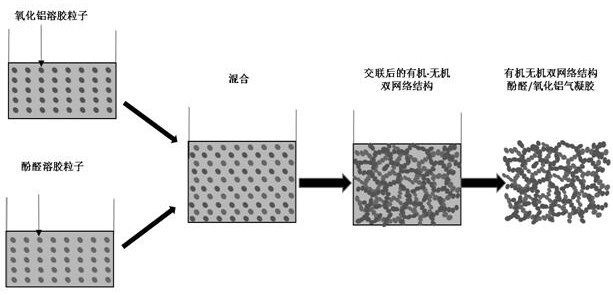

An organic-inorganic double network structure phenolic/alumina airgel composite material and its preparation method

A technology of alumina aerogel and network structure, which is applied in aerogel preparation, chemical instruments and methods, colloid chemistry, etc., can solve the problems of poor high temperature stability, phase transition and thermal insulation performance decline of silica aerogel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) Mix crystalline aluminum chloride, ethanol, and deionized water at a molar ratio of 1:25:30, stir at 60°C for 30 minutes to form a clear and transparent solution, cool to room temperature, and obtain a solution ;

[0023] (2) Mix resorcinol, formaldehyde, water and sodium carbonate in a molar ratio of 1:1.2:20:380 to obtain a solution ;

[0024] (3) the solution and solution Mix at a volume ratio of 1:1 and stir evenly; add a mixed solution consisting of methanol, acetic acid, and deionized water , stirred evenly, sealed and stood for 120min, the composite sol gradually gelled, and transformed into a phenolic / alumina composite gel; the solution Methanol, acetic acid, deionized water and solutions The molar ratio of aluminum is 6:0.5:0.3:1;

[0025] (4) Aging the phenolic / alumina composite gel in absolute ethanol for 48 hours, and replacing it with fresh absolute ethanol every 12 hours;

[0026] (5) Mix aluminum sec-butoxide, absolute ethanol and deioni...

Embodiment 2

[0031] (1) Mix crystalline aluminum chloride, ethanol, and deionized water at a molar ratio of 1:10:40, stir at 60°C for 50 minutes to form a clear and transparent solution, and add 1.2g of potassium titanate per 100mL of the solution Whiskers, stirred evenly, cooled to room temperature to obtain a solution ;

[0032] (2) Mix resorcinol, formaldehyde, water and sodium carbonate in a molar ratio of 1:0.7:10:260 to obtain a solution ;

[0033] (3) the solution and solution Mix at a volume ratio of 1:1, stir evenly, and add a mixed solution consisting of methanol, acetic acid, and deionized water , stirred evenly, sealed and stood for 120min; the composite sol gradually gelled and transformed into a phenolic / alumina composite gel. the solution Methanol, acetic acid, deionized water and solution The molar ratio of aluminum is 3:0.3:0.1:1;

[0034] (4) Aging the phenolic / alumina composite gel in absolute ethanol for 48 hours, and replacing it with fresh absolute etha...

Embodiment 3

[0040] (1) Mix crystalline aluminum chloride, ethanol, and deionized water at a molar ratio of 1:30:60, stir at 60°C for 60 minutes to form a clear and transparent solution, and cool to room temperature to obtain a solution ;

[0041] (2) Mix resorcinol, formaldehyde, water and sodium carbonate in a molar ratio of 1:2:30:450 to obtain a solution ;

[0042] (3) the solution and solution Mix at a volume ratio of 1:1, stir evenly, add 0.8g of mullite fiber per 100mL solution, and then add a mixed solution composed of methanol, acetic acid, and deionized water , stirred evenly, sealed and stood for 120min; the composite sol gradually gelled and transformed into a phenolic / alumina composite gel. the solution Methanol, acetic acid, deionized water and solution The molar ratio of aluminum is 8:0.2:0.4:1;

[0043] (4) Aging the phenolic / alumina composite gel in absolute ethanol for 48 hours, and replacing it with fresh absolute ethanol every 12 hours;

[0044] (5) Alumi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com