Modified carbon fiber reinforced silicone rubber thermal-insulation material and preparation method thereof

A fiber-reinforced and heat-insulating material technology, applied in the field of heat-insulating materials, can solve problems such as small specific surface area, poor wettability, and inability to form mechanical anchoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

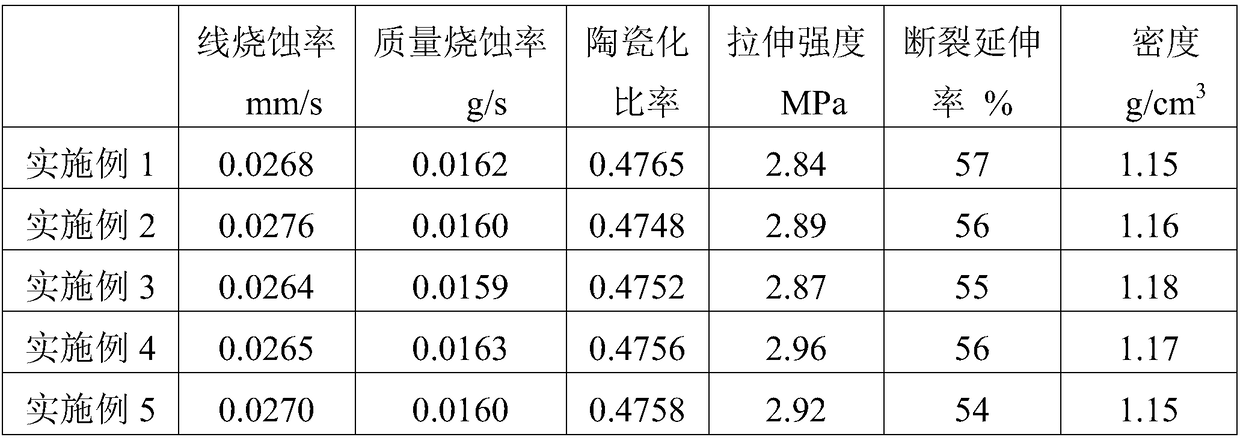

Examples

Embodiment 1

[0021] This example provides a modified carbon fiber reinforced silicone rubber thermal insulation material, which is prepared from the following raw materials: 50 parts of methyl vinyl silicone rubber, 50 parts of methyl vinyl phenyl silicone rubber, 25 parts of white carbon black part, 6 parts of graphene, 12 parts of modified carbon fiber, vulcanizing agent is 2,5-dimethyl-2, 1.0 part of 5-bis-hexane;

[0022] The preparation method of the modified carbon fiber is: place the carbon fiber in concentrated nitric acid, the mass volume ratio of the carbon fiber to the concentrated nitric acid is 1:50g / ml; treat it in a constant temperature water bath at 100°C for 2h, then place it in PEG6000 and Soak in the mixed aqueous solution of α-aminopropyltriethoxysilane for 4h, then wash to neutral drying; the mass fraction of PEG in the mixed aqueous solution is 3%, the mass fraction of α-aminopropyltriethoxysilane The score is 2%.

[0023] The preparation method of the modified carbo...

Embodiment 2

[0031] This example provides a modified carbon fiber reinforced silicone rubber thermal insulation material, which is prepared from the following raw materials: 40 parts of methyl vinyl silicone rubber, 60 parts of methyl vinyl phenyl silicone rubber, 20 parts of white carbon black part, 10 parts of graphene, 10 parts of modified carbon fiber, vulcanizing agent is 2,5-dimethyl-2, 1.5 parts of 5-bis-hexane;

[0032] The preparation method of the modified carbon fiber is: place the carbon fiber in concentrated nitric acid, the mass volume ratio of the carbon fiber to the concentrated nitric acid is 1:40g / ml; treat it in a constant temperature water bath at 100°C for 2h, then place it in PEG6000 and Soak in the mixed aqueous solution of α-aminopropyltriethoxysilane for 4h, then wash to neutral drying; the mass fraction of PEG in the mixed aqueous solution is 4%, the mass fraction of α-aminopropyltriethoxysilane The score is 1%.

[0033] The preparation method of the modified car...

Embodiment 3

[0041] This example provides a modified carbon fiber reinforced silicone rubber thermal insulation material, which is prepared from the following raw materials: 60 parts of methyl vinyl silicone rubber, 40 parts of methyl vinyl phenyl silicone rubber, 30 parts of white carbon black part, 3 parts of graphene, 15 parts of modified carbon fiber, 0.5 part of 2,4-dimethyl 2,4-bis-hexane;

[0042] The preparation method of the modified carbon fiber is: place the carbon fiber in concentrated nitric acid, the mass volume ratio of the carbon fiber to the concentrated nitric acid is 1:60g / ml; treat it in a constant temperature water bath at 100°C for 2h, then place it in PEG6000 and Soak in the mixed aqueous solution of α-aminopropyltriethoxysilane for 4h, then wash to neutral drying; the mass fraction of PEG in the mixed aqueous solution is 2%, the mass fraction of α-aminopropyltriethoxysilane The score is 3%.

[0043] The preparation method of the modified carbon fiber reinforced sil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com