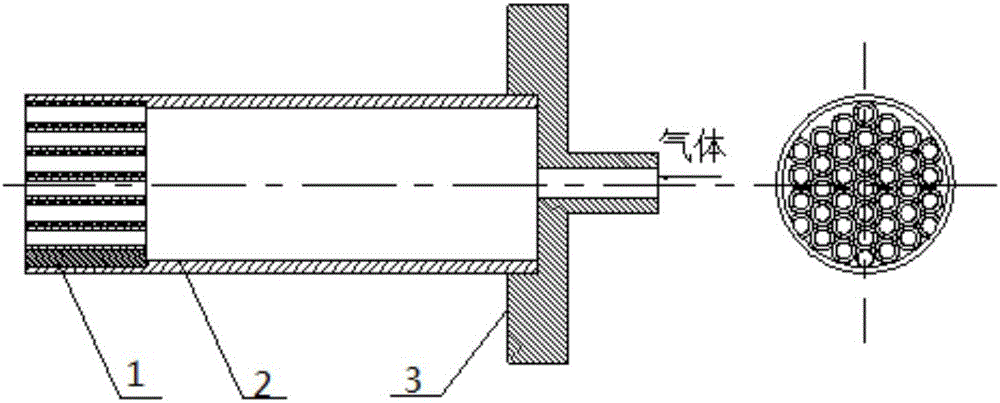

[0024] Such as figure 1 As shown, the multi-channel metal cathode includes a plurality of metal emitters 1, a cathode tube 2, and a gas path interface 3. The cathode tube is a tungsten tube with an inner diameter of Φ10, and 76 tungsten rods of Φ1*10 (diameter*length) are assembled inside. The gas path interface material is molybdenum, and the cathode tube and gas path interface are welded by electron beam.

[0025] The multi-channel metal cathode is installed in the vacuum chamber, the working principle diagram is shown in Figure 4 , the vacuum degree of the working environment is not less than 5×10 -1 Pa. When the flow rate of the argon working medium is 1-5mg / s, and the anode voltage is 80-120V, the emitted electron current reaches 80-200A, and the emission current density of the emitter material is 2.1-8.4A / cm 2 , which can meet the discharge requirements of magnetoplasma thrusters with a power of 10-50kW.

Embodiment 2

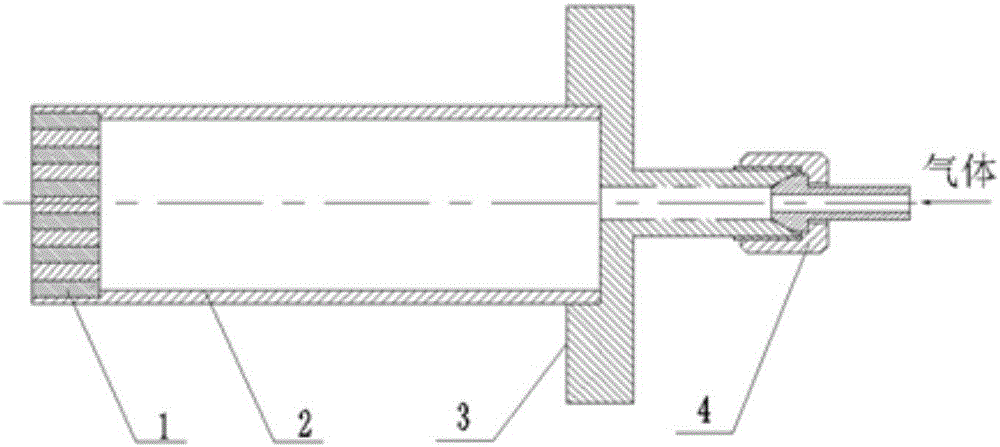

[0027] Such as image 3 As shown, the multi-channel metal cathode includes a plurality of metal emitters 1, a cathode tube 2, and a gas path interface 3. The cathode tube is a tungsten tube with an inner diameter of Φ10, and 76 tungsten rods of Φ1*10 (diameter*length) are assembled inside. The gas path interface material is molybdenum, the cathode tube and the gas path interface are welded by electron beam, and the gas path interface is a 60° horn The port is connected with the ball nut intake pipe.

[0028] The multi-channel metal cathode is installed in the vacuum chamber, the working principle diagram is shown in Figure 4 , the vacuum degree of the working environment is not less than 5×10 -1 Pa. When the flow rate of the argon working medium is 1-5mg / s, and the anode voltage is 80-120V, the emitted electron current reaches 80-200A, and the emission current density of the emitter material is 2.1-8.4A / cm 2 , which can meet the discharge requirements of magnetoplasma thr...

Embodiment 3

[0030] Such as figure 1 As shown, the multi-channel metal cathode includes a plurality of metal emitters 1, a cathode tube 2, and a gas path interface 3. The cathode tube is a tungsten tube with an inner diameter of Φ20, and 76 tungsten rods of Φ2*20 (diameter*length) are assembled inside. The gas path interface material is molybdenum, and the cathode tube and gas path interface are welded by electron beam.

[0031] The multi-channel metal cathode is installed in the vacuum chamber, the working principle diagram is shown in Figure 4 , the vacuum degree of the working environment is not less than 5×10 -1 Pa. When the flow rate of the argon working medium is 5-11mg / s, and the anode voltage is 100-200V, the emitted electron current reaches 200-500A, and the emission current density of the emitter material is 2.09-5.24A / cm 2 , which can meet the discharge requirements of magnetoplasma thrusters with a power of 50-100kW.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com